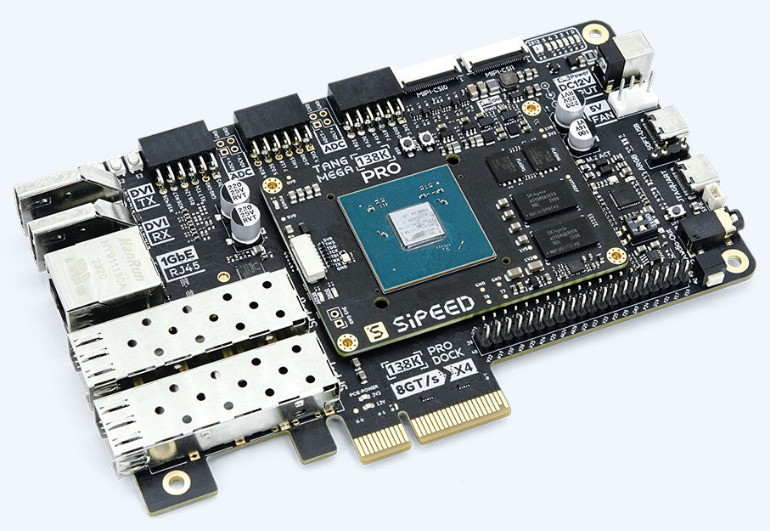

The Tang Mega 138K Pro Dock is Sipeed’s new RISC-V FPGA Development Board

Sipeed recently launched the Mega 138K Pro dev board. It's built around the GOWIN GW5AST RISC-V FPGA and features 2x SFP+ ports, a GbE port, dual DVI interfaces, 8x 12.5Gbps Serdes, and other peripherals. The Sipeed Tang series of boards are a family of FPGA development boards powered...

Continue Reading

Meet the Atom S3 Programmable Controller and the T-lite WiFi Thermal Camera

The highly integrated Atom S3 wireless programmable controller is one of the most recent releases from M5Stack Atom. Leveraging the power of the ESP32-S3FN8 chip, the compact controller offers high-performance value for a wide range of applications. It can be used as a microcontroller,...

Continue Reading

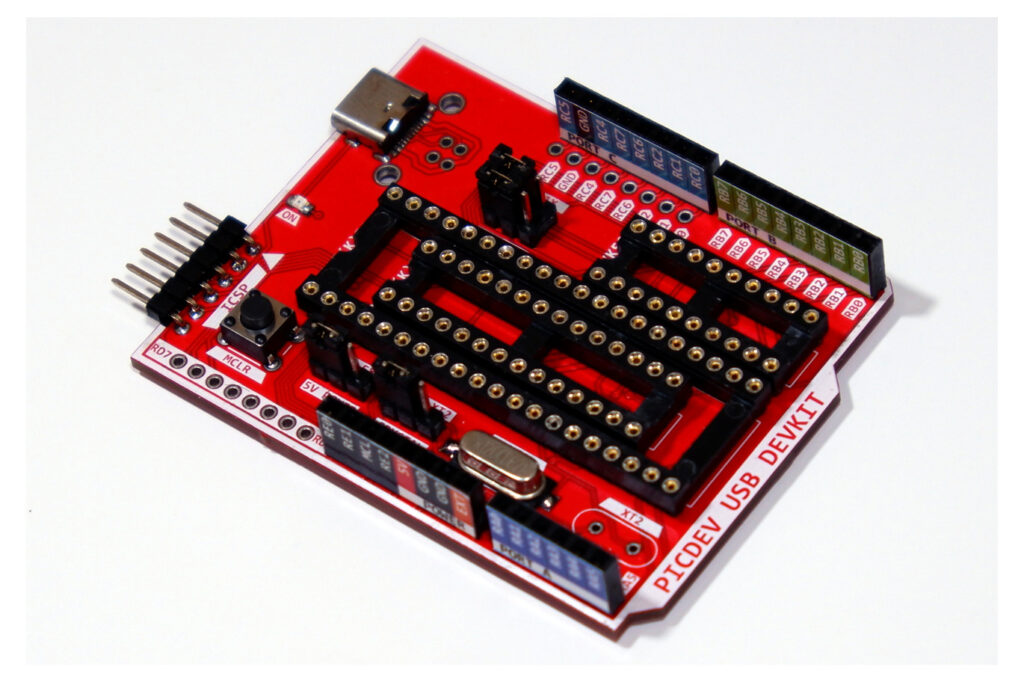

PICDEV USB Development Board Combines PIC18F’s capabilities with the Popular Uno Form Factor

Turkey-based MH-EDU-Electronics has designed a state-of-the-art development board made for versatility and ease of use, a game changer for all levels of developers. The new PICDEV USB development board unleashes the power of the Microchip PIC microcontrollers, follows after the Arduino...

Continue Reading

The BOXER-6617-ADN Blends Robust, Industrial Hardware with Low-Power, Efficient Processing

A ruggedized, tough industrial PC, the BOXER-6617-ADN is built for tough environments. Leading provider of embedded PC solutions, AAEON, is delighted to announce the official launch of the BOXER-6617-ADN, a robust, efficient industrial embedded PC featuring the Intel® Core™...

Continue Reading

SolidRun Unveils the Hummingboard 8P Edge AISBCwith Hailo-8 AI Processor

Fast-tracking the creation of powerful Edge AI inferencing applications, this new SBC enhances the i.MX 8M Plus SOC’s capabilities with a dedicated AI accelerator, vast expansion options and robust toolset SolidRun, a leading innovator in high-performance System on Module (SOM)...

Continue Reading

The UP 7000 Edge is a Palm-Sized Mini PC Hosting the Full Intel® Processor N-series Lineup

AAEON’s UP 7000 Edge is a tiny, versatile, and efficient option for a plethora of computing needs. AAEON’s UP brand, a leading producer of advanced developer boards and Mini PCs, has released the UP 7000 Edge, a Mini PC that hosts the full lineup of embedded Intel® Processor...

Continue Reading

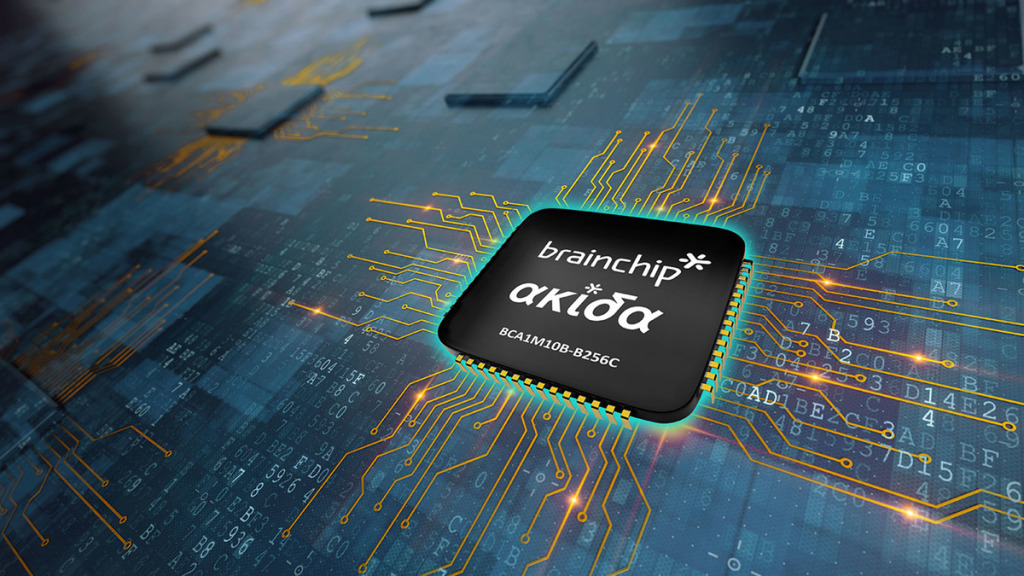

BrainChip develops Edge Box based on neuromorphic technology

Two companies, BrainChip and VVDN Technologies, came together to develop an edge box that is based on neuromorphic technology, which is an advanced AI technology that mimics the functioning of the human brain. The co-developed hardware solution can perform AI processing at the edge of a...

Continue Reading

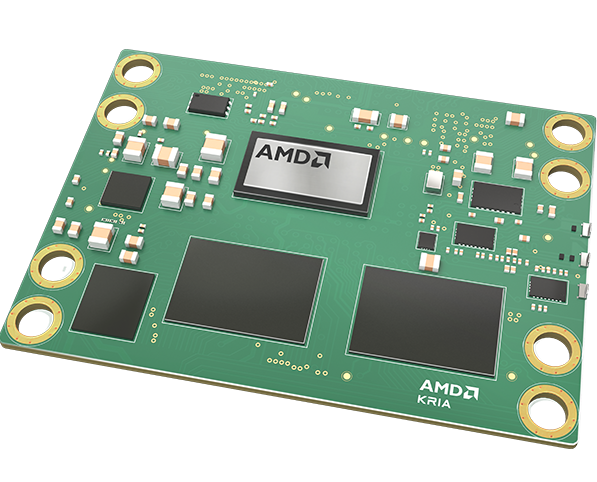

AMD launches Kria K24 system-on-module for use in industrial and commercial edge applications

AMD has introduced two new products, the AMD Kria K24 System-on-Module (SoM) and the KD240 Drives Starter Kit. These are part of the company's Kria portfolio, which focuses on providing adaptable System-on-Modules and developer kits for various applications. The AMD Kria K24 SoM is a...

Continue Reading