Espressif Systems Releases ESP32-C61 A Wi-Fi 6 and Bluetooth 5 SoC for Superior IoT Performance

Espressif Systems recently launched the ESP32-C61, an advanced System-on-Chip (SoC) with Wi-Fi 6 and Bluetooth 5 (LE). Building on its predecessors like ESP32-C2 and ESP32-C3, it shares similar specifications but adds support for BLE Mesh 1.1 protocol and faster Quad SPI PSRAM,...

Continue Reading

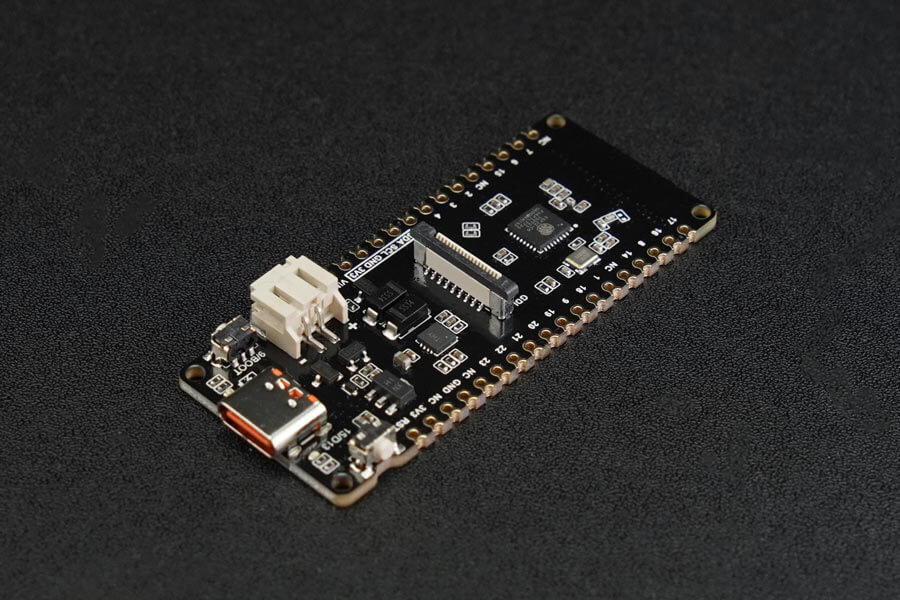

The FireBeetle 2 ESP32-C6 IoT Development Board with Wi-Fi 6, Bluetooth 5, Solar-Powered Support

The FireBeetle 2 ESP32-C6 is a compact and energy-efficient IoT development board that features the ESP32-C6 microcontroller and supports advanced connectivity options like Wi-Fi 6, Bluetooth 5, Zigbee 3.0, and Thread 1.3. Solar-powered charging and Target Wake Time technology for low...

Continue Reading

Waveshare’s PCIe to M.2 HAT+ for Raspberry Pi 5 is Priced at $8.99

Waveshare has released their new PCIe to M.2 HAT+, designed for the Raspberry Pi 5. This module is compatible with M.2 SSDs of sizes 2230 and 2242 and features a compact design at an affordable price. Update: After careful observation, I figured that there is a Design Flaw in this...

Continue Reading

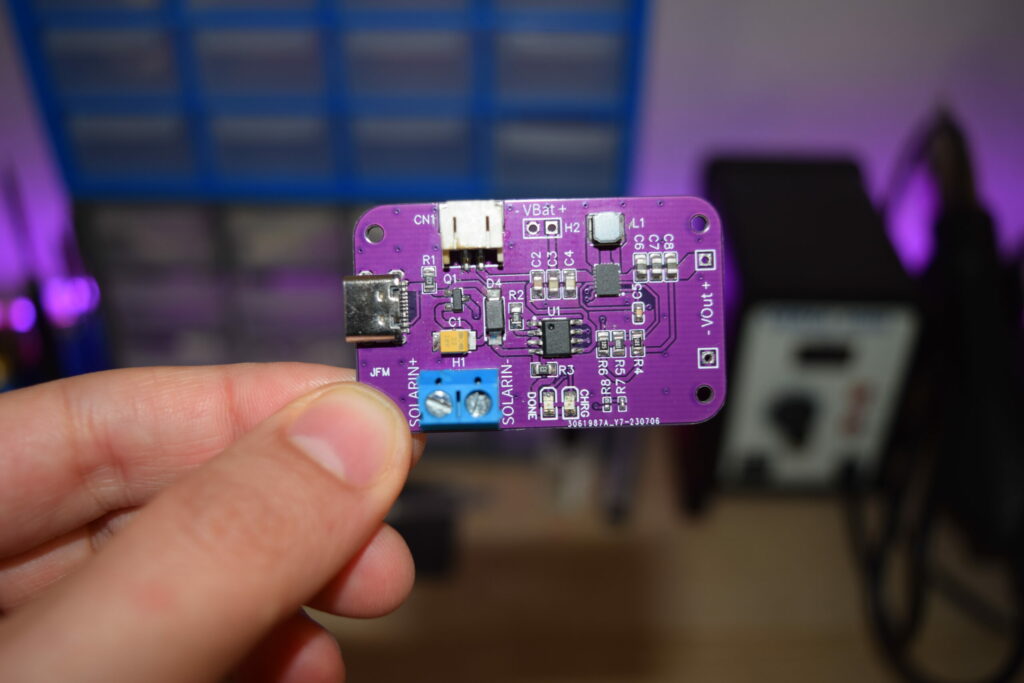

This Solar Buck-Boost Module Enhances Solar and USB Power Management for Embedded Systems

Juan Flores' Solar Buck-Boost Module is designed to charge a lithium-polymer battery using either a solar panel or USB power, providing a constant output voltage for noise-free power management for low-power applications. This board is designed to automatically switch between solar and...

Continue Reading

AAEON COM-R2KC6 is A High-Performance COM Express Module Based on AMD Ryzen R2000 Series CPU

AAEON COM-R2KC6 is a new COM Express module based on the Ryzen Embedded R2000 series of processors. The device comes in a Type 6 form factor and features four 4K displays and additional graphics via a PEG x4 slot, leveraging its AMD Radeon Vega 8 graphics. Previously we have covered...

Continue Reading

InfiRay Xinfrared T2S Plus Thermal Camera Review – A Smartphone Thermal Camera on a Tiny Package

Introduction For anyone with a knack for DIY projects, precision maintenance, or professional inspections, a thermal camera has become an invaluable addition to their tool collection. Looking back just a few years, they were very expensive and could only be found in military equipment....

Continue Reading

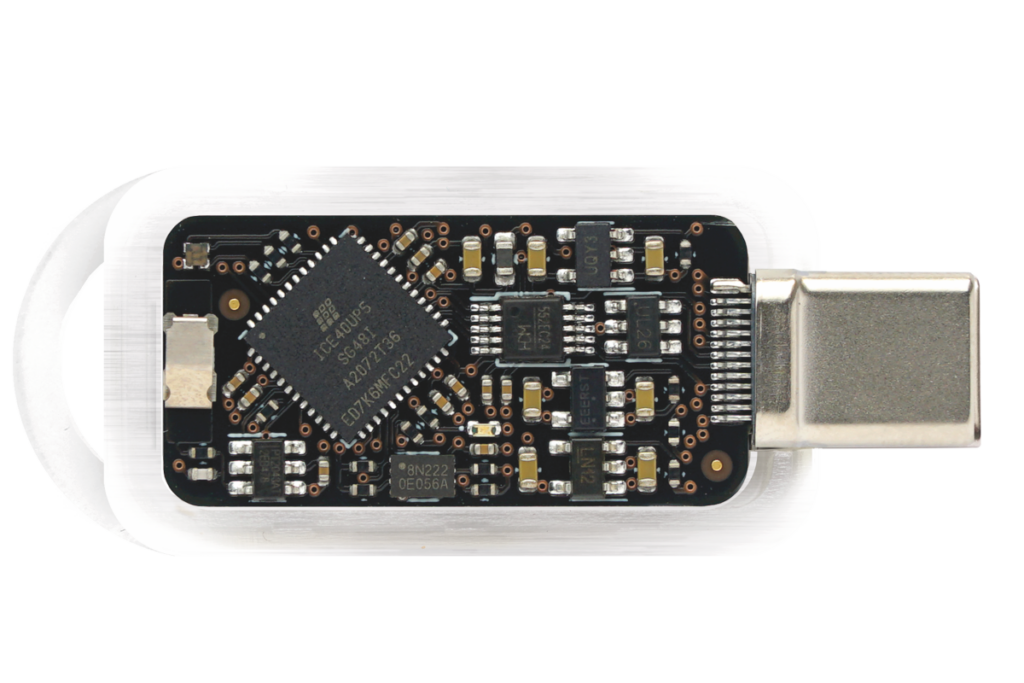

Tillitis Tkey is an open-source RISC-V security key in a USB-C case

Tillitis Tkey, an open-source RISC-V security key housed in a USB-C case, presents a unique approach to USB security tokens. Compact and straightforward, the TKey employs a 32-bit RISC-V core, specifically the PicoRV32, within a Lattice iCE40 UP5K FPGA. Distinguished by its departure...

Continue Reading

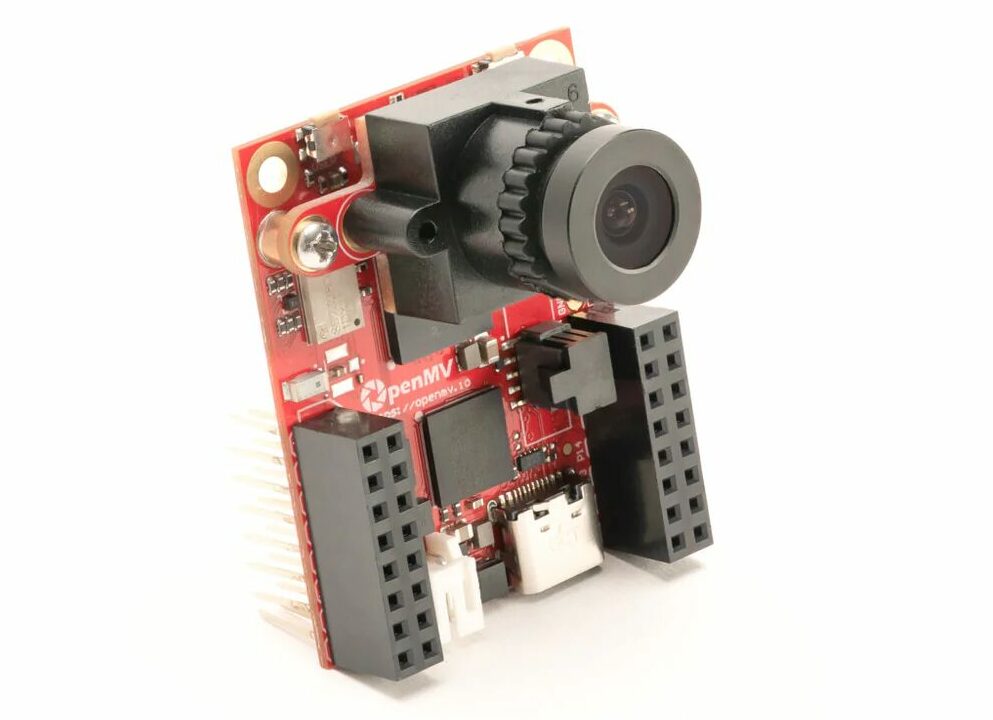

OpenMV Cam RT1062: Affordable Innovation in Machine Vision Now Available for $130

The OpenMV CAM RT1062 is a new camera from OpenMV that uses the powerful NXP RT1060 processor. You can write programs for it using MicroPython, a beginner-friendly version of Python. It has a fast USB-C connection, making it easy to connect to other devices. It also comes with an...

Continue Reading