Tag: Battery

BQ27220 – Single cell pack/system-side CEDV battery fuel (gas) gauge w/pre-programmed chemistry profiles

The Texas Instruments bq27220 battery fuel gauge is a single-cell gauge that requires minimal user configuration and system microcontroller firmware development, leading to quick system bring-up. The bq27220 device uses the Compensated End-of-Discharge Voltage (CEDV) algorithm for fuel...

Continue Reading

1-Cell Protection IC with Reset and Forced Standby Function for Li-Ion and Li-Polymer Batteries

Ricoh Electronic Devices has introduced a primary battery protection IC R5613 Series for rechargeable 1-cell Lithium-Ion and Lithium Polymer batteries. This Series is designed to enforce strict usage limits keeping the battery cell in optimal condition and preventing critical...

Continue Reading

Nexperia ASFET for 36 V DC motors

There is growing demand for 36 V DC motors, often being used with multi-cell lithium-ion battery packs, in an increasing range of applications There is growing demand for 36 V DC motors, often being used with multi-cell lithium-ion battery packs, in an increasing range of applications....

Continue Reading

Molex Disposable Thin-Film Battery stocked by Heilind Electronics

Heilind Electronics, a leading global distributor of electronic components and authorized global distributor for Molex, has expanded its selection of electronic component solutions with the company’s disposable thin-film battery. The thin-film batteries are zinc-carbon primary cells...

Continue Reading

Texas Instruments bq25960 Parallel Battery Charger

Texas Instruments bq25960 Parallel Battery Charger is a 98.1% peak efficiency, 8A battery charging solution using switch capacitor architecture for a 1-cell Li-ion battery. The switched cap architecture allows the cable current to be half the charging current, reducing the cable power...

Continue Reading

Analog Devices Inc. LTC3337 Primary Battery State of Health Monitor

Analog Devices Inc. LTC3337 Primary Battery State of Health (SOH) Monitor provides accurate, real-time readings of battery cell discharge, voltage, impedance, and temperature. The LTC3337 is designed to be placed in series with a primary battery with minimal associated series voltage...

Continue Reading

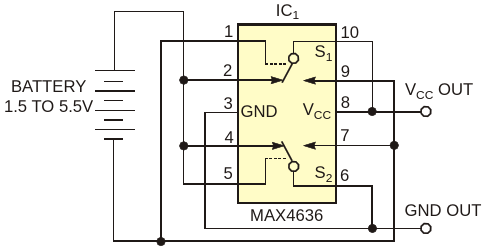

Circuit provides reverse-battery connection protection

A universal problem in battery-operated devices is the threat of damage when an end-user (never an engineer) inserts the battery backward. You can avoid damage by inserting a single diode or by using a diode-bridge configuration, but those fixes waste power and reduce the supply voltage...

Continue Reading

CATL Releasing their Fast-charging First Generation of Sodium-ion Batteries

(CATL) successfully held its first online launch event “Tech Zone” on July 29. Dr. Robin Zeng, chairman of CATL, unveiled the company’s first-generation sodium-ion battery, together with its AB battery pack solution - which is able to integrate sodium-ion cells and lithium-ion...

Continue Reading