Espressif’s ESP32-C5 Features a Dual-Band Wi-Fi 6 Radio with MU-MIMO, TWT, and More

Espressif Systems has recently introduced the ESP32-C5 a MCU with dual-band (2.4 & 5.0 GHz) WiFi-6 and Bluetooth 5.0 LE support. Previously we have seen Espressif release many MCU such as the ESP32-C6, and ESP32-C61, both of which are capable of handling 2.4GHz radio connectivity,...

Continue Reading

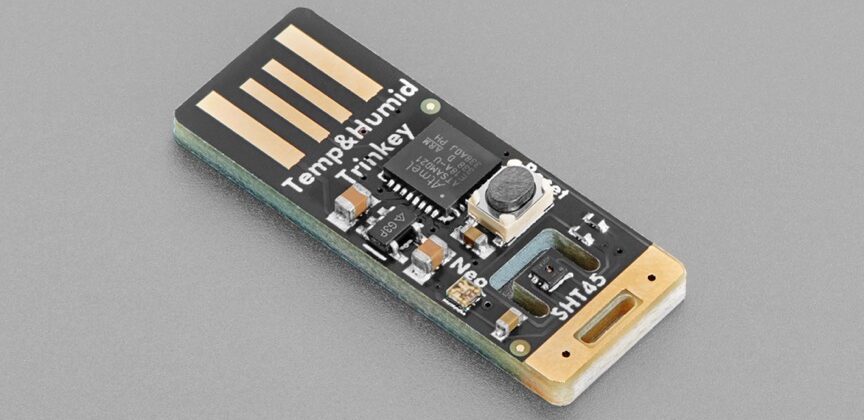

Adafruit’s Trinkey is A Thumb-Drive-Sized Temperature and Humidity Sensor

Adafruit has recently added two new members to the Trinkey family, the Adafruit SHT45 Trinkey and the Adafruit SHT41 Trinkey both of those are designed to add temperature and humidity-sensing capabilities to any USB HOST device. The main difference between the two boards lies in their...

Continue Reading

Experience Effortless Device Control with Openterface Mini-KVM

Openterface Mini-KVM offers a simple solution for managing headless devices like mini PCs, kiosks, or servers directly from your laptop or desktop. This plug-and-play tool lets you control your target device without needing extra peripherals such as keyboards, mice, or monitors. Key...

Continue Reading

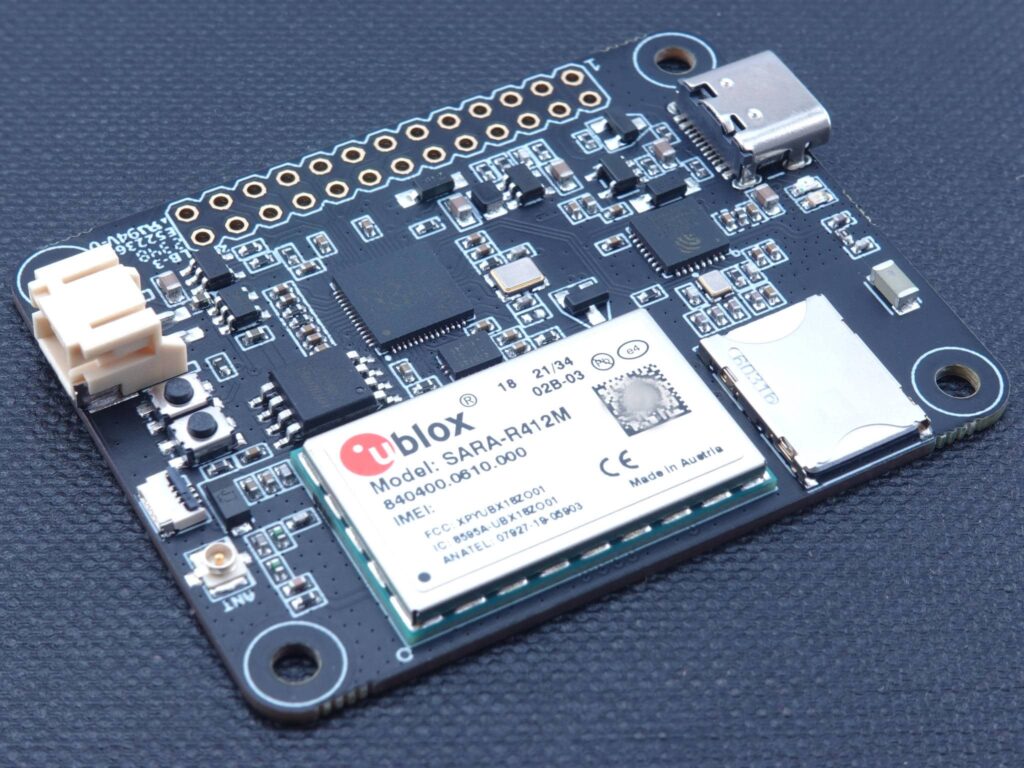

ILABS’ RP2040 Board Empowers IoT with Wi-Fi, BLE, and Cellular Support

ILABS, a leading European embedded electronics specialist, has unveiled the RP2040 Connectivity Board, a feature-rich development board centered around Raspberry Pi's cost-effective RP2040 microcontroller unit (MCU). This board is designed to offer comprehensive connectivity solutions...

Continue Reading

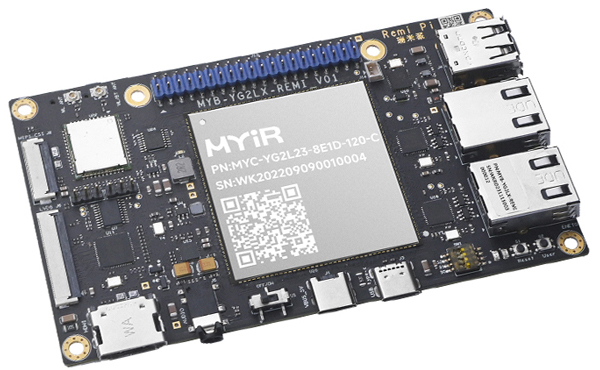

MYIR Unveils $55 Remi Pi Computer Board Powered by Renesas RZ/G2L MPU

MYIR has launched the Remi Pi, a unique and compact computer board that offers an affordable solution based on the Renesas RZ/G2L MPU, which takes into account the needs of serious product development and hobbyist creativity. The Remi Pi leverages the RZ/G2L, a dual-core Arm Cortex-A55...

Continue Reading

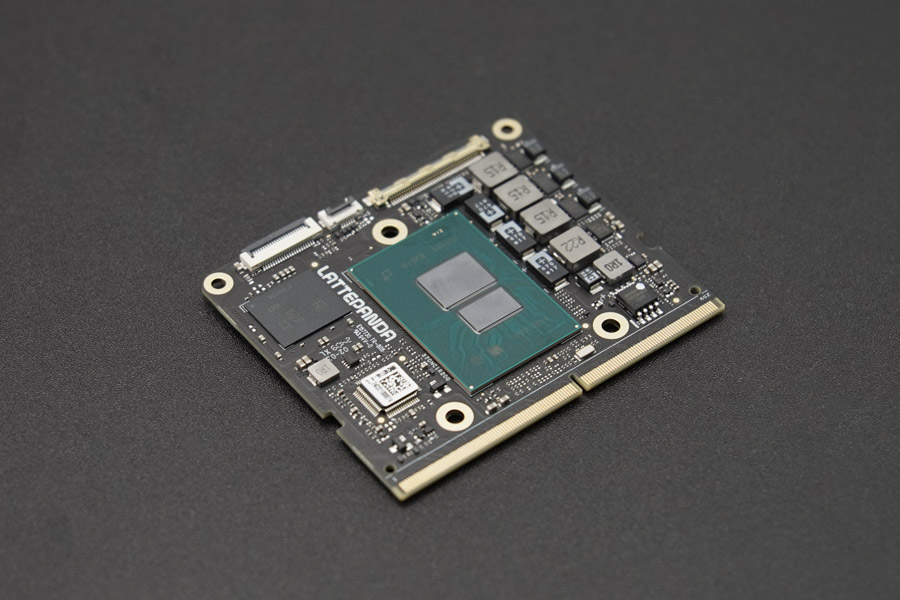

LattePanda Team Launches LattePanda Mu – a Micro x86 Compute Module for Custom Design Solutions

The LattePanda team launched the LattePanda Mu, an exceptional micro x86 compute module poised to swiftly empower custom design solutions. With an Intel N100 CPU, it is compatible with Windows and Linux operating systems. The LattePanda Mu demonstrates superior CPU performance compared...

Continue Reading

Qoitech ends 199 USD annual Pro subscription for IoT power analysis and optimization tools

Qoitech, a manufacturer of power analysis and optimization tools for embedded systems, has ended its $199 per annum license subscription previously charged for the Pro version of its software suite as it upgrades this to Otii Software 3.5. All the advanced Pro features for Otii Ace and...

Continue Reading

IBASE Showcases MediaTek Genio-based Edge AI Computer at Embedded World 2024

IBASE Technology Inc., a renowned provider in the design and manufacturing of edge computing solutions, will showcase its MediaTek Genio-based ISR500 rugged edge AI computer at Embedded World 2024, April 9-11, 2024. Feel free to visit IBASE booth 3-351 in Hall 3 for a closer look at the...

Continue Reading