Tag: ATtiny

ANT BBPS: An Efficient and Portable Breadboard Power Supply

ANT BBPS (breadboard power supply) is an open-source, compact power supply carefully designed to connect to the end of any M102 breadboard. It can be plugged directly into the power connection pins and does not interfere with anything else because of its unique shape. ANT BBPS offers an...

Continue Reading

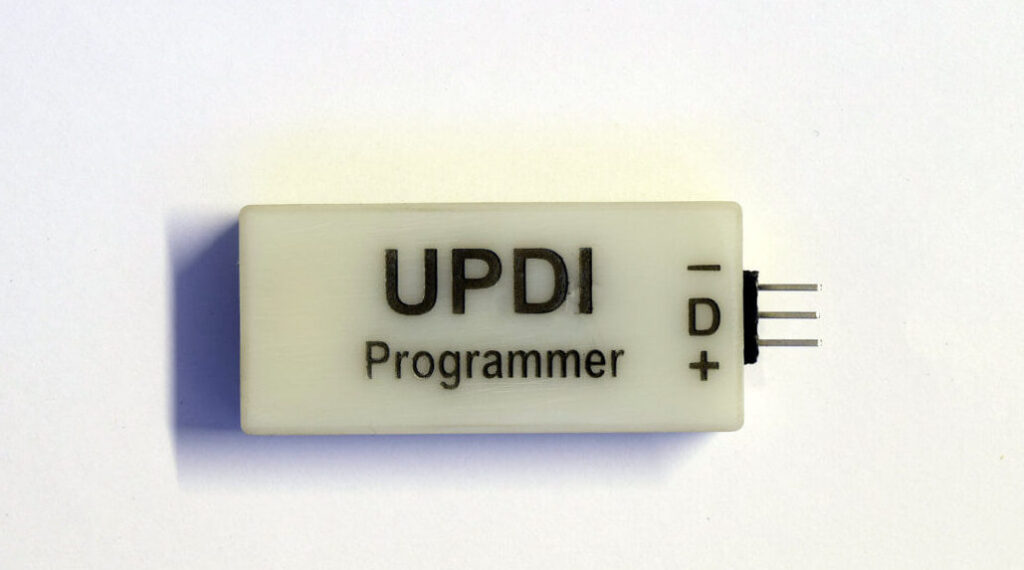

DIY UPDI USB Programmer is Low-Cost Alternative to Ready-Made Programmers

A UPDI USB programmer (Unified Program and Debug Interface) is basically an Atmel / Microchip proprietary programming interface used for some AVR microcontrollers like the ATtiny series. AVR is an 8-bit RISC architecture microcontroller that is developed by Atmel. With the newer...

Continue Reading

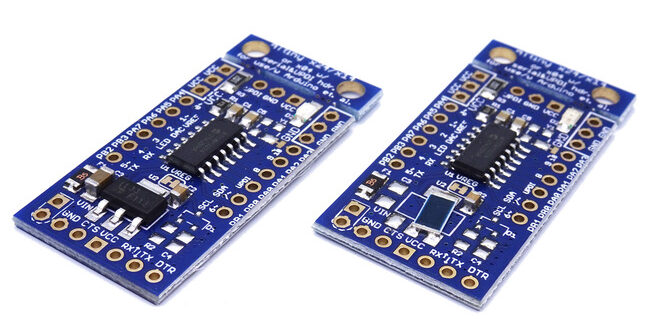

ATtiny Development Boards are Compatible with Arduino IDE

In recent years Atmel has been producing and releasing AVR microcontrollers that are equipped with a new set of peripherals. These microcontrollers use the AVR instruction set and open source AVR-GCC compiler that is used with the general AVR microcontrollers but they are differently...

Continue Reading

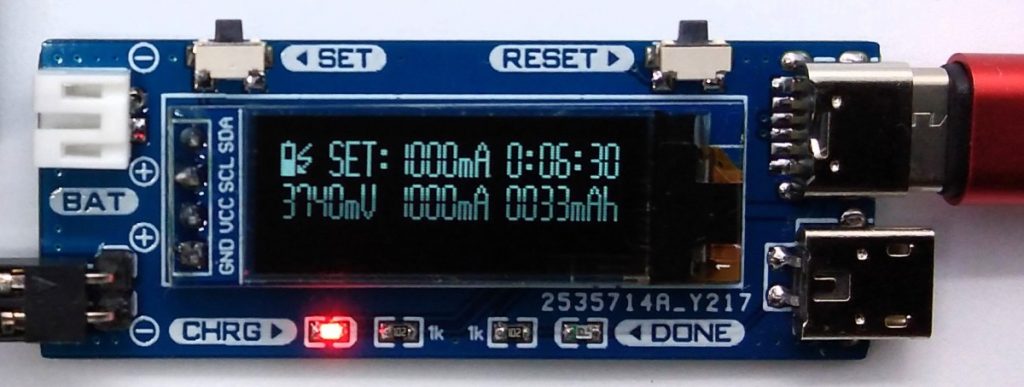

TinyCharger – Single Cell Li-Ion Battery Charger with Monitoring

TinyCharger is an ATtiny25/45/85-based, single-cell Li-ion battery charger with selectable charging current limit (100mA - 1000mA) and an OLED display for monitoring. For battery charging the TP4056 is used. The TP4056 is a complete constant-current/constant-voltage linear charger for...

Continue Reading

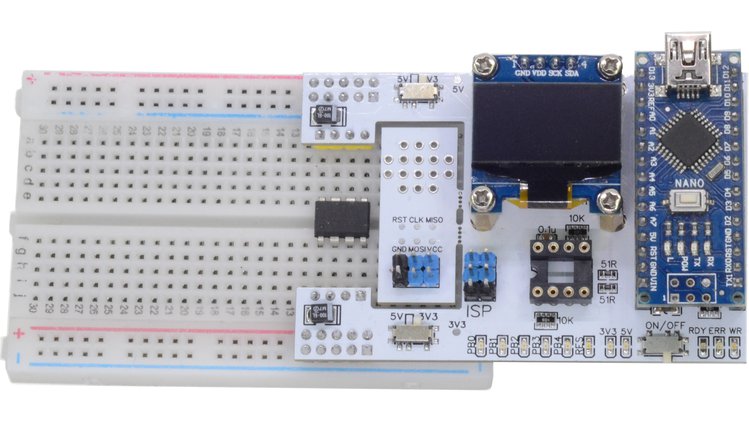

ATtiny Flasher – Breadboard Flashing Tool for the Atmel ATtiny

ATtiny Flasher is a handy device that allows you to use your favorite IDEs and debugging tools when developing for the ATtiny microcontroller. Enjoy the classic Arduino development experience while working with bare metal. Whether you’re a design engineer, a hobbyist, or someone...

Continue Reading

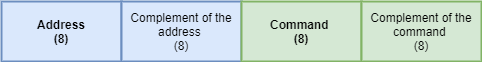

TinyDecoder – Cool IR Receiver and NEC Decoder with Arduino

Infrared has been around for a long while. It has proven to be reliable enough so that basically almost everything remote and short range, that came before home automation was cool enough to be considered a thing, and battled its place fairly with RF technologies, so it deserves some...

Continue Reading

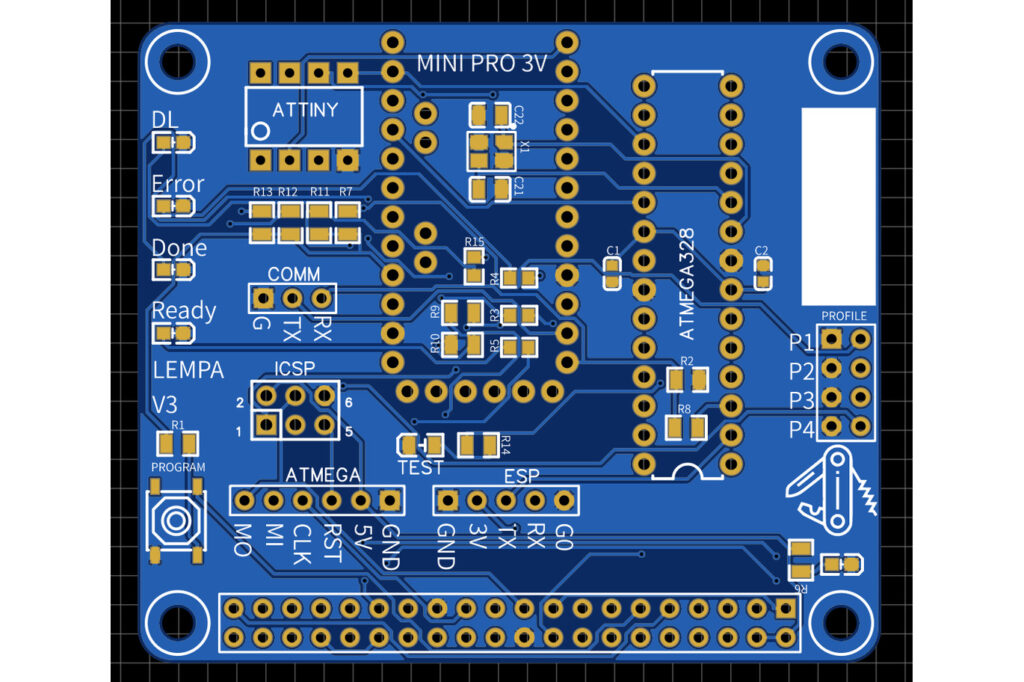

Turn Your Raspberry Pi Into a Standalone AVR/ESP Programmer with LEMPA

One of the challenges of developing and producing microcontroller-based hardware projects in a repeatable, small/medium volume, is the amount of work it takes to flash the MCUs with the required firmware. Another side of the problem for designers who work with diverse types of...

Continue Reading

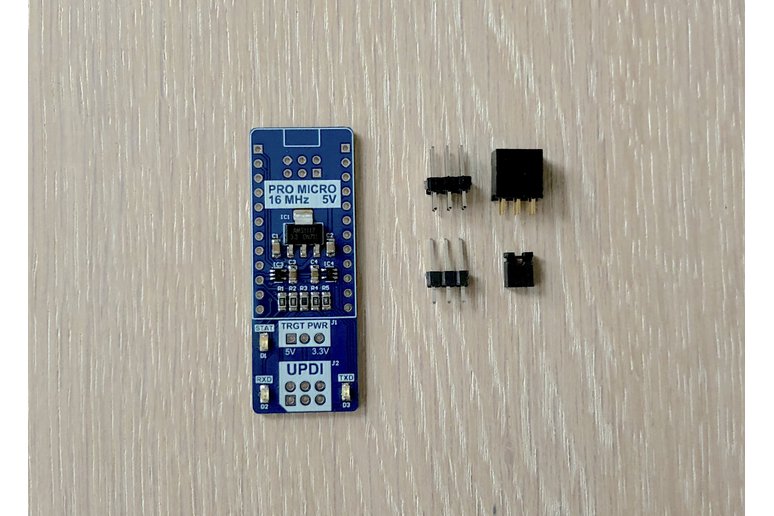

microUPDI – Pro-Micro Based UPDI Programmer

Thanks to the increased popularity of the recent ATtiny series of microcontrollers, there has been an increase in the number of open-source UPDI programmers out there. We have covered quite a number of them including the brilliant UPDI programmer compatible with Arduino IDE but we...

Continue Reading