Tag: DLP

TI packages DLP Pico projector display tech for “any low-cost processor”

With a $99 evaluation kit/module, Texas Instruments aims to widen design-ins of its projection-based, ultra-compact display technology. By Graham Prophet @ eedesignnewseurope.com Developers can, TI says, implement DLP (‘digital light processing’) display technology with almost...

Continue Reading

Meet Bean: The Ultimate Consumer SLA 3D Printer

Kudo3D Inc. is a startup company dedicated to bringing 3D printing technologies to consumers. It released the first generation 3D printer, the Titan 1, via a very successful Kickstarter campaign in 2014. Since then, they launched their second generation printers, the Titan 2 and Titan...

Continue Reading

ONO, $99 Smartphone-Powered 3D Printer

Born in 2014 from the simple idea of making 3D printing accessible for everyone, Filippo Moroni and Pietro Gabriele worked on new technology to develop a high quality 3D printer that was affordable and easy to use. Their goal was to make the most diffused printer in the world and to...

Continue Reading

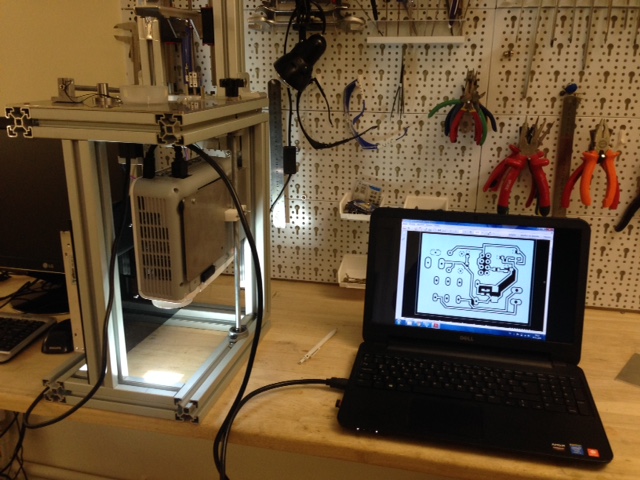

Making circuit boards with DLP projector

Nuri ERGİNER managed to create his own PCBs using a DLP projector and photo-resist dry film. Every Maker like me dream a PCB printer which can quickly and precisely convert our electronic idea into a psychical circuit board. I know there are plenty of project going on the subject....

Continue Reading

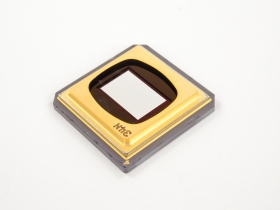

Fastest, highest-resolution DLP chipset for 3D print/lithography

by Graham Prophet @ edn-europe.com: With its latest micro-mirror-based light-steering chip, Texas Instruments says, applications developers can innovate with more than 4 million micromirrors to enable high throughput digital imaging applications. Presented as its highest speed...

Continue Reading