PicoScope 4-Channel 16GHz Sampler-Extended Real-Time Oscilloscopes

The PicoScope 9404-16 brings very high-speed performance at less than half the cost of other traditional benchtop solutions with four high-resolution 12-bit channels driven by up to 5TS/s (0.2ps) equivalent-time sampling Saelig Company, Inc. has introduced the PicoScope 9404-16 SXRTO,...

Continue Reading

ST-5S Smart Tweezers™ for On-board L/C/R Measurements and PCB Testing

This intelligent measurement tool is a new type of handheld LCR meter that can quickly test, identify, and measure board-mounted surface-mount and leaded devices without the need to remove them from a circuit board. Saelig Company, Inc. has introduced the ST-5S Smart Tweezers™...

Continue Reading

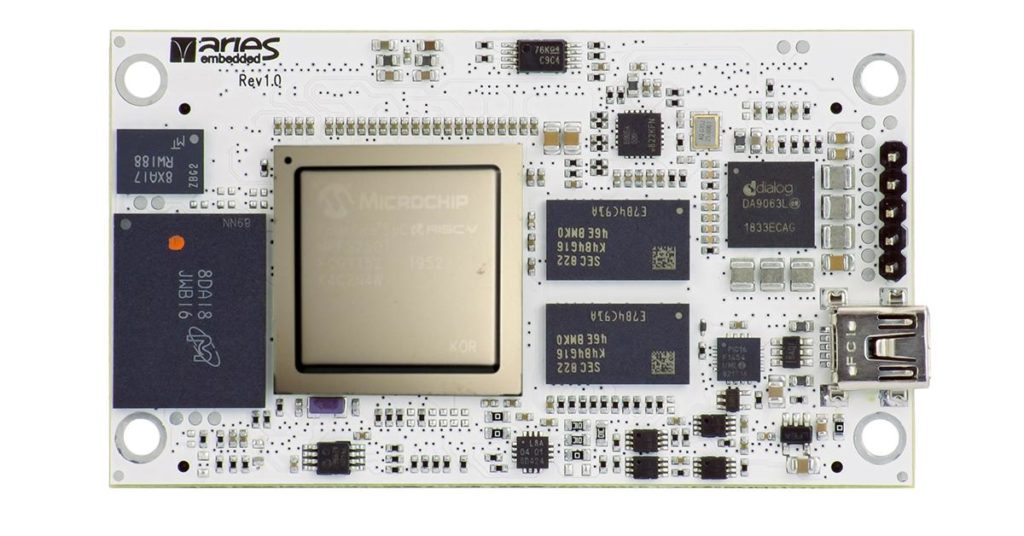

M100PFS – PolarFire RISC-V SoC-FPGA Module

The M100PFS is based on the PolarFire SoC FPGA architecture by Microsemi and combines high-performance 64-bit RISC-V cores with outstanding FPGA technology. The platform integrates a hardened real-time, Linux capable, RISC-V-based MPU subsystem on the mid-range PolarFire FPGA family,...

Continue Reading

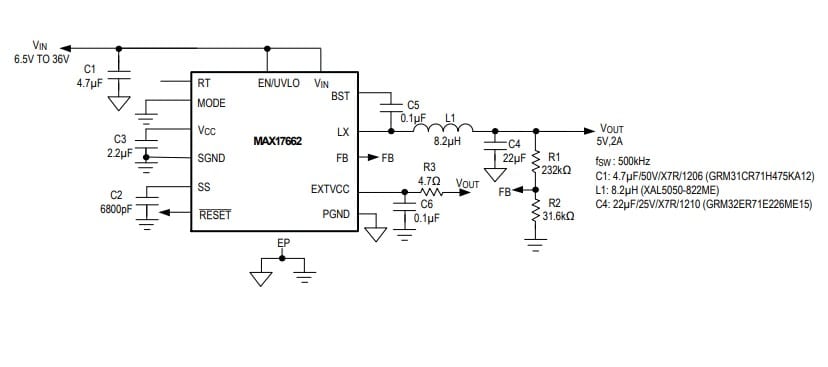

5V/2A Synchronous DC-DC Converter IC Evaluation Kit

The MAX17662BEVKITB# evaluation kit (EV kit) from Maxim Integrated Products provides a proven design to evaluate the MAX17662B high-efficiency, synchronous step-down dc-dc converter. The EV kit provides 5V/2A at the output from a 6.5V to 36V input supply. Applications are expected to...

Continue Reading

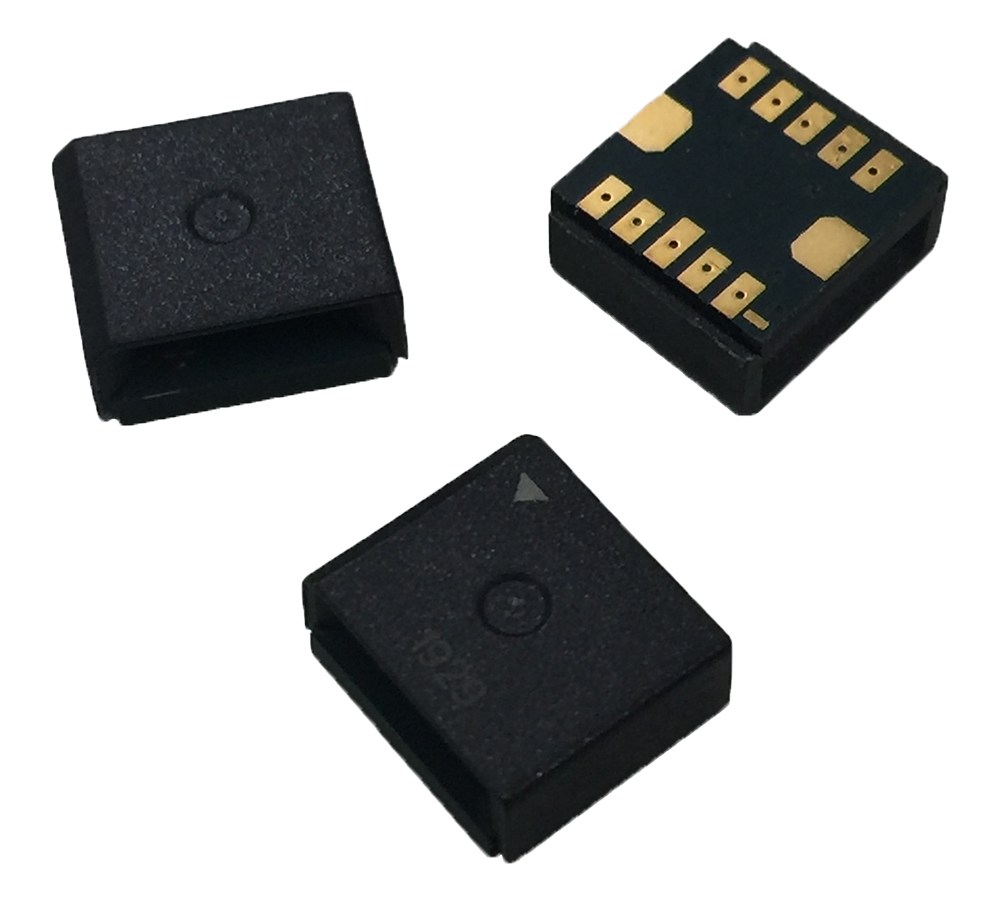

Air Velocity Sensors With Digital I2C Output for Thermal Management and Filter Monitoring Applications

Posifa Technologies announced the new PAV3000 series of economical, high-performance air velocity sensors with digital I2C output and a surface-mount footprint for thermal management and filter monitoring in even the most space-constrained locations. Unlike thermistor-based solutions,...

Continue Reading

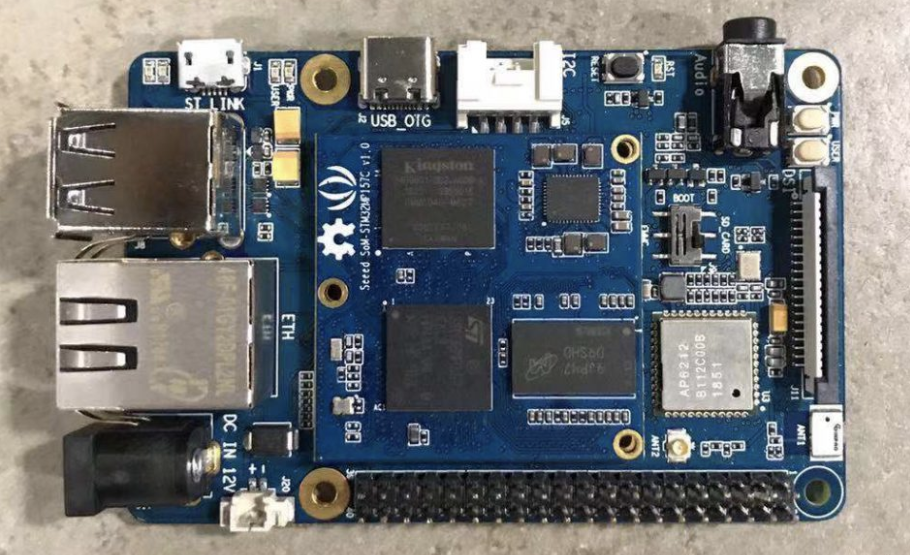

Seeed’s Odyssey – STM32MP157C SBC features cortex-A7 and M4 processor

Odyssey-STM32MP157C joins τηε growing list of SBCσ developed by SeeedStudio. It comprises a baseboard device called the NPi-STM32MP157C and an SoM device based on an STMicroelectronics’ Arm Cortex A7/M4 hybrid SoC called the SOM-STM32MP157C. SeeedStudio explains that it's...

Continue Reading

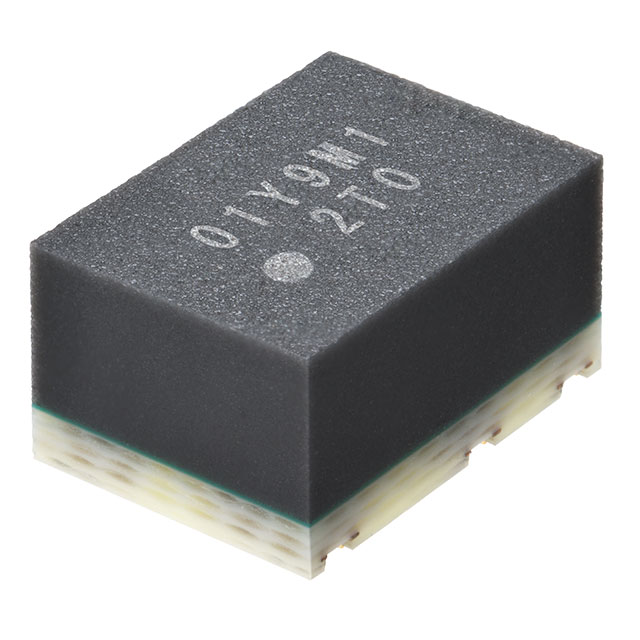

World’s First MOS FET Relay Module “G3VM-21MT” with Solid State Relay in “T-type Circuit Structure”

OMRON Corporation of Kyoto, western Japan globally released its new MOS FET (*1) relay module “G3VM-21MT” on December 2, 2019. The product is the first electronic component in the world (2) to adopt a “T-type circuit structure” (3). With a T-type circuit structure...

Continue Reading

Powerful, compact and ready2use – the new Kontron System-on-Module (SoM)

Kontron, a leading global provider of IoT/Embedded Computing Technology (ECT), will present its new System-on-Module (SoM) based on the latest processor and memory technology at the Embedded World trade fair in Nuremberg. The new SoM SL i.MX8M Mini provides an excellent and...

Continue Reading