MaTouch is A ESP32-S3 Based Rotary Display Module for IoT Applications

MaTouch is a rotary encoder with a circular display attached to it. This nifty device is designed and developed by Makerfabs and powered by an ESP32-S3 module. Priced at $44.80 this this compact gadget features Bluetooth and Wi-Fi capabilities and can be used for IoT applications. A...

Continue Reading

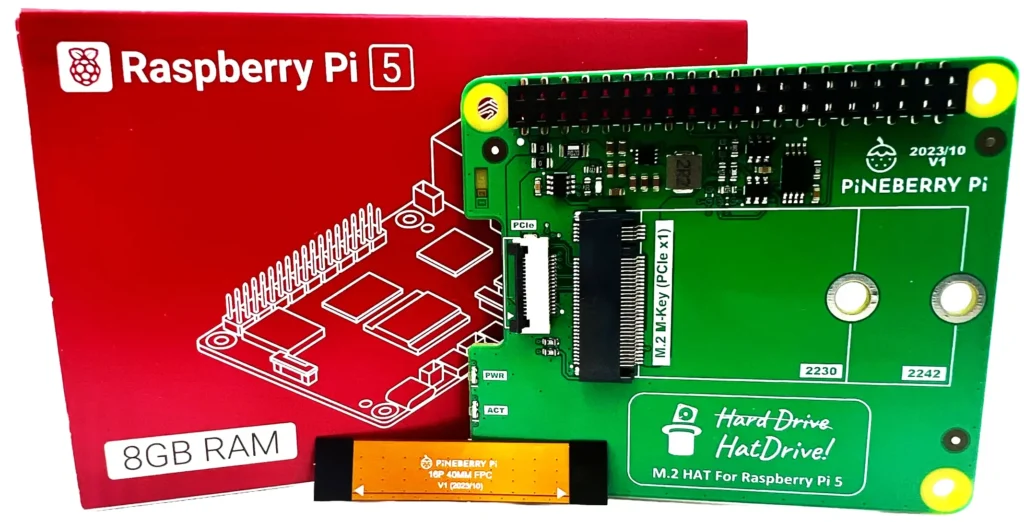

Expand Raspberry Pi 5 Storage with Pineberry Pi’s NVMe Hats

To fully harness the capabilities of the PICe on Raspberry Pi 5, Pineberry Pi has released two new PICe NVMe Expansion Boards The HatDrive Top and HatDrive Bottom. Both bordas are designed to increase the storage capacity of Raspberry Pi 5 using NVMe technology. A few months back, the...

Continue Reading

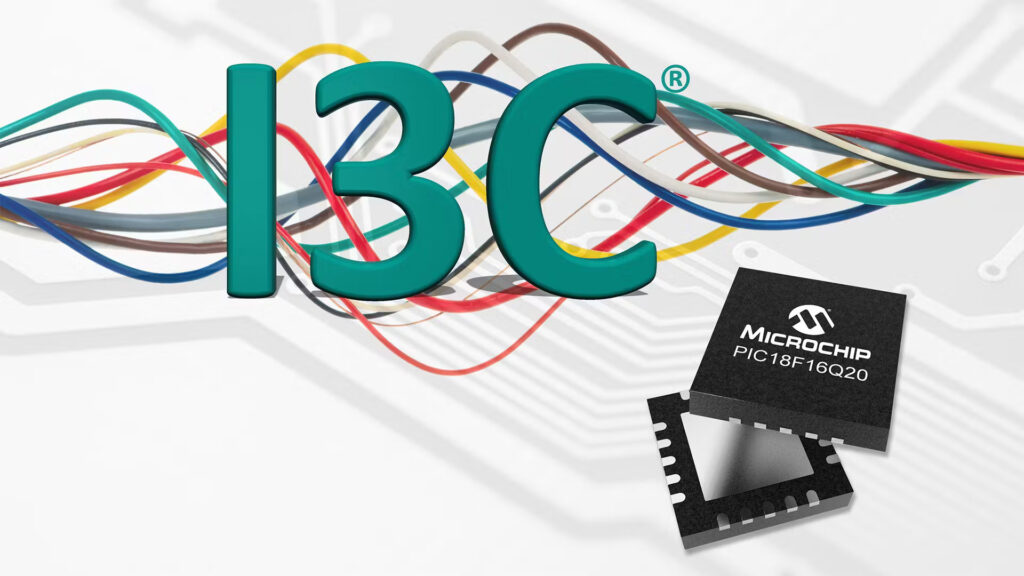

Microchip’s PIC18-Q20: Microcontroller with native I3C interface compatibility

Microchip has introduced the PIC18-Q20 microcontroller product line, bringing forth a set of versatile chips available in 14- and 20-pin packages. These microcontrollers not only support multi-voltage I/O but also mark a significant milestone as the first low-pin count microcontroller...

Continue Reading

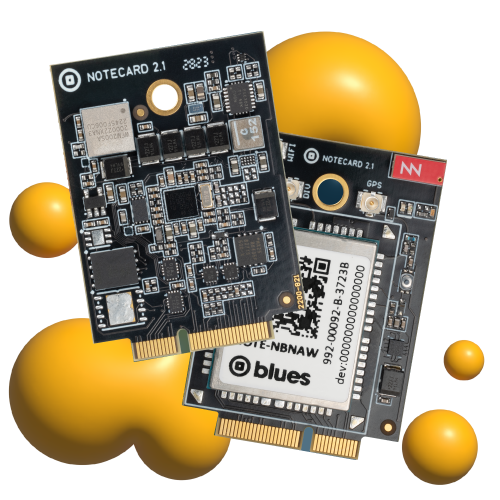

Blues Wireless released a new line of Notecards supporting Wi-Fi and cellular connectivity

Streamlining IoT Connectivity with Blues Wireless's Notecards and Notehub Blues Wireless, a provider of IoT connectivity, has announced a new line of Notecards. A Notecard is a versatile and compact IoT connectivity module that facilitates easy and efficient...

Continue Reading

Make Wireless Pentesting Easy with ESP32-DIV

ESP32-DIV is a palm-sized wireless pen-testing device powered by an ESP32. It features an ST7735 TFT LCD display and can perform Packet Monitoring, Wi-Fi Scanning, Beacon Spamming, and Deauth Detection. The ESP32-DIV combines the powerful ESP32 microcontroller with an ST7735 TFT LCD...

Continue Reading

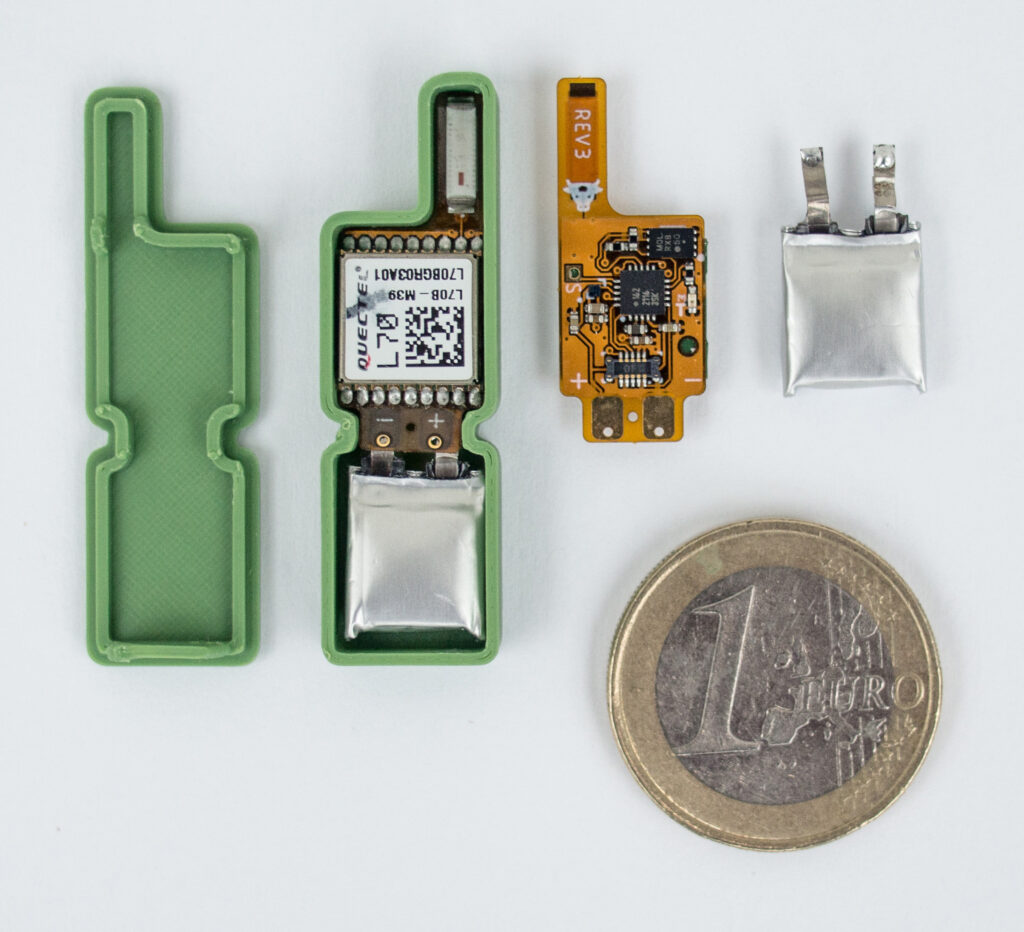

TickTagOpenSource is an Open-Source GPS Logger for Wildlife Tracking

Built on an open-source sentiment, TickTagOpenSource is a versatile GPS tracker featuring customizable hardware and user-friendly firmware. Complementing these features is an intuitive Android app, accompanied by detailed assembly guides and numerous other resources. In wildlife...

Continue Reading

Arduino Announces Major Upgrades to Cloud Platform, Enhancing IoT Experience

In a recent update, the Arduino team announced significant updates to their Arduino Cloud platform, while taking notes on user feedback to enhance its functionality and design. Improvements include a new user interface, improved sketch management, and enhanced IoT project templates. In...

Continue Reading

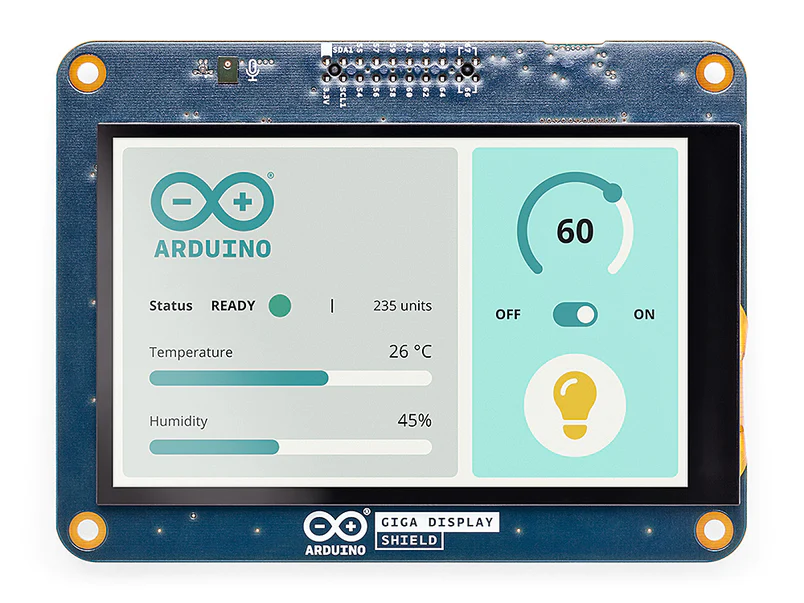

Taking UI Design to the Next Level with Arduino’s GIGA Display Shield

The Arduino GIGA Display Shield is feature-packed, with a multitouch display, microphone, IMU for motion, and the option to add a camera sensor. Arduino is calling on makers to elevate their user interface design skills by introducing the Arduino GIGA Display Shield. This add-on board...

Continue Reading