Tag: ADC

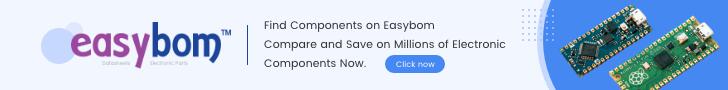

SparkFun Pro Micro – ESP32-C3 Features a Qwiic Connector

SparkFun has recently announced the "SparkFun Pro Micro - ESP32-C3" board, an ESP32-C3-based development board featuring SparkFun's Qwiic Connect System. This compact board includes Wi-Fi, Bluetooth, GPIO, SPI, UART, I2C, I2S, and all the necessary hardware required for advanced IoT and...

Continue Reading

Danalogx’s Microamp-Meter- High-speed Wi-fi Current Meter and Micro SD card Logger – A Review

MicroAmp-Meter The DanalogX MicroAmp-Meter is a device that functions as a high-speed Wi-Fi current profiler and Micro SD card logger. The MicroAmp-Meter is a highly efficient portable current meter that can quickly measure and plot the current consumption of embedded devices. It is an...

Continue Reading

Analog Devices Inc. AD4130-8 Ultra Low Power 24-Bit Sigma-Delta ADC

Analog Devices Inc. AD4130-8 Ultra Low Power 24-Bit Sigma-Delta ADC is a high precision measurement solution for low bandwidth battery-operated applications. The AD4130-8 features a fully integrated analog front end (AFE). It includes a multiplexer for up to 16 single-ended or eight...

Continue Reading

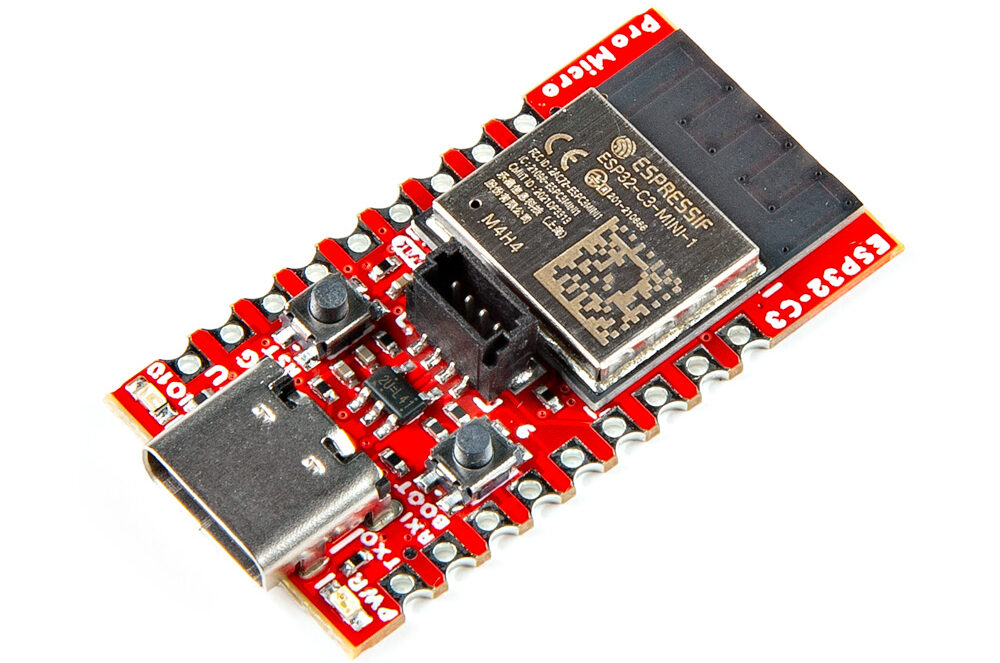

Add PlainDAQ Carrier Board to Raspberry Pi Pico for Analog Functionality

We have already come across tens if not hundreds of Raspberry Pi’s in-house silicon tapeout RP2040 integrated boards. The RP2040 was first seen in Raspberry Pi’s own microcontroller board– RPi Pico that features a dual-core Arm Cortex-M0+ processor with 264KB internal RAM and...

Continue Reading

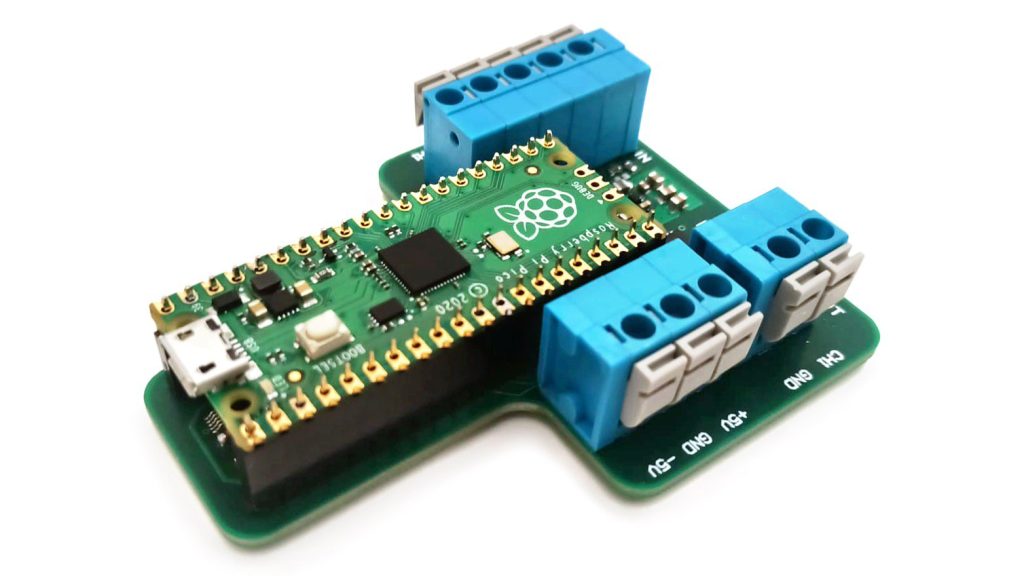

+/-10V (Dual 10V) to Single-Supply Signal Converter for ADC

This board will make your work easy if you want to interface +/- 10V (Dual 10V) device or sensor to single-supply signal ADC. This tiny project has been made for industrial and process control applications and provides an easy interface between +/-10V (Dual 10V) sensor or device to...

Continue Reading

Latest Olimex board brings 10-channel 32-bit to OSHW builds

If your project demands some high precision analog measurements, then here is a new Olimex BB-ADS1262 that can help get the job done easily; with up to 10 channels of 32-bit ADC conversion, the new BB-AD S1262 breakout board is considered a great add-on for microcontrollers. Before,...

Continue Reading

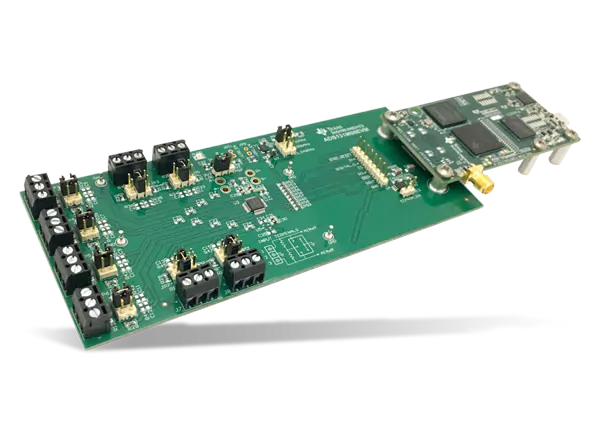

ADS131M08 8-Channel Simultaneous Sampling Delta-Sigma (ΔΣ) ADC

Texas Instruments' 24-bit, 32 kSPS ADC is optimized for cost-sensitive applications that require simultaneous sampling Texas Instruments' ADS131M08 8-channel, simultaneously-sampling, 24-bit ΔΣ ADC offers wide dynamic range, low power, and energy-measurement-specific features. These...

Continue Reading

Binho Multi-Protocol USB Host Adapter supports I2C, SPI, 1wire and more

The new Binho multi-protocol USB host adapter powered by the USB connection to a host PC allows you to interface your computer directly to hardware circuits. The Binho adapter has support for 12C @ 3.4 MHz max clock, SPI @12MHz max clock, Dallas 1wire, Atmel single wire interface, UART...

Continue Reading