Tag: pick and place

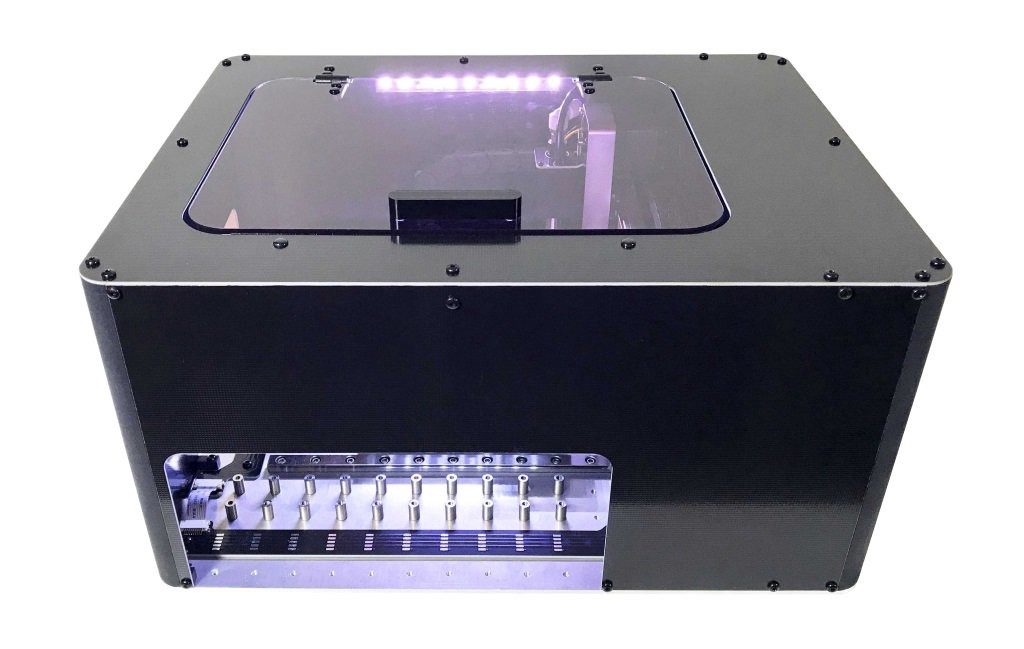

Amoeba Robotics’ Boarditto – An Affordable Pick and Place Machine

Hong Kong-based Amoeba Robotics is set to launch a pick and place machine for engineers, designers, and makers to conveniently automate the assembly of their PCBs ontop of their desks, with a more affordable price range going for $1,950. This is incredible because most pick and place...

Continue Reading

XPlotter, The All-In-One Plotter, Engraver and Laser Cutter

XPlotter is an affordable and easy to use desktop plotter, Laser cutter and engraver. It is designed to create a new definition of plotter. By integrating the laser engraver and cutter into the mechanism, it becomes a versatile desktop tool for artists, craftsmen and makers to set their...

Continue Reading

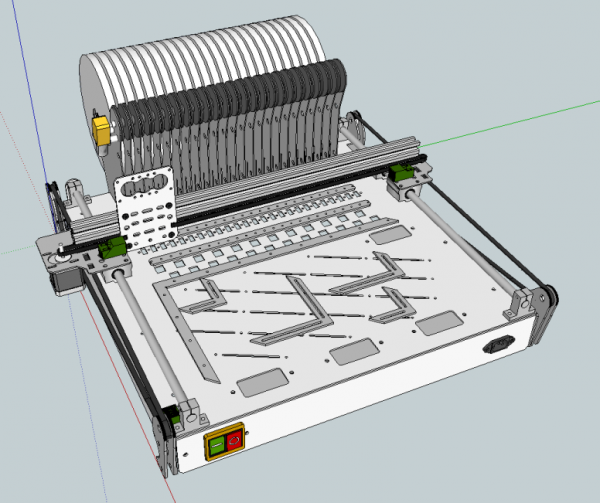

Open Source Pick and Place Machine

Peter van der Walt @ OpenHardware.co.za has published his newest machine design – an open source pick and place machine. Open Source Pick and Place Machine -...

Continue Reading

Makerarm: The Robot That Can Make Anything!

A complete digital fabrication system for makers everywhere: 3D print, laser, carve, plot, assemble, pick/place + more on your desktop! Makerarm: The Robot That Can Make Anything! -...

Continue Reading

Makerarm – The first robotic arm that makes anything, anywhere

Makerarm just lauched on kickstarter. It's a penknife for the DIY world, it can make almost anything by changing the toolhead! A complete digital fabrication system for makers everywhere: 3D print, laser, carve, plot, assemble, pick/place + more on your desktop! Makerarm works...

Continue Reading