MI1000 Mini-ITX Motherboard Featuring 14th Gen Intel Core Processors and R680E PCH

IBASE Technology Inc., a leading innovator in industrial PC solutions, unveils the MI1000 Mini-ITX motherboard today. Engineered to support the latest 14th/13th/12th Gen Intel® Core™ i9/i7/i5/i3 DT processors (RPL-S Refresh Platform) with up to 65W TDP, these motherboards excel...

Continue Reading

ASRock Industrial Leads with SBC-262M-WT Motherboard Powered by Intel Atom x7433RE for Next-Generation Edge Computing

ASRock Industrial is thrilled to announce the launch of its latest innovation, the SBC-262M-WT 3.5” SBC Motherboard, a new benchmark in edge computing, powered by the advanced Intel® Atom® x7433RE Processor (Amston Lake). Designed with enhanced CPU and GPU performance, this...

Continue Reading

Hailo Closes New $120 Million Funding Round and Debuts Hailo-10, A New Powerful AI Accelerator Bringing Generative AI to Edge Devices

Hailo’s funding now exceeds $340 million as the company introduces its newest AI accelerator specifically designed to process LLMs at low power consumption for the personal computer and automotive industries, bringing generative AI to the edge. Hailo, the pioneering chipmaker of edge...

Continue Reading

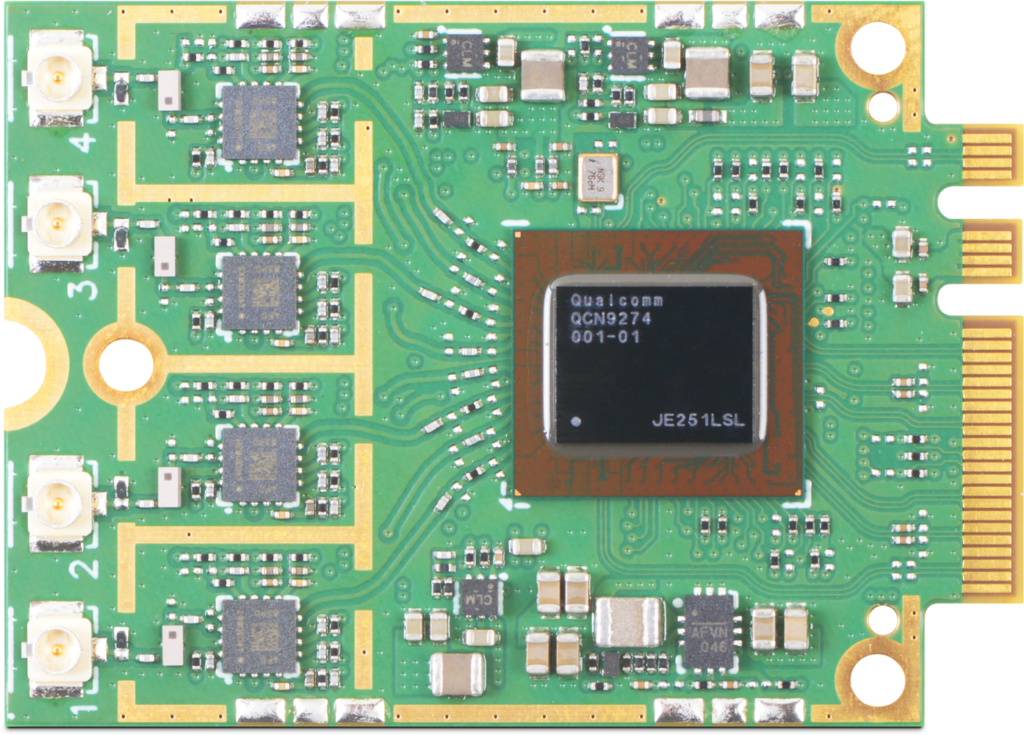

Noni Radio Module: Unlocking WiFi-7 Connectivity with Qualcomm’s Chipsets

The Noni module, powered by Qualcomm’s QCA9274/QCA6274 chipsets, revolutionizes wireless connectivity with advanced WiFi-7 capabilities packed into a versatile M.2 A+E form factor. Tailored for a diverse range of applications, this module thrives in both commercial and industrial...

Continue Reading

Introducing Olimex’s ESP32-H2-DevKit-LiPo: Empowering IoT Enthusiasts with Affordable Connectivity

Bulgarian open hardware specialist Olimex has revealed its latest innovation, the ESP32-H2-DevKit-LiPo. This compact, cost-effective development board is specifically crafted for individuals keen on delving into Matter devices and the Internet of Things (IoT). At the heart of the...

Continue Reading

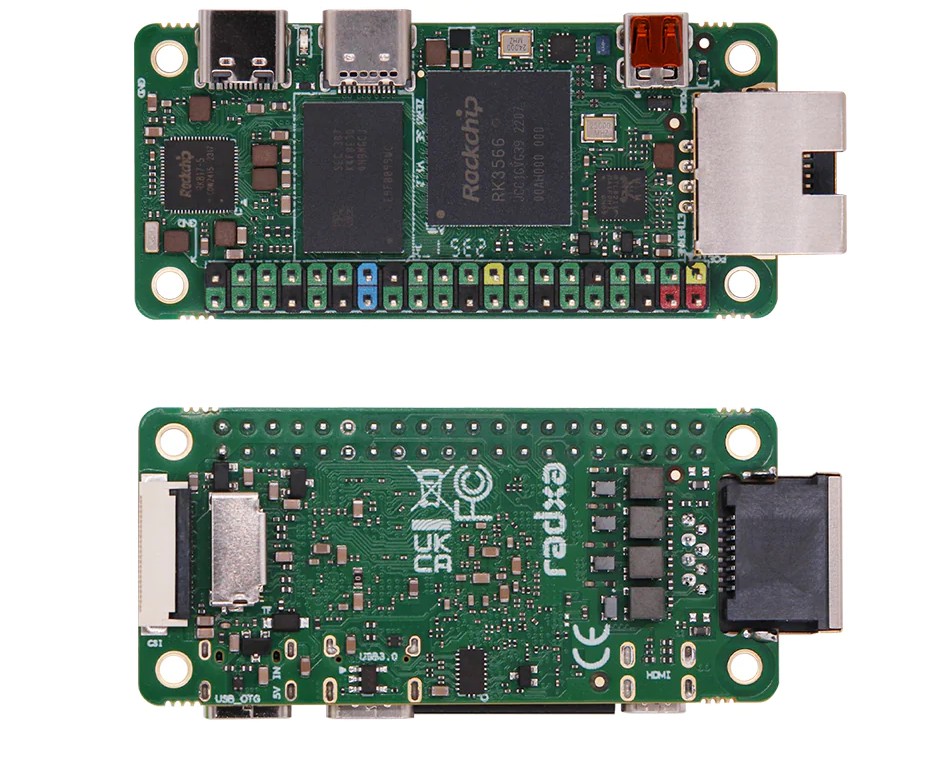

Radxa ZERO 3E SBC is Now Availabe for $15.99

In a previous post, we discussed the Radxa Zero 3W & 3E, both powered by the Rockchip RK3566 and designed to mimic the form factor of the Raspberry Pi Zero 2W and Orange Pi Zero 2W. At that time, Radxa had not disclosed its pricing. However, they have recently announced that these...

Continue Reading

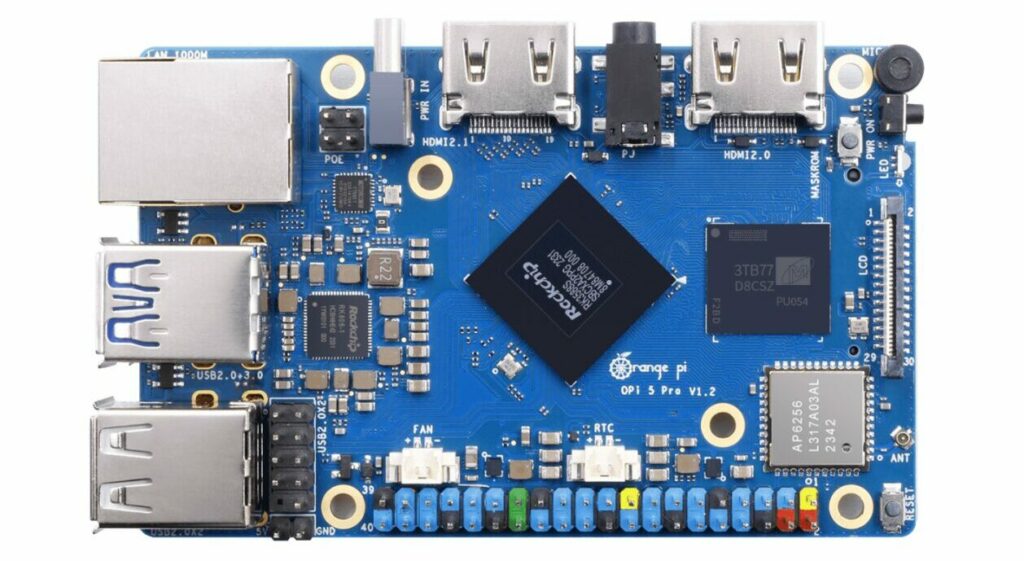

Upcoming Orange Pi Pro to Feature K3588S Chipset with LPDDR5 RAM and PoE+ support

In a recent announcement, orange has recently announced some key details about their latest Orange Pi 5 Pro SBC. From that, we know this new board will be built around the RK3588S SoC and It will have a GbE port with PoE+ support, M.2 Key slot for expansion, and Wi-Fi5/BT5.0...

Continue Reading

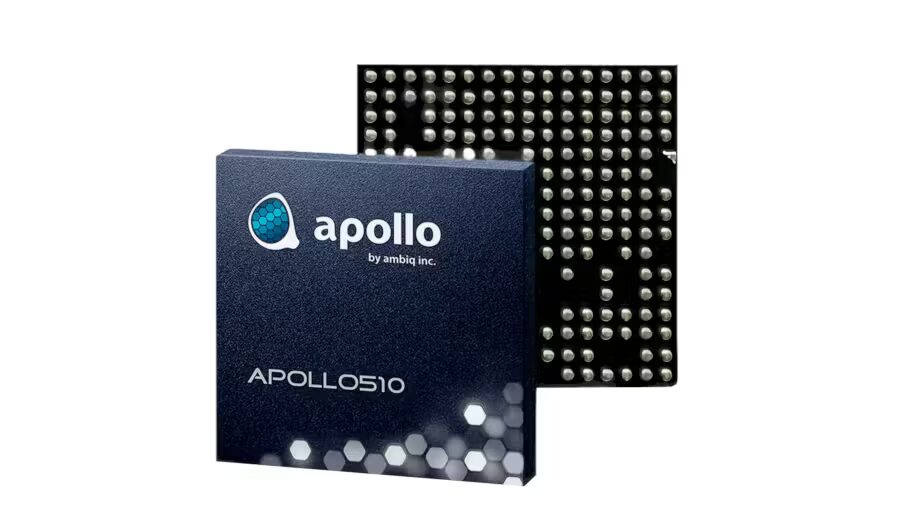

Ambiq Introduces Apollo510 Chip: Pioneering Energy-Efficient Edge AI

Ambiq, renowned for low-power "intelligent devices," has introduced its cutting-edge Apollo510 system-on-chip (SoC), heralding a significant advancement in energy efficiency and performance for edge AI applications. The Apollo510 brings forth a remarkable 30-fold improvement in power...

Continue Reading