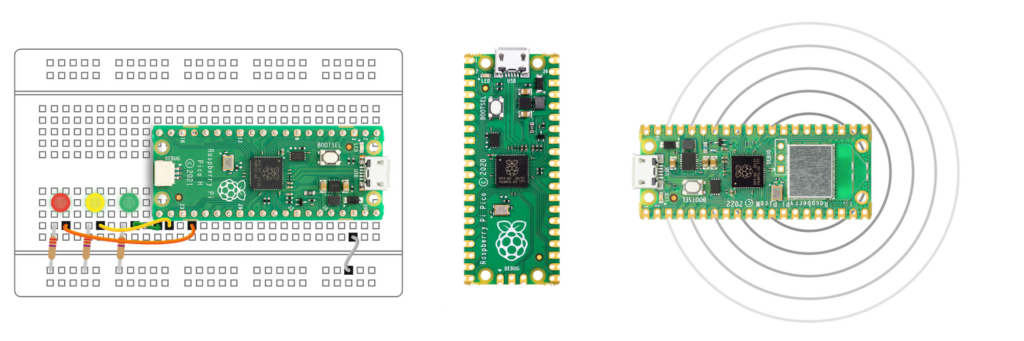

New Software Update Enables Bluetooth for Pico W

In a recent announcement, Raspberry Pi has released 1.5.1 of the C SDK along with the latest MicroPython build. This update enables Bluetooth on the Raspberry Pi Pico W. Launched last year, the Raspberry Pi Pico W is a small, $6 computer module that can be used for various electronics...

Continue Reading

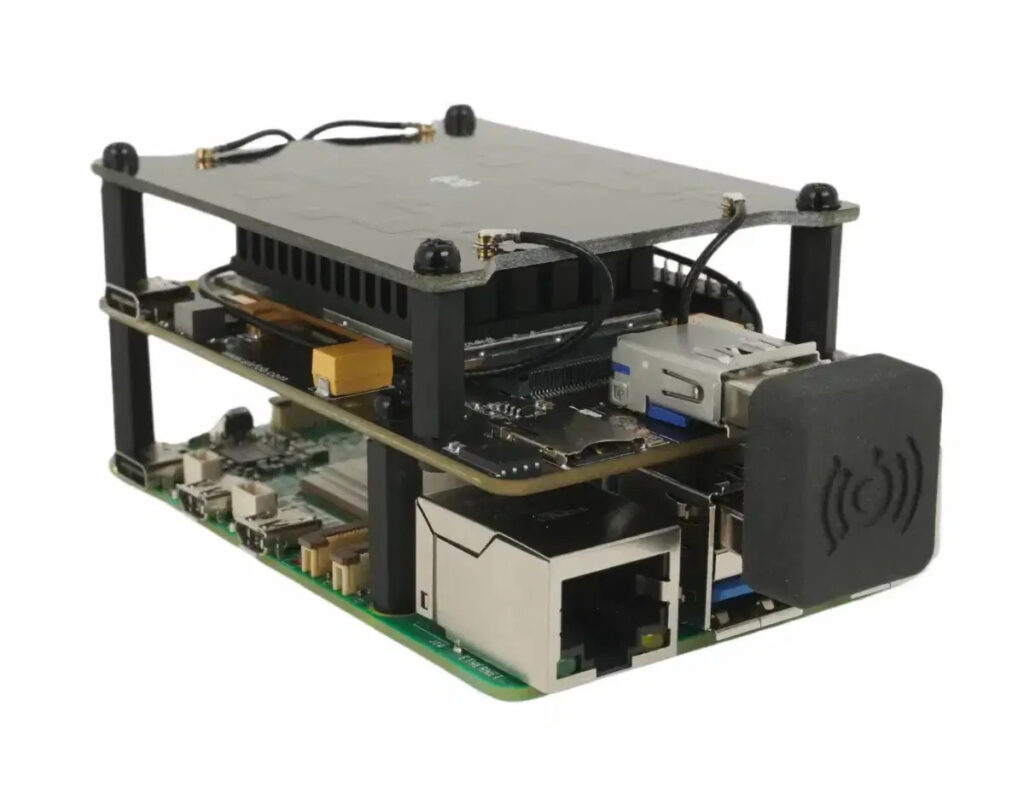

Sixfab 5G Raspberry Pi 5 Kit Featuring Quectel RM502Q-AE M.2 Module

The New Sixfab 5G HAT for Raspberry Pi 5 features a Raspberry Pi HAT powered by the Quectel RM502Q-AE 5G Sub-6GHz M.2 module for global use (excluding China). Additionally, the HAT features a unique internal antenna designed by SixFab for Sub-6 frequency bands and comes with a USB 3.0...

Continue Reading

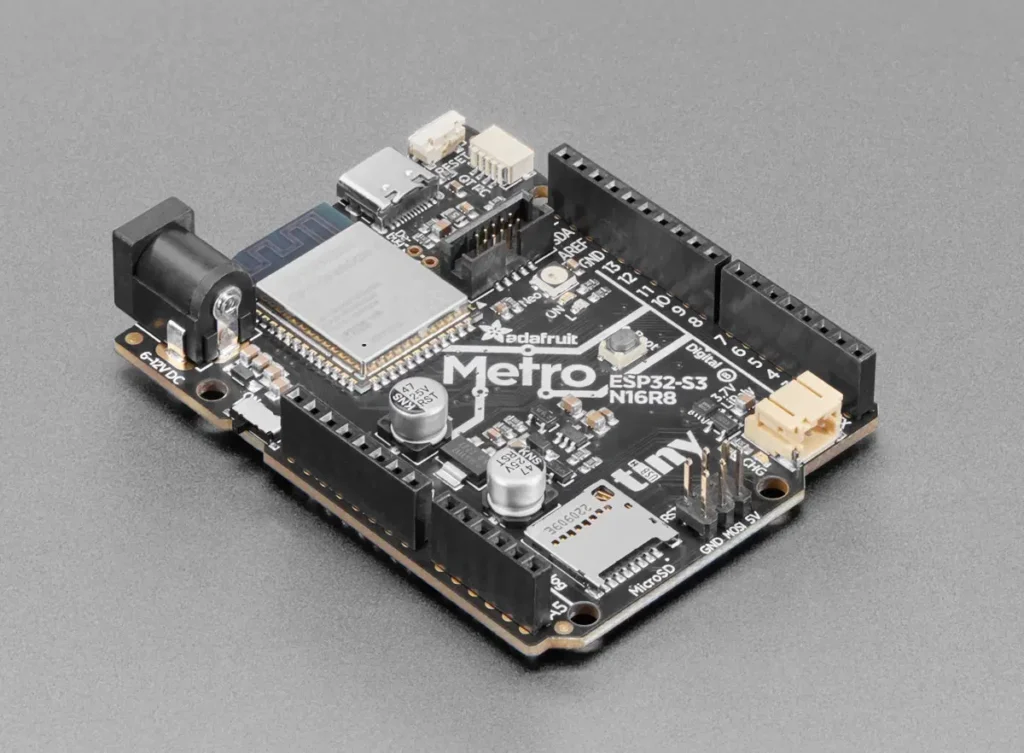

Metro ESP32-S3 is The Next Generation IoT Board with Circuit Python Support

The Adafruit Metro ESP32-S3 is a development board based on the ESP32-S3, designed in a form factor similar to an Arduino UNO or Adafruit Metro. The board features built-in Wi-Fi Bluetooth capabilities and can be programmed with Arduino or Circuit Python. The core of the board is an...

Continue Reading

Elecrow’s LR1302 is A LoRa Gateway Module for Advanced IoT Applications

The LR1302 is a new and advanced LoRa gateway module with a mini PCIe form factor. Powered by Semtech's SX1302 chip, this device can achieve high performance with low power consumption. It can handle 8-channel data transmission, which makes it suitable for applications like industrial...

Continue Reading

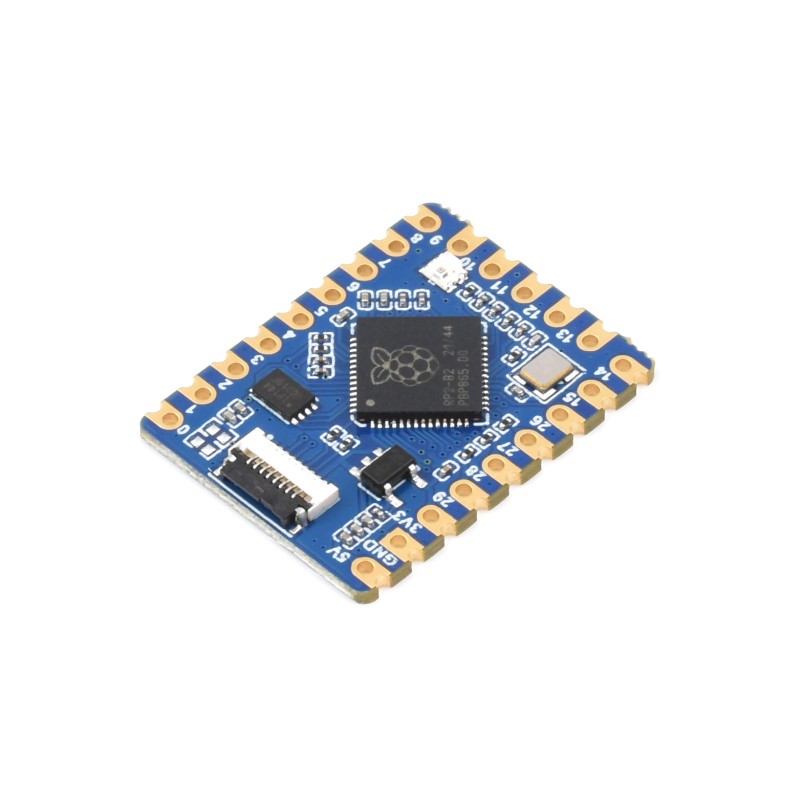

Waveshare RP2040-Tiny: Compact Power with USB-C and Buttons

Tiny Raspberry Pi RP2040 module connects to USB-C + buttons board via FPC connector The Waveshare RP2040-Tiny enters the scene as a noteworthy addition to the family of Raspberry Pi RP2040 modules. In the company of counterparts like Pimoroni Tiny 2040, DFRobot Beetle RP2020, and...

Continue Reading

EDATEC’s AI-Enabled Vision System is Powered By RPi CM4

The ED-AIC2100 and ED-AIC2000 are two new AI camera modules powered by the RPi CM4, and designed for industrial and commercial applications. These camera systems are equipped with the Broadcom BCM2711 CPU and offer storage options of 8GB, 16GB, or 32GB eMMC. They feature a...

Continue Reading

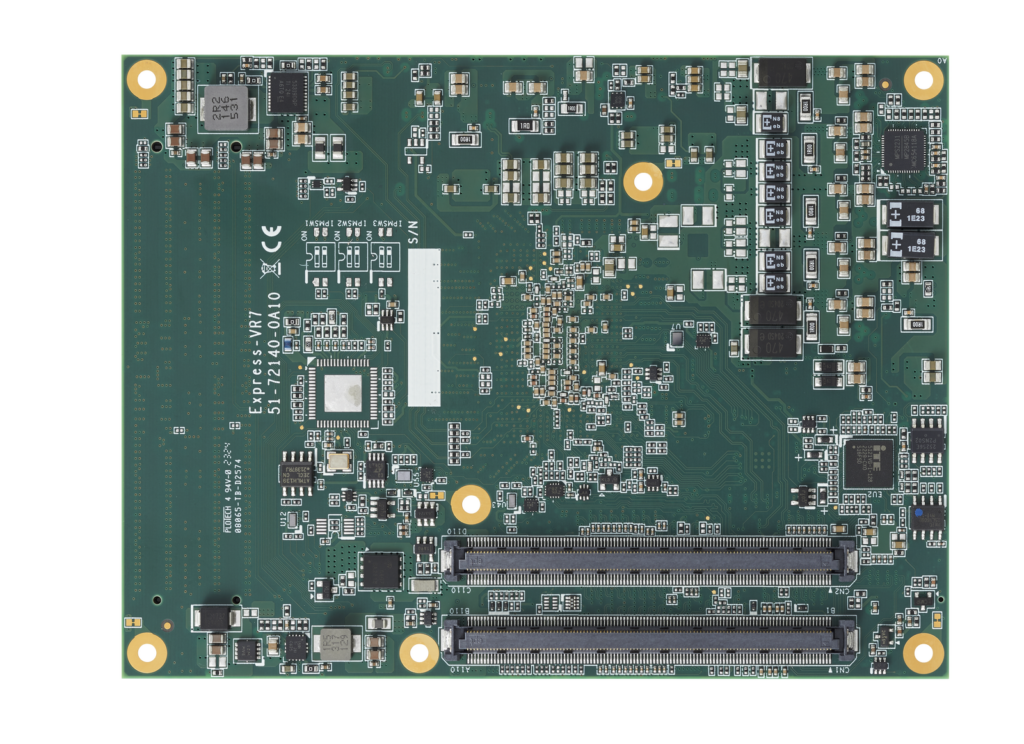

ADLINK introduces COM-Express Type 7 module with the best performance per watt in its class

Powered by AMD® Ryzen™ Embedded V3000, the module features up to 8 cores at 15W, 45W, integrated 2x10G Ethernet, with extreme temperature options for various networking use cases Summary: ADLINK brings 8 cores at 15W, 45W TDP in its latest COM Express Basic size Type 7...

Continue Reading

Boondock Echo is A Two-Way Radio with AI and Keyword Alert Features

The Boondock Echo is an internet-backed, two-way radio attachment with advanced features like recording, playback, denoise, transcribing, and translation. Additionally, it offers keyword-based notifications, enhancing communication efficiency and monitoring. Boondock Echo connects to a...

Continue Reading