Author: mixos

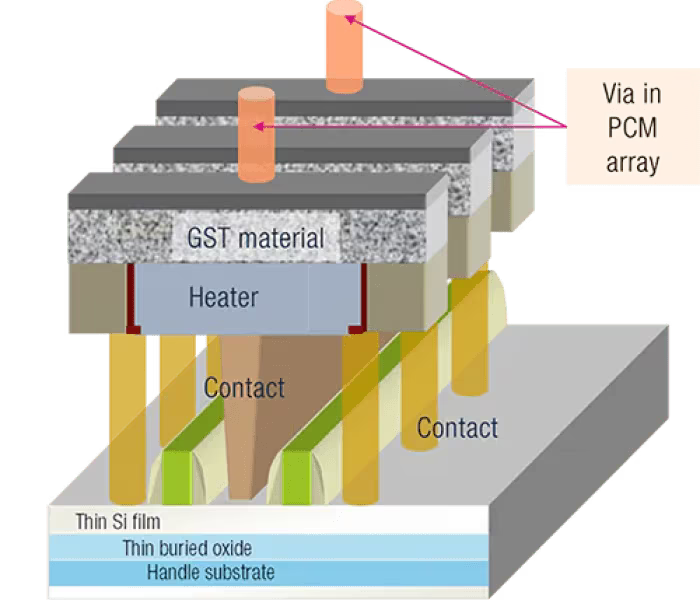

STMicroelectronics breaks the 20nm barrier for cost-competitive next-generation microcontrollers

Highlights First STM32 microcontroller based on new technology to sample to selected customers in the second half of 2024. 18nm FD-SOI with embedded phase change memory (ePCM) to deliver a leap in performance and power consumption. STMicroelectronics announces an advanced...

Continue Reading

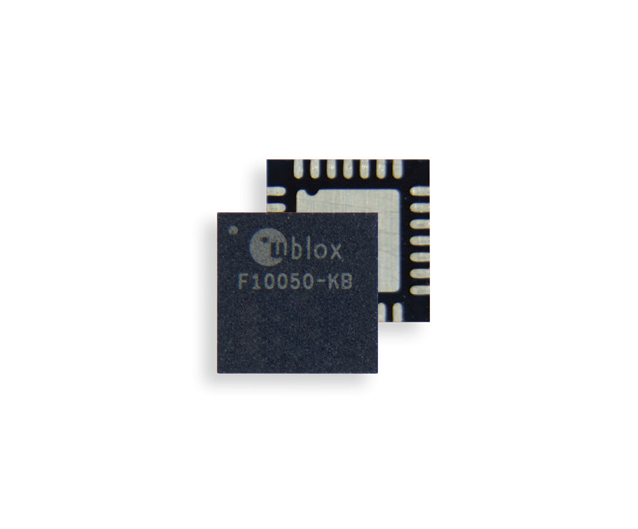

u-blox launches new GNSS platform for enhanced positioning accuracy in urban environments

The u-blox F10 platform increases positioning accuracy by reducing multipath effects, simplifying the process of promptly locating a vehicle. u-blox, a global provider of leading positioning and wireless communication technologies and services, has announced F10, the company’s first...

Continue Reading

AAEON’s VPC-5640S Drives Innovation for Embedded In-Vehicle Solutions

Power, ruggedness, and versatility put the VPC-5640S in poll position in the race for the in-vehicle application market. AAEON, a leader in embedded edge platforms, introduces the VPC-5640S, a Multi-PoE & Fanless Appliance powered by the 12th Generation Intel® Core™...

Continue Reading

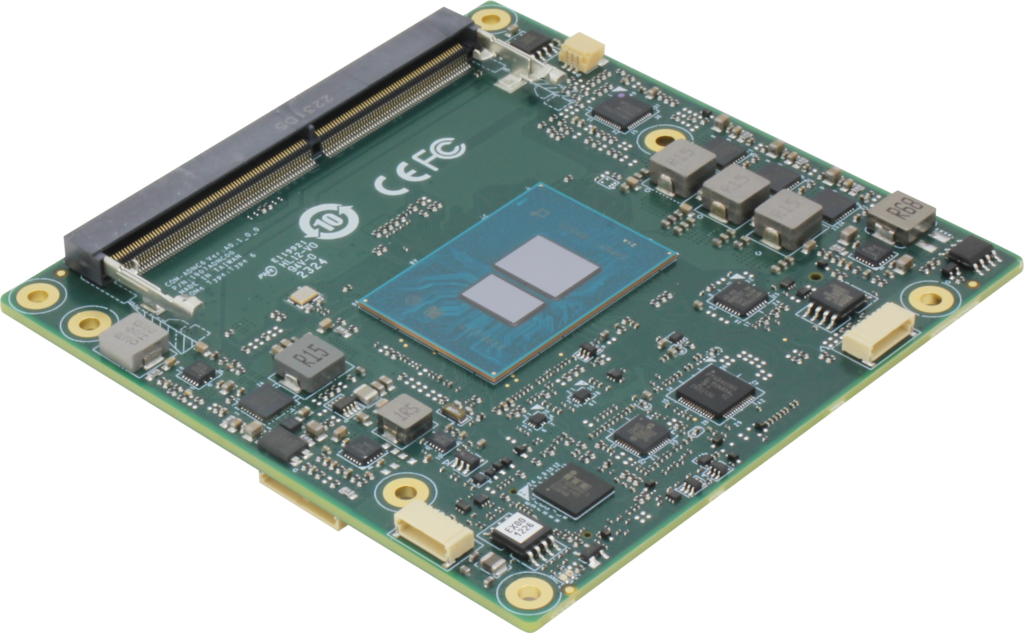

AAEON Unveils Intel-Powered COM Express Modules to Corner the Advanced Robotics and Edge Gateway Markets

The COM-RAPC6 and COM-ADNC6 offer diverse processor lineups, exceptionally versatile interfaces, and wide-temperature operation for the needs of any industrial project. AAEON, a leading provider of Computer-on-Modules, has today announced the launch of two new COM Express Type 6...

Continue Reading

STMicroelectronics’ high-performance microcontrollers pave the way to new innovations

New STM32H7R/S microcontrollers raise embedded-application performance to new levels for next-generation smart devices in factories, buildings, infrastructure, eHealth STMicroelectronics, a global semiconductor leader serving customers across the spectrum of electronics applications,...

Continue Reading

STMicroelectronics powers up the intelligent edge with second-generation STM32 microprocessors

Highlights: New STM32MP2 MPUs with 64-bit processing and edge AI acceleration Built for speed, security, and reliability Leverage STM32 ecosystem for rapid development and secure provisioning STMicroelectronics, a global semiconductor leader serving customers across the...

Continue Reading

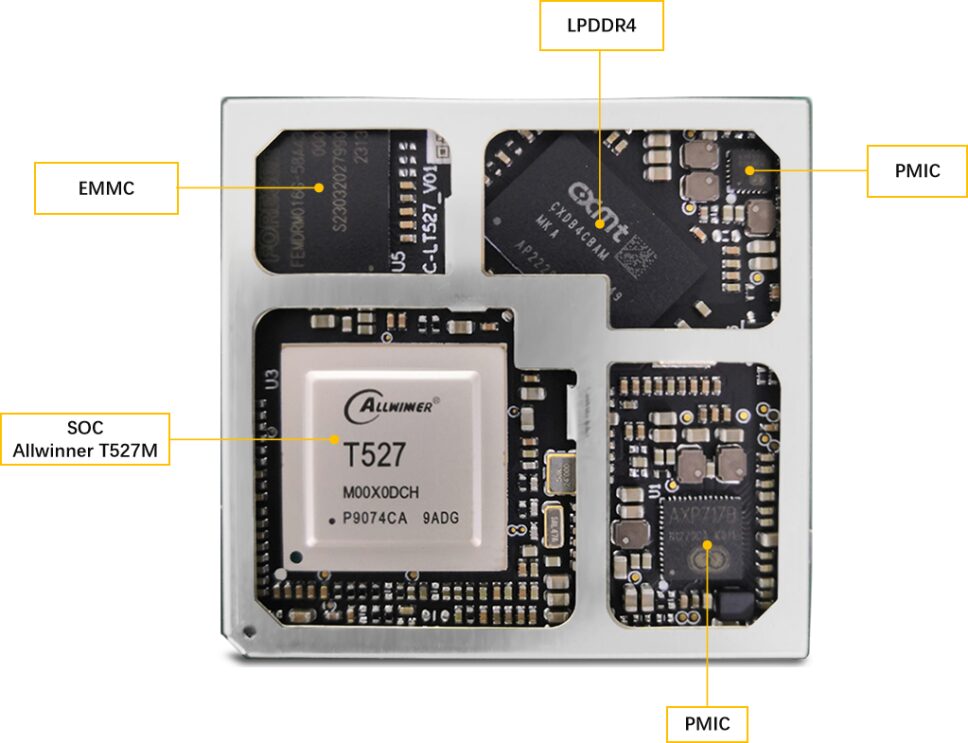

MYIR Launches New SOM Based on Allwinner T527 Octa-core Processor

cover photo: MYC-LT527 Top-view and Bottom-view (delivered with shielding cover installed by default) MYIR has launched the MYC-LT527, a cost-effective System-on-Module (SoM) that is equipped with the Allwinner T527 AI platform SoC. This SoC delivers superior computing power with its...

Continue Reading

Unveiling Ultra-Low Latency Video Streamer for Live Streaming in 2024

Over the years, streaming media has been gaining traction, whether it be live broadcasts of events or the use of drone technology for various applications. However, achieving low latency whilst streaming becomes challenging when it comes to actual live streaming in real time....

Continue Reading