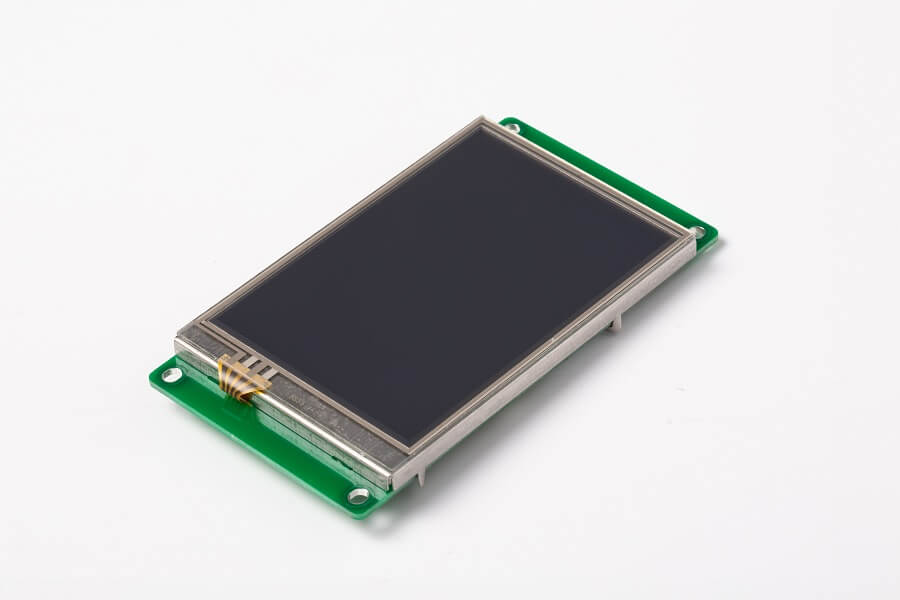

How to use STONEtech STVC035WT-01 intelligent TFT LCD module with Arduino

Displays have over time, emerged as one of the best ways to drive user interactions on any device. They make it easy to collect inputs and present information (outputs) to users in a graphical, easy to understand format. This usefulness has led to improvements in their quality, with...

Continue Reading

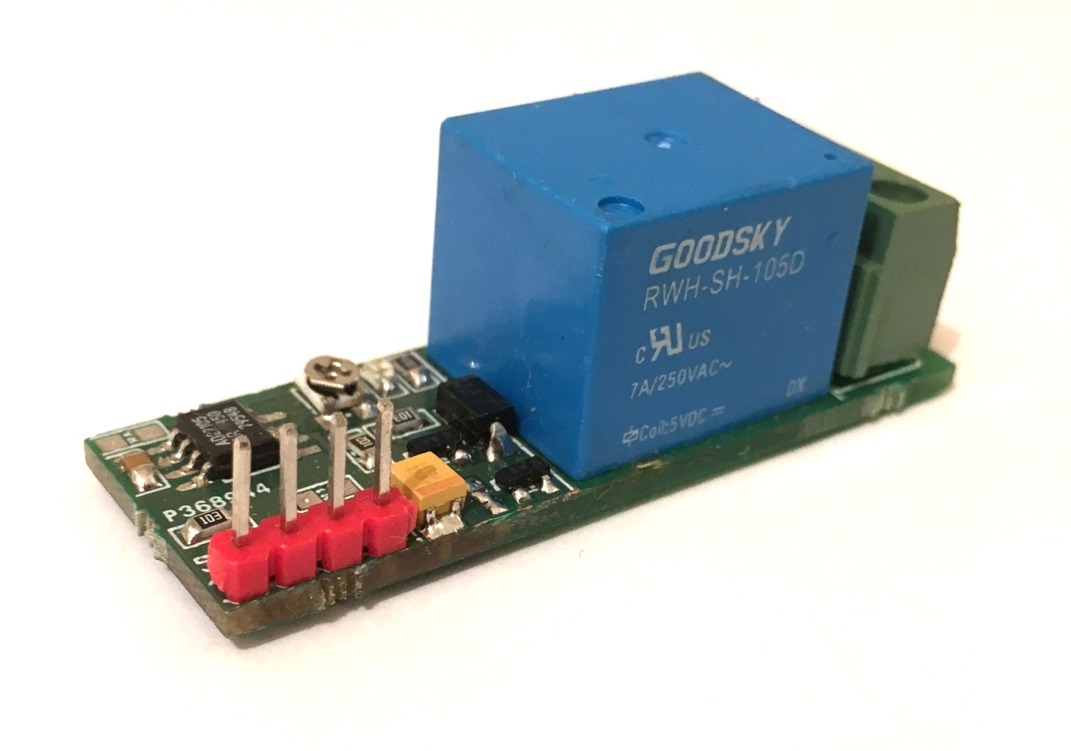

Programmable Thermostatic Switch using AD22105

This project simply switches the system OFF or ON whenever the temperature rises at the desired set point. The desired setpoint can be set using a fixed resistor R6 or PR1 trimmer potentiometer. Use any of at a time R6 or PR1. You can calculate the setpoint resistor R6 using the...

Continue Reading

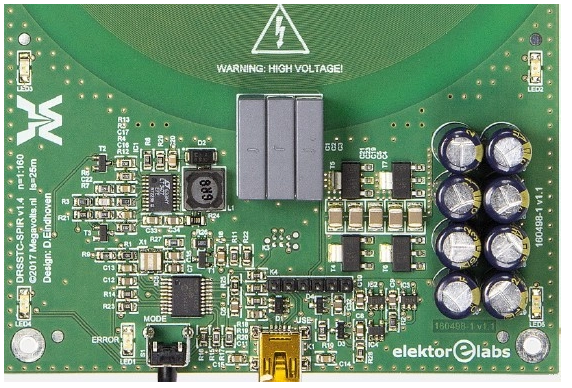

Free Elektor Article – Spiral MicroTesla

Original publication: Elektor magazine 6/2017, page 58. Author: Daniel Eindhoven. Free download expires Friday 27 December 2019. 1. Introduction It seems to be an unwritten rule in Hollywood: there must be an assortment of devices that crackle and spark in the lab of a mad scientist....

Continue Reading

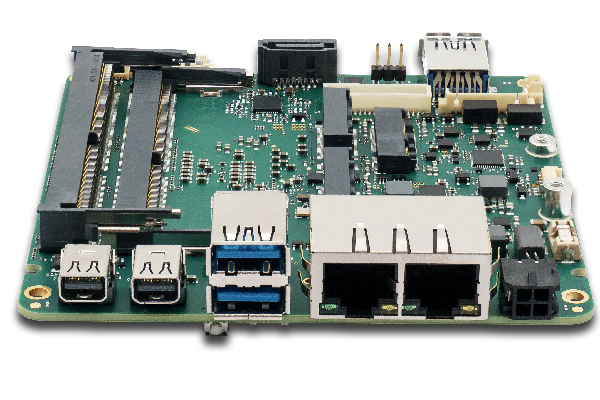

EEPD Launches AMD Ryzen Embedded NUC Boards & Mini PCs

Interest in SBCs is growing and even though their capabilities have improved over the years, there is a yearning for more, from processing power to IOs. To add to their already impressive line of SBC offerings, EEPD (Electronic Equipment Production and Distribution) recently announced...

Continue Reading

STMicroelectronics TCPP01-M12 USB Type-C Port Protection

STMicroelectronics TCPP01-M12 USB Type-C Port Protection is a single-chip solution that facilitates the migration from USB legacy connectors type-A or type-B to USB Type-C connectors. This Type-C port protection features overvoltage protection on VBUS, adjustable up to 22 V, with...

Continue Reading

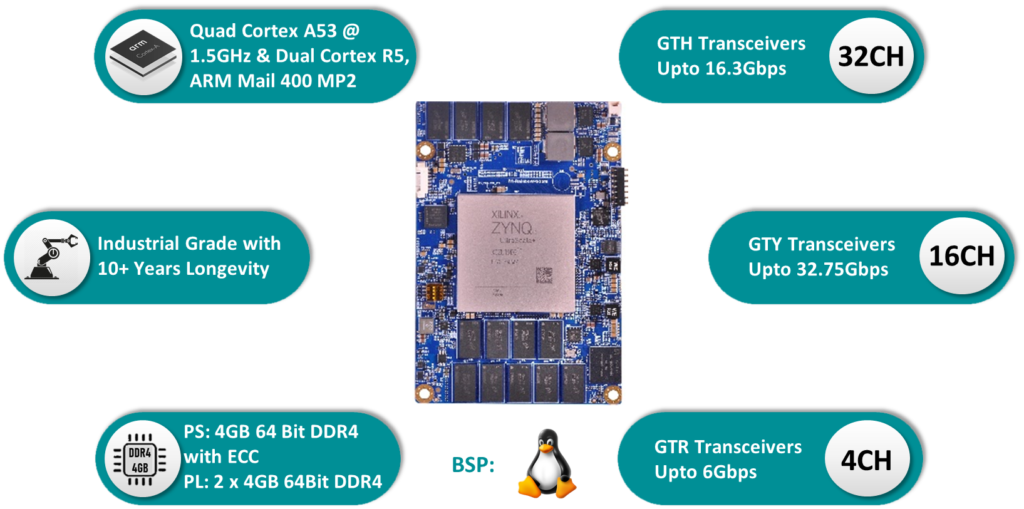

iWave Systems Introduces a SOM based on ZU19EG / ZU17EG / ZU11EG Xilinx ZynQ UltraScale+ MPSOC

iWave Systems introduces a powerful SOM (System on Module) with six heterogeneous ARM processor cores (four 64-bit ARM Cortex-A53 and two 32-bit ARM Cortex-R5 Cores), an ARM Mali-400 MP2 GPU, and a big chunk of the latest-generation UltraScale+ programmable logic cells scaling all the way...

Continue Reading

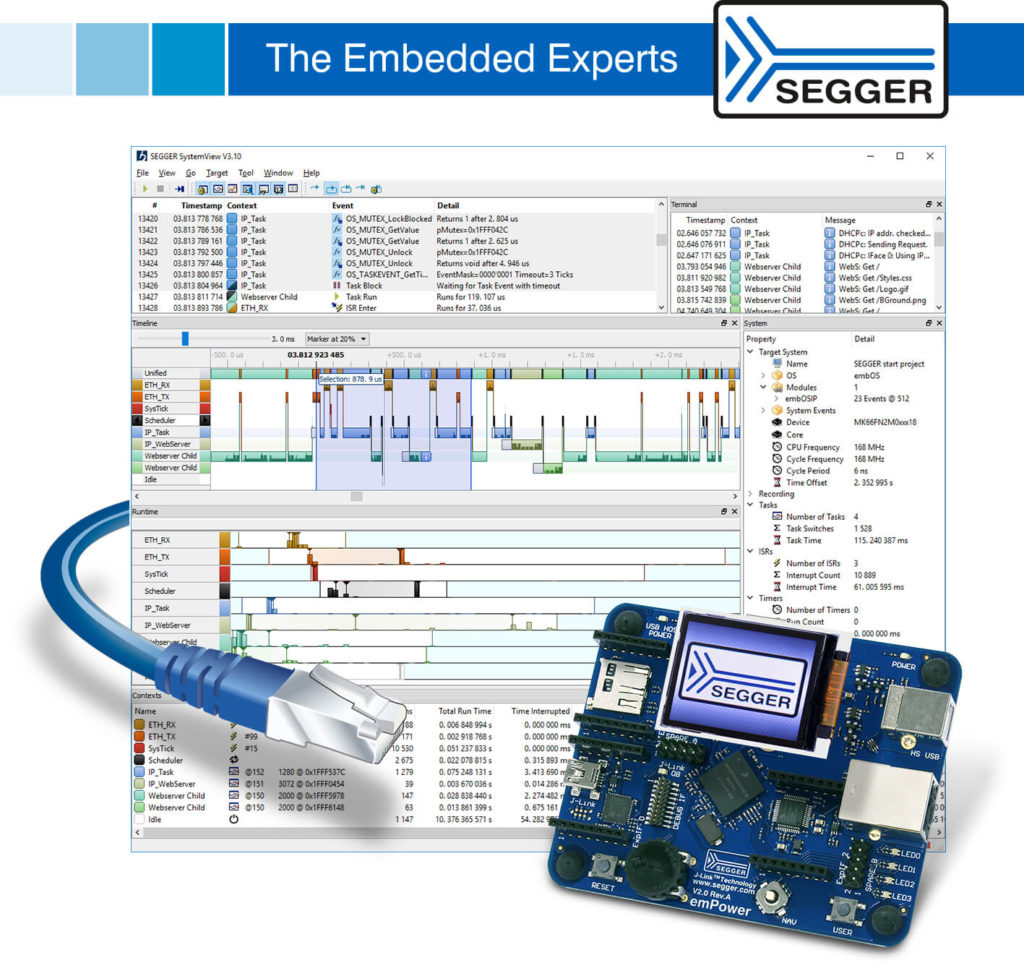

SEGGER’s SystemView adds data acquisition via UART and TCP/IP

SEGGER announces the release of SystemView V3.10, a major update to its system verification tool for embedded systems. The most significant enhancement is the addition of real-time data acquisition via UART or TCP/IP. Any system with UART or TCP/IP connection, typically Ethernet, can...

Continue Reading

High speed switching N-channel MOSFET for general purpose

Torex Semiconductor has launched its new XP231N0201TR (30V withstand voltage) for MOSFETs. The product is a general-purpose N-channel MOSFET with low on resistance and high speed switching. It can be used for various applications such as relay circuits and switching circuits. The gate...

Continue Reading