Tag: Motor

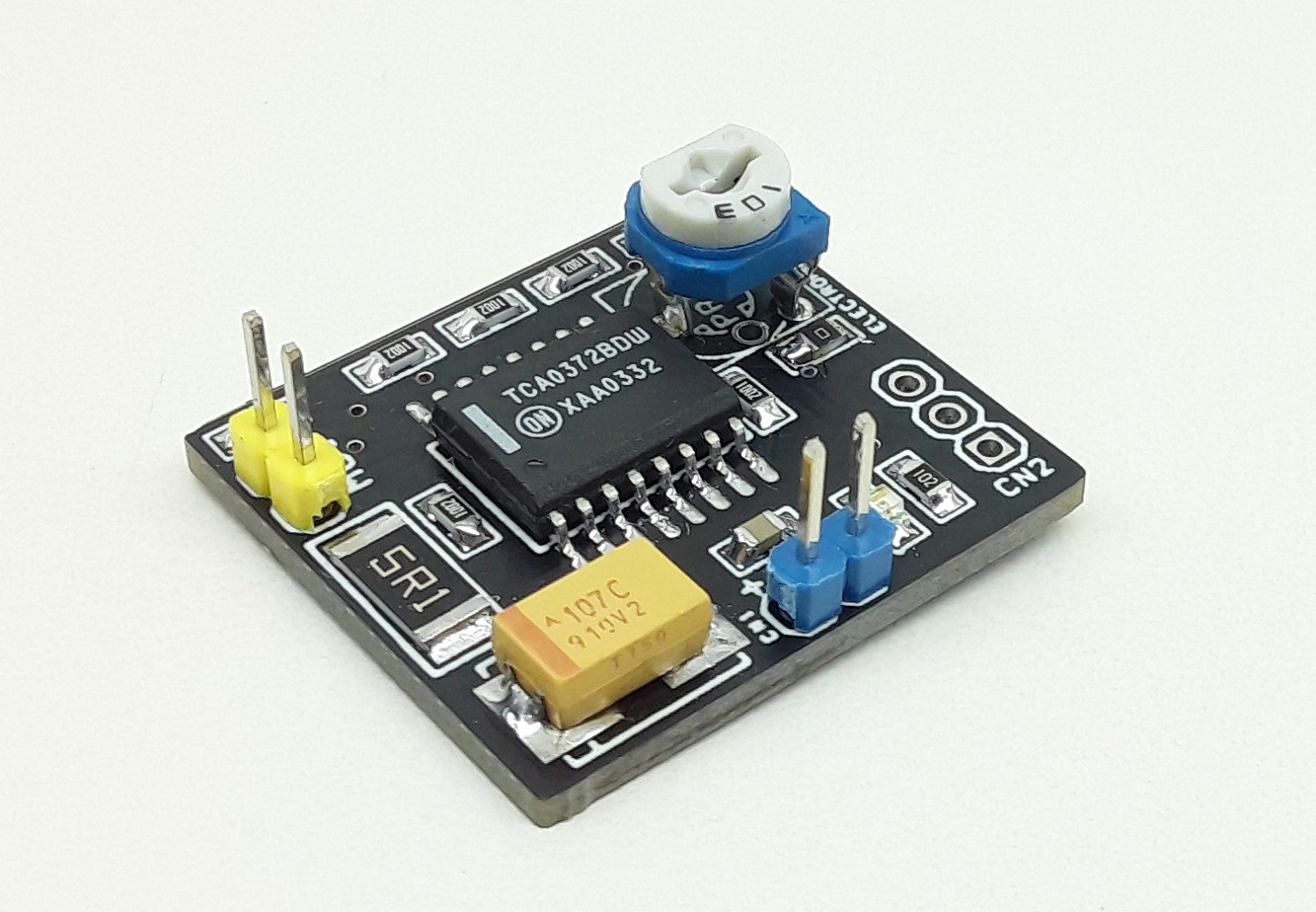

Bidirectional Speed Control for DC Motors

This is a very simple bidirectional speed control of a small DC brushed motor. The project is built using power OPAMP TCA0372 which can drive a load up to 1A. Connecting a small DC motor and trimmer pot will control the motor forward/reverse operation along with speed control. A Trimmer...

Continue Reading

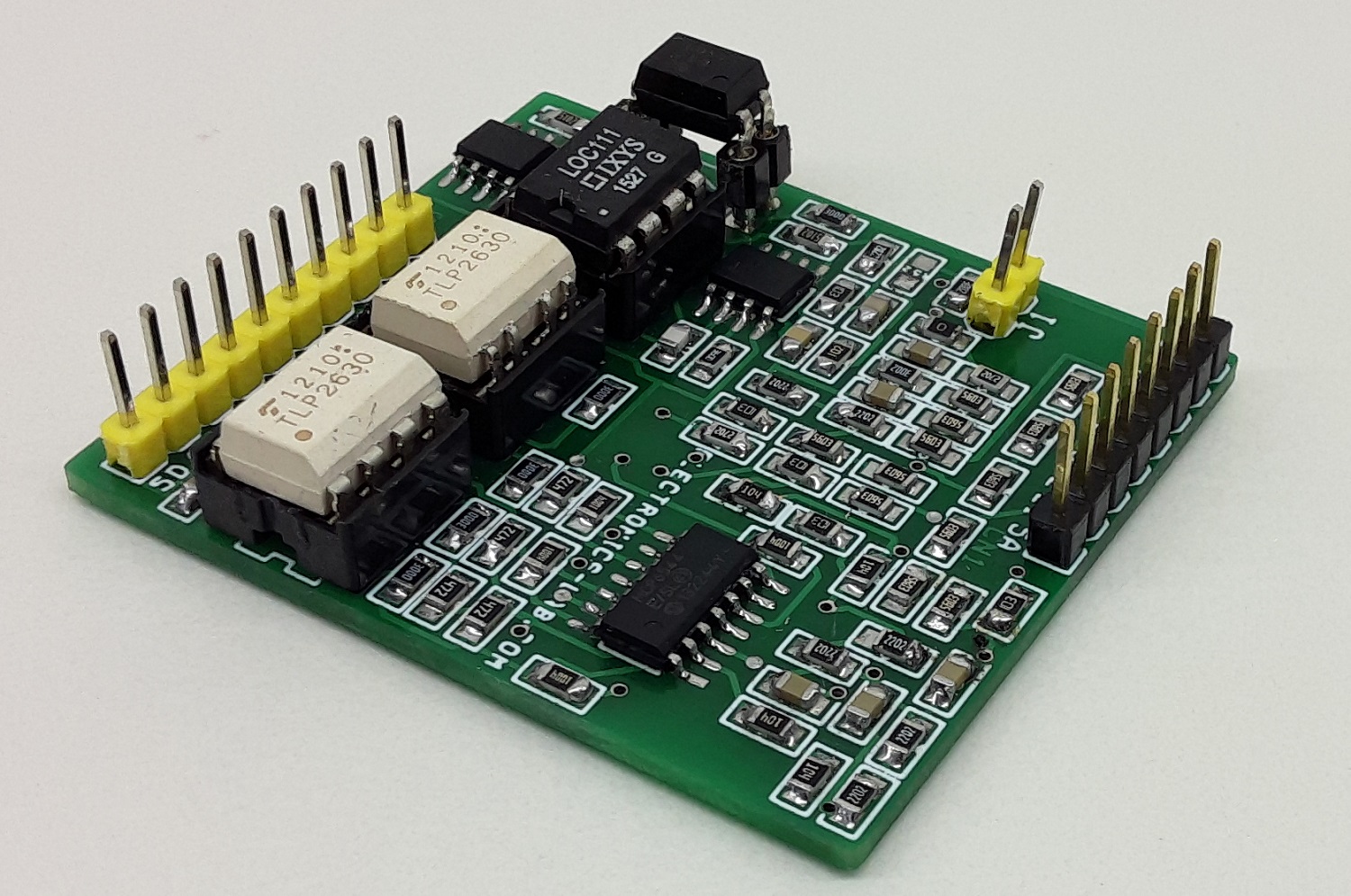

Signal Conditioner for Sensorless BLDC Operations

This is a back EMF signal conditioning circuit that can be used to develop high-voltage sensorless motor drivers. When a sensorless algorithm is used to control the BLDC motor speed, the Back EMF (BEMF) signals are used. Based on zero crossing of BEMF signals, motor commutation is...

Continue Reading

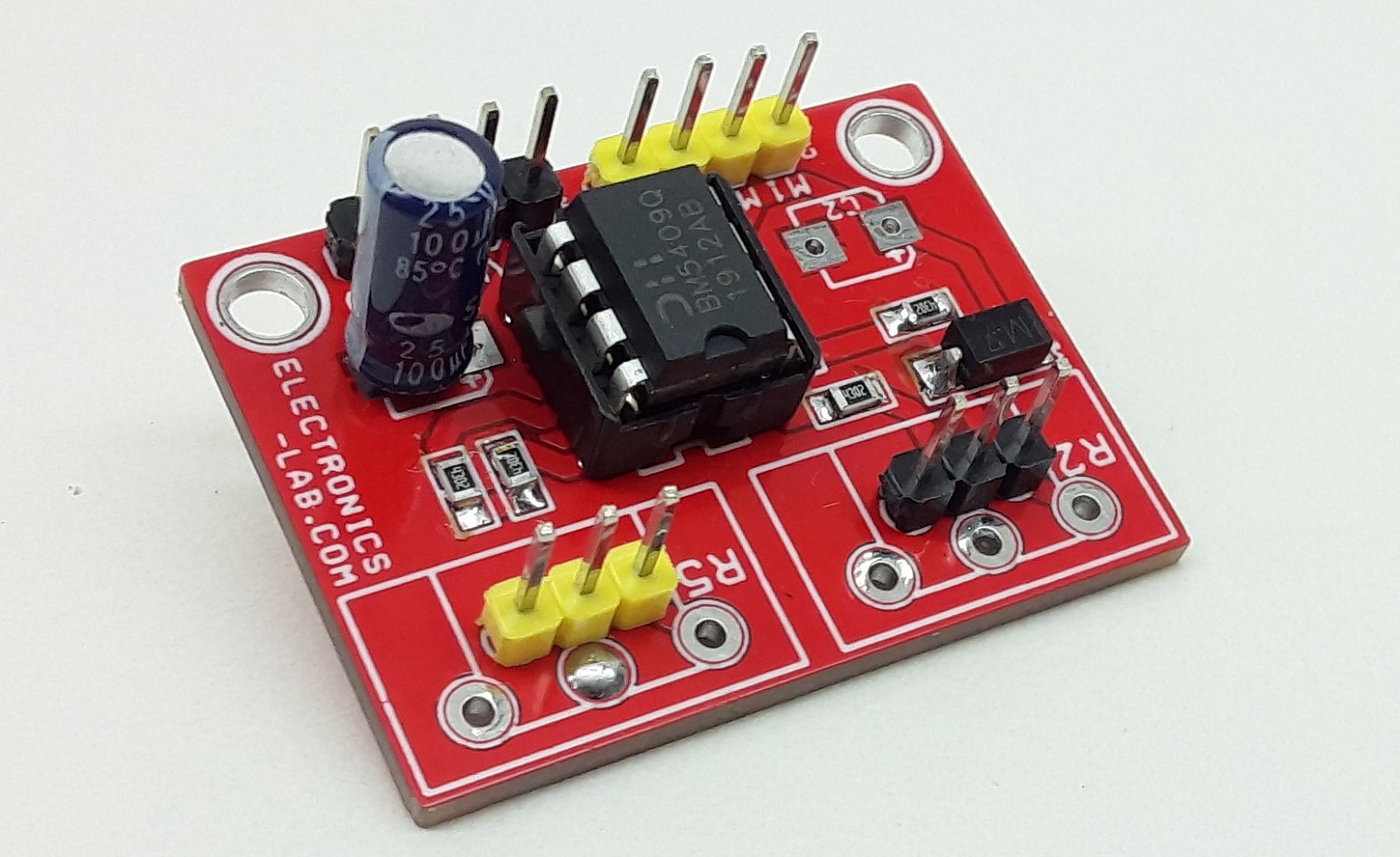

Closed Loop Analog Position Control using Brushed DC Motor and Potentiometer

The project presented here is a low-cost position control closed-loop analog-servo using brushed DC motor and potentiometer as feedback. This project provides all necessary active functions for a closed-loop servo system using a Brushed DC Motor and potentiometer mounted on the output...

Continue Reading

STSPIN32G4 – High performance 3-phase motor controller with embedded STM32G4 MCU

STMicroelectronics' high-performance 3-phase motor controller features an unprecedented level of integration and flexibility. STMicroelectronics' STSPIN32G4 is a high-performance 3-phase motor controller featuring an unprecedented level of integration and flexibility. It packs a...

Continue Reading

Nexperia ASFET for 36 V DC motors

There is growing demand for 36 V DC motors, often being used with multi-cell lithium-ion battery packs, in an increasing range of applications There is growing demand for 36 V DC motors, often being used with multi-cell lithium-ion battery packs, in an increasing range of applications....

Continue Reading

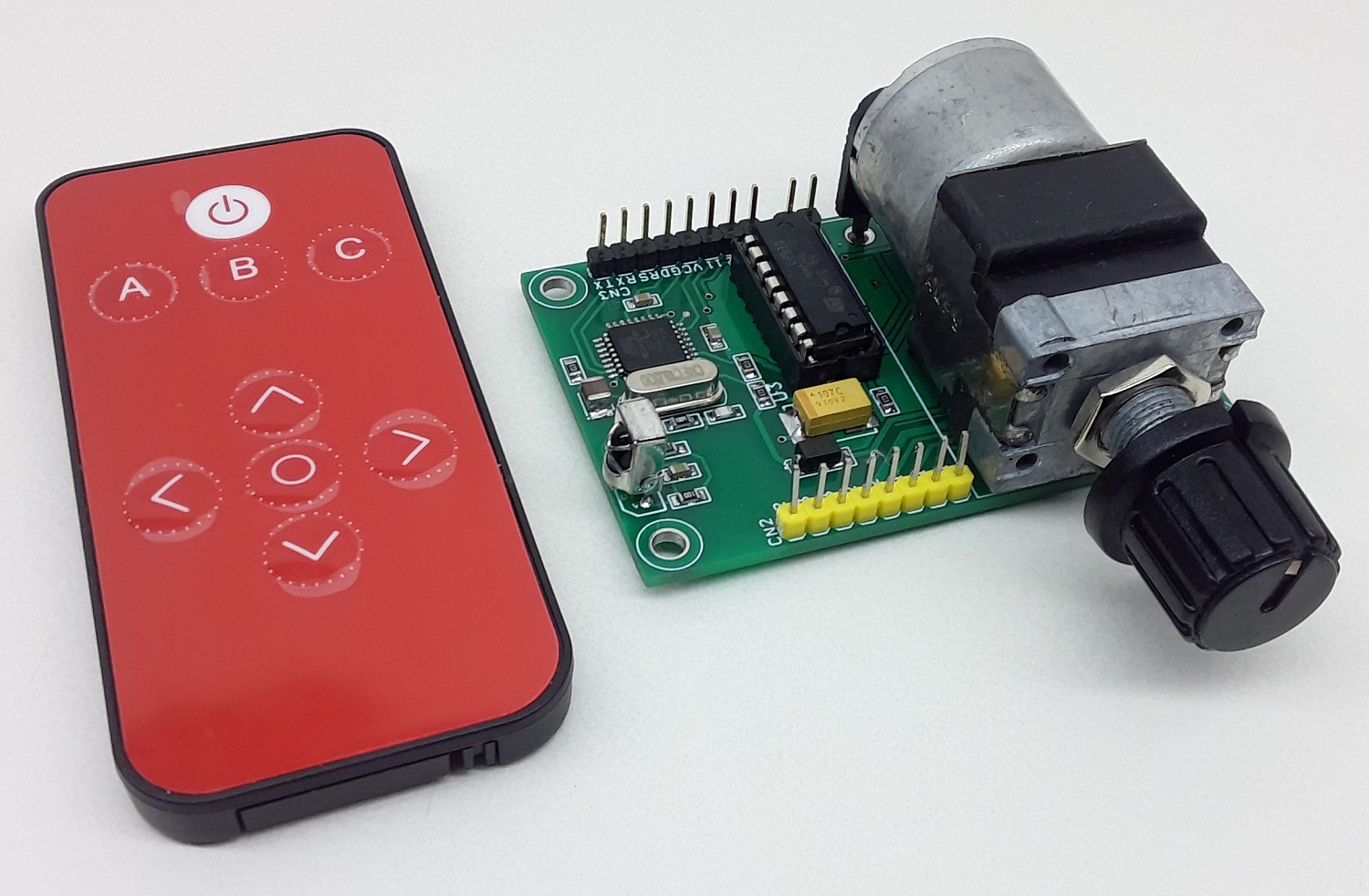

IR Remote Controlled Motorized Potentiometer – Arduino Compatible

This is an Infrared Remote controlled motorized potentiometer controller. It’s an open-source project built on the Arduino platform and compatible with Arduino IDE for custom programming. The project consists ATMEGA328 microcontroller, IR sensor, L293D motor driver, ALPS Motorized...

Continue Reading

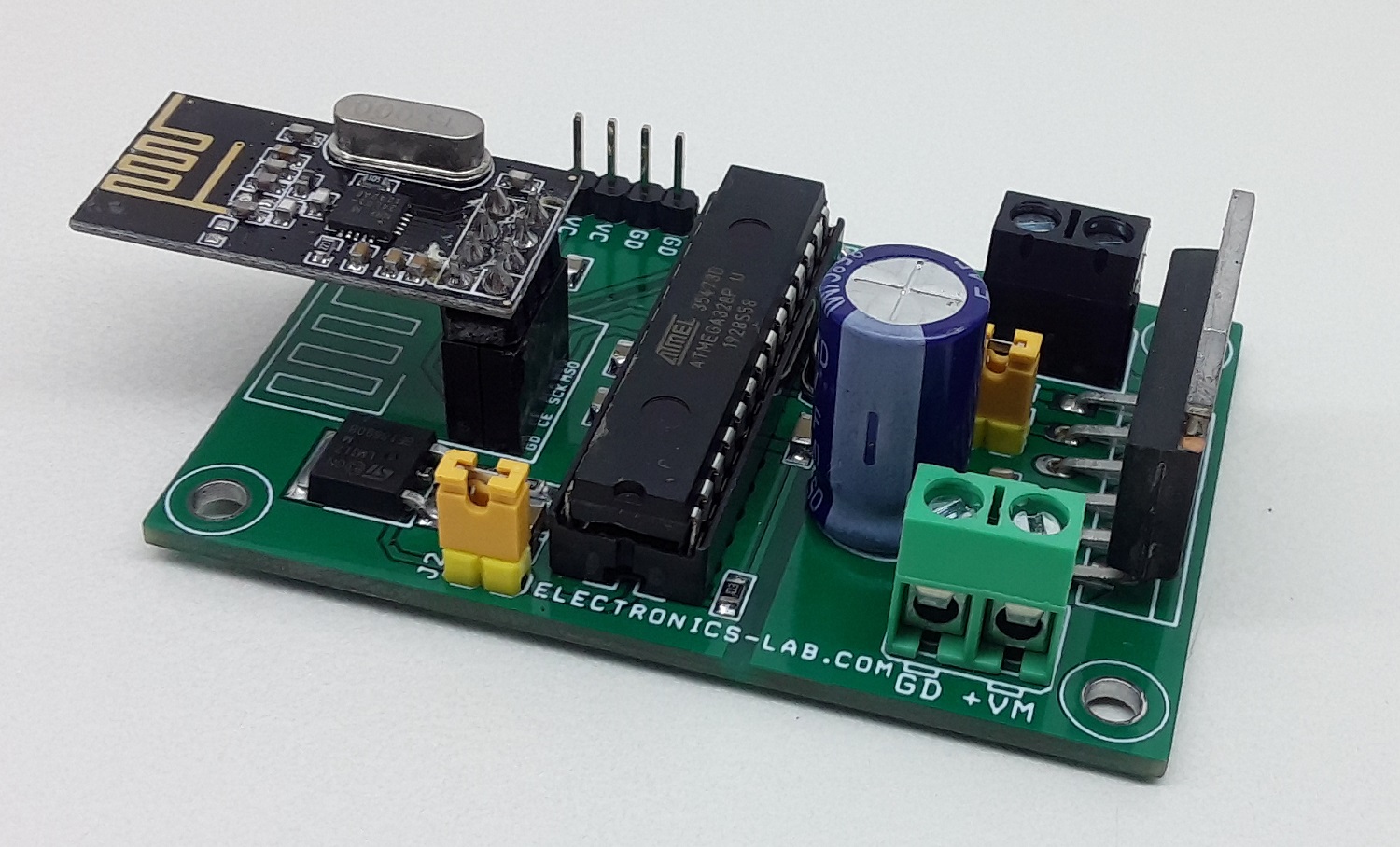

DC Motor Speed, Direction and Brake Control with NRF24L01 RF Module – Arduino Compatible

This is Arduino compatible hardware that can control a single DC motor speed, direction, and brake using an RF remote control. The project is based on an ATMEGA328 microcontroller, H-Bridge DC motor driver chip LM18201, NRF24L01 RF module, 5V Regulator, 3.3V regulator and other...

Continue Reading

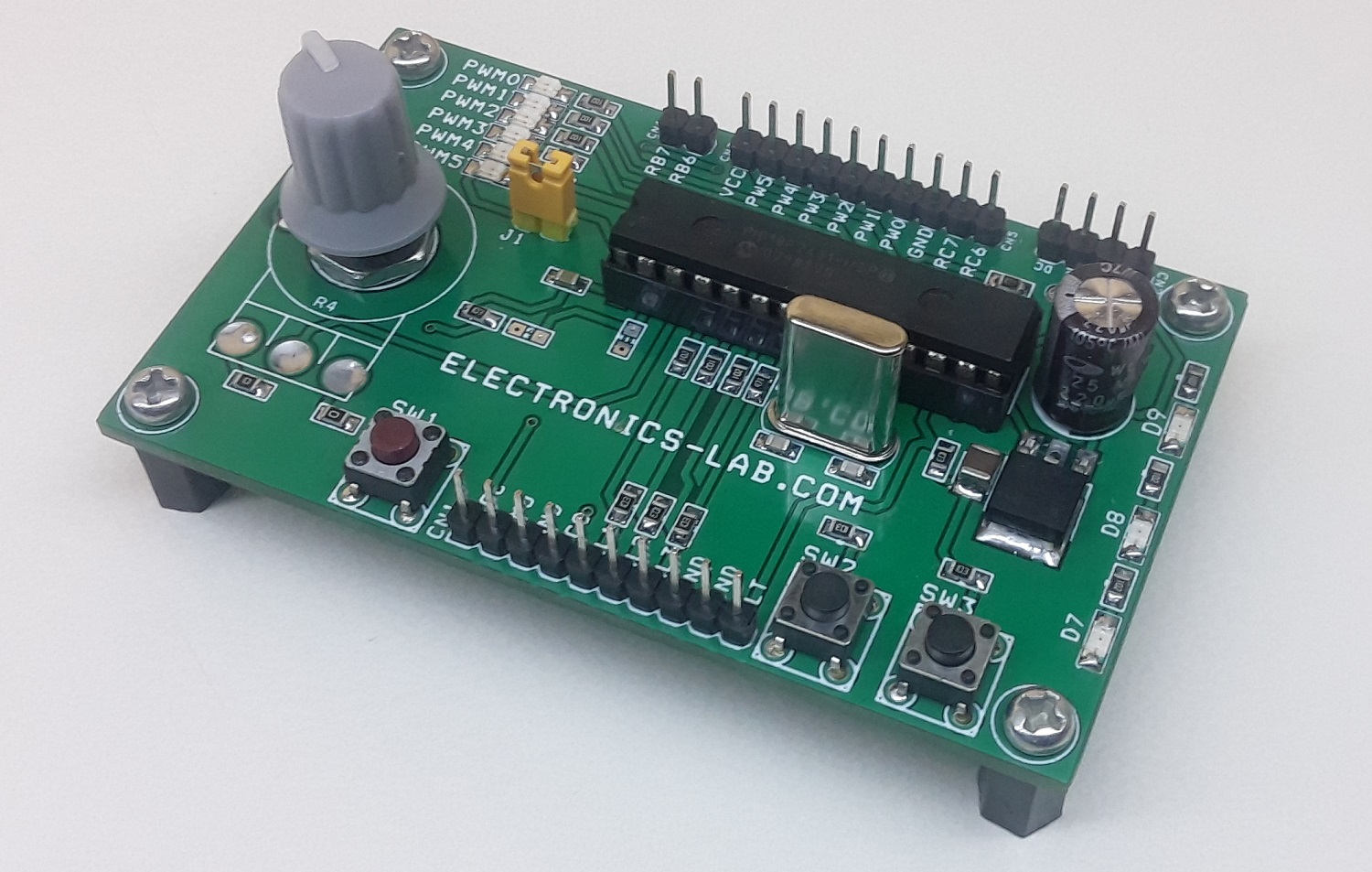

Development board for Brushless Motor, DC Brushed Motor, AC Motors (Pre-Driver)

The project described here is a pre-driver for brushless motors with a hall sensor. The board incorporates many features like current monitor, fault, speed control, direction control motor start/stop using tactile switches, various function LEDs, 6 PWM LEDs. By combining it with a...

Continue Reading