Tag: Reflow

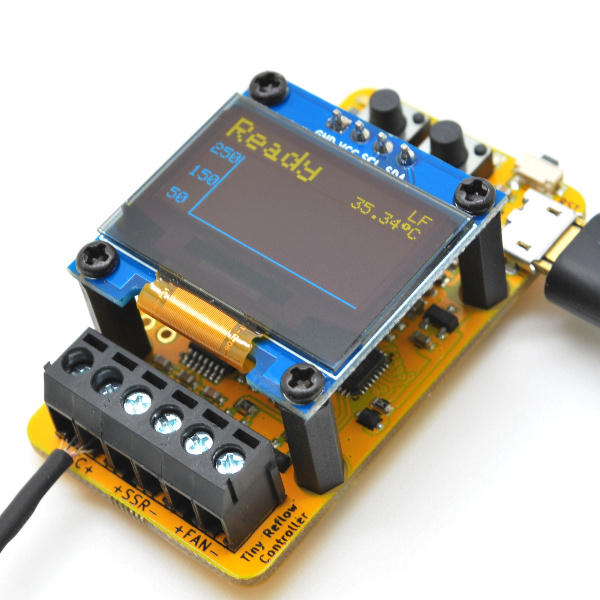

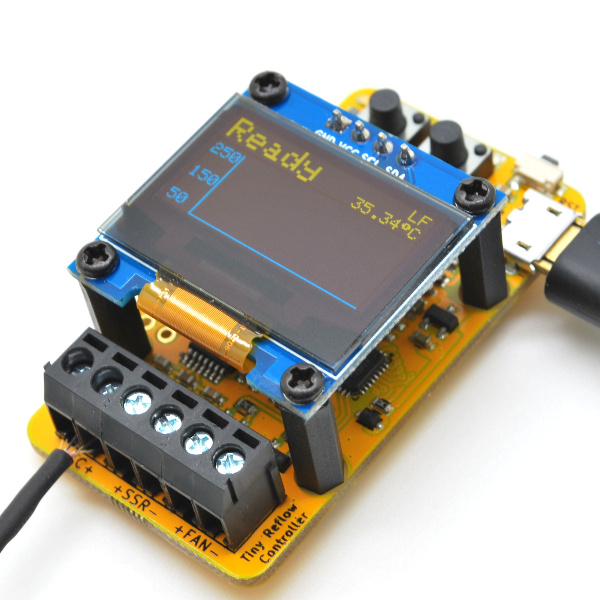

Tiny Reflow Controller with OLED display

Last time we examined how to build a DIY Reflow Oven controller using the Tiny Reflow Oven Controller v1 by Rocket Stream. However, Rocket Stream recently released the Tiny Reflow Controller V2 and for today’s tutorial, we will attempt to build this second version. The Tiny Reflow...

Continue Reading

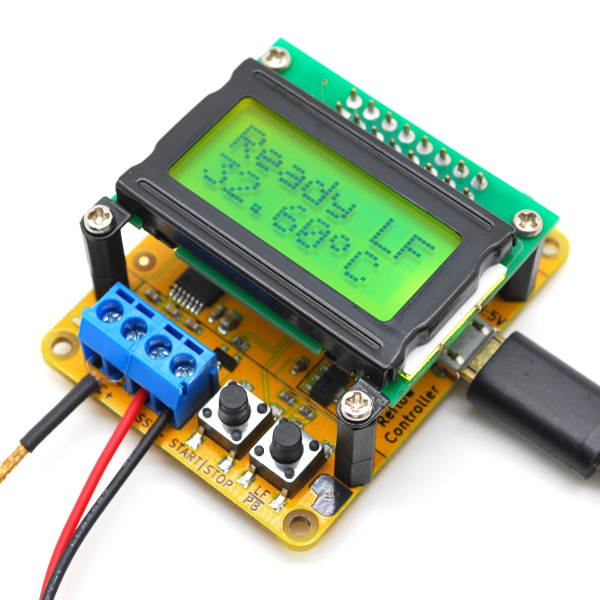

Tiny Reflow Controller with character LCD

Reflow ovens are an important part of the development of PCB for electronic products when using surface mount components. They provide a route through which PCBs can be quickly populated with SMD components, however, for accurate results, the heat across the oven needs to be controlled...

Continue Reading

New Convection Reflow Oven for Soldering with 6 Heating Zones

Neoden USA, a distributor of Neoden products in the US, is pleased to announce the launch of their new desktop reflow oven, Neoden IN6. The reflow oven is equipped with 6 heating zones, 3 of them are located at the top and the other 3 are located at the bottom. The multiple zones will...

Continue Reading

Tiny Reflow Controller V2 features an OLED display

Rocketscream.com released their all-in-one Arduino compatible reflow controller powered by ATmega328P with OLED screen and built-in USB port. This reflow controller replaces the beloved "Tiny Reflow Controller V1" which had a character LCD display. Let's see what's new on this...

Continue Reading

REFLO – Compact, open, and smart PCB reflow oven

REFLO is a stylish, portable reflow oven for creators and makers to easily, quickly, and professionally prototype their IoT device, wearable, small robot, etc. REFLO’s features: Portable at only 6” x 6” x 2” - it’s the worlds smallest reflow oven Efficient as it...

Continue Reading

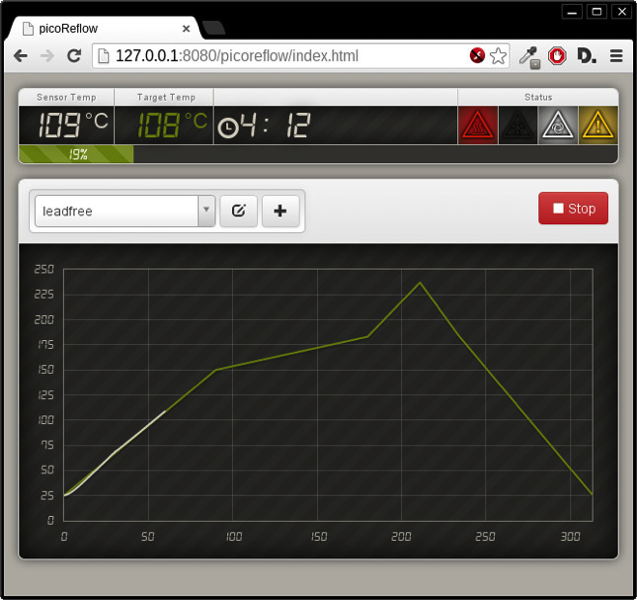

How to Control a Reflow Oven with Raspberry Pi

Here is a great Raspberry Pi based Reflow oven controller from "apollo-ng" on GitHub. You can edit your temperature curve on your browser and Rasberry Pi controls the solid state relays and fan. Turns a Raspberry Pi into a cheap, universal & web-enabled Reflow Oven Controller. Of...

Continue Reading

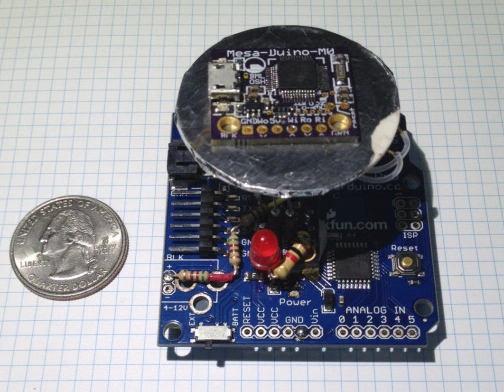

1″ 100W Hot-Plate for SMT Reflow

This is a small hot-plate for SMT reflow soldering build upon an Arduino Pro and controlled using PWM and high side power MOSFETs. Black Mesa Labs has been using a $20 hot plate for a year now for soldering QFN ICs to PCBs. Only issue so far has been the size ( 10″x10″x3″ ) and...

Continue Reading

SMD Soldering Reflow Oven

Here is a nice tutorial on how to build your own reflow soldering oven using ControLeo2 reflow oven controller. This particular instructable is based on the ControLeo2 reflow oven controller by Peter Easton. This is by far the best I've come across and the software is fully open...

Continue Reading