Freeze 75 spray will enable you to find faulty component or also to protect components from overheating during soldering.

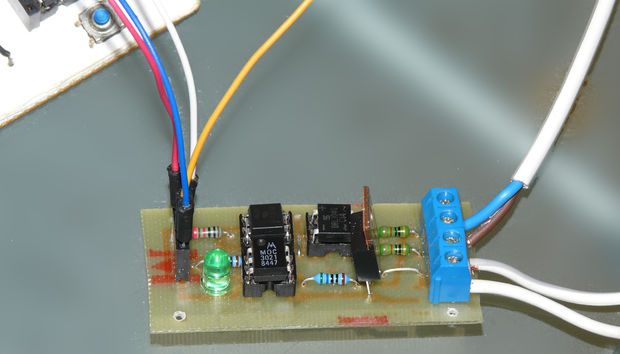

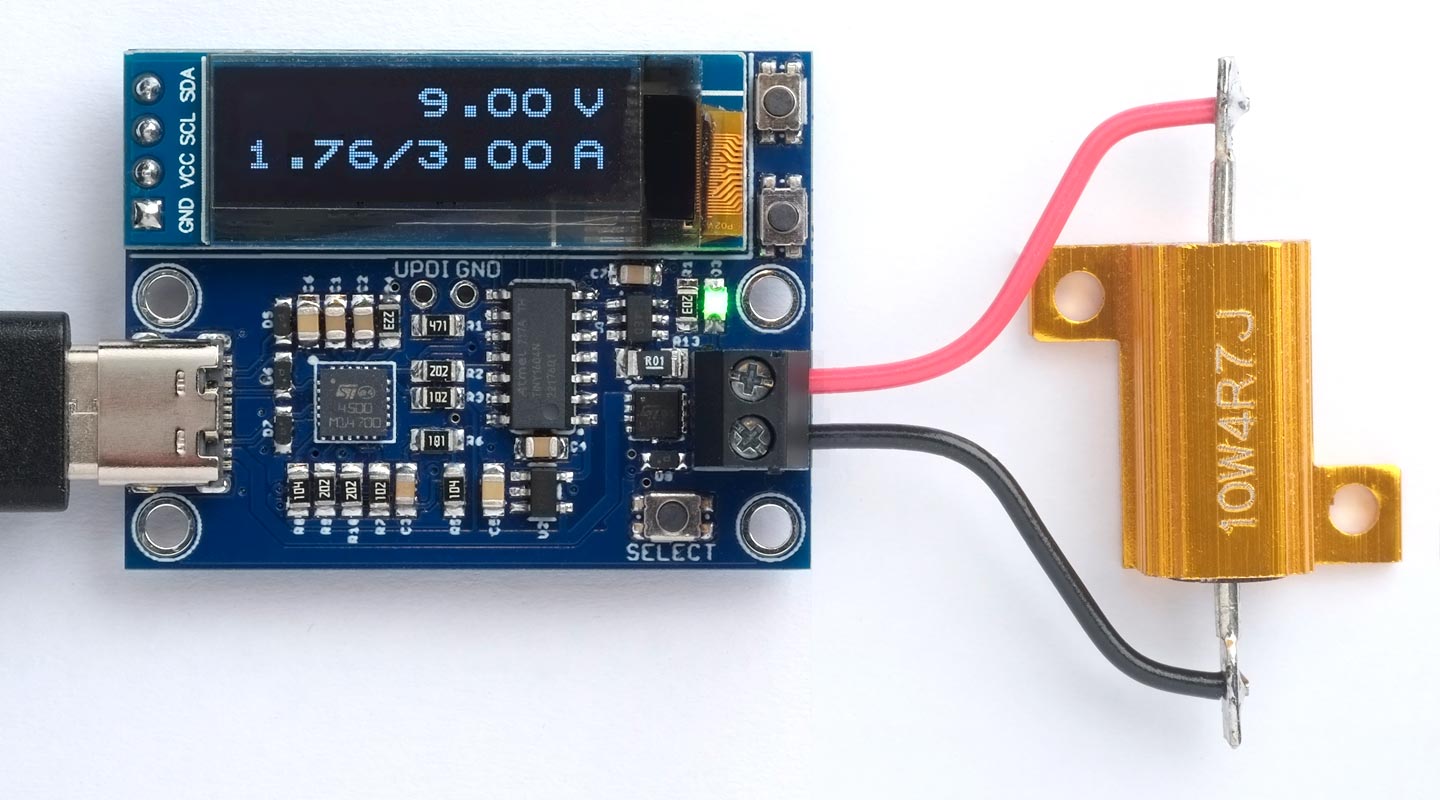

A device operates OK until it reaches stable operating temperature … a typical situation in praxis usually caused by a faulty component or faulty (cold) joint. Localization of such a fault is easy only if we can cool down (locally) a given component or a given joint. It´s often possible to suppose a source of malfunction, but to be able to localize it exactly, we´d need to change temperature of only one component or only a small PCB area. Right for this purpose a well known spray Freeze 75, is designed, able to cool down (freeze) a given component very significantly – in laboratory testing down to -52°C. And what about other possibilities of usage?

There are a lot of them. For example a local (preventive) cooling at soldering of temperature-sensitive components like temperature fuses or cooling of sensitive components near a soldered joint (for example soldering of a relatively bulky RF connector at a sensitive RF component, protection of plastic parts etc.) Another unusual help is at removing a rubber-like sticky substances from various places and textile. A typical example is removing of a chewing gum. Freeze 75 is also used in medicine, in machine engineering for shrinkage of small components etc.

How does the Freeze 75 function?

Again we´ll call for help a grammar school physics. When we go out of a swimming pool, we usually feel cold, even though there´s a warm weather outside. The reason is the water evaporating from our skin. Evaporating liquid consumes heat from a given surface. This is also a case of Freeze 75, which is filled by liquids with boiling point deeply below the frost point thus taking a lot of heat from a surface on which it is applied. Freeze 75 is non-flammable, non-explosive at all usual conditions and it also doesn´t attack plastics. It´s only advisable to be careful at components sensitive to sudden temperature changes. For absolutely highest safety in critical applications, the Freeze 75 Super is available, which is non-explosive at any circumstances.

After application of Freeze 75 in moisty environment a small amount of water can condense on a given component, consequently freezing into a whitish coating. This coating will gradually defreeze and evaporate or it can be readily removed by a water miscible solvent like for example Kontakt WL. Freeze 75 (originally marked as Kalte 75) we keep on stock in 200ml as well as 400 ml package. Detailed information will give you the Freeze 75 datasheet.

Freeze 75 – and you have a temperature under control – [Link]