Tag: Robots

Learn Robotics with Raspberry Pi

A guide to building robots with the Raspberry Pi microcomputer. Learn Robotics with Raspberry Pi ($24.95, 200 pp., January 2019) brings beginners into robotics by focusing its robot-building projects around a $35 credit card-size Raspberry Pi microcomputer. The book’s 19 year-old...

Continue Reading

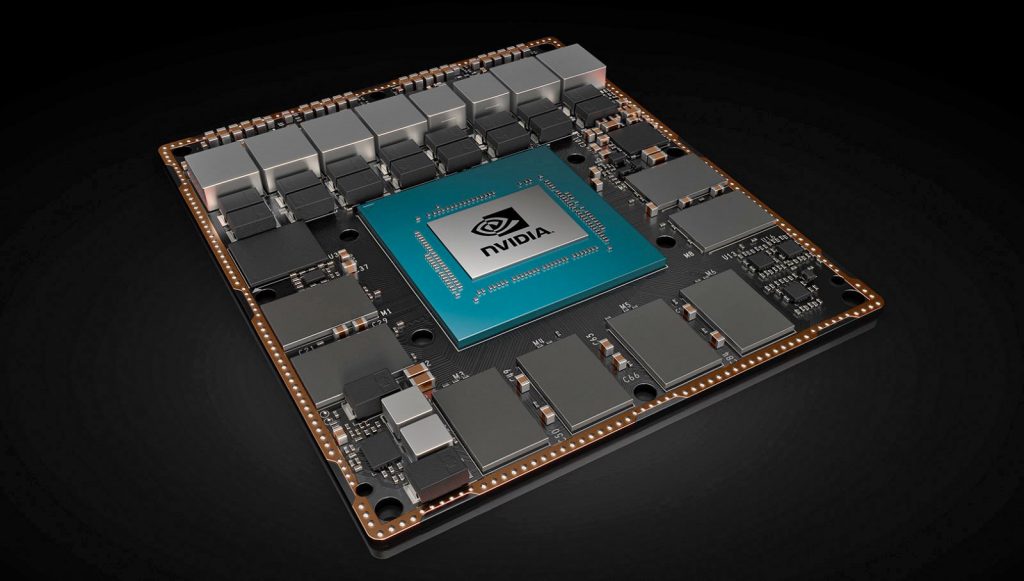

Nvidia’s Jetson Xavier is an AI Computer boasting a $10,000 Worth Of Power For Your Machines and Robots

NVIDIA Jetson Xavier is the latest addition to the Jetson platform. It’s an AI computer for autonomous machines, delivering the performance of a GPU workstation in an embedded module for a consumption under 30W. With multiple operating modes at 10W, 15W, and 30W, Jetson Xavier has...

Continue Reading

IQ Motor Module – An Integrated Motor With A Closed Loop Controller And Position Sensor

The drone industry is booming, and the technology is just… cool, to put it plainly. Flying robots, many of which are completely autonomous delivering our goods and also spying on us. Makers and hobbyist are getting on the bandwagon, making their customized drones with available parts....

Continue Reading

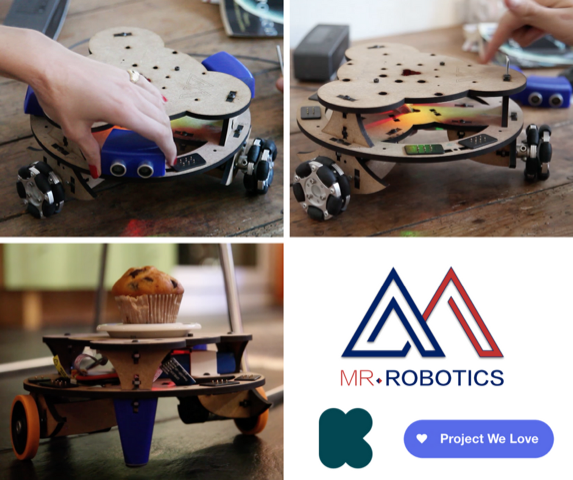

Robby – A Simple and Powerful Robot to Learn Electronics and Programming

Over the years we have seen a significant interest in people wanting to learn electronics and programming but are mostly handicapped with what they could build. Over time, learning has been proven to be more reliable when learning is more practical, and we can quickly grasp the concept...

Continue Reading

Pulurobot – An Open Source Heavy Load Bearing Application Robot Powered by the Raspberry Pi

If you have seen the starship delivery robots by Starship Technologies, you will know how cool delivery robot can be. Pulurobotics have released a set of low-cost opensource robots that are capable of carrying heavy loads and can be reconfigured to do several tasks. Application...

Continue Reading

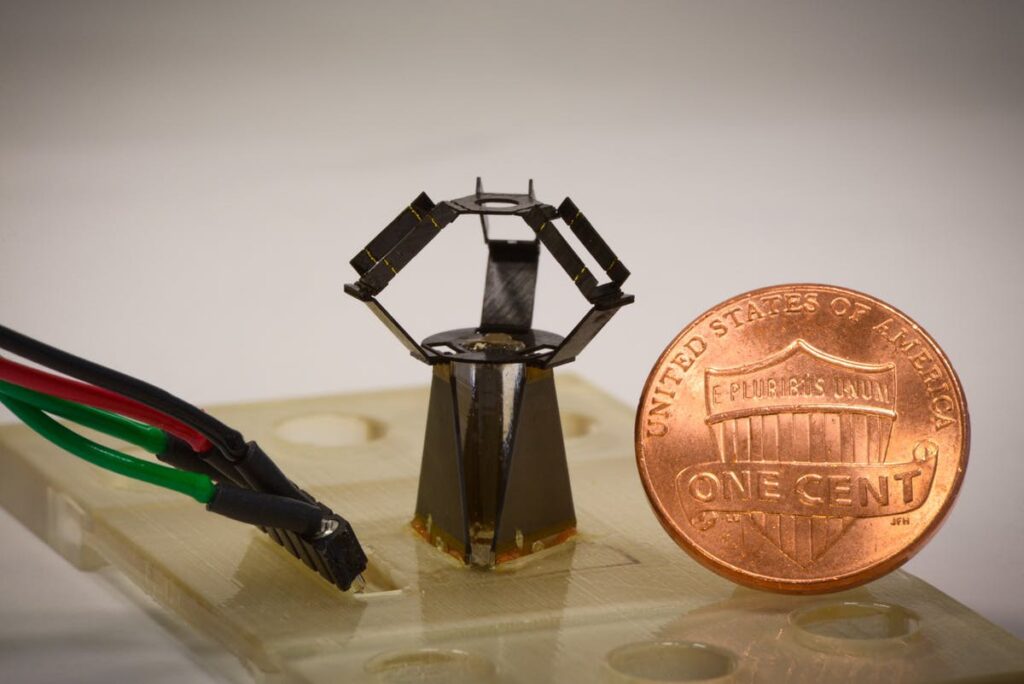

milliDelta Robot- High speed and Precision in a Compact Design

Delta robots are machines with three arms designed to move at high speeds and perform precise tasks. The three arms are connected to a universal join at the base, and the device uses parallelograms that restrict the movement avoiding rotation. As a result, they can move in x, y, and z...

Continue Reading