IBASE Showcases MediaTek Genio-based Edge AI Computer at Embedded World 2024

IBASE Technology Inc., a renowned provider in the design and manufacturing of edge computing solutions, will showcase its MediaTek Genio-based ISR500 rugged edge AI computer at Embedded World 2024, April 9-11, 2024. Feel free to visit IBASE booth 3-351 in Hall 3 for a closer look at the...

Continue Reading

High Performance. Future-Proof. Empowering Next-Gen AI

Toradex, a leading embedded systems solutions provider, has launched its newest family of pin-compatible and scalable System on Modules (SoMs) - Aquila. Aquila is tailored for demanding applications in the fields of medical, industrial and robotics. Engineered with a focus on rugged...

Continue Reading

Rohde & Schwarz introduces new R&S NPA family of compact power analyzers for all power measurement requirements

A new family of Rohde & Schwarz power analyzers is now available in three models to meet all requirements for measuring voltage, current, power and total harmonic distortion on both DC and AC sources. The R&S NPA101 power meter provides all basic measurements, the R&S NPA501...

Continue Reading

Rohde & Schwarz presents new R&S NGC100 power supply series with market-leading functions

The latest DC power supplies from Rohde & Schwarz for every-day manual use in the laboratory as well as for automated applications offer an extremely wide range of functions for entry level instruments. The R&S NGC100 power supply series includes one, two, and three-channel...

Continue Reading

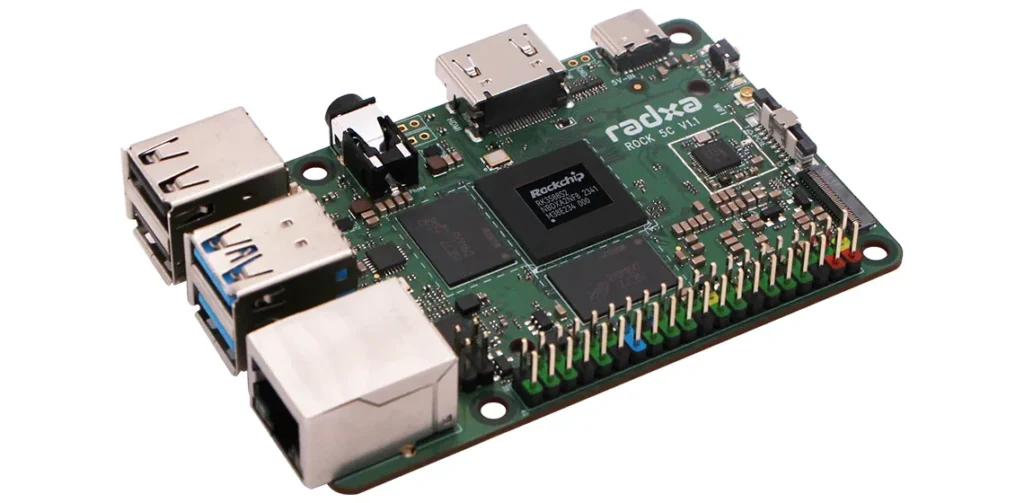

Radxa’s Latest ROCK 5C and ROCK 5C Lite Boast PCIe 2.1 Interfaces and PoE Support

Radxa has recently launched two new single-board computers - the ROCK 5C and the ROCK 5C Lite. The ROCK 5C is built around the RK3588S SoC, while the ROCK 5C Lite is built around the RK3582 SoC. The company has made these boards fundamentally different; the only commonalities between...

Continue Reading

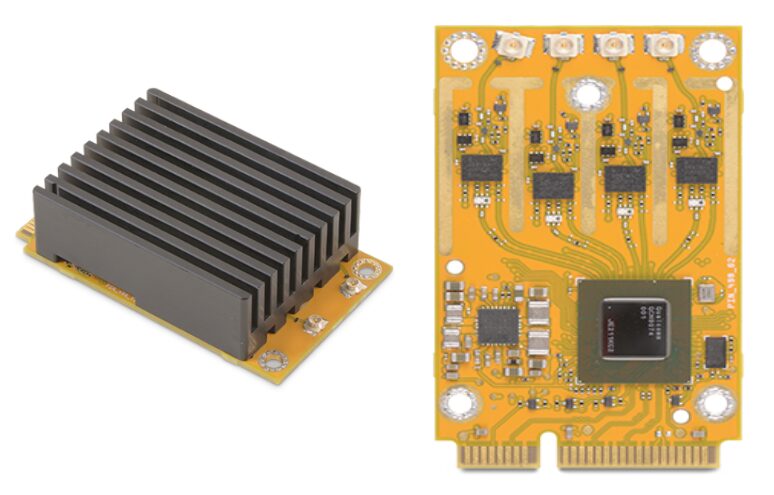

Introducing Mini Pini: A Powerful Wi-Fi 6 Module with OpenWrt Support

The Mini Pini emerges as a cutting-edge Wi-Fi 6 radio module engineered to effectively tackle the challenges of demanding wireless environments. Leveraging Qualcomm's advanced QCN9074/72 chipset, this product promises efficient and reliable wireless performance across various...

Continue Reading

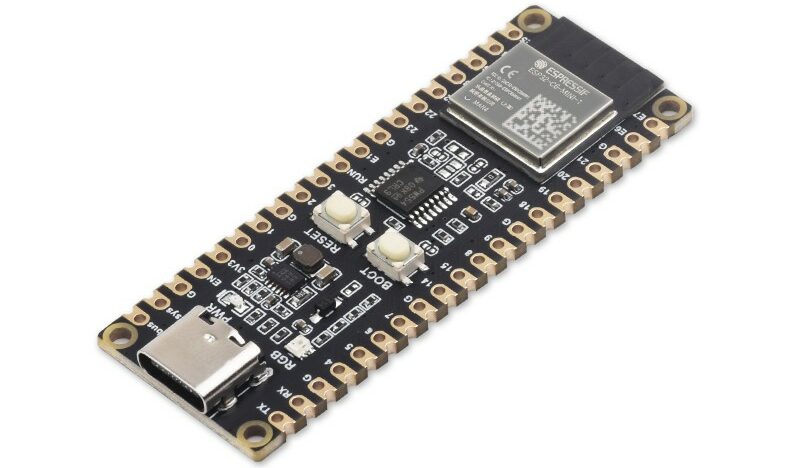

Waveshare’s New ESP32-C6-Pico Board Shares the Same Form Factor as the Raspberry Pi Pico

Waveshare has recently launched a new ESP32-C6-Pico Board that has a similar form factor to the Raspberry Pi Pico. However, instead of an RP2040 chip, the board is built around an ESP32-C6-MINI-1 module. This little tweak makes the board compatible with a series of Waveshare LED...

Continue Reading

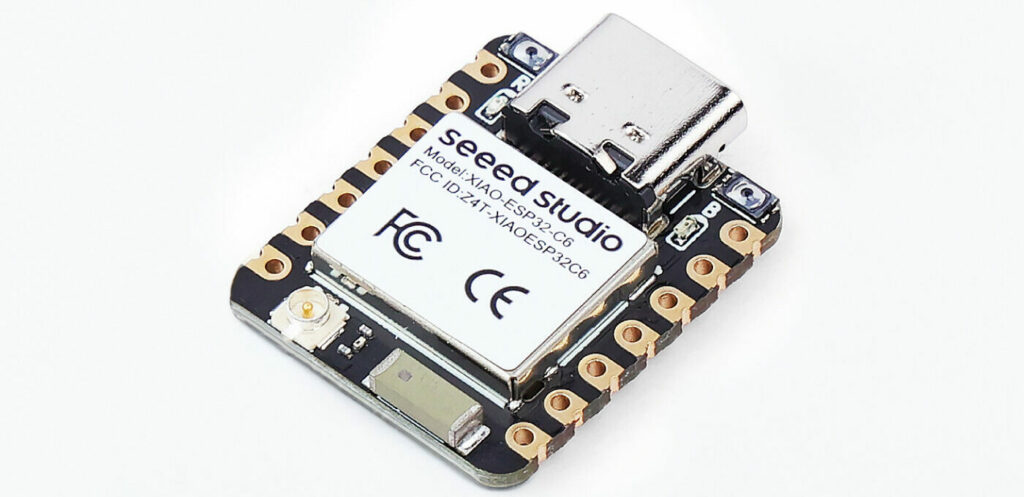

Seeed Studio XIAO ESP32C6 Dev Board Features a Compact Form Factor

SeeedStudio has recently introduced XIAO ESP32C6 Dev Board with Wi-Fi 6/Bluetooth 5 and integrates Matter compatibility all built onto a thumb-size footprint. After the initial release of the ESP32-C6 SoC last year we have seen boards like the SparkFun ESP32-C6 Thing Plus, the ePulse...

Continue Reading