Tag: IBM

Introducing HyperAIBox’s Compact PCs: Powered by Rockchip 3568 and Rockchip 3588 Processors

IBM is introducing new tools to make it easier for developers to write code for quantum computers. Qiskit Patterns is a set of tools that helps developers map classical problems, optimize them for quantum circuits, and execute them using Qiskit Runtime. With Qiskit Patterns and Quantum...

Continue Reading

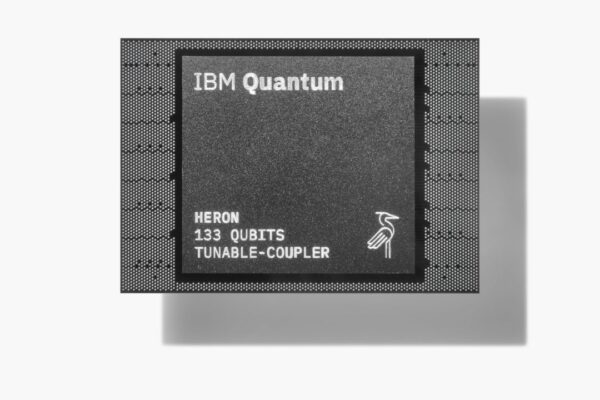

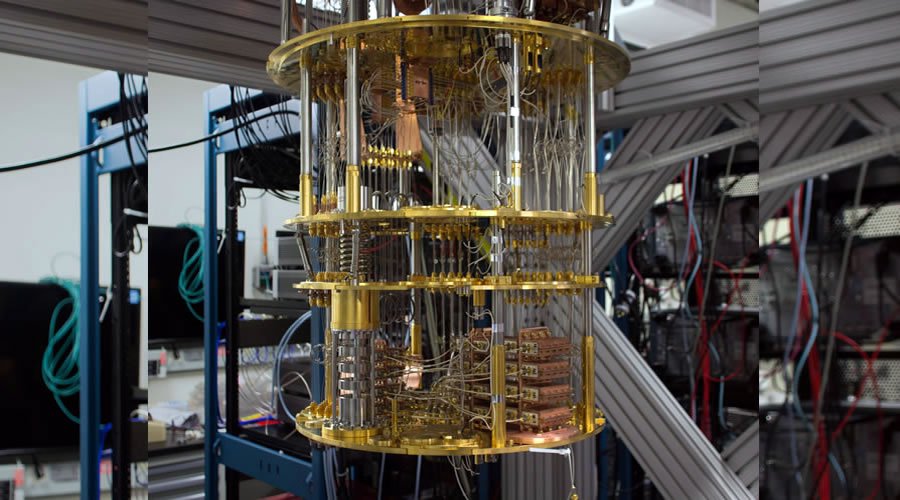

IBM Advances Quantum Computing Roadmap with Heron Chip and System Two Launch

IBM has recently revealed updates to its quantum roadmap, marking a significant milestone by introducing the 133-qubit Heron chip and the groundbreaking System Two quantum computer. Heron stands out as the inaugural member of a new series of scalable quantum processors, meticulously...

Continue Reading

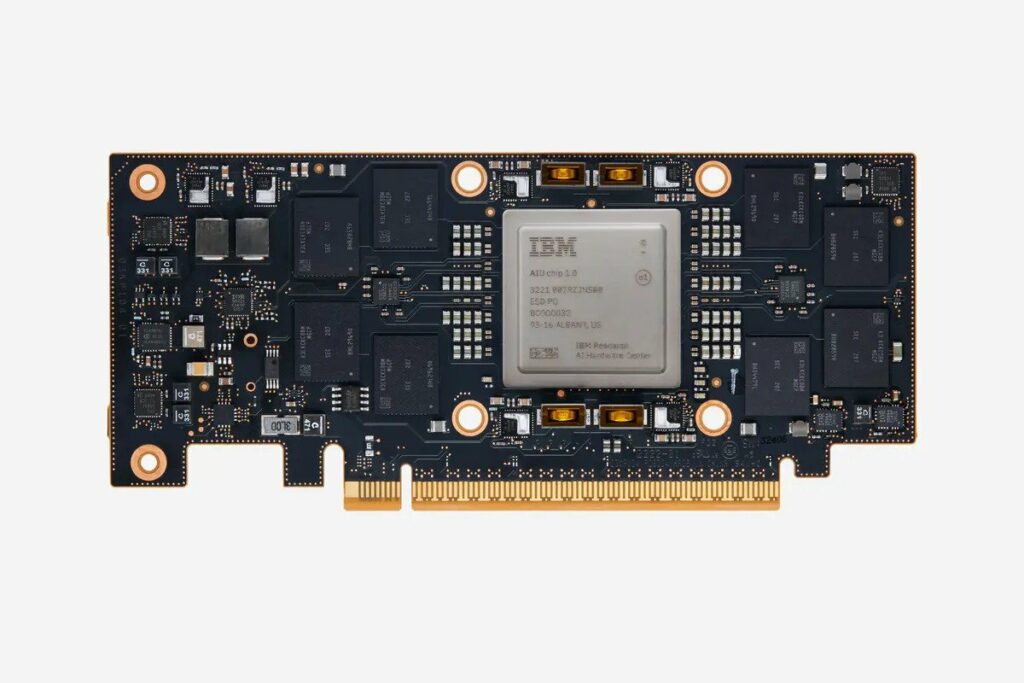

IBM has launched Artificial Intelligence Unit– Ready to replace CPU for deep learning training

IBM believes that computing power and AI models have grown exponentially, but the supporting hardware to train them and run them on servers in the cloud or edge devices hasn’t advanced. IBM Research AI Hardware Center has decided to launch an application-specific integrated circuit...

Continue Reading

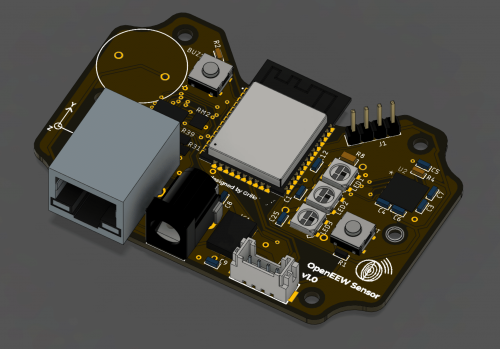

Grillo, IBM and Linux to accelerate deployment of open source earthquake early warning (EEW) detection systems

Earthquakes are shifts or vibrations in the earth's crust caused by a sudden release of violent energy and the effects that come with them, especially with the large ones, can be devastating. The earlier citizens are warned ahead of its occurrence, the better their chances of...

Continue Reading

A circuit board from the Saturn V rocket, reverse-engineered and explained

Ken Shirriff writes on his blog: In the Apollo Moon missions, the Saturn V rocket was guided by an advanced onboard computer system built by IBM. This system was built from hybrid modules, similar to integrated circuits but containing individual components. I reverse-engineered a...

Continue Reading

Google Bristlecone, The Race To Quantum Supremacy

On Monday, March 05, 2018, research scientists from the Google Quantum Al lab whose goal is to build a quantum computer that can be used to solve real-world problems, presented their latest quantum processor called Bristlecone at the annual American Physical Society meeting in Los...

Continue Reading

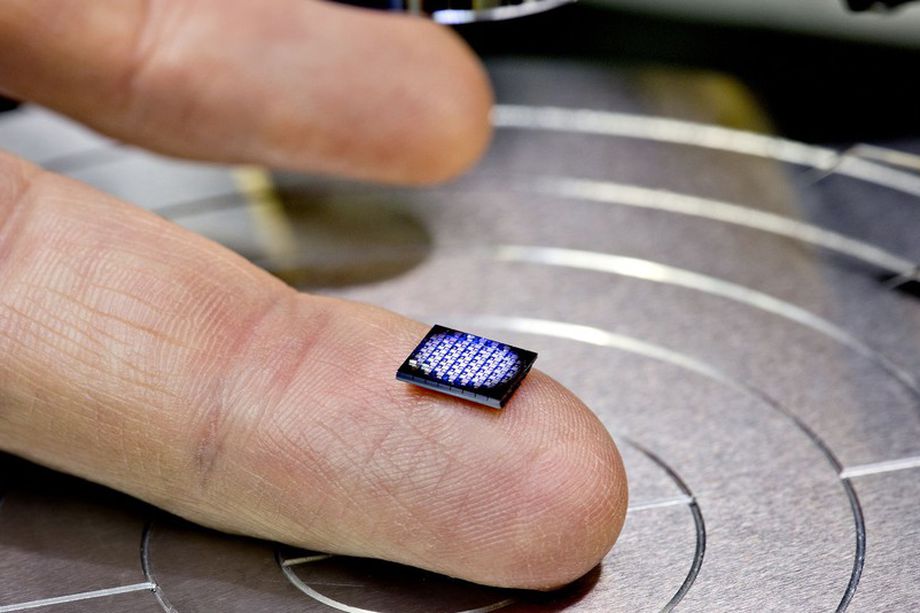

IBM just unveiled the ‘world’s smallest computer’

by Paul Miller @ theverge.com The computer is 1mm x 1mm, smaller than a grain of fancy salt, and apparently costs less than ten cents to manufacture. To be clear, the picture above is a set of 64 motherboards, each of which hold two of this tiny computer. IBM claims the computer has...

Continue Reading

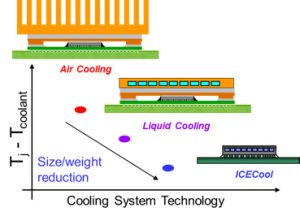

ICECool – An Intra-Chip Cooling System That Is More Efficient

In the Moore’s Law race to keep improving computer performance, the IT industry has turned upward, stacking chips like nano-sized 3D skyscrapers. But those stacks have their limits, due to overheating. Researchers from IBM have solved this problem by developing an intra-chip...

Continue Reading