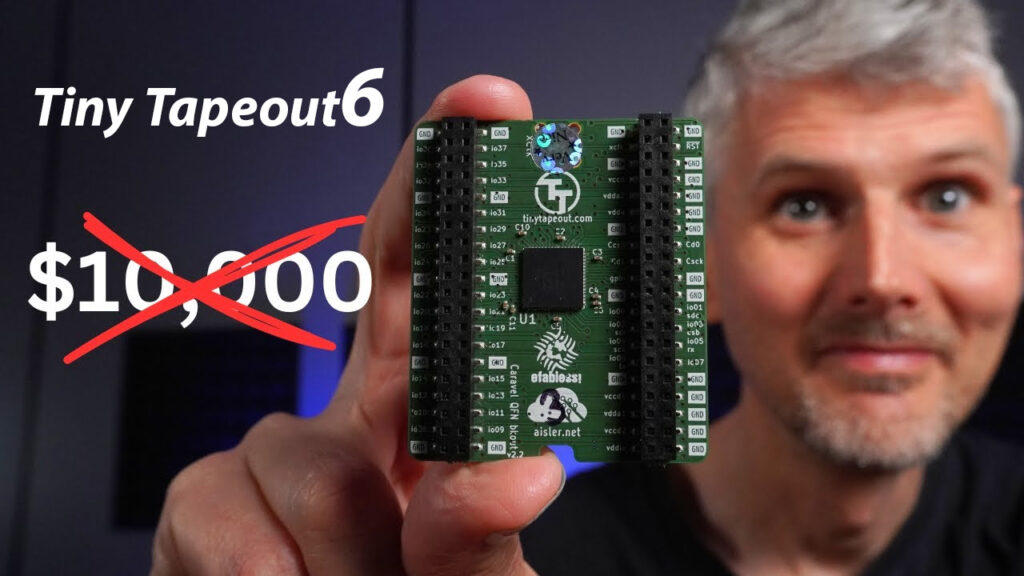

From Idea to Chip Design in Minutes – With Tiny Tapeout 6 You Can Design your Custom Silicon for Just $300

With Tiny Tapeout 6, you can design your custom ICs, get them fabricated, and then receive them on a development board, all for only $300. Matthew Venn has announced the launch of Tiny Tapeout 6, an educational program designed to assist beginners with their chip design. Participants...

Continue Reading

Industrial OpenWrt gateway features MediaTek MT7628 SoC, WiFi, LTE, and GNSS connectivity

The Atreyo AG-702 is an industrial OpenWrt gateway powered by the MediaTek MT7628 processor, featuring dual Ethernet and WiFi connectivity alongside an integrated LTE and GNSS modem capable of accommodating two SIM cards. This gateway boasts isolated RS485 and RS232 interfaces for...

Continue Reading

Revolutionizing Wireless Connectivity: Exploring the Compex WLE7002E25 WiFi 7 Mini PCIe Module

The Compex WLE7002E25 is a WiFi 7 module designed in a standard mini PCIe form factor, ensuring compatibility with existing systems using WiFi 4 or WiFi 5 modules. This compatibility simplifies integration for device manufacturers, as they do not need to modify their hardware to...

Continue Reading

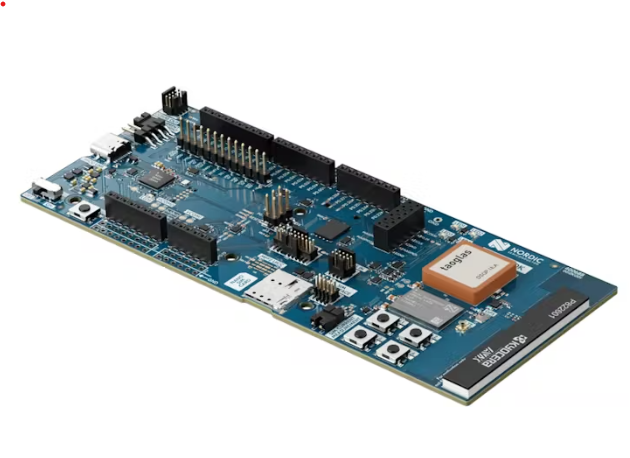

Exploring the Security and Performance Features of nRF9151: A Breakdown of Arm Cortex-M33, TrustZone, and CryptoCell

The newly developed System-in-Package (SIP) is a significant advancement for power-efficient cellular projects. It features a 64MHz Arm Cortex-M33 processor, LTE-M/NB-IoT cellular connectivity, and DECT NR+ connectivity, all integrated into a single chip. What sets this SIP apart is its...

Continue Reading

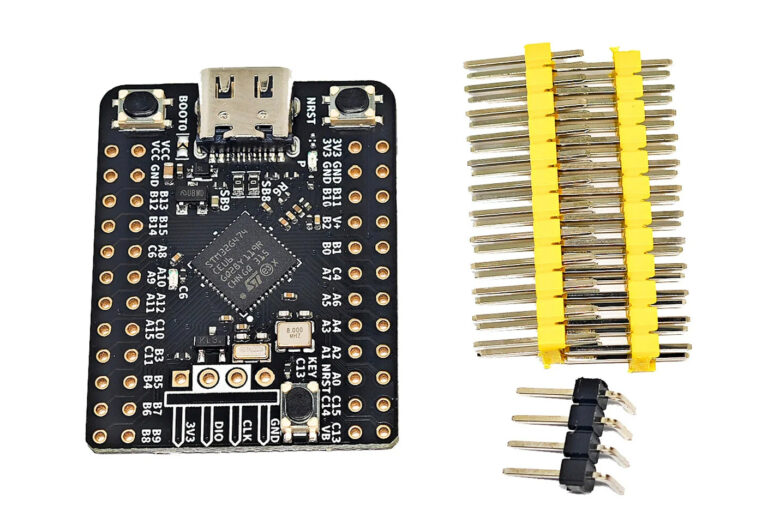

Introducing WeAct STM32G4: Tiny Development Board with Versatile Microcontroller Options

The WeAct STM32G4 is a compact development board that utilizes the STMicro STM32G4 Arm Cortex-M4F mixed-signal microcontroller. This microcontroller operates at a clock speed of 170 MHz and comes equipped with DSP (Digital Signal Processing) instructions, making it suitable for a wide...

Continue Reading

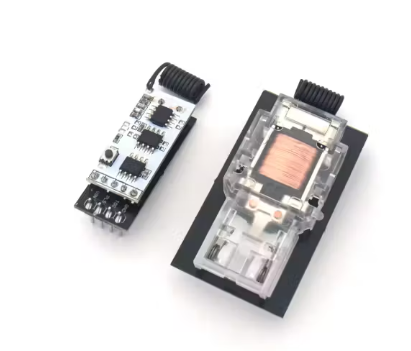

Questwise Ventures Introduces Energy-Harvesting Wireless Transmitter/Receiver for IoT Connectivity

Los Gatos-based Questwise Ventures has launched a new gadget that aims to deliver Internet of Things (IoT) connectivity without the need to power the transmitting side — by using an energy-harvesting push-button capable of driving its radio. Questwise Ventures, based in Los Gatos,...

Continue Reading

Vodafone and Lime Microsystems Unveil Upgraded 5G Network-in-a-Box with Raspberry Pi 5 Integration

Cellular network giant Vodafone and software-defined radio specialist Lime Microsystems have announced they will be showing off a revamped version of their 5G network-in-a-box device, built around a Raspberry Pi 5 single-board computer. Vodafone and Lime Microsystems have collaborated...

Continue Reading

PiEEG A Raspberry Pi Shield for Measuring Biosignals like ECG, EMG, and EEG, Available for Just $350

PiEEG is an 8-channel, open-source shield for Raspberry Pi, designed to easily measure EEG, EMG, and ECG biosignals. It's user-friendly and compatible with various electrodes, making it easy to explore complex biosignals without needing specialized equipment. Researchers at Heriot-Watt...

Continue Reading