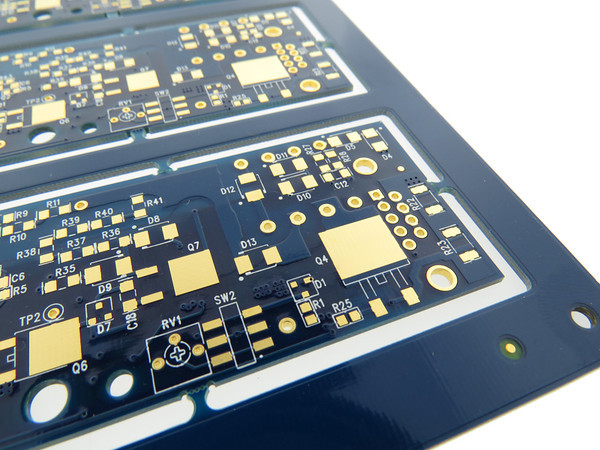

Tag: PCBA

Free Functional Testing For All PCBA Orders | Enjoy Agile Service by Seeed Fusion Right Now!

Exciting Announcement!!! A Brand New Free Functional Testing launched! With the aim to guarantee superior product quality and enhance customer satisfaction, Seeed Fusion introduced Free Functional Testing Plan two years ago, which garnered tremendous positive responses. Today, we are...

Continue Reading

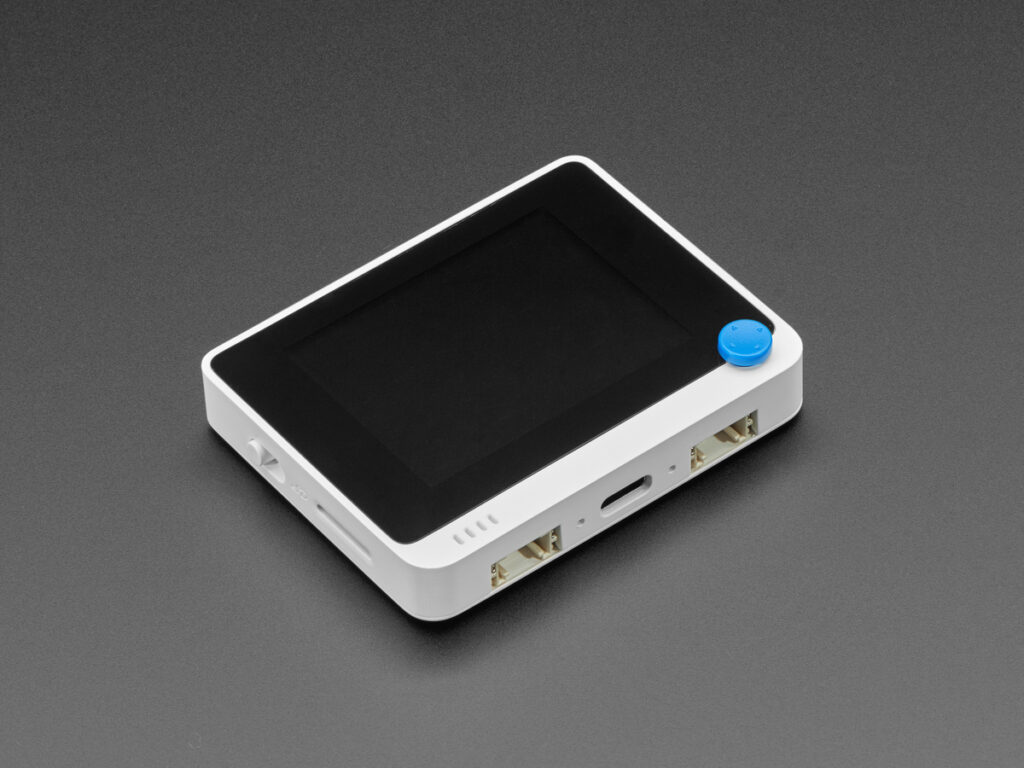

Join the Open Source Hardware Movement and Fabricate Your Own Wio Terminal for A Chance To Get 2x Free PCBA from Seeed Fusion

Hey Community! Are you ready to unleash your creativity and take the open-source hardware movement to the next level? We are passionate about open-source hardware and believe that it has the power to transform the world. That’s why we’re taking it to the next level with open...

Continue Reading

Invigorate your Inspiration for IoT with LoRa-E5 and FREE Seeed Fusion PCBA Prototypes

BIG NEWS!! To accelerate the development of IoT, Seeed is sponsoring Lora-E5 projects with the Seeed Fusion PCB Assembly Service for all hardware enthusiasts, designers, makers, and engineers around the world! Explore LoRa-E5 & the Seeed Fusion PCBA Service STM32WL module LoRa-E5...

Continue Reading

Seeed Studio Makes Design for Assembly (DFA) Review Free for All PCB Assembly Orders with Seeed Fusion

Good news! Seeed Studio is now including the highly acclaimed Design for Assembly (DFA) review with every PCBA order – 100% free! They say “No prices have been hiked up or additional fees squeezed in anywhere, go ahead, check. We simply cannot understate the value of this service,...

Continue Reading

What Is Turnkey PCB Assembly?

PCB Assembly is a process that requires knowledge not just of PCB components and assembly but also of printed circuit board design, PCB fabrication and a strong understanding of the final product. Circuit board assembly is just one piece of the puzzle to delivering the perfect product...

Continue Reading

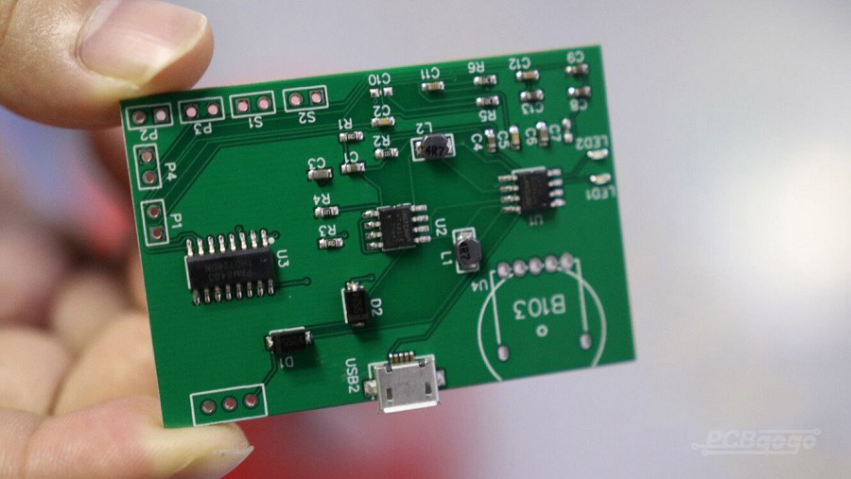

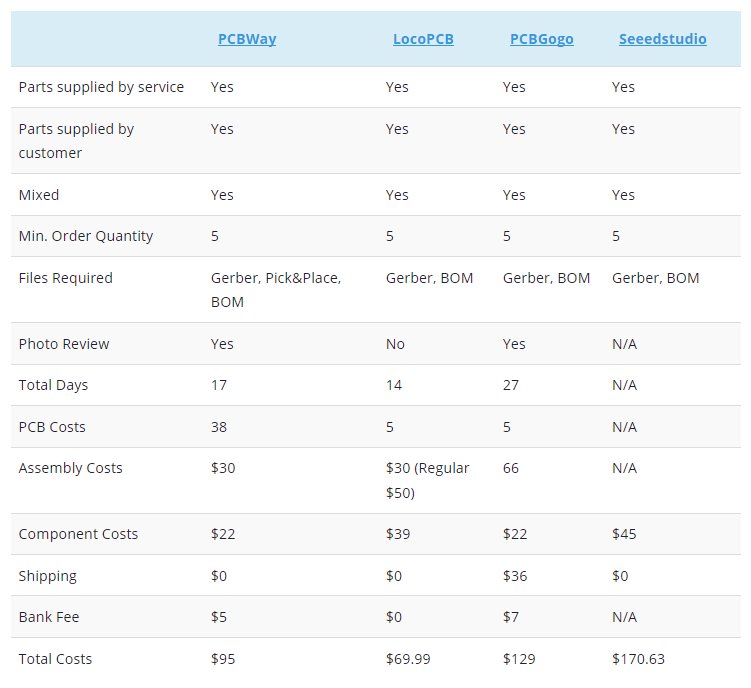

PCBA Service Review – Comparing PCBWay vs LocoPCB vs PCBGogo vs Seeedstudio

Daniel Eichhorn @ blog.squix.org, shares his experience with some popular PCBA services and documents his finding on his blog. He writes: Until recently I believed that having PCBs assembled by a professional service is either too costly for small batches or not possible at all. That...

Continue Reading

CHOOSING A SURFACE FINISH FOR FINE-PITCH COMPONENTS

by CARMEN ZHENG @ www.seeedstudio.com Today we are going to share with you a real case study involving a Seeed Fusion PCBA customer’s design. At the time of placing the order, the customer requested the default HASL surface finish, but listed in their Bill of Materials was a 0.4mm...

Continue Reading

Seeed Studio Fusion PCBA Service – Free Assembly for 5 PCBs

To the ire of many, manufacturing in small quantities have often led to sky high prices, hindering many makers from translating their ideas to reality. Now, to eliminate cost barriers and enable even more makers to experience the flexibility and convenience of turnkey PCB fabrication...

Continue Reading