Paul Price’s ESP32 Dev Board is Just About the Tinyest ESP32 Dev Board Possible

Youtuber Paul Price has built what could be the smallest and most functional ESP32 DEV board possible. The board contains the ESP32-C3 SoC, a few passive components, and a USB connector for programming. Impressively, he could fit all that on the tip of his finger. In his video, Paul...

Continue Reading

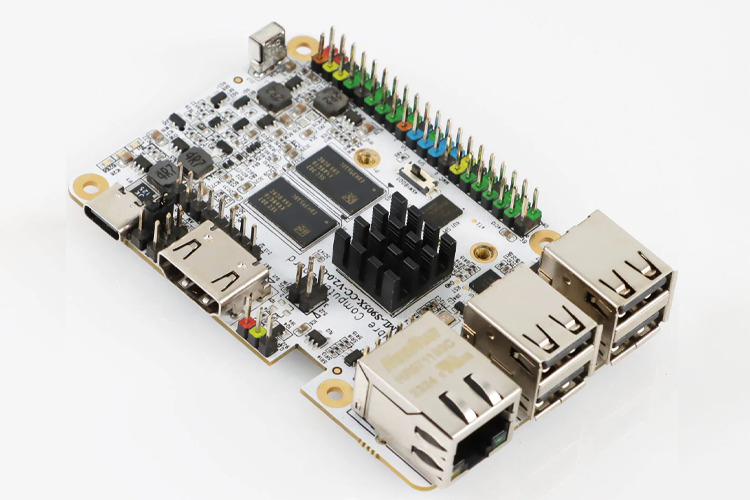

From Le Potato to Sweet Potato: A Modern Twist on the Classic Le Potato with Power-over-Ethernet

Libre Computer Sweet Potato is a Raspberry-like SBC with Power-over-Ethernet (PoE) and USB-C. Based on the Amlogic S905X SoC, this board is designed for industrial and commercial applications. Libre Compute has just unveiled "Sweet Potato," the successor to its "Le Potato" Single...

Continue Reading

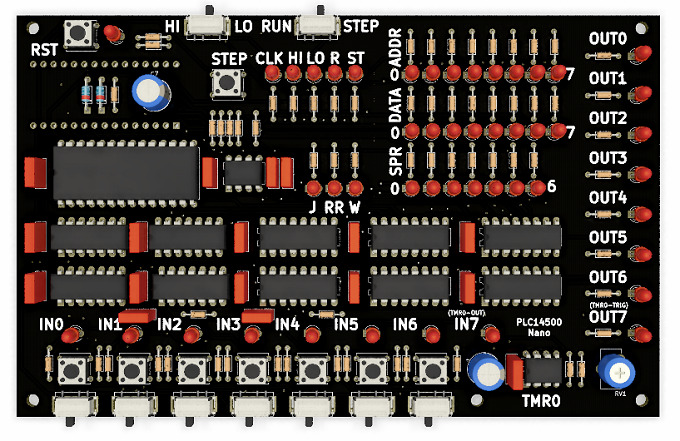

Rediscovering the MCU Magic of the 70s with Nicola Cimmino’s PLC14500 Nano Trainer

The PLC14500 Nano is a retro-style trainer kit intended for the user to familiarize with the Motorola MC14500 1-bit ICU (Industrial Control Unit), PLCs, and Ladder Logic. Over 50 LEDs on the board show the status of the system bus and registers, giving great insight into how the...

Continue Reading

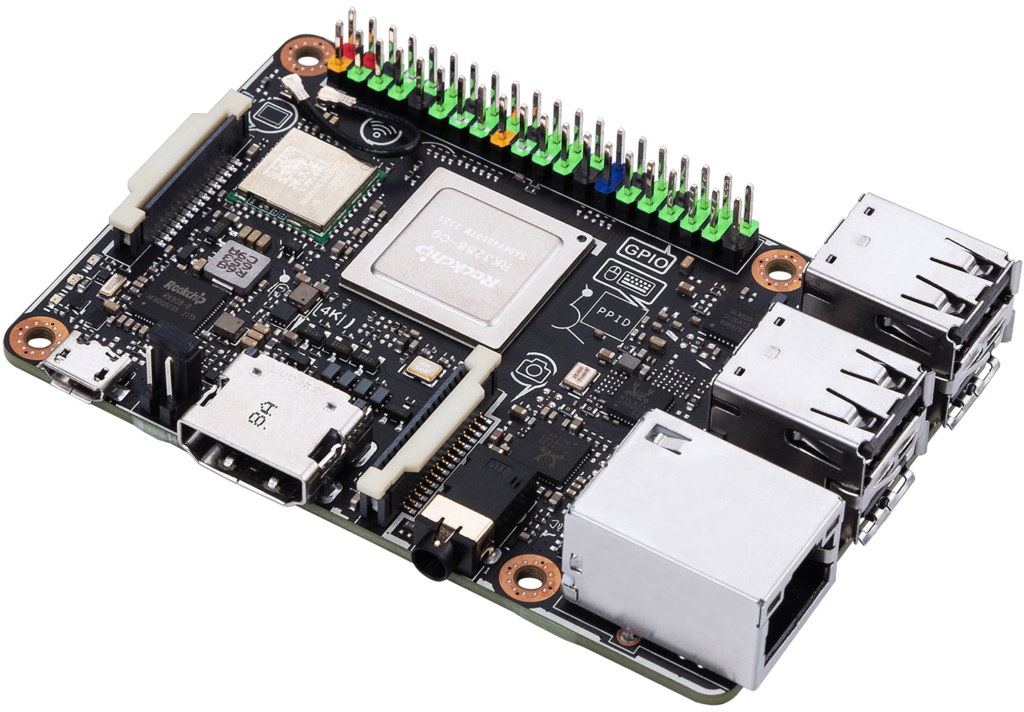

Asus Unveils Tinker Board R2.0 Powered by Rockchip RK3288 – A Small yet Powerful SBC

Asus recently announced its second-generation Tinkerboard, the Tinker Board R2.0. Powered by a quad-core Rockchip RK3288 processor, this single-board computer (SBC) features a Gigabit Ethernet port, dual display ports, and additional camera support. With its credit card-sized form...

Continue Reading

iWave Systems’ iW-RainboW-G30M System-on-Module and iW-RainboW-G30D Development Kit

iWave Systems has designed a new SoM that is based on the highly power-efficient AMD Xilinx ZU4/ZU5/ZU7 Zynq UltraScale+ FPGA MPSoC which is claimed to deliver advanced capabilities to LiDAR sensors. The new iW-RainboW-G30M SoM best suits scientific and military projects such as point...

Continue Reading

M5Dial – 1.28-inch round TFT touchscreen & ESP32-S3

As a versatile embedded development board, M5Dial integrates the necessary features and sensors for various smart home control applications. It features a 1.28-inch round TFT touchscreen, a rotary encoder, an RFID detection module, an RTC circuit, a buzzer, and under-screen buttons,...

Continue Reading

The Perfect Pair: Creative and xMEMS Labs Partner to Deliver Superior High-Fidelity TWS Earbuds

Creative Technology is excited to announce a strategic partnership with xMEMS Labs, the pioneers in solid-state fidelity, bringing in a new era of audio excellence for users worldwide by incorporating xMEMS' cutting-edge micro-electro-mechanical system (MEMS) solid-state speaker...

Continue Reading

CUI Devices Launches New Thermal Design Services

CUI Devices’ Thermal Management Group today announced the official launch of its new thermal design services. With a team of thermal management experts, CUI Devices’ industry-leading thermal design services employ advanced simulation tools and decades of expertise to identify...

Continue Reading