Tag: SeeedStudio

Seeedstudio LinkStar-H68K-1432 V2 is A Tiny Pocket Router with 2x1GbE + 2×2.5GbE ports

After the succession of LinkStar-H68K, Seed Studio has announced LinkStar-H68K-1432 V2 a pocket-sized router powered by the Rockchip RK3568 SoC. The most interesting feature of this router is that it features 2 x 1GbE and 2 x 2.5GbE ports with dual-band Wi-Fi 6 and a 4K-capable HDMI 2.0...

Continue Reading

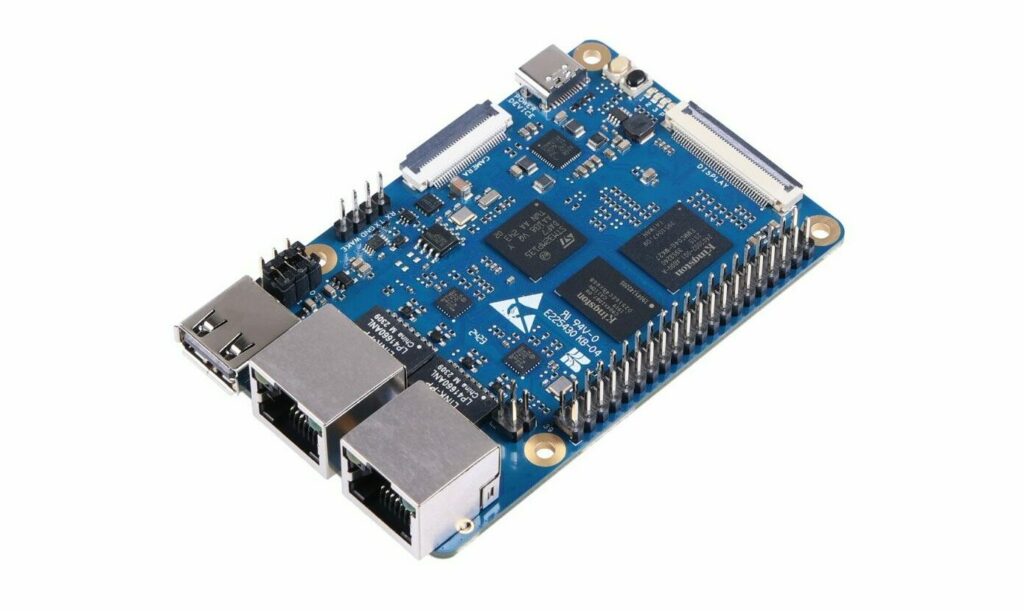

ODYSSEY – STM32MP135D SBC Offers High Performance

SeeedStudio has recently featured the ODYSSEY-STM32MP135D, which is a Single Board Computer, and a compact and high-performance piece of technology that packs a powerful punch. This impressive board houses a 32-bit Arm Cortex-A7 STM32 MPU within its compact 8.5cm x 5.6cm dimensions,...

Continue Reading

Free Functional Testing For All PCBA Orders | Enjoy Agile Service by Seeed Fusion Right Now!

Exciting Announcement!!! A Brand New Free Functional Testing launched! With the aim to guarantee superior product quality and enhance customer satisfaction, Seeed Fusion introduced Free Functional Testing Plan two years ago, which garnered tremendous positive responses. Today, we are...

Continue Reading

Open up new IoT possibilities with Seeed XIAO BLE for TinyML and Seeed Fusion PCBA service

Seeed Studio has just released the highly anticipated addition to the XIAO series, Seeed XIAO BLE – nRF52840, a powerful Bluetooth LE microcontroller supporting multiple protocols including Bluetooth 5.0, NFC and Zigbee. What’s so special about it? Seeed XIAO BLE and the...

Continue Reading

Invigorate your Inspiration for IoT with LoRa-E5 and FREE Seeed Fusion PCBA Prototypes

BIG NEWS!! To accelerate the development of IoT, Seeed is sponsoring Lora-E5 projects with the Seeed Fusion PCB Assembly Service for all hardware enthusiasts, designers, makers, and engineers around the world! Explore LoRa-E5 & the Seeed Fusion PCBA Service STM32WL module LoRa-E5...

Continue Reading

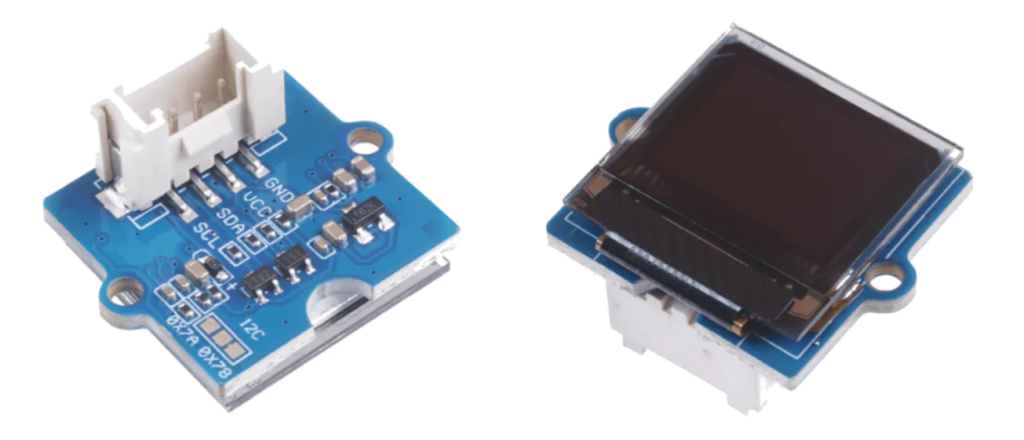

Seeed Studio Grove SSD1306 0.66″ OLED Display

Seeed Studio Grove SSD1306 0.66" OLED display is a monochrome 64×48 resolution display with a user-friendly design and Grove I2C interface in a 20mm×20mm ultra-small package. The Grove SSD1306 0.66" OLED Display offers a smaller screen compared to the other OLED (Organic Light...

Continue Reading

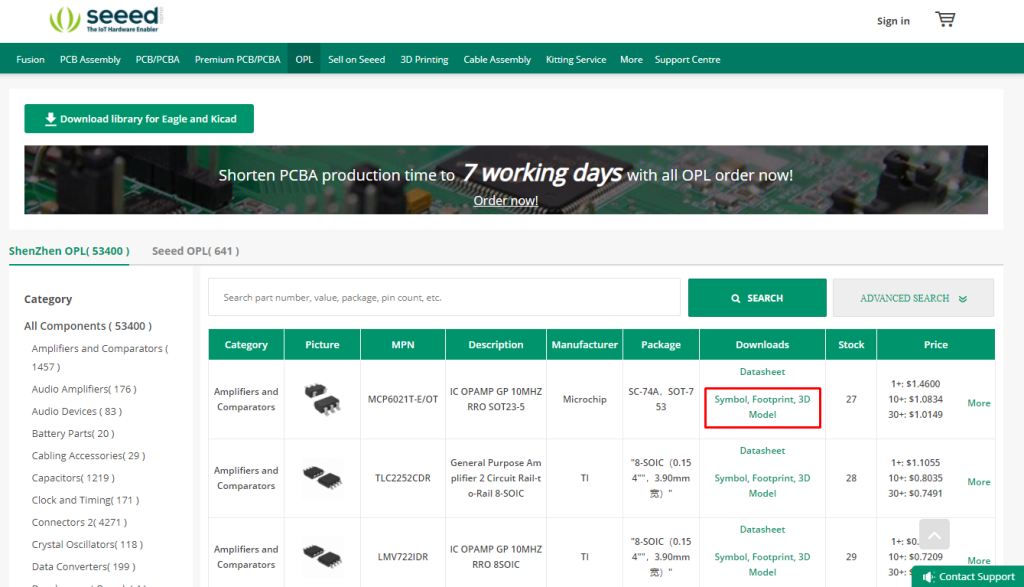

Seeed’s Open Parts Library (OPL) adds SnapEDA models for faster electronics production

The addition of SnapEDA CAD models into the OPL further streamlines parts selection, design and manufacturing Today, Seeed, a leading global PCB manufacturer based in Shenzhen, is adding SnapEDA computer-aided design (CAD) models to the Seeed and ShenZhen Open Parts Libraries (OPLs),...

Continue Reading

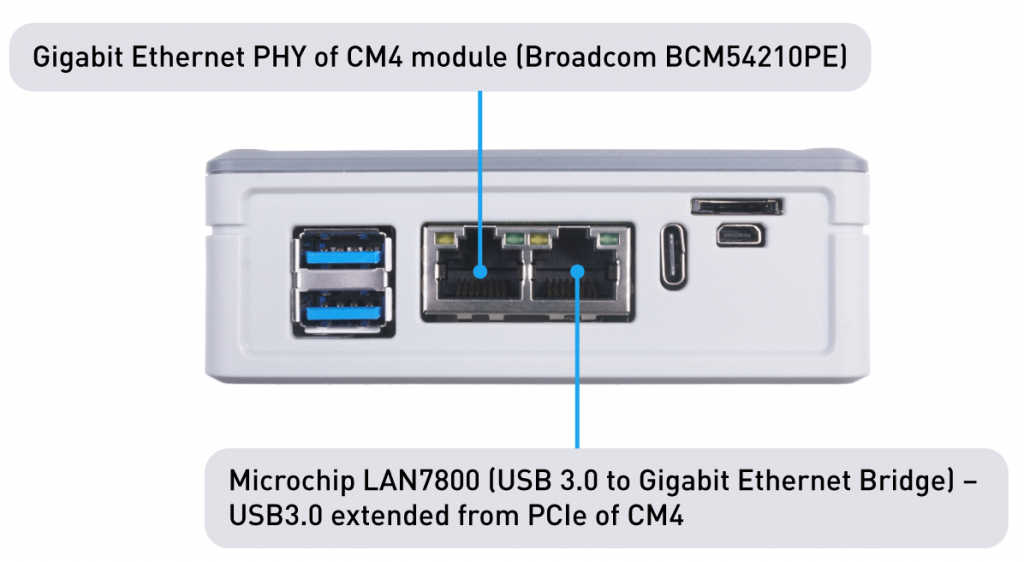

4GB RAM/32GB eMMc Raspberry Pi CM 4 Powered Router with Dual Gigabit Ethernet

Efficient routing applications require effective bandwidth management, reduced network management cost, flexible function selection, friendly management interface with a fast boot time amongst other features which are usually tedious with hard routers. This is why a Shenzhen,...

Continue Reading