Tag: Servo

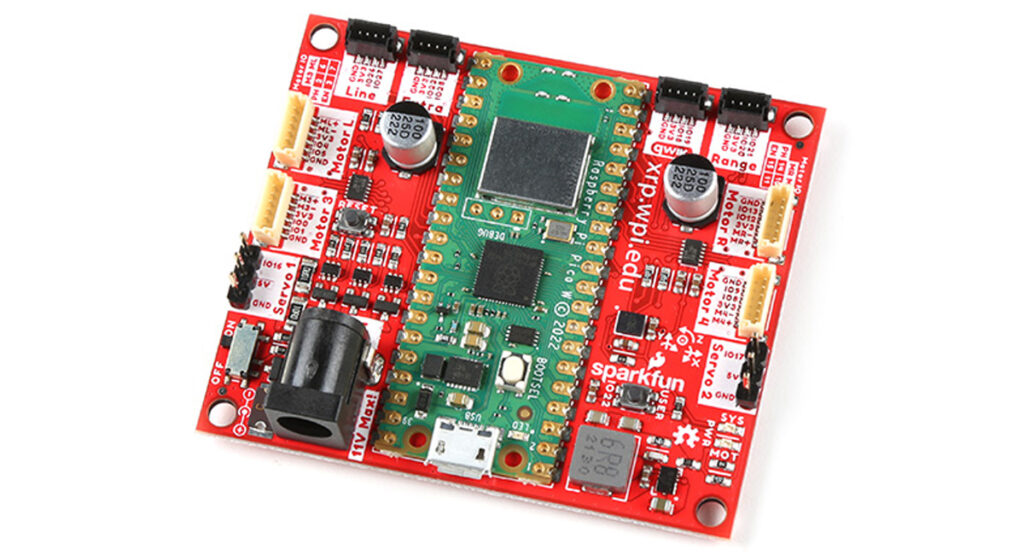

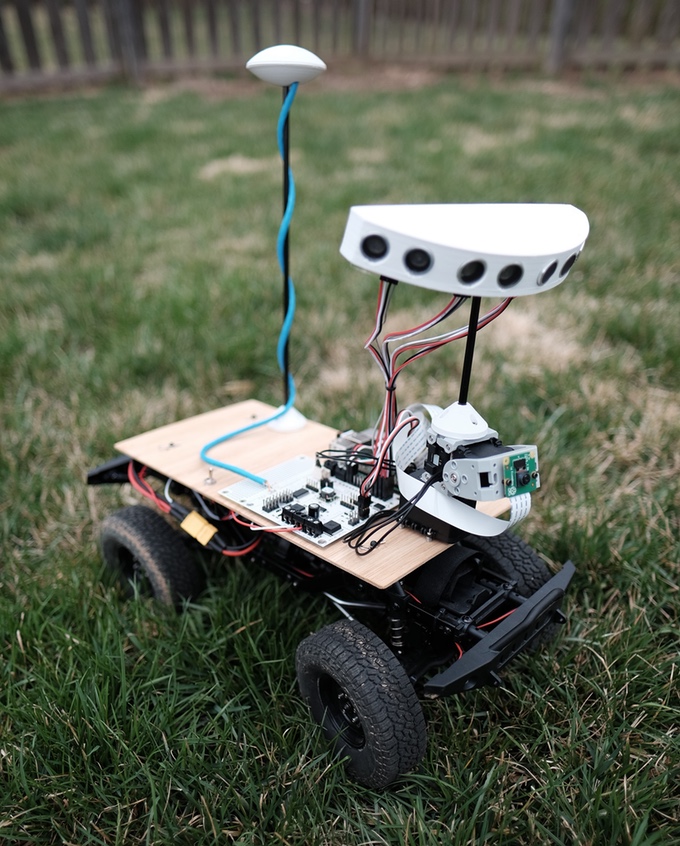

SparkFun’s New Experiential Robotics Platform (XRP) Is Designed for Hands-On Learning and Educational Use

The Experiential Robotics Platform (XRP) integrates a Raspberry Pi Pico W and a 6-axis motion sensor with Blockly, Python, and WPILib for educational robotics development. Designed for tool-free assembly, it enables progression from basic to advanced robotics projects for students and...

Continue Reading

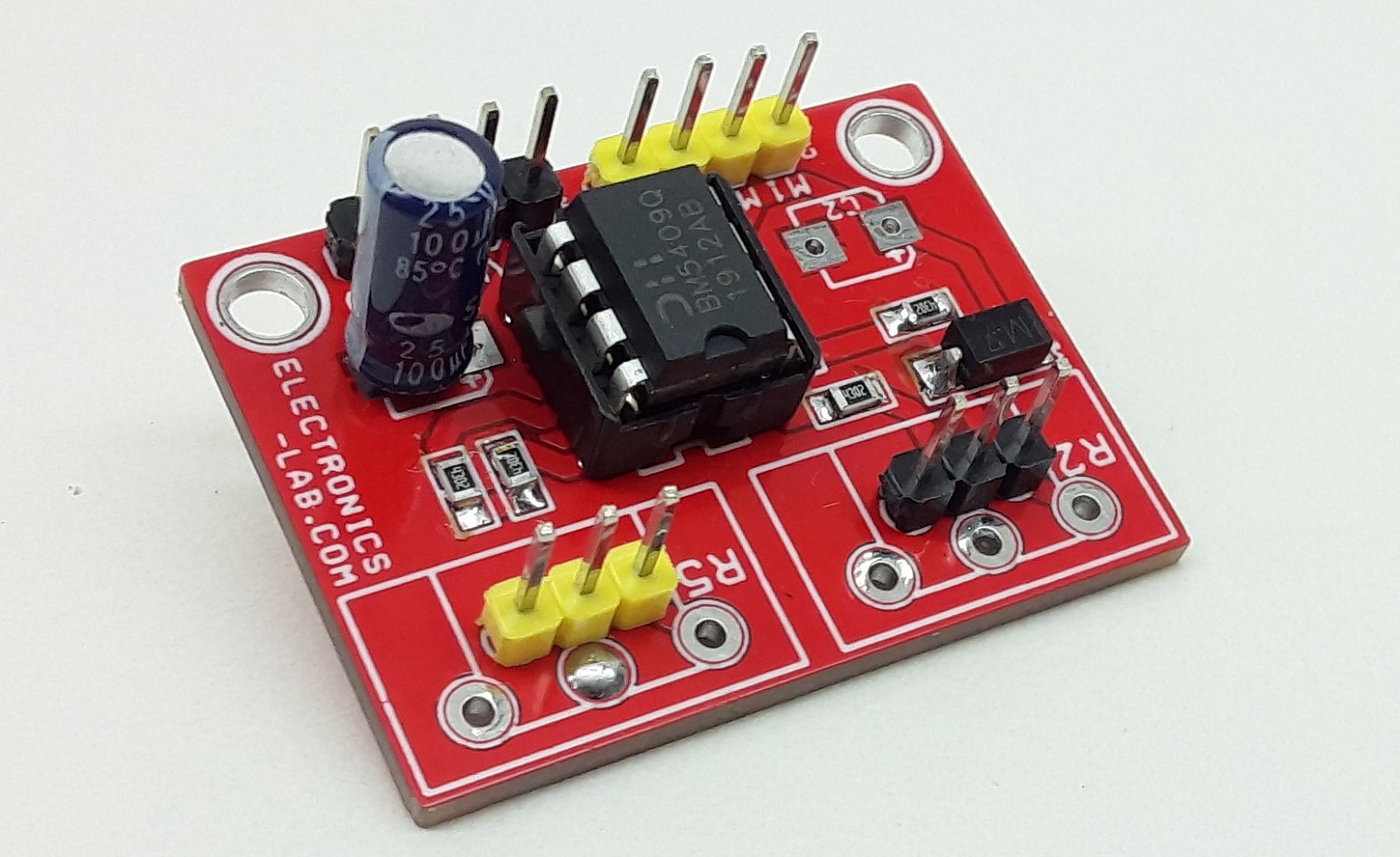

Closed Loop Analog Position Control using Brushed DC Motor and Potentiometer

The project presented here is a low-cost position control closed-loop analog-servo using brushed DC motor and potentiometer as feedback. This project provides all necessary active functions for a closed-loop servo system using a Brushed DC Motor and potentiometer mounted on the output...

Continue Reading

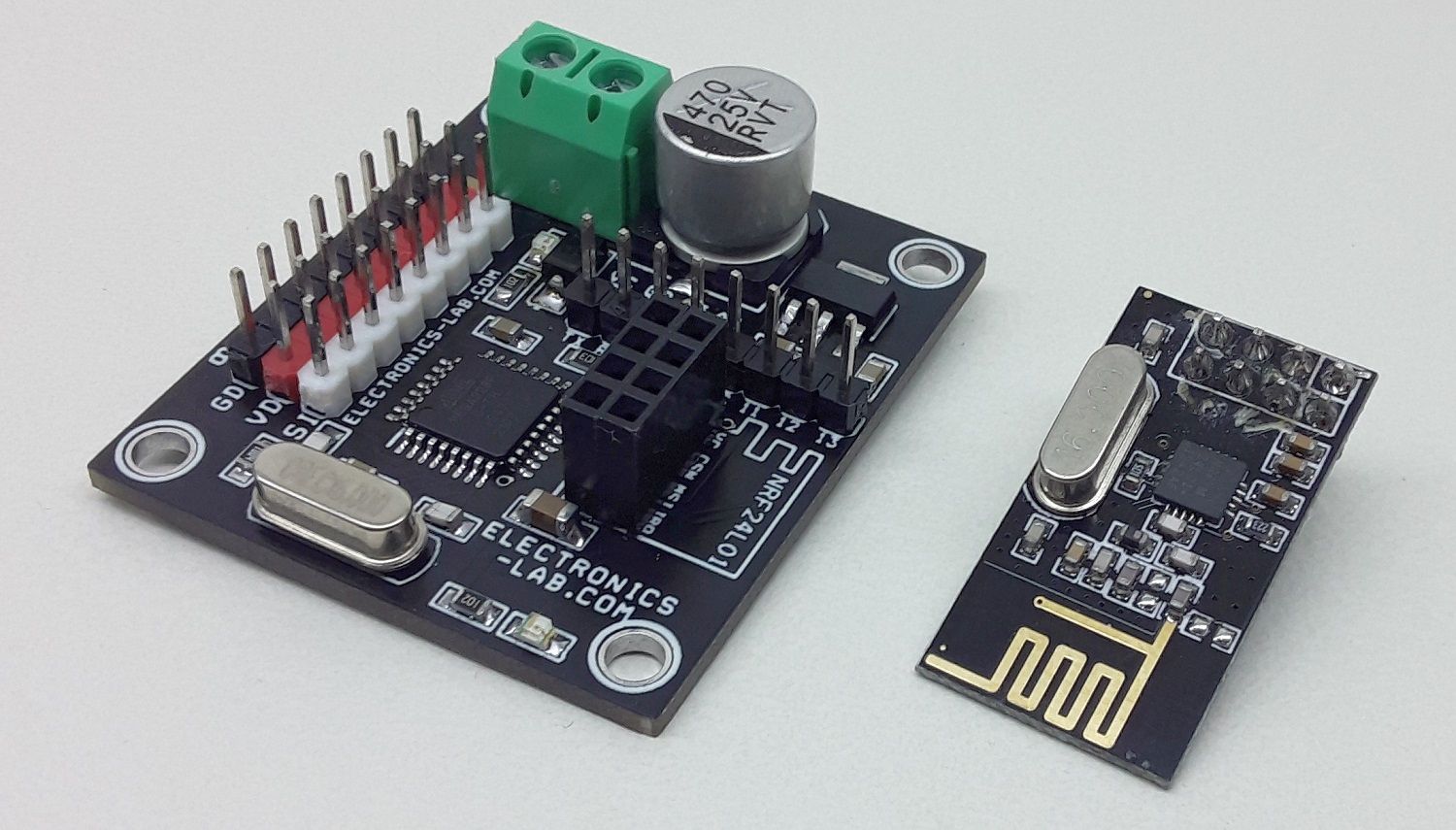

8 Channel RC Servo Driver Over RF Link using NRF24L01 RF Module – Arduino Compatible

This is an easy-to-build open-source Arduino compatible board that enables driving 8 RC servos over NRF24L01 RF Link. The project can be used as a standalone RC servo driver or 8 channel RF remote-controlled RC servo Receiver. An optional OLED display option can be used to develop RC...

Continue Reading

Joystick Controlled 2 x RC Servo motors – Arduino Compatible

This project enables easy control of 2 RC servo motors using a thumb joystick. This is an Arduino compatible project and it consists of a thumb joystick, ATMEGA328 microcontroller, filter capacitor on dc supply, and other components. The thumb joystick has 2 axes, X and Y. The joystick...

Continue Reading

Teknic’s brushless servo motors are now available online

Hudson™ industrial grade brushless servo motors have been used by high-volume OEM companies for over a decade. These rugged, reliable motors have powered automated equipment in a variety of markets including medical, AOI, and CNC equipment (just to name a few). These...

Continue Reading

Trinamic Introduces the TMCM-1617 Servo Controller Module

TRINAMIC Motion Control GmbH & Co. KG announced the TMCM-1617 single-axis servo controller module designed for servo drives with 18A RMS and 8 to 28V DC supply voltage. Achieving high-current loop frequencies to minimize current ripple, the potted module enables smaller electric...

Continue Reading

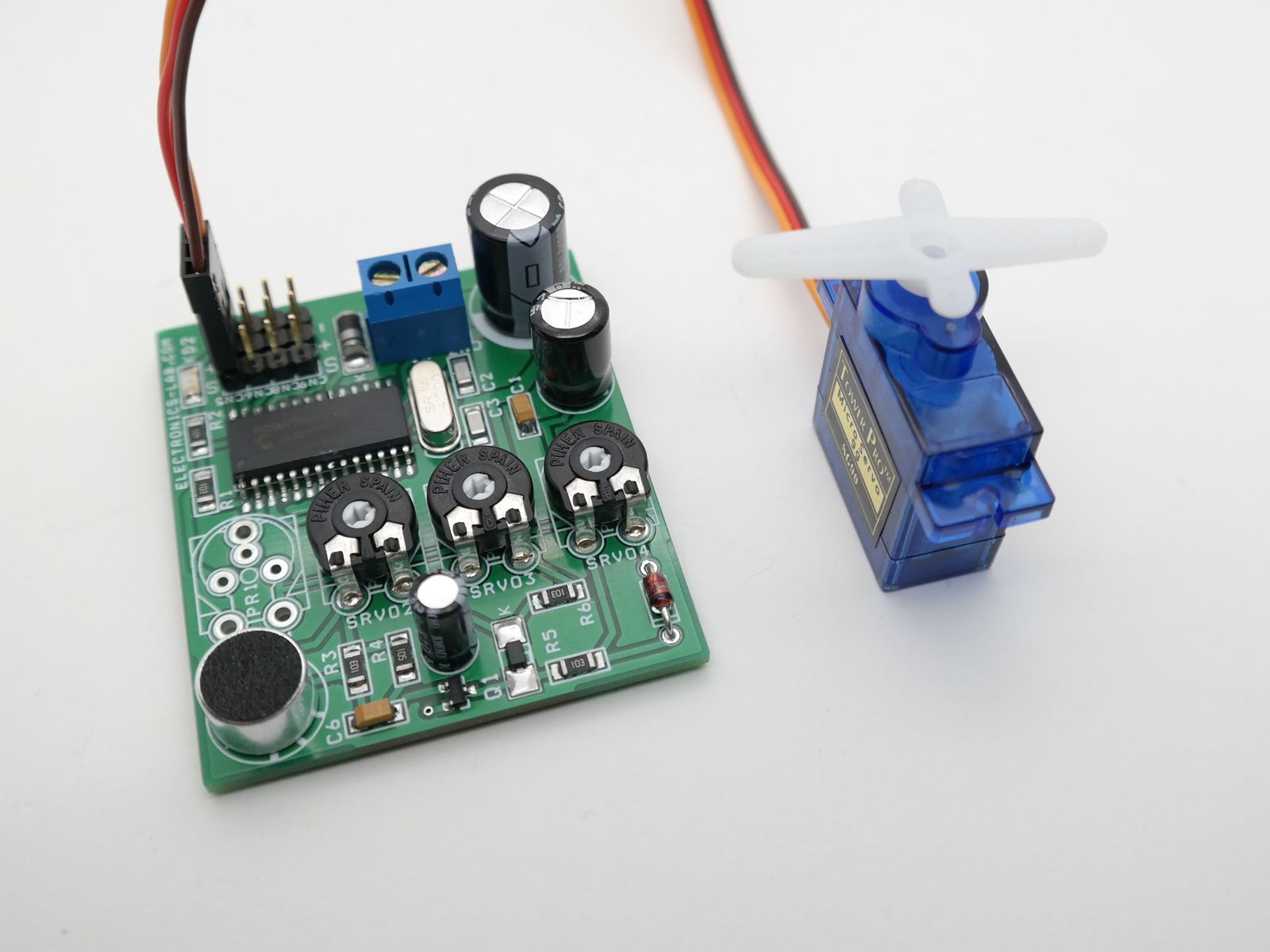

Sound to RC Servo Driver

This project is designed for Animatronics and Puppeteer applications, however it can be used in other applications like sound responsive toys, robots etc. Especially this project helps to move the jaw or mouth of animatronics creature. The project moves RC servo once receives any kind...

Continue Reading

Robot Core – The Ultimate Raspberry Pi Robot Controller

The Robot Core, which is a robot control board for the Raspberry Pi and Arduino, brings many different elements into one awesome package. It allows you to efficiently control motors, servos, and read sensor data without needing 3-4 additional boards to hookup. Several Robot Core boards...

Continue Reading