-

Posts

41 -

Joined

-

Last visited

-

Days Won

2

Content Type

Profiles

Forums

Events

Posts posted by Ashish Adhikari

-

-

In this tutorial I am going to show you guys how to make an Arduino or NodeMCU based Weather Station using DHT11 or DHT22 temperature and humidity sensor and display it using an OLED Display.

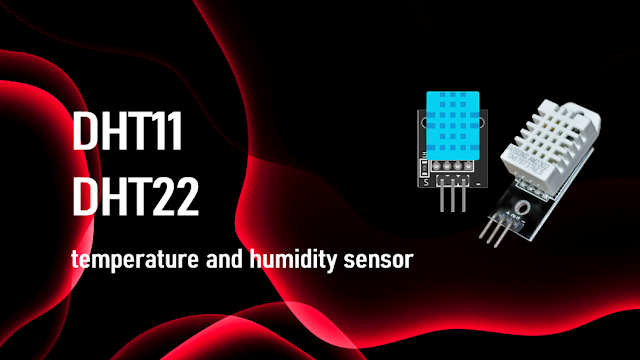

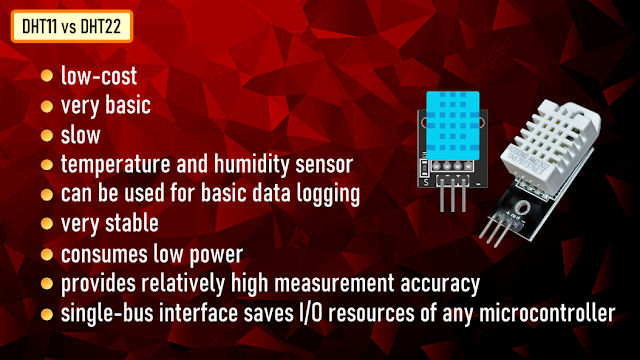

DHT11 vs DHT22

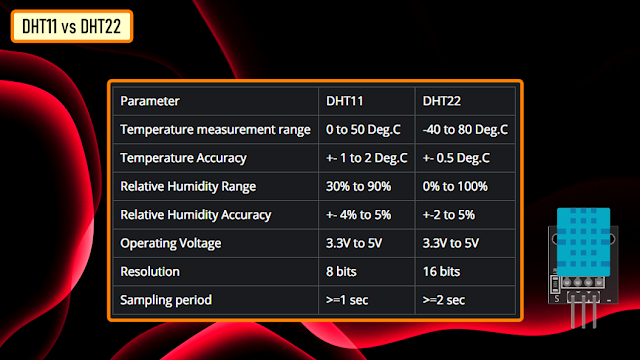

The DHT11 and DHT22 are both low-cost very basic and slow temperature and humidity sensors which can be used for basic data logging.Despite being slower, they are very stable and consumes low power and provides relatively high measurement accuracy. The single-bus digital signal is output through a built-in ADC which is easy to read using any microcontroller. Single bus interface saves the I/O resources of any microcontroller board.The operating voltage is between 3.3V to 5V and the sampling period for DHT11 is 1Hz or one reading every second and for DHT22 is 0.5Hz or one reading every two seconds. Hence, you can not query them more than once every second or two.The DHT sensors are made of two parts, a capacitive humidity sensor and a Negative Temperature Coefficient or NTC temperature sensor (or thermistor).The NTC temperature sensor is actually a variable resistor whose resistance decreases with increase in the temperature.For measuring humidity, two electrodes with a moisture holding substrate between them is used. When the humidity changes, the conductivity of the substrate changes or in other words the resistance between these electrodes changes. This change in resistance is measured and processed and is sent to the microcontroller.A very basic chip inside the sensor does the analog to digital conversion and spits out a digital signal which is read using a microcontroller.Here is a comparison chart of the two sensors. Looking at this it is very clear that DHT22 outshines the DHT11 in every aspect.However, if accuracy is your concern, and you are ready to pay a bit higher price, go for DHT22. Otherwise, DHT11 should be good enough for you.OLED Display

OLED or organic light-emitting diode is a light-emitting diode (LED) in which the emissive electroluminescent layer is a film of organic compound (millions of small LED lights) that emits light in response to an electric current.OLEDs are used to create digital displays in devices such as television screens, computer monitors, portable systems such as mobile phones, hand-held game consoles and PDAs. An OLED display works without a backlight because it emits visible light.There are many types of OLED displays available in the market based on their:- Sizes

- Color

- Brands

- Protocol

- SPI (Serial Peripheral Interface) or I2C

- Passive-matrix (PMOLED) or active-matrix (AMOLED) control scheme

To know more about OLED Display and to know how to connect multiple OLED Displays using TCA9548 multiplexer check out my tutorial number 7OLED Display with Arduino and NodeMCU link is in the description below: https://www.youtube.com/watch?v=_e_0HJY0uIoLets have a closer at these two displays.At the back of these displays there are heaps of SMD capacitors and resistors soldered on-board; but, since its an I2C device we only care about these 2 pins (SCL and SDA)The display connects to Arduino using only four wires – two for power (VCC and GND) and two for data (serial clock SCL and serial data SDA), making the wiring very simple. The data connection is I2C (I²C, IIC or Inter-Integrated Circuit) and this interface is also called TWI (Two Wire Interface).The on-board pins can be in different order, so always triple check before hooking it up to your project.Operating voltage is between 3v to 5v but, it is best to use the guidance from the manufacturer's datasheet.Sometimes we need to use 2 displays in our projects. So, how can we achieve this?The trick is to have a configurable address on your display. This unit has a configurable address between 0x78 and 0x7A. Just by unsoldering the 0Ohm resistor from one side and hoking it up to the other side or just by putting a global solder we can change the address.In picture these displays look very big. But, practically speaking they are tiny. They are made of 128 x 32/64 individual OLED pixels and do not require any back-light. Just have a look at this and see how small it is. Even though they are small they can be very useful in any electronic projects.Setup Using Arduino

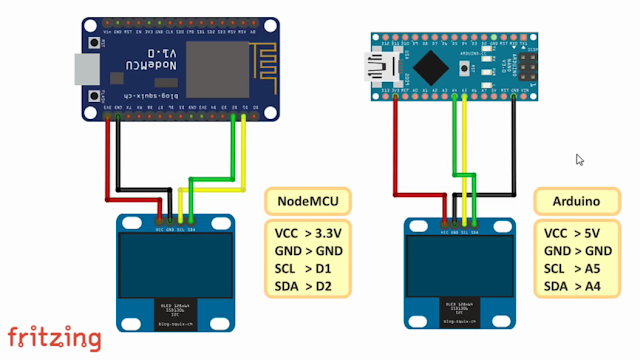

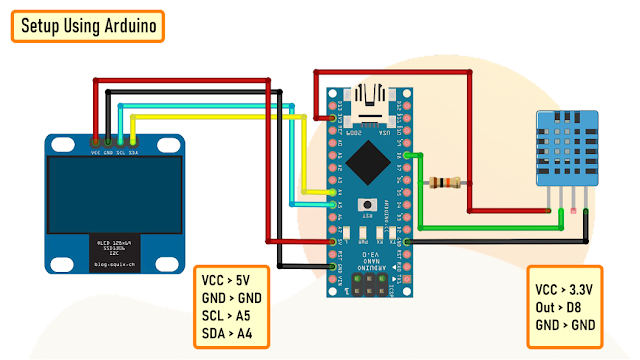

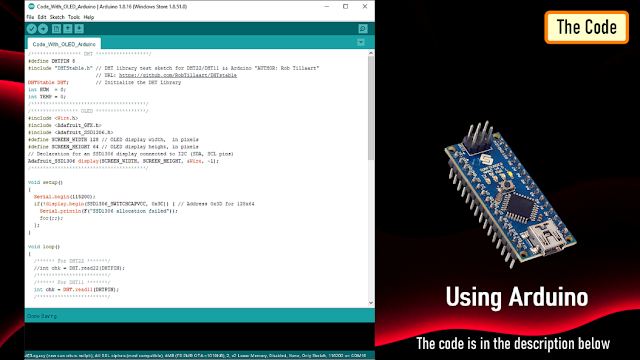

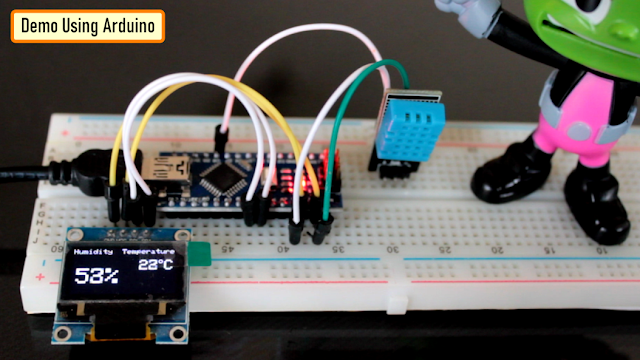

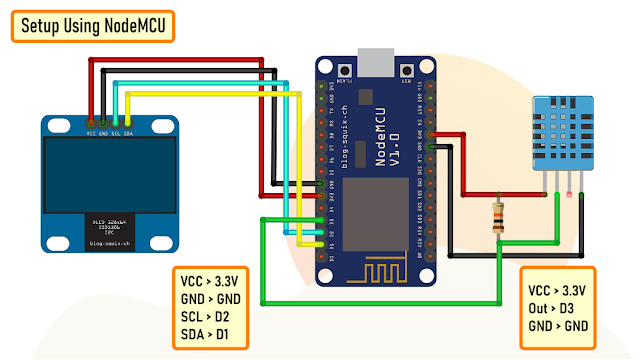

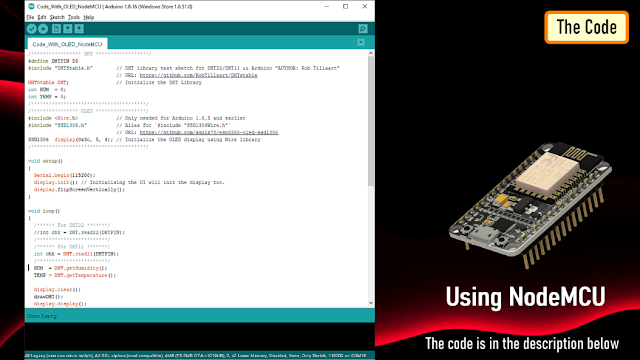

The setup using either Arduino or NodeMCU is very simple.We just need to connect the OLED to the I2C Pins and the Temperature and Humidity sensor to any one of the Digital pins.In this setup I have connected the OLED to A5 and A4 and the Sensor to D8.Now, lets look at the code. Lets start by including the DHT and OLED libraries.Then, in the setup section we initialize the display and then in the loop section we loop through every 2 seconds and read the sensor and display the result on the OLED display.Setup Using NodeMCU

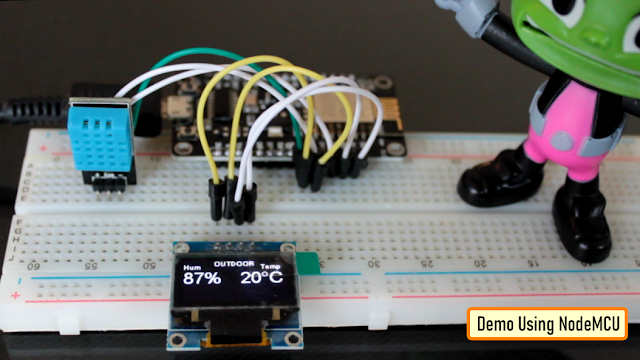

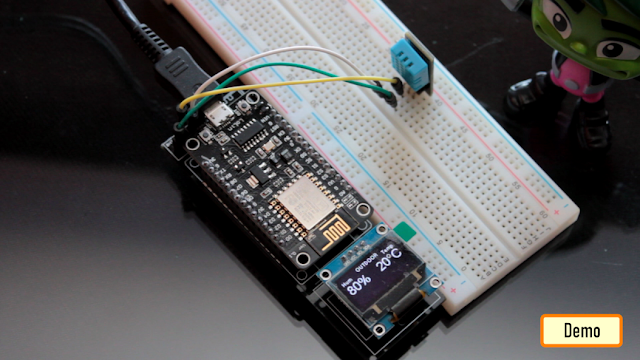

Same as the previous setup, the OLED display connects to the NodeMCU using D2 and D1 pins and the Sensor connects to the D3 pin.The code starts by including the DHT and OLED libraries.Then, in the setup section we initialize the display and then in the loop section we loop through every 2 seconds and read the sensor and display the result on the OLED display.So, this is how the actual setup looks like.The Board

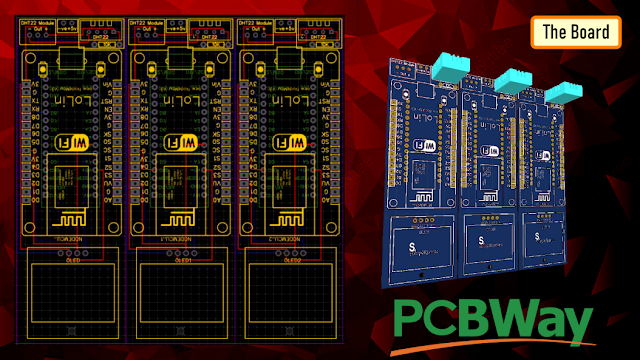

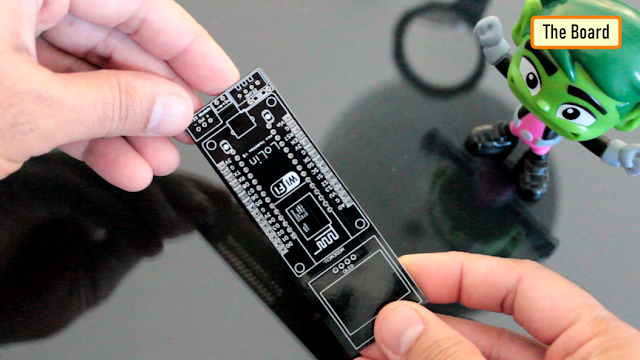

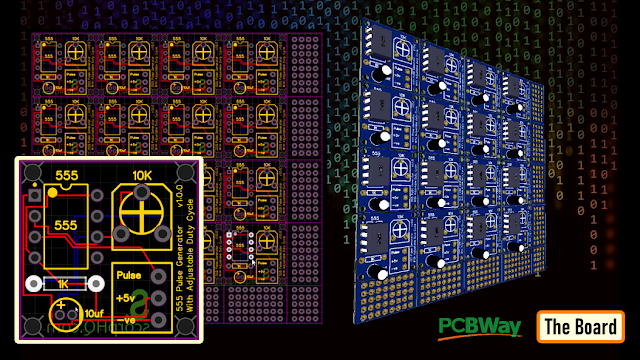

So, this is how my board looks like in 2d and 3d.There are 3 breakout boards in this 100cm x 100cm assembly. Each board can be used with either Arduino or NodeMCU and DHT11 or DHT22 sensor or sensor module.The Board can be used with either NodeMCU or Arduino Nano.Temperature and humidity readings can be collected using either a DHT11 or DHT22 Module or by using one of these sensors with a 10K resistor.The bottom section of the board is for the OLED display. The attached gerber is bit different from what you see on screen. I made some modifications in the final version and moved the sensors a bit far from the microcontrollers.Soldering

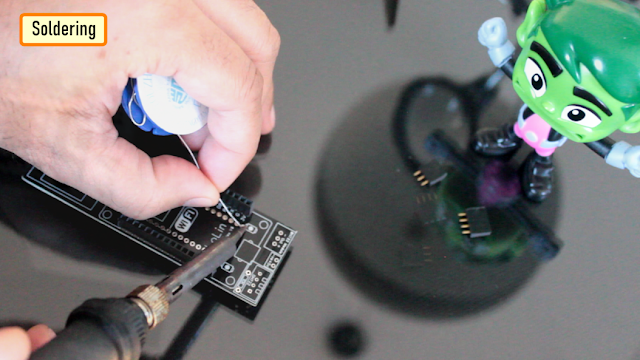

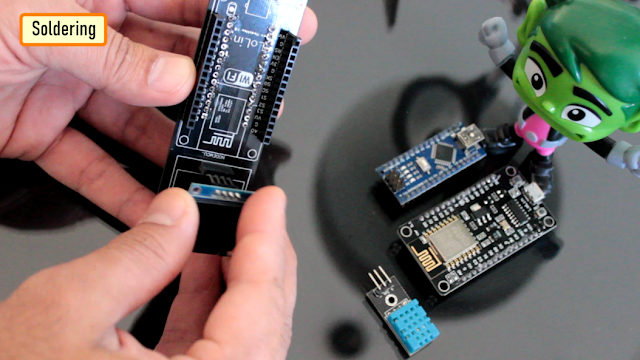

Since I care a lot about my Sensors and Microcontrollers I am not soldering them directly to the board. Instead I am soldering, female pin headers to the board which will house all the sensors and microcontrollers.Just for the sake of this video I am soldering female pin headers on both sides for Arduino and NodeMCU. However, In your setup you will need either Arduino or NodeMCU.Final Demo

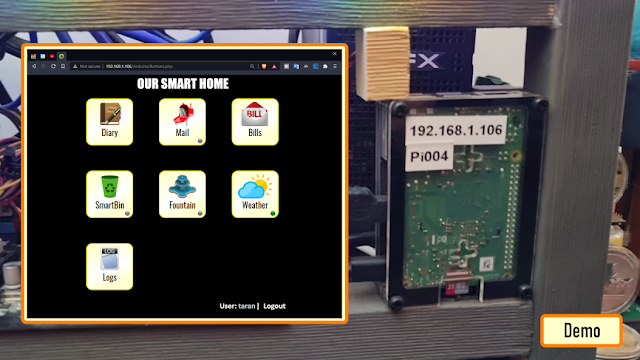

Lets first test this with an Arduino.Now, lets test this setup using a NodeMCU board.Looks perfect, I am going to use this board in my next project where I will be sending Temperature and Humidity readings to my Raspberry Pi based home server where I will be storing it in a MySQL database, so stay tuned....Thanks

Thanks again for checking my post. I hope it helps you.If you want to support me subscribe to my YouTube Channel: https://www.youtube.com/user/tarantula3Blog Posts:1. DHT11 & DHT22: https://diyfactory007.blogspot.com/2021/09/temperature-and-humidity-monitor-using.html2. OLED Tutorial: https://diyfactory007.blogspot.com/2018/07/oled-i2c-display-arduinonodemcu-tutorial.htmlVideo references:1. DHT11 & DHT22: https://youtu.be/w5tBtHsl7b42. OLED Tutorial: https://www.youtube.com/watch?v=_e_0HJY0uIoCode:Code_With_OLED_Arduino : https://drive.google.com/file/d/1EEdhPuUiy8xWSD_s41iYAccTz8w-QF9C/view?usp=sharingCode_With_OLED_NodeMCU : https://drive.google.com/file/d/1WFtdyu90gAqxhJq-Pur7w8fvXuuM85lt/view?usp=sharingCode_With_PHP_NodeMCU : https://drive.google.com/file/d/1bT08x-h39NS1LdkCCH2F3ySG3hrht9U4/view?usp=sharingCode_With_PHP_OLED_NodeMCU: https://drive.google.com/file/d/1ji5TEvLbhe3GJiDgQRowDws5PdZZXqf9/view?usp=sharingLibraries:"DHTStable.h" : https://github.com/RobTillaart/DHTstable"SSD1306.h" : https://github.com/squix78/esp8266-oled-ssd1306Adafruit display library: https://github.com/adafruit/Adafruit_SSD1306Adafruit GFX library: https://github.com/adafruit/Adafruit-GFX-LibrarySupport My Work:BTC: 1M1PdxVxSTPLoMK91XnvEPksVuAa4J4dDpLTC: MQFkVkWimYngMwp5SMuSbMP4ADStjysstmDOGE: DDe7Fws24zf7acZevoT8uERnmisiHwR5stETH: 0x939aa4e13ecb4b46663c8017986abc0d204cde60BAT: 0x939aa4e13ecb4b46663c8017986abc0d204cde60LBC: bZ8ANEJFsd2MNFfpoxBhtFNPboh7PmD7M2Thanks, ca again in my next tutorial. -

The 555 timer IC is an integrated circuit that is used in a variety of timer circuits, pulse generators and oscillator applications. The heart of the module is the 555 timer IC that is wired as an astable multivibrator, generating pulses from about 4Hz to 1.3Khz.

This circuit can be used in any project, that requires positive pulses.

To demonstrate the operation, a LED is used at the output of the IC to show the visual indication of the output pulses.

The output frequency of pulses can be adjusted using a potentiometer. The circuit can be operated from any voltage between 5 to 15 volt DC.

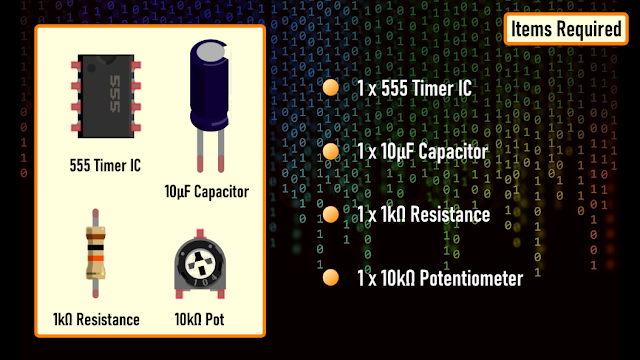

Items Required

For this project we need:

- 1 x 555 Timer IC

- 1 x 10µF Capacitor

- 1 x 1kΩ Resistance and a

- 1 x 10kΩ Potentiometer

Circuit Diagram

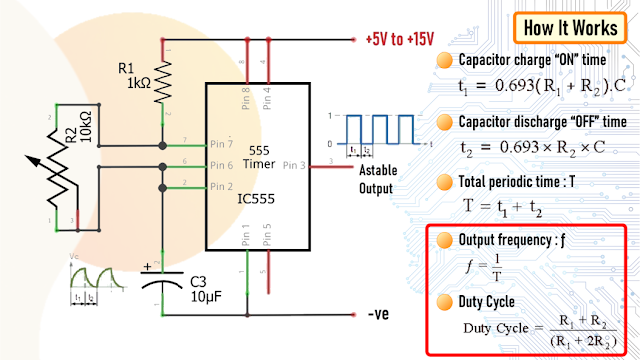

The circuit is very simple.

By connecting pin 2 and 6 we put the 555 timer in astable mode. Astable mode causes the 555 timer to re-trigger itself, producing a stream of pulses [PWM Signals] as long as its hooked up to a power supply.

Pin number 3 is the output pin. By changing the values of R1, R2, and C3 we can change the frequency of output pulses generated at pin number 3.

How It Works

The working voltage of the circuit is between 5V~15V DC.

As previously discussed 555 timer generates PWM signals when set up in an astable mode by connecting the pin 2 and 6 together.

During each cycle capacitor C3 charges up through both R1 and R2 resistors but discharges itself only through resistor R2 as the other side of R2 is connected to the discharge terminal pin 7.

Changing the values of R1, R2, and C3 will change the frequency of output pulses, or different duty cycle of the square wave coming out of pin 3.

By changing the value of R2 we can change the duration of the OFF cycle.

In this setup the ON time depends on the resistor R1, the left side of the pot and the capacitor C3, while the OFF time depends on the capacitor C3 and the right side of the pot.

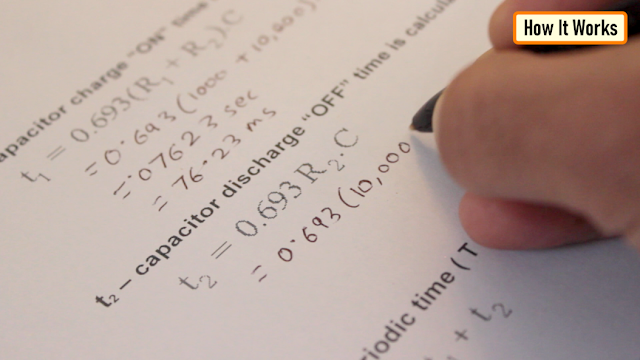

Now, lets calculate the output frequency and the duty cycle of the output waveform.

In my setup I have resistance R1 = 1kΩ, R2 = 10kΩ and capacitor C = 10uF

There are many online calculators to calculate this online. I will provide a link to one of the astable calculators in the description below: https://ohmslawcalculator.com/555-astable-calculator

Lets first calculate the value of t1 or the 'capacitor charge “ON” time which is 0.693(R1 + R2 ) * C3. Putting the values together we get 76.23 milliseconds.

Now, for capacitor discharge “OFF” time or t2 we need to multiply 0.693 to R2 and C3, which then gives us a value of 69.3 milliseconds.

Next, the total periodic time T is equal to t1 + t2 which comes out to be 145.53 milliseconds.

The output frequency, ƒ is therefore comes out to be to 6.871Hz.

Which gives a duty cycle value of 52.38%

If you want to have more control over the charging and discharging use a higher value for R2 (100K) and lower value for R1 (1K). That way you will have 99% control over the charging and discharging resistance in the circuit.

The maximum output current of this IC is 200mA therefore to drive a higher current load of up to 1A we have to use a transistor like the BD135.

For driving a much higher current than 1A you can use other high current transistors like TIP31, 2N3055, etc. with a good heatsink. TIP122 can only go up to about 1.5 amps without a heatsink, however it can go up to 5 amps with a good heatsink. IRLB8743 FET is good to around 20 amps without a heatsink.

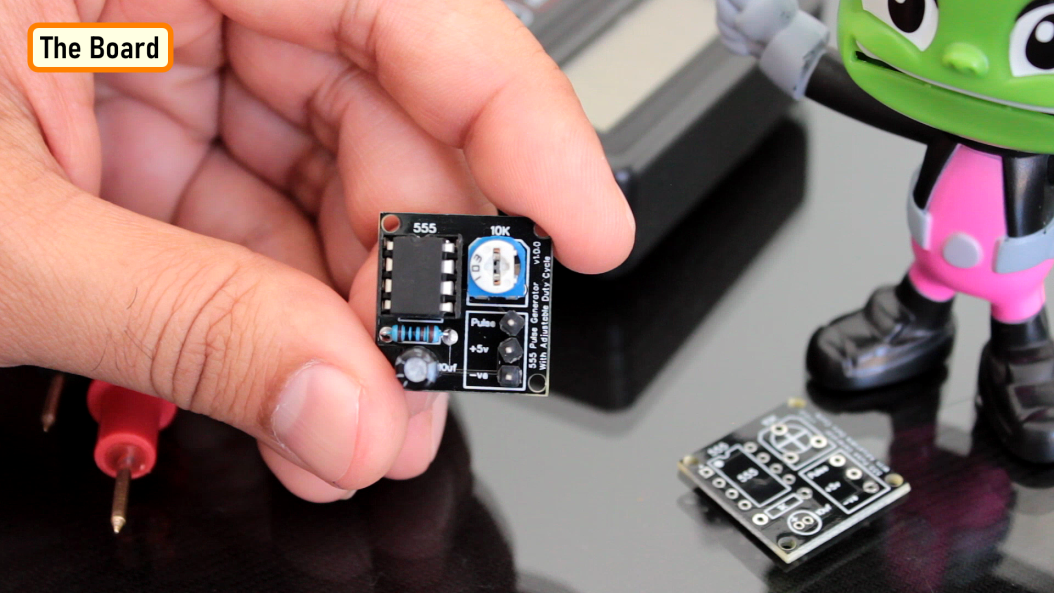

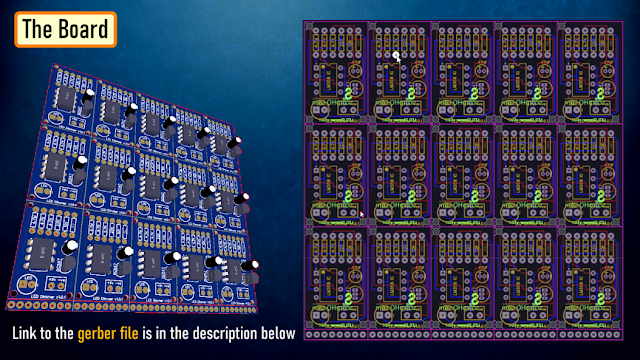

The Board

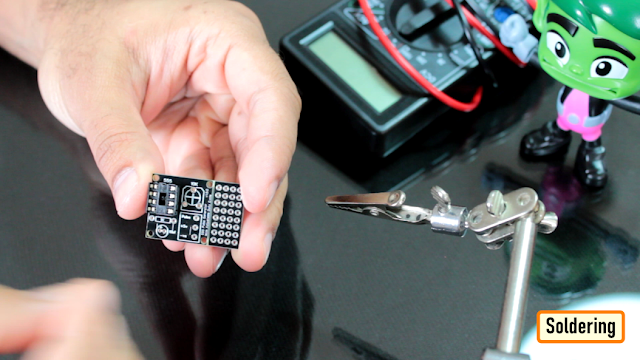

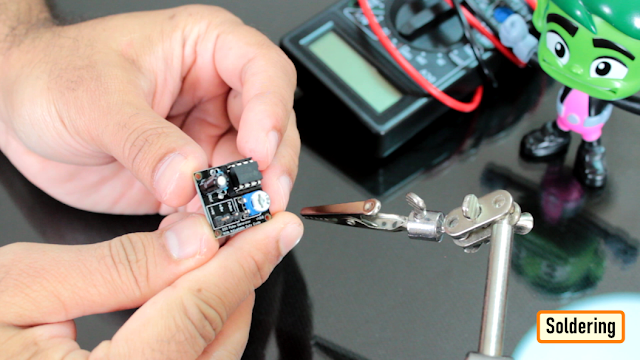

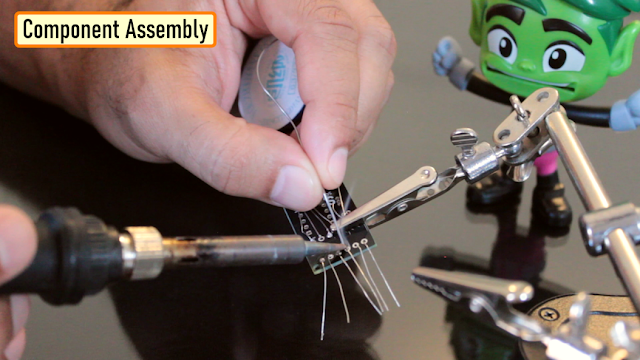

So this is how my board looks like. There are 16 breakout boards in this 100cm x 100cm assembly. You can download the gerber file from the link below and order it from PCBWay.Soldering

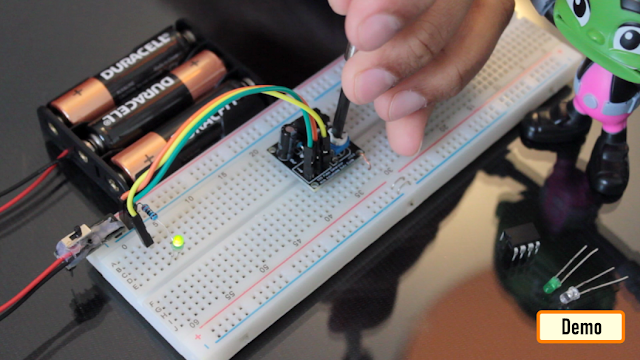

Lets start by soldering the IC Base to the board. Then lets solder the potentiometer to the board. After that lets solder the R1 resistor to the board followed by the C3 capacitor to the circuit board. Once done lets place the 555 timer IC to the IC base.Demo

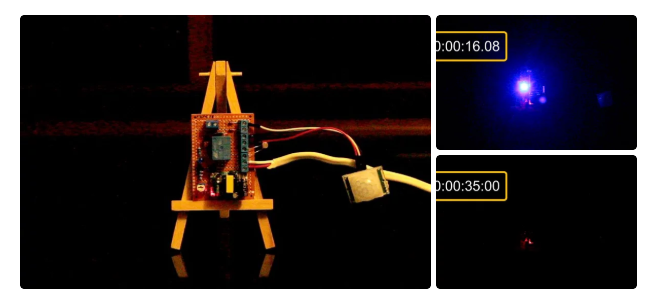

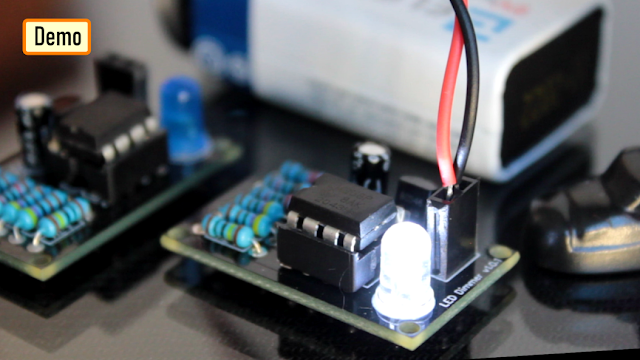

So, this is the final appearance of the board. I am adjusting the output frequency of pulses using the 10K potentiometer.Applications and Uses

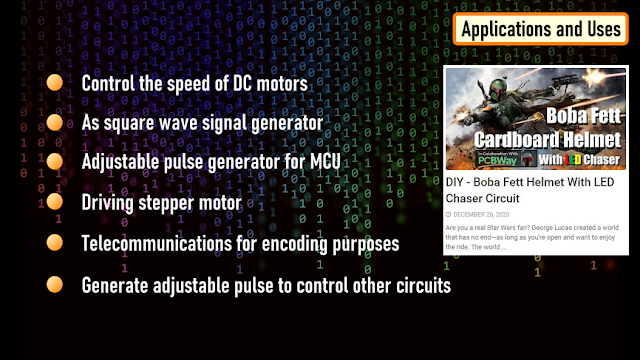

- This circuit can be used to control the speed of DC motors

- As square wave signal generator

- Adjustable pulse generator for MCU

- Driving stepper motor

- Telecommunications for encoding purposes

- Generate adjustable pulse to control other circuits

I have used this in few of my projects like:

- DIY - Boba Fett Helmet With LED Chaser Circuit : https://youtu.be/vtO_GD0SS2s

- LED Chaser Circuits Using IC4017 and Arduino : https://youtu.be/F6V1AjESWbU

- DIY - LAN CABLE TESTER : https://youtu.be/PSK5Aa-byHA

Thanks

Thanks again for checking my post. I hope it helps you.If you want to support me subscribe to my YouTube Channel: https://www.youtube.com/user/tarantula3

Full Blog Post: https://diy-projects4u.blogspot.com/2021/07/555-pulse-generator-module-how-it-works.html

Video: https://youtu.be/bMAnipPOjFo

Related Videos:

1. DIY - Boba Fett Helmet With LED Chaser Circuit : https://youtu.be/vtO_GD0SS2s

2. LED Chaser Circuits Using IC4017 and Arduino : https://youtu.be/F6V1AjESWbU

3. DIY - LAN CABLE TESTER : https://youtu.be/PSK5Aa-byHA

Gerber File: https://drive.google.com/file/d/1YE5vznhAcQx2cmlXouRhn2yxZB3Lb2RK/view?usp=sharing

Calculator: https://drive.google.com/file/d/17dTw22opXIw8WI4-knUZu4rr6k-6zlxV/view?usp=sharing

Schema: https://drive.google.com/file/d/1K635sLu-J3UQzEibjANlfm8ywCgy4tJ0/view?usp=sharing

Support My Work

- BTC: 1M1PdxVxSTPLoMK91XnvEPksVuAa4J4dDp

- LTC: MQFkVkWimYngMwp5SMuSbMP4ADStjysstm

- DOGE: DDe7Fws24zf7acZevoT8uERnmisiHwR5st

- ETH: 0x939aa4e13ecb4b46663c8017986abc0d204cde60

- BAT: 0x939aa4e13ecb4b46663c8017986abc0d204cde60

- LBC: bZ8ANEJFsd2MNFfpoxBhtFNPboh7PmD7M2

Thanks, ca again in my next tutorial.

-

Whether you prefer to unwind the evening with a good book, play games on your phone, or wanna have some cozy time with your partner, the right bedside lighting can make a lot of difference.

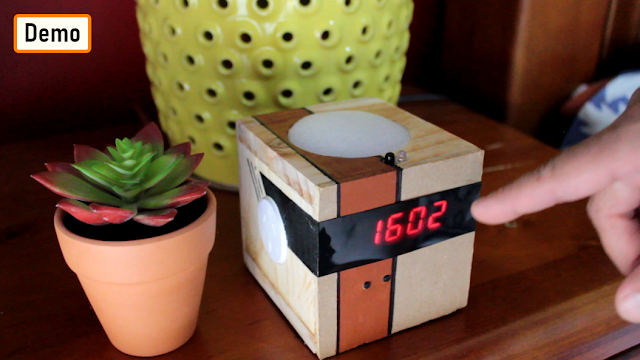

In this project, I am going to make a touchless multipurpose bedside lamp, which will also include a digital clock, two power-ports and a USB charger.

Sponsors

This video is sponsored by PCBWay.

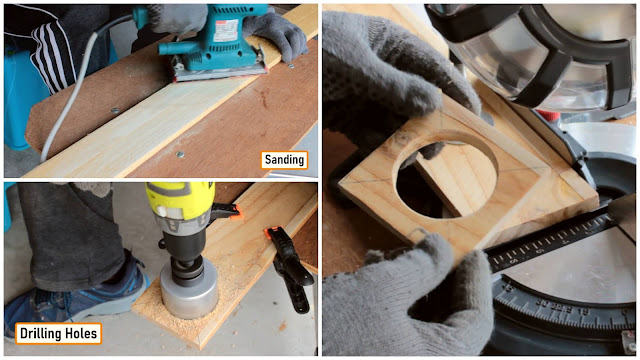

Woodwork

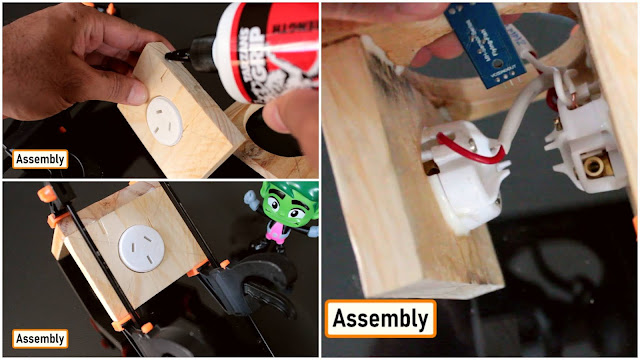

Lets start the project by sanding a pallet planks to give it a nice and smooth texture.Then, lets drill 3 holes for the top and the 2 sides of the night lamp.After drilling the holes lets extract the sides from the plank using a chop-saw or a hand-saw.My pallet plank is 9.5cm wide and the lamp will be square in shape. So, rest of the measurements are based on that.

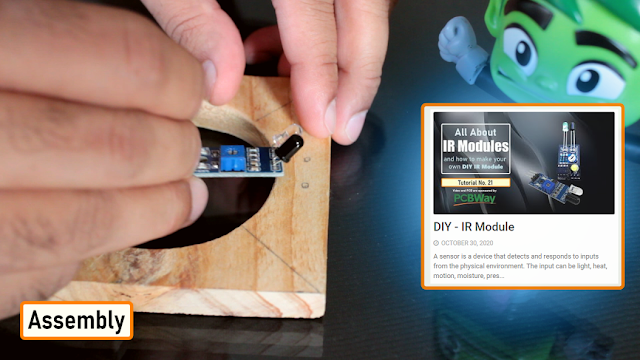

Assembly

Once all the sides were ready its was time for me to join them all together.

First of all I am getting the 2 x sides ready by gluing the power sockets into the holes.

Next, I drilled 2x more holes for the IR sensor.

If you want to know more about IR sensors please check out my "Tutorial No 21 : DIY - IR Module : https://www.youtube.com/watch?v=_M8FQIPi1qk"

Next, one by one using wood glue I am joining the 2 x sides to the top of the lamp. At first I thought of using nails to join the sides, but soon I realized that by all means it was a very bad idea. Before gluing the 2nd side I connected the two power ports together using a copper wire.

Alright now, Lets look at the electronics bit.

Electronics

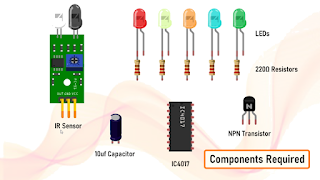

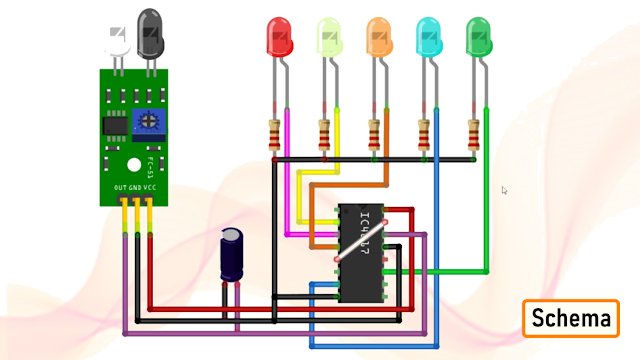

For the electronics bit we need:

- 1 x IR Sensor

- 5 x Colored LEDs

- 5 x 220Ω Resistors

- 1 x 10uf Capacitor

- 5 x 2N2222 NPN Transistor

- 1 x 4017 IC

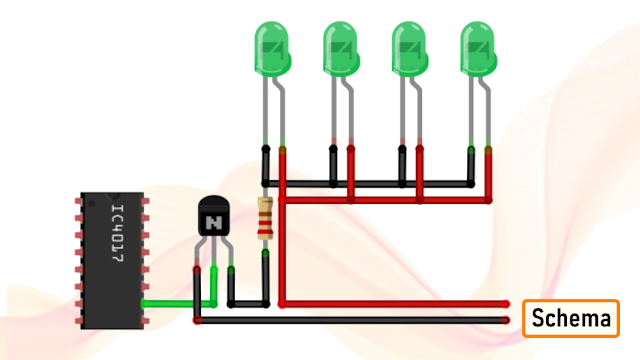

4017 is a Decade Counter IC, it can count from 0 to 10. When a clock signal is received on Pin-14 the output turns to high one by one in a sequence.

The signal from the IR-Sensor clocks the 4017 decade counter. Whenever a pulse is received at the clock input of IC, the counter increments the count and activates the corresponding output PIN. In our project we only need to count upto 5 so the 6th output from Pin-5 will be given to the Reset Pin-15. Sending a high signal to Pin-15 will reset the counter and it will skip counting the rest of the numbers and will start from the beginning. A capacitor is added to filter out too frequent detection of object by the IR sensor.

To add a cluster of LEDs to the circuit, we just need to feed the output from the IC to a transistor and the cluster can then be connect to the transistor. Similar to this setup.

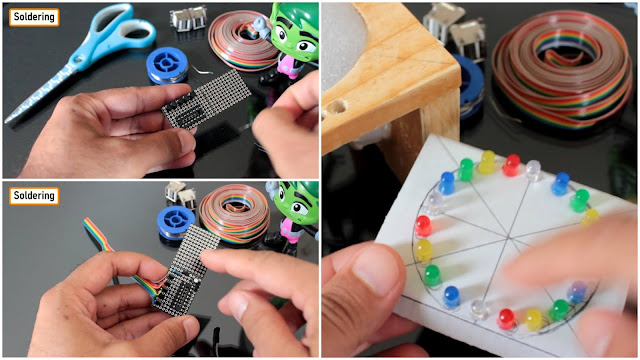

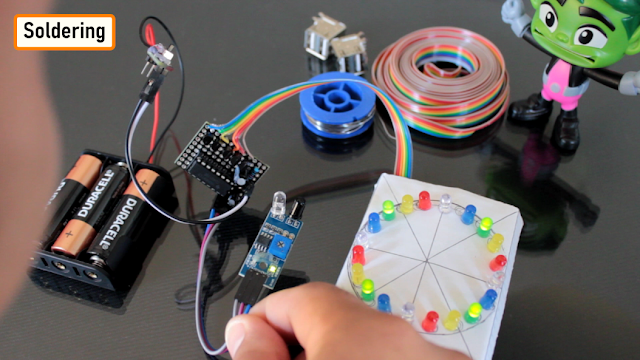

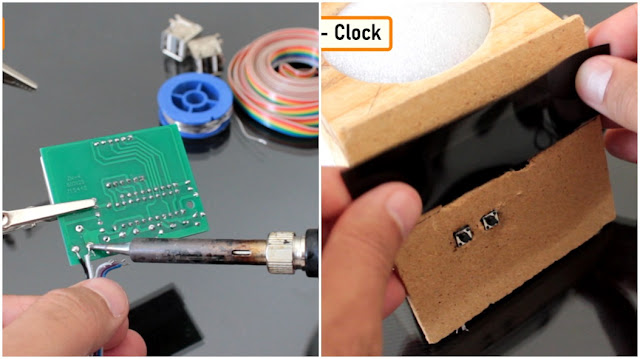

Top - Soldering Components

So, now lets start putting the components together. Lets solder the IC base followed by the 5 x NPN Transistors. Then, lets solder the 220Ω Resistors and the 10uf Capacitor to the board. I also added few pin headers to the board, 3 for the IR Sensor and 2 for the 5v power supply. The transistors are connected to the ribbon of wire which then connects to the cluster of LEDs that will slide under the top section.

Before putting the circuit into production lets do a quick test. Bang, nailed it..

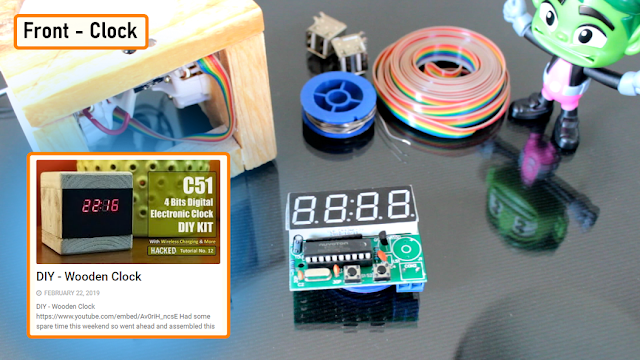

Front - Clock

For the front bit I am using a 4-Bits DIY Electronic Digital Clock which I bought from AliExpress for just AU$2.40.

If you want to know more about this clock please checkout my "Tutorial No 12 : DIY - Wooden Clock : https://youtu.be/Av0riH_ncsE "

I moved the 2 push button switches from the board to the front panel of this lamp. My initial plan was to cover this entire setup with timber veneer sheet. However, I could not find one that was thin enough to not completely hide the 7-segment display. So, I ended up putting a black plastic film over the 7-segment display.

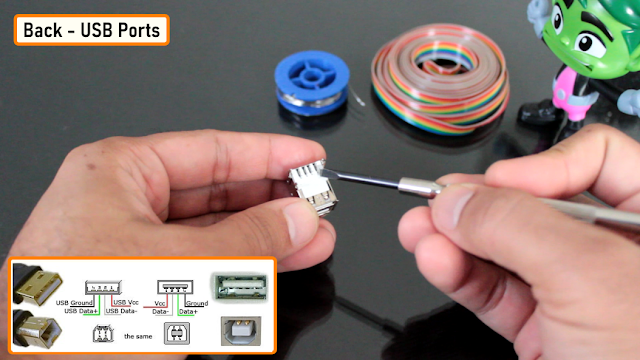

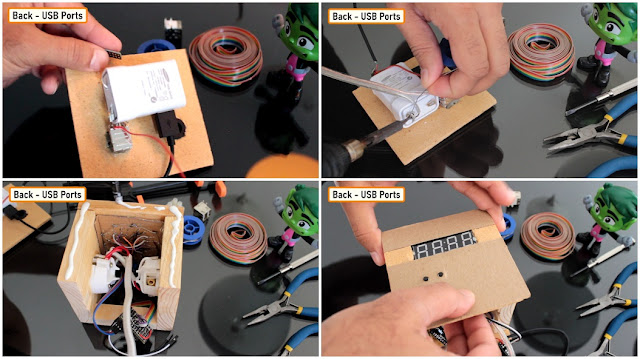

Back - USB Port

The back bit will host the USB ports and will also have a hole for the AC power chord.

Lets have a look at this USB port. When I am holding a USB port upside down the left most pin is the -ve pin and the rightmost is the +ve pin. The middle two are the data pins which I am not going to use in this project.

I used a Rubber Grommet to safeguard the power chord's hole.

To power the electronics bit I am using a USB charger. I glued the USB charger to the back bit of the lamp. I soldered the power supply cable to the USB charger and then hot-glued to protect it from touching the other electrical and electronic components.

Then I glued the back and the front plates of the lamp to the wooden frame. I soldered all the electronics components to the USB charger.

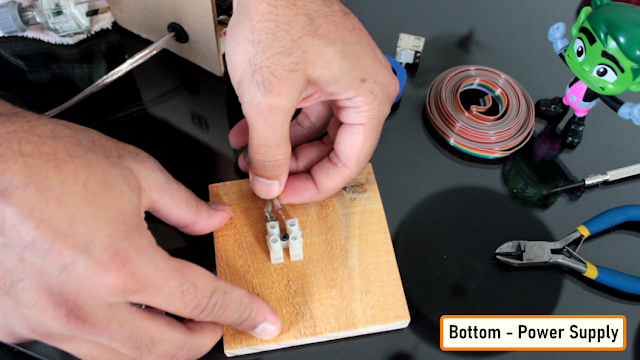

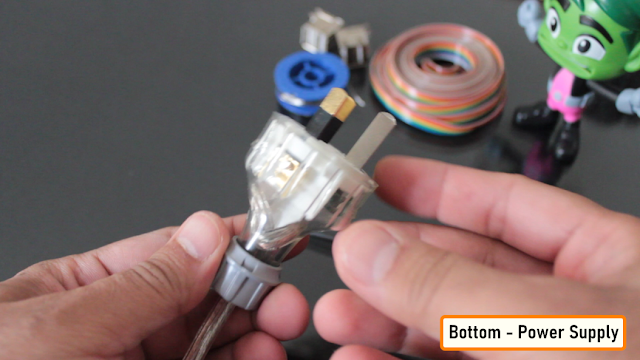

Bottom - Power Supply

The bottom bit will hold the AC Power Cables. Since I don't want the AC cables to float around and cause short circuits inside the lamp, I screwed them to the base of the lamp.Painting

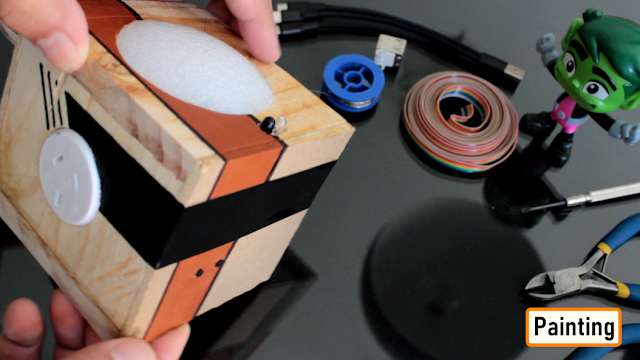

I painted the lamp a little bit to give it a modern look. Next, I superglued the black plastic film and painted its edges to match the whole setup.

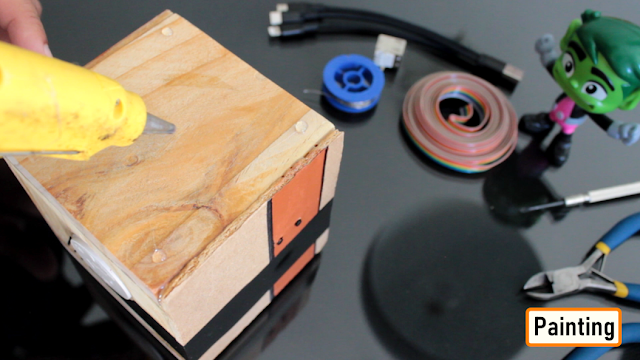

To finalize the setup, I added a bit of hot-glue to the bottom of the lamp. These glue drops will stop this lamp from scratching my bedside table top.

Demo

This project was an attempt to make things touchless. Hope you guys enjoyed it.

Thanks

Thanks again for checking my post. I hope it helps you.

If you want to support me subscribe to my YouTube Channel: https://www.youtube.com/user/tarantula3

Full Blog Post: https://diyfactory007.blogspot.com/2021/05/touchless-multifunctional-bedside-lamp.html

Video: https://youtu.be/r1r9jIgtcEk

Links:

Tutorial No 21 : DIY - IR Module :: https://www.youtube.com/watch?v=_M8FQIPi1qk

Tutorial No 12 : DIY - Wooden Clock :: https://youtu.be/Av0riH_ncsE

Music: Nocturne - Asher Fulero

Music: Simple - Patrick Patrikios

Support Me:

- BTC: 1M1PdxVxSTPLoMK91XnvEPksVuAa4J4dDp

- LTC: MQFkVkWimYngMwp5SMuSbMP4ADStjysstm

- DOGE: DDe7Fws24zf7acZevoT8uERnmisiHwR5st

- ETH: 0x939aa4e13ecb4b46663c8017986abc0d204cde60

- BAT: 0x939aa4e13ecb4b46663c8017986abc0d204cde60

- LBC: bZ8ANEJFsd2MNFfpoxBhtFNPboh7PmD7M2

Thanks, ca again in my next tutorial.

-

Have an awesome project in mind using some LEDs. In that project I will be using some LED Fading Effect and few LED Chaser Circuits. But before jumping onto that, I thought I should create a short tutorial and show you guys how to fade a LED with or without an Arduino automatically or manually using a potentiometer.

Video: https://youtu.be/IIUsdICycOwSponsors

This video is sponsored by PCBWay.PCBway: only $5 for 10 pcbs from https://www.pcbway.com/?from=CZcouplePCBWay specialize in manufacturing of very high quality, low-volume, colored PCBs at a very budgetary price. In addition to the standard PCBs, you can also order Advanced PCBs, Aluminum PCBs, FPC/Rigid-flex PCBs. They also provide PCB assembly and other related service which can meet your needs to the greatest extent.The ordering process from PCBWay is very easy. Once I had my design ready, I just had to upload the gerber file to the PCBWay's website and select the type, color and any other customization that I want and then just send it for fabrication.For my project, I choose the black color. PCBWay ships from china to most of the countries of the world within 3 to 7 business days. Talking about the quality, its absolutely mind-blowing.

This video is sponsored by PCBWay.PCBway: only $5 for 10 pcbs from https://www.pcbway.com/?from=CZcouplePCBWay specialize in manufacturing of very high quality, low-volume, colored PCBs at a very budgetary price. In addition to the standard PCBs, you can also order Advanced PCBs, Aluminum PCBs, FPC/Rigid-flex PCBs. They also provide PCB assembly and other related service which can meet your needs to the greatest extent.The ordering process from PCBWay is very easy. Once I had my design ready, I just had to upload the gerber file to the PCBWay's website and select the type, color and any other customization that I want and then just send it for fabrication.For my project, I choose the black color. PCBWay ships from china to most of the countries of the world within 3 to 7 business days. Talking about the quality, its absolutely mind-blowing.Without Arduino

Lets first create the fader circuit without an Arduino. The base of this circuit is an operational amplifier IC named LM358. In this circuit, initially, the LED slowly glows with increasing brightness & after reaching its maximum brightness, the LED slowly dims its brightness and the process continues.Automatic Fading

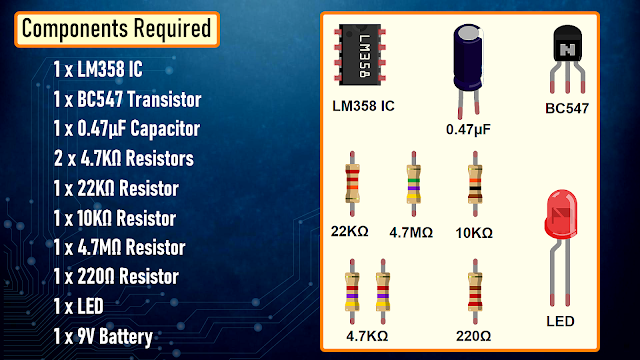

Components Required

For the Non-Arduino bit we need:- 1 x LM358 IC

- 1 x BC547 Transistor

- 1 x 0.47µF Capacitor

- 2 x 4.7KΩ Resistors

- 1 x 22KΩ Resistor

- 1 x 10KΩ Resistor

- 1 x 4.7MΩ Resistor

- 1 x 220Ω Resistor

- 1 x LED

- and a 9V Battery

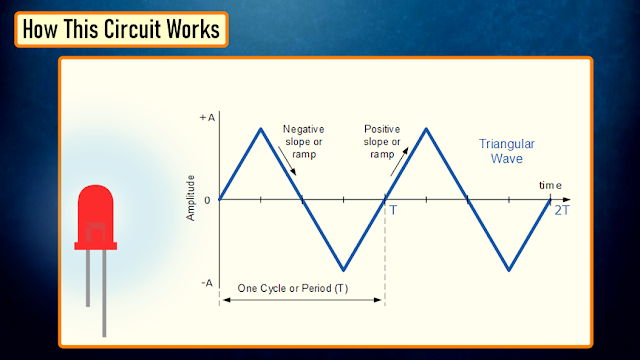

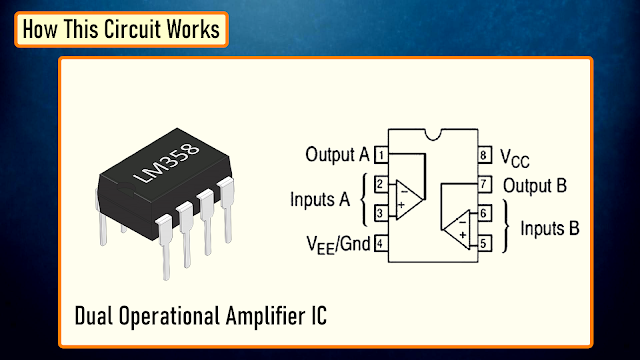

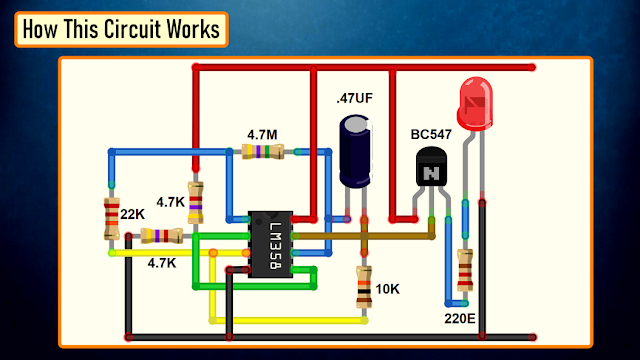

How This Circuit Works

To get the fading effect we need to generate a series of triangular waves.Because of the triangular waves, the LED starts glowing slowly and then slowly dims off and the cycle continues.This setup is done using the LM358 IC. LM358 is a dual operational amplifier (Op-Amp) IC, integrated with two op-amps powered by a common power supply. Pins 1, 2, and 3 are one op-amp channel, and pins 5, 6, and 7 are the 2nd op-amp channel.As the capacitor charges and discharges the state of the PIN 3 switches from high to low and based on that the PIN 2 of the op-amp obtains the desire output. If you want to know more about this IC, please check out my "Tutorial No 21 : DIY - IR Module" : https://youtu.be/_M8FQIPi1qk.So, basically the op-amp here is used for voltage level detection. In this circuit, we are applying a voltage on positive pin (PIN-3) and the voltage to be detected is applied at negative pin (PIN-2).The transistor acts as a signal amplifier. You will need this if you are attaching a cluster of LEDs however for just 1 LED you can simply remove it.The Board

So, this is how my board looks like in 2D and 3D.There are 15 breakout-boards in this 100cm x 100cm assembly.Component Assembly

Now, lets solder all the components to the board. Lets first solder all the resistances to the board. Then lets solder the transistor followed by the capacitor to the board. After that lets solder the LED and the female pin header. To conclude the setup, lets solder the IC base and then install the IC into it.Demo

So, this is how it looks like.Good thing about LEDs is that they can be easily controlled as compared to the traditional light bulbs. Which means you can easily change their intensity based on your need. Just by making a slight modification to this circuit you can change the brightness of a LED Lamp when someone walks in or out of a room.Manual Fading Using PWM

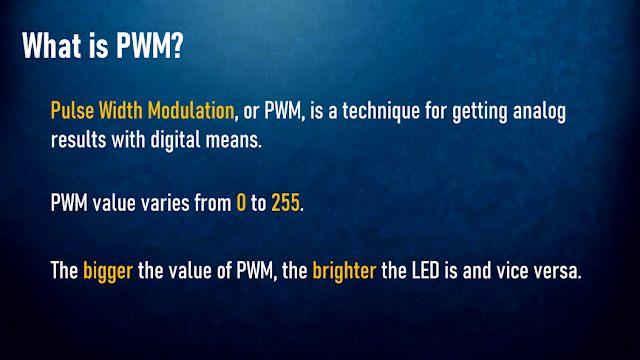

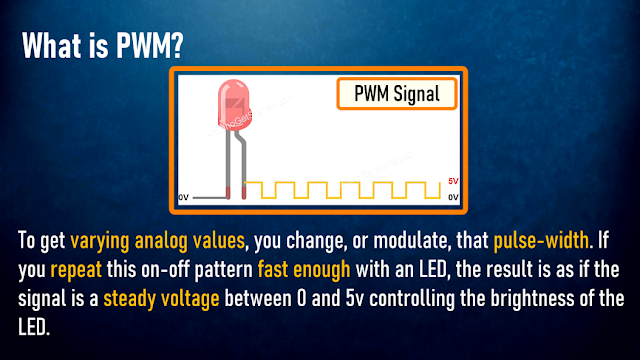

Now, if you want to get the same dimming effect but want to manually control the intensity, you will have to find a way to modulate the pulse sent to the LED or group of LEDs using a potentiometer. I am going to do this by generating PWM Signals.What is PWM?

Pulse Width Modulation, or PWM, is a technique for getting analog results with digital means.PWM value varies from 0 to 255. The bigger the value of PWM, the brighter the LED is and vice versa.- If PWM = 0, it is same as GND, so the LED will be OFF- If PWM = 255, it is same as VCC, so the LED will be fully ONTo get varying analog values, you change, or modulate, that pulse-width. If you repeat this on-off pattern fast enough with an LED, the result is as if the signal is a steady voltage between 0 and 5v controlling the brightness of the LED.In this setup, we are going to use the 555 Timer IC in Astable mode (A free-running multivibrator that has NO stable states but switches continuously between two states this action produces a train of square wave pulses at a fixed known frequency) to generate the PWM Signals. 555 Timer IC will vary the voltage delivered to the LEDs to achieve the Dimming effect of the LED.Components Required

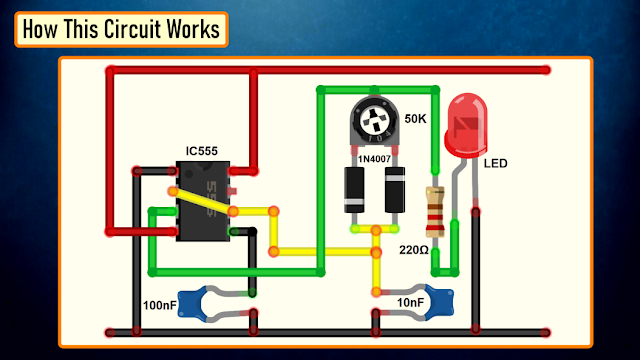

For this setup we need:- 1 x 555 Timer IC

- 1 x LED

- 1 x 220Ω Resistor

- 2 x 1N4007 Diodes

- 1 x 50KΩ Potentiometer

- 1 x 10nF Capacitor

- 1 x 100nF Capacitor

- and a 5V Battery

How This Circuit Works

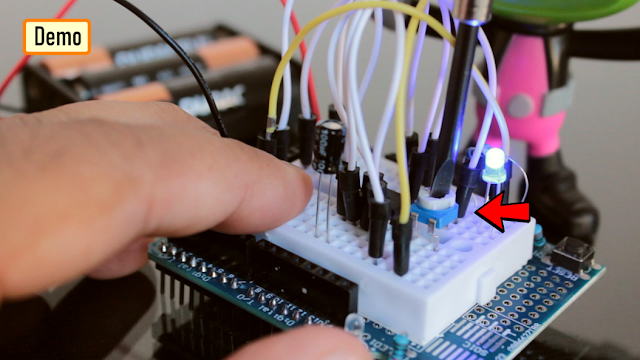

Based on the charging and discharging timings of the Capacitor, a PWM Signal is generated at PIN 3 (OUT PIN) of the 555 Timer IC. The output is then sent to the LED to produce the dimming effect.Demo

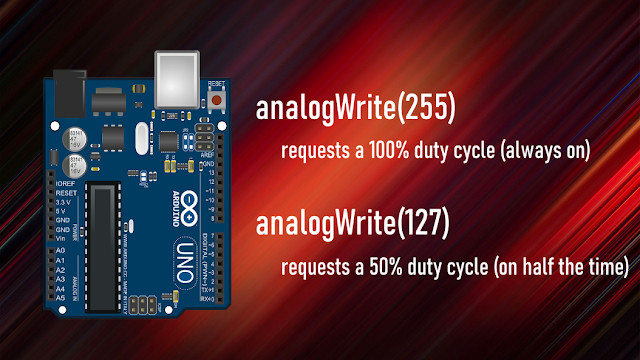

So, this is how it looks like.By rotating the knob of the 10K Pot we can adjust the brightness of the connected LED.With Arduino

Now, lets repeat these setups using an Arduino. The beauty of Arduino is that it has 6 digital pins that can be used as PWM outputs (3, 5, 6, 9, 10, and 11). PWM signals are sent using the analogWrite() function by passing a value between 0 - 255.- analogWrite(255) requests a 100% duty cycle (always on),- and analogWrite(127) is a 50% duty cycle (on half the time), and so on.Components Required

For this setup we need:- Arduino UNO/Nano whatever is handy

- 1 x Breadboard

- 1 x LED

- 1 x 220Ω Resistor

- 1 x 10KΩ Potentiometer

Automatic Fading

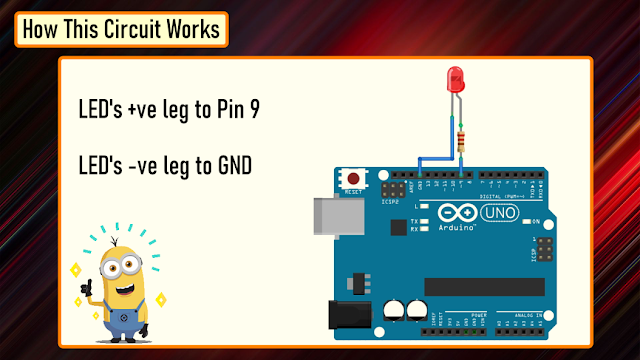

Connect the positive leg of your LED to the digital output PIN9 of your Arduino through a 220Ω resistor. Connect the negative leg directly to the GND. That it, that's how simple it is.The Code

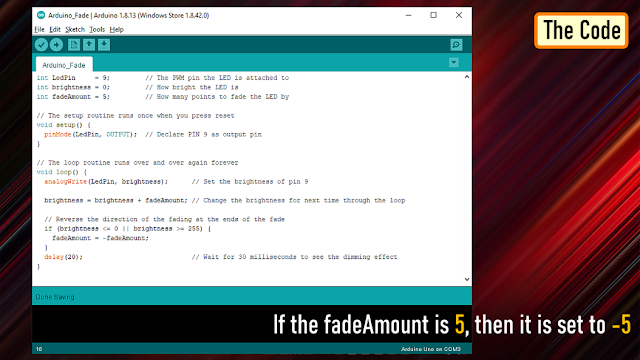

After declaring PIN 9 as LedPin, and setting up the pinMode in the setup() section, we are going to loop through and dim the LED in the loop section.By gradually increasing the PWM value from 0 to 255, and then back to 0 we can get the fading effect. In this sketch, the PWM value is set using a variable called 'brightness'. Each time in the loop, it increases by the value of the variable 'fadeAmount'.If brightness is at either extreme of its value (either 0 or 255), then 'fadeAmount' is changed to its negative. So, if the fadeAmount is 5, then it is set to -5 and if it is -5, then it is set to 5. The next time through the loop, this change causes brightness to change its direction. A delay is added to control the speed of the fading effect.Demo

So, this is how it looks like.Manual Fading

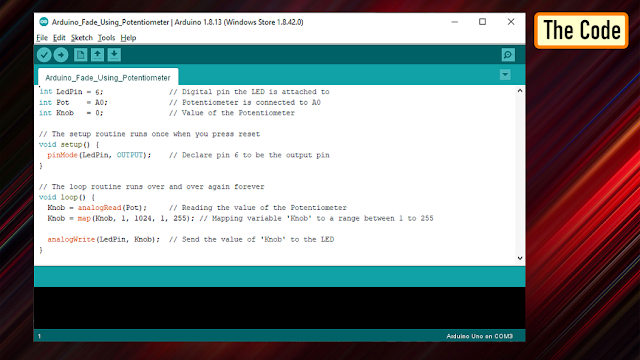

Connect the positive leg of your LED to the digital output PIN6 of your Arduino through a 220Ω resistor. Connect the negative leg directly to the GND. Connect the left (or right) pin of the 50KΩ PoT to VCC and then connect the right (or left) pin of the PoT to the GND. Now, connect the 'data' pin of your potentiometer to the Analog PIN 'A0' of the Arduino.In this circuit, the potentiometer is working as a voltage divider. One of the outer pins is connected to the GND, the other to Vcc and the middle pin is the voltage output. The wiper position in this setup determines the output voltage.Now, lets have a look at the code.The Code

Based on my setup, I set the LedPin as 6 and Potentiometer pin Pot as A0. Another variable 'Knob' is used to read and store the value of the potentiometer.pinMode of the LedPin is set to OUTPUT and we don't need to do anything for the PoT as its default value is already set as input.In the 'loop()' section I am first reading the value of the PoT using the 'analogRead()' function and then mapping its value between 1 to 255. A potentiometer intakes a value between 1 and 1024, but in our setup it has to be between 1 to 255. The 'map()' function divides the value read from the potentiometer into equal intervals of 1/255, which is then sent to the LED using the 'analogWrite()' function.Demo

So, this is how it looks like.Thanks

Thanks again for checking my post. I hope it helps you.If you want to support me subscribe to my YouTube Channel: https://www.youtube.com/user/tarantula3Video: https://youtu.be/IIUsdICycOwGerber File:The Code:1. Automatic Fading : https://drive.google.com/file/d/1hab3sISIlurrPQBat80OLb90RXqQKzLZ/view?usp=sharing2. Manual Fading Using PoT : https://drive.google.com/file/d/1TzXdVO5lVjPNaw_NPSUexIye3WZGJ6cj/view?usp=sharingBTC: 1M1PdxVxSTPLoMK91XnvEPksVuAa4J4dDpLTC: MQFkVkWimYngMwp5SMuSbMP4ADStjysstmDOGE: DDe7Fws24zf7acZevoT8uERnmisiHwR5stETH: 0x939aa4e13ecb4b46663c8017986abc0d204cde60BAT: 0x939aa4e13ecb4b46663c8017986abc0d204cde60LBC: bZ8ANEJFsd2MNFfpoxBhtFNPboh7PmD7M2Thanks, ca again in my next tutorial. -

A Chaser Circuit consists of a clocked IC or other electronic unit like an Arduino that drives an array of LEDs in such a way that individual LEDs (or small groups of LEDs) turn on and off in a predetermined and repeating sequence, thus producing a visually attractive display in which one or more ripples of light seem to repeatedly run through a chain or around a ring of LEDs.In this tutorial I am going to create 3 chaser circuits using Arduino and IC4017 decade counter.

Sponsors

PCBWay specialize in manufacturing of very high quality, low-volume, colored PCBs at a very budgetary price. In addition to the standard PCBs, you can also order Advanced PCBs, Aluminum PCBs, FPC/Rigid-flex PCBs. They also provide PCB assembly and other related service which can meet your needs to the greatest extent.The ordering process from PCBWay is very easy. Once I had my design ready, I just had to upload the gerber file to the PCBWay's website and select the type, color and any other customization that I want and then just send it for fabrication.For my project, I choose the black color. PCBWay ships from china to most of the countries of the world within 3 to 7 business days. Talking about the quality, its absolutely mind-blowing.

PCBWay specialize in manufacturing of very high quality, low-volume, colored PCBs at a very budgetary price. In addition to the standard PCBs, you can also order Advanced PCBs, Aluminum PCBs, FPC/Rigid-flex PCBs. They also provide PCB assembly and other related service which can meet your needs to the greatest extent.The ordering process from PCBWay is very easy. Once I had my design ready, I just had to upload the gerber file to the PCBWay's website and select the type, color and any other customization that I want and then just send it for fabrication.For my project, I choose the black color. PCBWay ships from china to most of the countries of the world within 3 to 7 business days. Talking about the quality, its absolutely mind-blowing.Using IC555 and IC4017

Lets first create the chaser circuit using the IC4017 decade counter and IC555 timer IC.Components Required

- For the Non-Arduino bit we need:

- 2 x 4017 Decade Counter IC

- 1 x 555 Timer IC

- 1 x 10 K Potentiometer

- 1 x 1 Kilo Ohm Resistor

- 1 x 100 Ohm Resistor

- 1 x 100 MFD Capacitor

- 20 x Zener Diodes and

- 10 x Red LEDs

Circuit Diagram

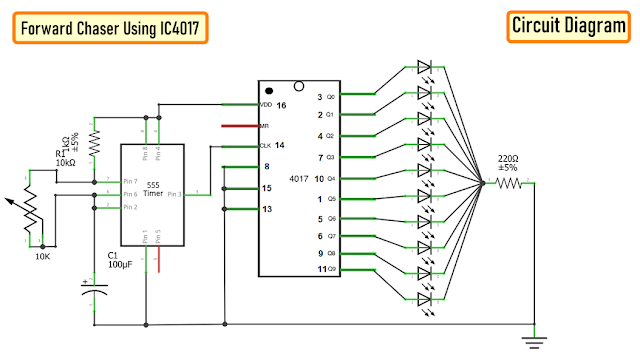

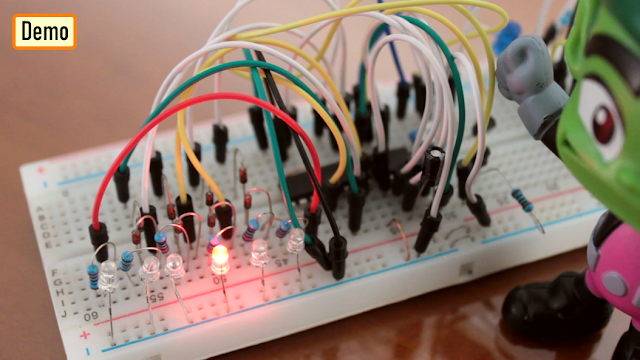

1. Forward Chaser

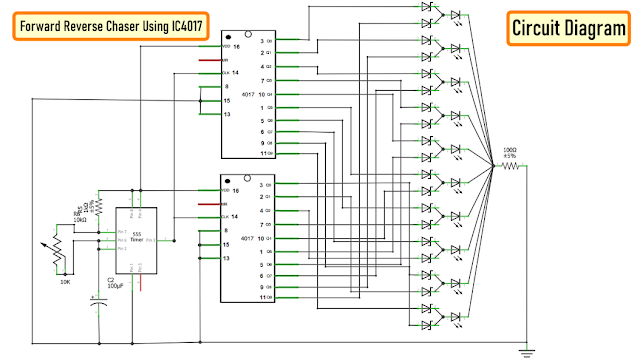

The circuit is very simple.The 555 Timer IC operates as a clock oscillator or clock generator. The output on PIN-3 goes high causing a shift.The signal from the 555 IC clocks the 4017 decade counter. Output of 555 timer IC on PIN-3 is given as an input to 4017 IC through PIN-14. Whenever a pulse is received at the input of IC 4017, the counter increments the count and activates the corresponding output PIN. This IC can count upto 10, so we have attached 10 LEDs to the circuit.By increasing or decreasing the value of resistance of the 10K pot we can adjust the speed of the chaser circuit.Since only one LED will be turned on at a given time, I have attached just one 220ohm current limiting resistor to the cluster of LEDs.Demo: So this is how it looks like.2. Forward Reverse Chaser using 2 x IC4017

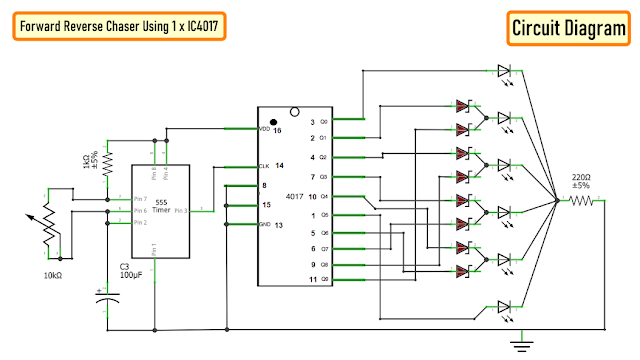

Now, to give the forward and reverse effect we are attaching another 4017 IC to this circuit. If lets say the 1st IC connects from 1 to 10 (left to right) then the second one should connect from 10 to 1 (right to left). However, now we cannot connect the counter ICs directly to the LEDs as we did before. We have to use Diodes to stop the reverse flow of current to the 2nd IC.We have also lowered the value of the current limiting resistor to 100ohms as at a given time 2 LEDs will be on, one running from left and one from the right hand side.Demo: Now lets do a quick test. By lowering the speed I can get the desired forward and reverse effect. By removing one of the 4017 ICs we can get the effect that I demonstrated in the previous example.3. Forward Reverse Chaser using 1 x IC4017

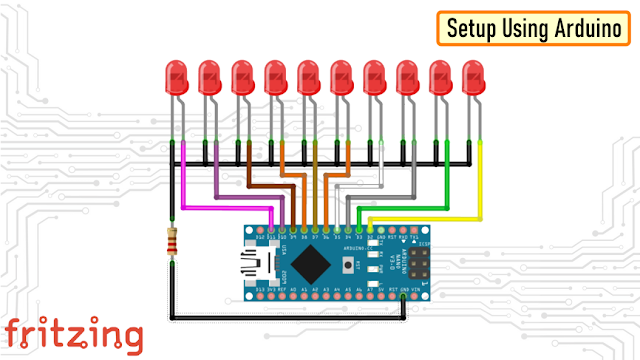

To get a forward reverse effect using one 4017 IC we need to connect 8 diodes to the circuit. The 1st and the 6th LED will be directly connected to the IC4017. The LEDs at the far end will get signals from only one pin however the one in the middle will receive signals from 2 x pins and hence we need diodes to stop the reverse flow of the current.Demo: So this is how it looks like.Using Arduino

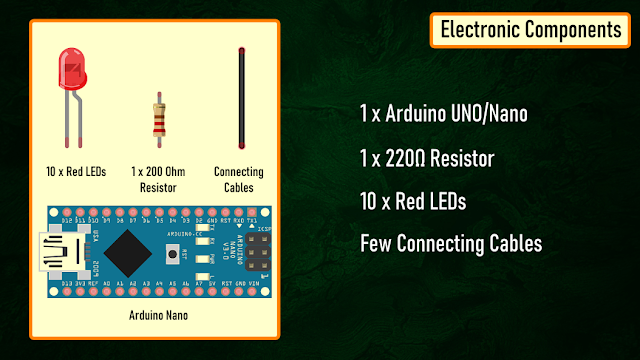

Now, I am going to repeat the same setup using an Arduino.Components Required

- For the Arduino bit we need:

- 1 x Arduino Uno/Nano (whatever is handy)

- 1 x 220 Ohm Resistor

- 10 x Red LEDs

- Few Connecting Cables

The beauty of using an Arduino is that the setup remains the same for all the previously shown circuits, the only thing that changes is the code. So, I am going to use this simple setup for the rest of the tutorial.Circuit Diagram

1. Forward Chaser

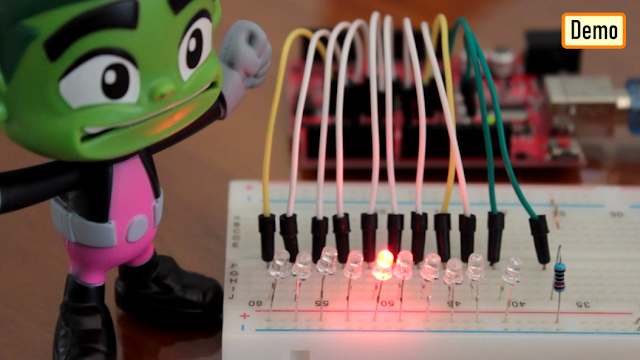

Code: The code for the forward chaser is very simple. Start by defining the constants and the global variables that will be used throughout the code.Then in the setup section define the pin modes.Now, in the loop section we are going to start by turning off all the LEDs followed by turning one LED on at a time. A counter is used to tell the loop which LED to turn on in the next cycle. Once the value of the counter reaches 10 (the maximum number of LEDs) the counter resets to 1 and the 1st LED lights up and the cycle continues.Demo: So this is how it looks like.2. Forward Reverse Chaser

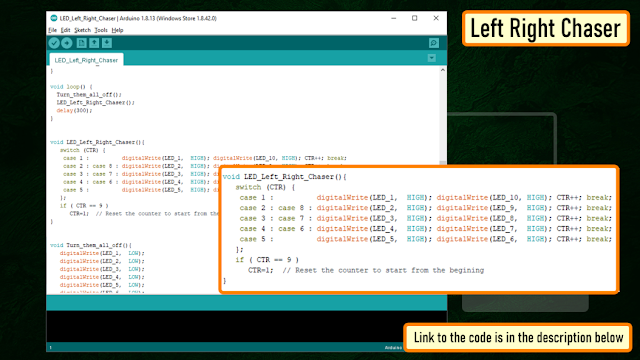

Code: The code is same as the previous setup. The only thing that changes is the function that deals with the LEDs. In this setup we cycle through LED 1 to LED 10 and then reverse from LED 9 to LED 1. The counter resets when the max count is reached.Demo: So this is how it looks like.3. Left-Right Chaser

Code: The setup is exactly the same as the previous two setups. This function is the one which turns on the LEDs at the two far ends and then the one before that and likewise until they cross each other. The counter is reset when the max count is reached.Demo: So this is how it looks like.PCF8574 8-bit GPIO Port Extender

Using a PCF8574 8-bit GPIO Port Extender we can add even more LEDs to this setup.PCF8574 becomes a life saver when you run out of pins on your Arduino. This "GPIO (General Purpose Input Output) pin extender" provides an additional 8 pins (P0 ~ P7) which can be used to 'output a signal' or 'read a signal as an input'.These modules run on the I2C bus, and if daisy-chained you can connect upto 8 of these devices in a project. Each device will give us an additional 8-bits of GPIO enabling 64 GPIOs in total.To know more about this IC please check out my tutorial number 10 : "PCF8574 GPIO Extender - With Arduino and NodeMCU".Thanks

Full Blog Post: https://diy-projects4u.blogspot.com/2021/01/led-chaser-circuits-using-ic4017-and.htmlVideo: https://youtu.be/F6V1AjESWbUGerber File:Code:2. Forward Reverse: https://drive.google.com/file/d/1Oag8kxbvfxZg7StFrYzWwtcqQx6okwzd/view?usp=sharing3. Left Right:https://drive.google.com/file/d/17ZEsKU3OFrcjaJpvyUJMQbHQ-lznbp0H/view?usp=sharingSketch:2. Without Arduino: https://drive.google.com/file/d/1LdxcS1BXf3GtQTRhWCoCZKm6ppRwsc5k/view?usp=sharing- BTC: 1M1PdxVxSTPLoMK91XnvEPksVuAa4J4dDp

- DOGE: DDe7Fws24zf7acZevoT8uERnmisiHwR5st

- LTC: LedWPdTaUzr5iaJx8garkcykSs1DZU1FAx

- ETH: 0xB62a901Ee6cE24f3153CA6ae565C2A6533066faA

- BAT: 0xB62a901Ee6cE24f3153CA6ae565C2A6533066faA

- BCH: 14xJhpswSAQi375S39yDFsrBFtDoiLVX1J

-

Trying to explain dialup to a pre-teen will evoke the same wild-eyed bewilderment as “a dinosaur was as-big-as this house”. We can’t go off what our parents did because two tin cans connected by a string isn’t really the same these days and probably it would look like a piece of junk for the new and upcoming generations.However, the truth is "life is busy" and hence we don’t spend enough time with our children. Children need high-quality time with parents and caregivers - the QUALITY of time spent with them is much more important than the QUANTITY of time.Christmas was the perfect time to explore and setup this bonding. With a bit of help from my little monster and by using The Most Complete Starter Kit from ELEGOO I created this small Christmas Village for my little monster.

Components Used [Village Creation]

-----------------------------------------------To create the cardboard village we need:- Cardboard Sheets

- A4 Paper

- Permanent Marker or Pen

- Scissor and a Knife

- Hot Glue Gun or Wood Glue

Adding a bit color would have made my project even more attractive however I just left it all in white.Paper Templates

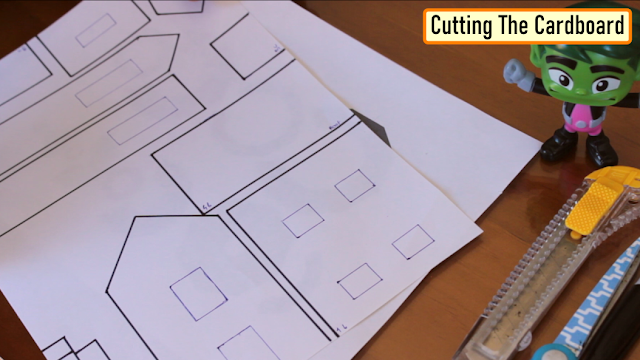

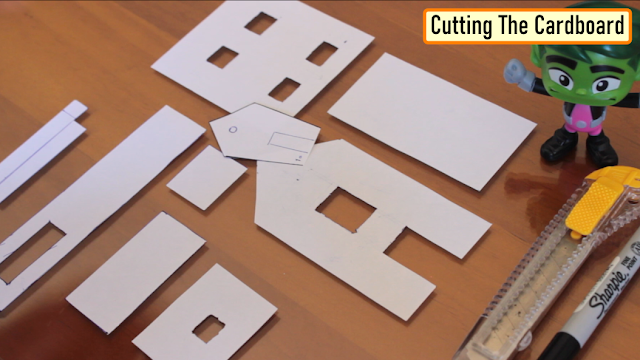

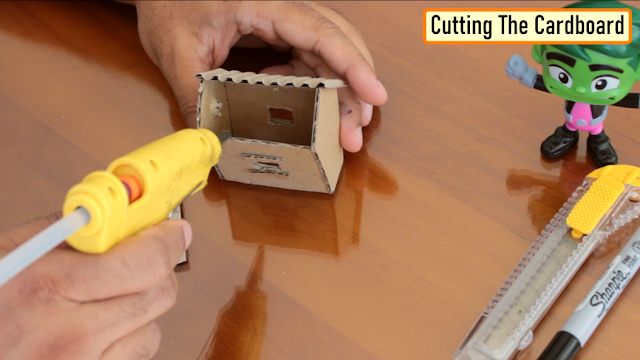

---------------------I created 2 x PDF files with all the measurements in it. The links to the PDF files is in the description below. After printing the PDFs on A4 sheet, I extracted the shapes from it using a paper cutting scissor.Cutting The Cardboard

-------------------------------Then I traced the paper-cutouts on pieces of cardboard and using both scissor and knife I extracted all the pieces of cardboard that I need for this project.Using a hot-glue gun I joined all the cardboard cutouts.Be very careful while using a hot-glue gun. Use gloves as much as possible to avoid the hot glue from burning your hand and fingers.By using wood-glue instead of hot-glue you can get a cleaner and stronger finish, but hot glue is faster. Hot glue can also be more forgiving as you can re-heat and re-glue if you're unsatisfied with your seam.Try applying the glue from the inner side as much as possible to leave the outer side neat and clean.Meaningful connections are all about quality of time and not quantity of time. Keep it simple and connect with your child in ways that make sense for your lifestyle and relationship. Each connection has a lasting impact and provides the support and reassurance that your child needs. Although the days with little kids often seem long; however, the years fly-by. Use this practical and purposeful blueprint to enjoy the moments you have together.Color or Not To Color

----------------------------So, this is how it looks like. As advised earlier, adding a bit color would have made my project even more attractive however I just left it all in white.I created this wooden frame on which the village will sit. This frame will also house the electronic components inside it.Components Used [Electronics]

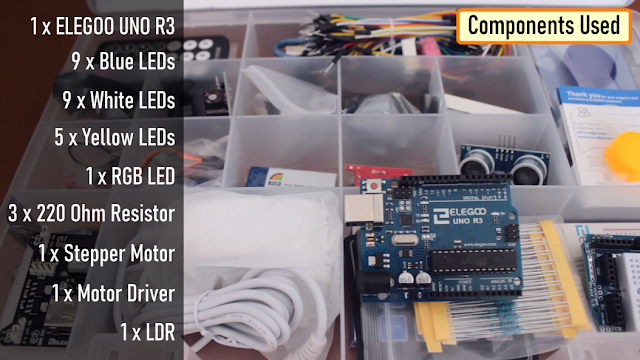

----------------------------------------Now for the Electronics bit we need the "The Most Complete Starter Kit from ELEGOO".This kit has all the components that are required for this project.- 1 x ELEGOO UNO R3

- 9 x Blue LEDs

- 9 x White LEDs

- 5 x Yellow LEDs

- 1 x RGB LED

- 3 x 220 Ohm Resistor

- 1 x Stepper Motor

- 1 x Stepper Motor Driver

- 1 x LDR

Adding LEDs

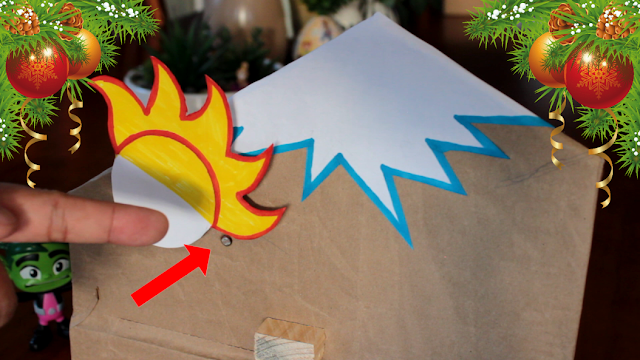

-----------------Using the soldering iron I made few holes around the pathway. These holes are for the Blue and White LEDs which will blink alternately. Adding RGB-LEDs would have definitely given this a better look and feel.Next, I added a RGB-LED to the water-feature. Later, I will add a bit of cotton on top of this which may look like flowing water.SUN & MOON

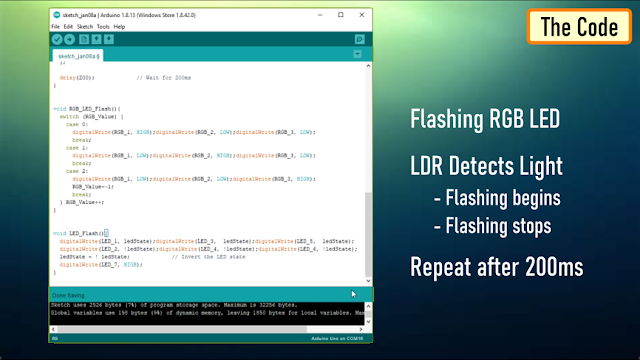

-------------------So, this is how the final setup looks like. I added some hills at the back for the rising and setting of the sun and the moon.The logic is very simple.A DC-Motor or Stepper-Motor rotates the Half Sun and Half Moon. A LDR is placed in a way that the Sun rays can cover it up.When the moon side is up the sun rays cove the LDR and vice-versa. This LDR acts as a switch and turns on and off the blue and white flashing LEDs. With the same logic you can go even more creative than what I did.Coding

---------The DC Motor run off the 5V pin of the Arduino so we don't need to code anything for that.For the rest of the code I am looping through and flashing the RGB LEDs followed by checking if the LDR has detected any light and then waiting for 200ms before repeating the process again.Thanks

----------Thanks again for checking my post. I hope it helps you.If you want to support me subscribe to my YouTube Channel: https://www.youtube.com/user/tarantula3Cardboard Templates:BTC: 35ciN1Z49Y1bReX2U7Etd9hGPWzzzk8TzFDOGE: DDe7Fws24zf7acZevoT8uERnmisiHwR5stLTC: MQFkVkWimYngMwp5SMuSbMP4ADStjysstmETH: 0x939aa4e13ecb4b46663c8017986abc0d204cde60BAT: 0x939aa4e13ecb4b46663c8017986abc0d204cde60Thanks, ca again in my next tutorial. -

Tutorial - Reed switch

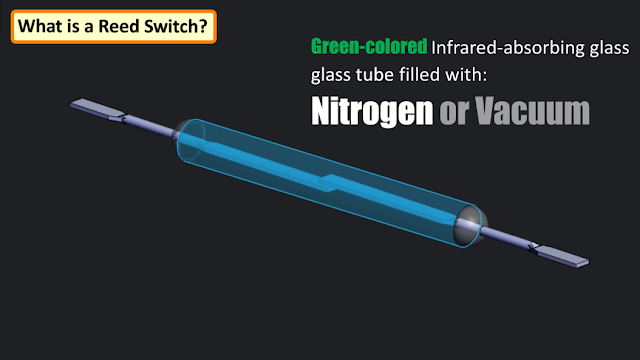

Reed switch was invented in 1936 by Walter B. Ellwood in the Bell Telephone Labs. Reed Switch consists of a pair of ferromagnetic (something as easy to magnetize as iron) flexible metal contacts typically nickel-iron alloy (as they are easy to magnetize and doesn't stay magnetized for long) separated by only a few microns, coated with a hard-wearing metal such as Rhodium or Ruthenium(Rh, Ru, Ir, or W) (to give them a long life as they switch on and off) in a hermetically sealed (airtight) glass envelope (to keep them dust and dirt free). The glass tube contains an inert gas (An inert gas is a gas that does not undergo chemical reactions under a set of given conditions) typically Nitrogen or in the case of high voltage it is just a simple vacuum.

In production, a metal reed is inserted in each end of a glass tube and the end of the tube heated so that it seals around a shank portion on the reed. Green-colored Infrared-absorbing glass is frequently used, so an infrared heat source can concentrate the heat in the small sealing zone of the glass tube. The glass used is of a high electrical resistance and does not contain volatile components such as lead oxide and fluorides which can contaminate the contacts during the sealing operation. The leads of the switch must be handled carefully to prevent breaking the glass envelope.

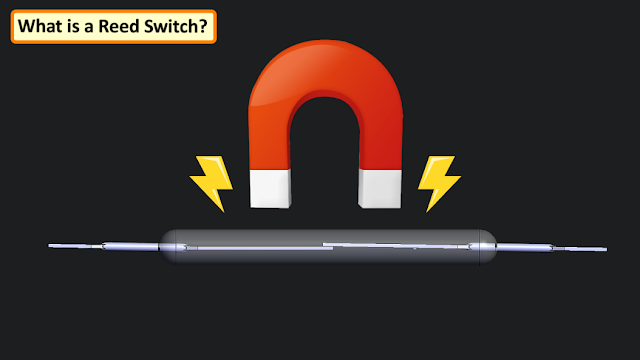

When a magnet is brought in close proximity to the contacts, an electro-mechanical force field is generated and the stiff nickle iron blades become magnetically polarized and gets attracted to each other, completing the circuit. When the magnet is removed the switch returns to its open state.

Since the contacts of the Reed Switch are sealed away from the atmosphere, they are protected against atmospheric corrosion. The hermetic sealing of a reed switch makes them suitable for use in explosive atmospheres where tiny sparks from conventional switches would constitute a hazard.

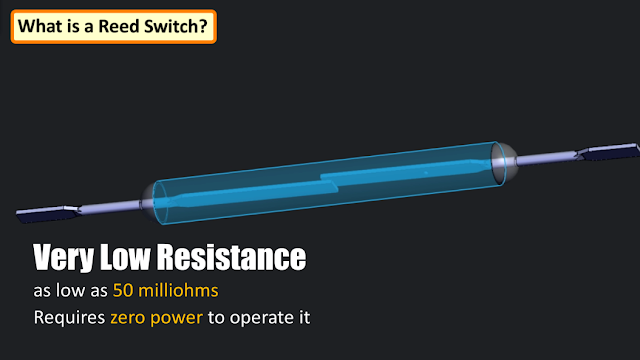

A Reed Switch has very low resistance when closed, typically as low as 50 milliohms hence a Reed Switch can be said to require zero power to operate it.

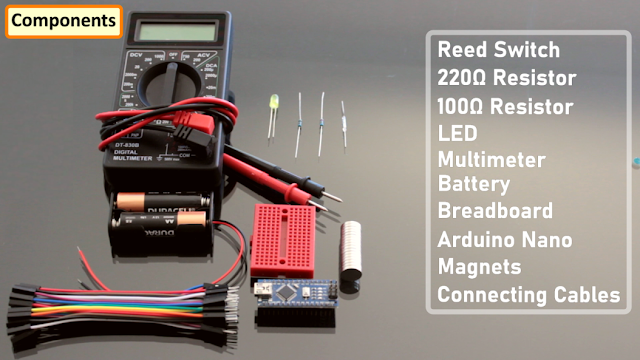

Components

------------------

For this tutorial we need:

- Reed Switch

- 220Ω Resistor

- 100Ω Resistor

- LED

- Multi-meter

- Battery

- Breadboard

- Arduino Nano

- Magnets and

- Few Connecting Cables

Demo

--------

Using a multi-meter I am going to show you how a Reed Switch works. When I bring a magnet close to the switch the multi-meter shows a continuity as the contact touches each other to completing the circuit. When the magnet is removed, the switch returns to its normally open state.

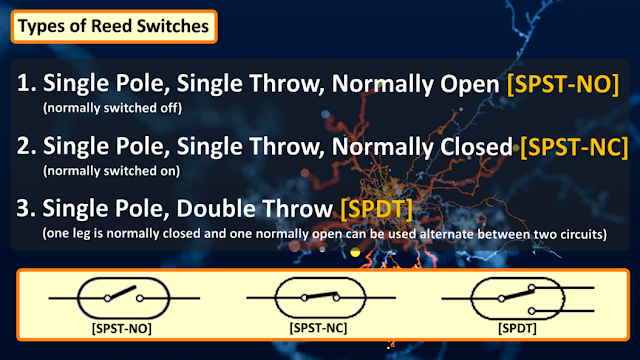

Types of Reed Switches

----------------------------------

There are 3 basic types of Reed Switches:

1. Single Pole, Single Throw, Normally Open [SPST-NO] (normally switched off)

2. Single Pole, Single Throw, Normally Closed [SPST-NC] (normally switched on)

3. Single Pole, Double Throw [SPDT] (one leg is normally closed and one normally open can be used alternate between two circuits)

Although most reed switches have two ferromagnetic contacts, some have one contact that's ferromagnetic and one that's non-magnetic, while some like the original Elwood reed switch have three. They also vary in shapes and sizes.

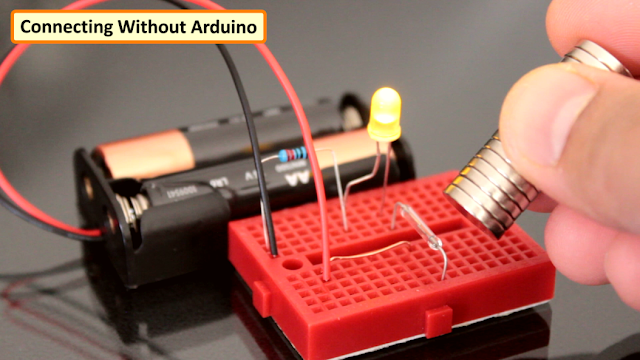

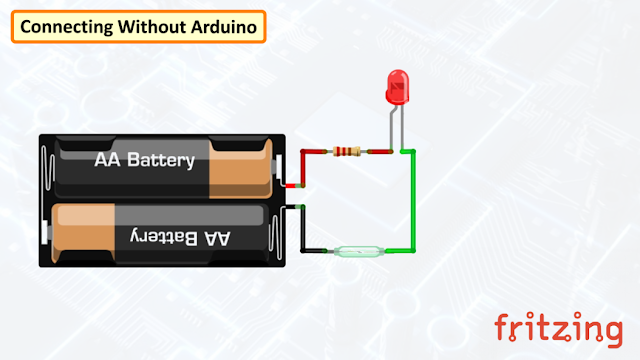

Connecting Without Arduino

-----------------------------------------

Lets first test the Reed Switch without an Arduino. Connect a LED in series with the Reed Switch to a battery. When a magnet is brought in close proximity to the contacts, the LED lights up when the nickle-iron blades inside the switch attracts each other, completing the circuit. And, when the magnet is removed the switch returns to its open state and the LED turns off.

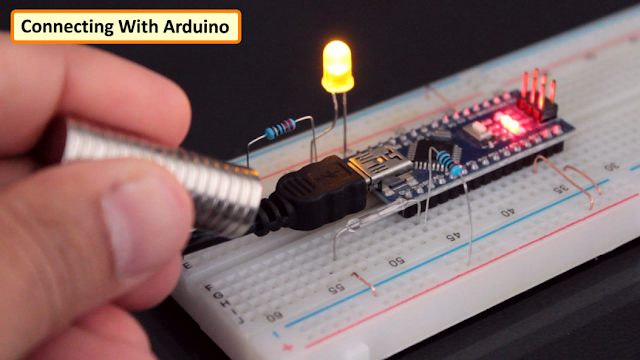

Connecting Reed Switch to Arduino

---------------------------------------------------

Now, lets connect the Reed Switch to an Arduino. Connect the LED to the pin 12 of the Arduino. Then connect the Reed Switch to the pin number 13 and ground the other end. We also need a 100ohm pull-up resistor connected to the same pin to allow a controlled flow of current to the digital input pin. If you want, you can also use the internal pull-up resistor of the Arduino for this setup.

The code is very simple. Set the pin number 13 as Reed_PIN and pin number 12 as LED_PIN. In the setup section, set the pin-mode of the Reed_PIN as input and LED_PIN as output. And Finally in the loop section, turn on the LED when the Reed_PIN goes low.

Same as before, when a magnet is brought in close proximity to the contacts, the LED lights up and, when the magnet is removed the switch returns to its open state and the LED turns off.

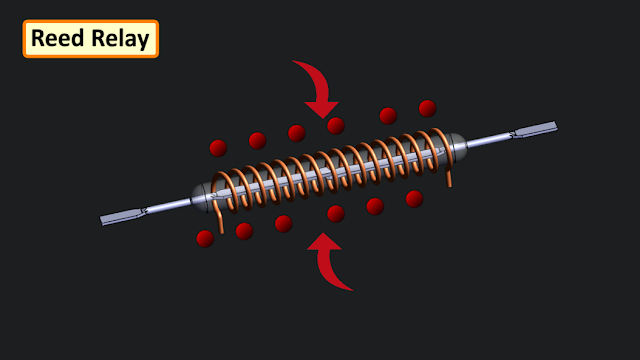

Reed Relay

----------------

Another widespread use of Reed Switch is in the manufacturing of Reed Relays.

In a Reed Relay the magnetic field is generated by an electrical current flowing through an operating coil which is fitted over "one or more" Reed Switchs. The current flowing in the coil operates the Reed Switch. These coils often have many thousands of turns of very fine wire. When the operating voltage is applied to the coil a magnetic field is generated which in turn closed the switch in the same way the permanent magnet does.

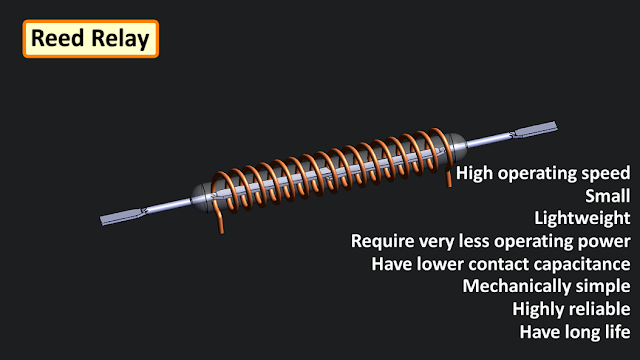

Compared to armature-based relays, Reed Relays can switch much faster, as the moving parts are small and lightweight (although switch bounce is still present). They require very less operating power and have lower contact capacitance. Their current handling capacity is limited but, with appropriate contact materials, they are suitable for "dry" switching applications. They are mechanically simple, offer high operating speed, good performance with very small currents, highly reliable and have long life.

Millions of reed relays were used in telephone exchanges in the year 1970s and 1980s.

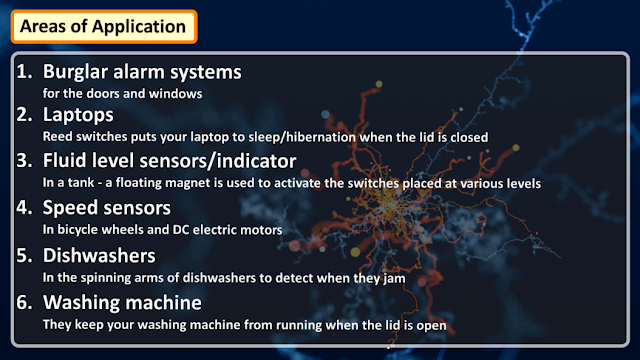

Areas of Application

-----------------------------

Just about everywhere you go, you'll find a Reed Switch nearby that’s quietly doing its job. Reed switches are so pervasive that you’re probably never more than a few feet away from one at any given time. Some of their areas of application are in:

1. Burglar alarm systems for the doors and windows.

2. Reed switches puts your laptop to sleep/hibernation when the lid is closed

3. Fluid level sensors/indicator in a tank - a floating magnet is used to activate the switches placed at various levels.

4. Speed sensors on bicycle wheels/ DC electric motors

5. In the spinning arms of dishwashers to detect when they jam

6. They keep your washing machine from running when the lid is open

7. In the thermal cut-offs in electric showers, to stop the water heating to dangerous levels.

8. They know if the car has enough brake fluid and whether or not your seat belt is fastened.

9. Anemometers with rotating cups have reed switches inside that measure the speed of the wind.

10. They are also used in applications which make use of their extremely low leakage of current.

11. Old keyboards, in vehicles, industrial systems, Household appliances, telecommunication, medical appliances, Clamshell phones and more......

On the relays side they are used for automatic cut sequences.

Life

-----

The mechanical motion of the reeds is below the fatigue limit of the materials, so the reeds do not break due to fatigue. Wear and life are almost entirely dependent on the electrical load's effect on the contacts along with the material of the reed switch. Contact surface wear occurs only when the switch contacts open or close. Because of this, manufacturers rate life in number of operations rather than hours or years. In general, higher voltages and higher currents cause faster wear and shorter life.

The glass envelope extended their life and can be damaged if the reed switch is subjected to mechanical stress. They’re cheap, they’re durable, and in low-current applications, depending on the electrical load, they can last for about a billion actuation.

Thanks

----------

Thanks again for checking my post. I hope it helps you.

If you want to support me subscribe to my YouTube Channel: https://www.youtube.com/user/tarantula3

Full Blog Post: https://diy-projects4u.blogspot.com/2020/07/reed-switch.html

Video: https://youtu.be/WA1tp-f81p8

Support my work:

BTC: 35ciN1Z49Y1bReX2U7Etd9hGPWzzzk8TzF

LTC: MQFkVkWimYngMwp5SMuSbMP4ADStjysstm

ETH: 0x939aa4e13ecb4b46663c8017986abc0d204cde60

DOGE: DDe7Fws24zf7acZevoT8uERnmisiHwR5st

TRX: TQJRvEfKc7NibQsuA9nuJhh9irV1CyRmnW

BAT: 0x939aa4e13ecb4b46663c8017986abc0d204cde60

BCH: qrfevmdvmwufpdvh0vpx072z35et2eyefv3fa9fc3z

#ReedSwitch #ReedRelay #Arduino -

The very first program you write when you start learning anew programming language is: "Hello World!".The program itself does nothing more than printing a “Hello World” text on the screen.So, how do we get our Arduino to display the "Hello World!"?In this video, I will be showing you how to get started with the small 0.91 (128x32) and 0.96 (128x64) I2C OLED displays.There are 100s of tutorials on the web explaining the same thing in different ways, but I couldn't find one that tells me all about the OLED display and how to use it in different scenarios. It took me some time to work it all out. So, I thought I should create a tutorial on what I have learned and combine all the features and ways the OLED displays can be used in our projects.

Step 1: Things We Are Going to Learn Today

In this video we will be talking about:- What is an OLED display?- Then we will have a closer look at the 0.91 (128x32) and 0.96 (128x64) I2C OLED displays- Next we will talk about installing the Adafruit Library to your Arduino IDE- Then we will connect NodeMCU and Arduino to an OLED display- Next we will have a look at the code and display some graphics and text on it- We will also talk about applying Custom Fonts and displaying Images- Then we will connect Multiple OLEDs to a micro-controller using I2C Multiplexer- Finally, we will talk about few common errors people make while using the OLED displaysStep 2: Hardware Requirement

For this tutorial we need:- A Breadboard- A 0.91" (128x32) and 0.96" (128x64) I2C OLED displays- Arduino UNO/NANO (whatever is handy)- NodeMCU- TCA9548A I2C multiplexer- Few Connecting Cables- and a USB cable to upload the codeStep 3: What Is an OLED Display?

OLED or organic light-emitting diode is a light-emittingdiode (LED) in which the emissive electroluminescent layer is a film of organic compound (millions of small LED lights) that emits light in response to an electric current.OLEDs are used to create digital displays in devices such as television screens, computer monitors, portable systems such as mobile phones, hand-held game consoles and PDAs. An OLED display works without a backlight because it emits visible light.There are many types of OLED displays available in themarket based on their- Sizes- Color- Brands- Protocol- SPI (Serial Peripheral Interface) or I2C- Passive-matrix (PMOLED) or active-matrix (AMOLED) control schemeIn this tutorial, I am going to talk about connecting theblue color 0.91 (128x32 OLED) and 0.96 (128x64 OLED) I2C OLDE displays to an Arduino NANO and NodeMCU. I2C bus technology uses only 2 pins of the MCU so we have heaps available for other sensors.Step 4: Closer Look

Lets have a closer at these two displays.At the back of these displays there are heaps of SMD capacitors and resistors soldered on-board; but, since its an I2C device we only care about these 2 pins (SCL and SDA)The display connects to Arduino using only four wires – two for power (VCC and GND) and two for data (serial clock SCL andserial data SDA), making the wiring very simple. The data connection is I2C (I²C, IIC or Inter-Integrated Circuit) and this interface is also called TWI (Two Wire Interface).- The on-board pins can be in different order, so always triple check before hooking it up to your project.- Operation voltage is between 3v to 5v but, it is best to use the guidance from the manufacturer's datasheet.- Sometimes we need to use 2 displays in our projects. So, how can we achieve this?The trick is to have a configurable address on your display. This unit has a configurable address between 0x78 and 0x7A. Just by unsoldering the 0Ohm resistor from one side and hoking it up to the other side or just by putting a global solder we can change the address. We will talk about it in depth when we hook up multiple displays to an Arduino in the later section of this tutorial.In picture these displays look very big. But, practically speaking they are tiny. They are made of 128 x 32/64 individual OLED pixels and do not require any back-light. Just have a look at this and see how small it is. Even though they are small they can be very useful in any electronic projects.Step 5: Library

There are several libraries available to control thesedisplays. In past I have used the "u8glib library" but I find the AdaFruit library very easy to understand and use in our projects. So, I am going to use the AdaFruit library in this tutorial.To control the OLED display you’ll need the "adafruit_GFX.h" library and the "adafruit_SSD1306.h" library.There are two ways you can download and install the library to your Arduino IDE.Method 1Go to the "Library manager" and search "adafruit_SSD1306" and "adafruit_gfx"Select the latest version and hit the Install button.Once installed you can use these libraries in your program.Method 2These two libraries can be also be downloaded from github (you need both):I will provide the links in the description below.The display library: https://github.com/adafruit/Adafruit_SSD1306The GFX library: https://github.com/adafruit/Adafruit-GFX-LibraryOnce downloaded, copy the Adafruit_SSD1306-master folder from the downloaded zipped file into the Arduino libraries folder. This folder is usually found at Documents > Arduino > libraries on Windows systems. On Linux it is usually found at home folder > Arduino > libraries. Finally in the Arduino library folder, rename the Adafruit_SSD1306-master folder to Adafruit_SSD1306. Even if you don’t rename that’s fine.Now, lets have a look at the "Adafruit_SSD1306.h"fileTwo things we need to know in this library:1. If you want to use the smaller display use the default 128_32 otherwise for the bigger display comment the 128_32 and uncomment the 128_642. If you have soldered the 0x7A Address on the board (which we will talk about later) then use the 7 bit 0x3D address for the bigger displays, otherwise use the default 0x3C address. For the smaller displays the address is 0x3C.Step 6: Wiring 128 X 64/32 OLEDs

Lets start by connecting the NodeMCU to the display.The first and most important thing to note is that some of the displays may have the GND and VCC power pins swapped around. Check your display to make sure that it is the same as the image. If the pins are swapped, make sure to change the connections to the Arduino or NodeMCU.- NodeMCU OLED WiringOLED VCC – NodeMCU 3.3VOLED GND – NodeMCU GNDOLED SCL – NodeMCU D1OLED SDA – NodeMCU D2- Arduino Uno OLED WiringOLED VCC – Arduino 5VOLED GND – Arduino GNDOLED SCL – Arduino Uno A5OLED SDA – Arduino Uno A4- Arduino MEGA 2560 OLED WiringOLED VCC – Arduino 5VOLED GND – Arduino GNDOLED SCL – Arduino MEGA 2560 pin 21OLED SDA – Arduino MEGA 2560 pin 20Step 7: Code

Adafruit library comes with really good examples for both128x32 and 128x64 displays.The Library is located under File > Examples > Adafruit SSD1306 > and then the display type in the Arduino IDE.We are going to use the 128x32 I2C example and will modify it to work with both 128x64 and 128x32 displays fist by hooking it up to an Arduino and then to a NodeMCU board.The code starts by including both the Adafruit libraries. In this tutorial I am going to stress on only those parts of the code which are necessary for us to load on both boards and displays. If you want to know more about the code please drop a comment on my blog or in the comments section below and I endeavour to get back to you.- First we are going to load the code to an Arduino Nano connected to a 128x32 display.We can use the code as is without any modifications.128x32 uses 0x3C address so this bit looks all good here, lets double check the header library, yes its also using the 0x3C address and the display type is 128x32.- Now lets connect the 128x64 display. As we know it uses the 0x3C address by default so we don't need to update the address in either the code or the library.We just need we need to comment the 128_32 and uncomment the 128_64 in the header library and change the LCDHEIGHT to 64 in our code.- Now to run the same code on a NodeMCU we need to change one more line in our code.The "#define OLED_RESET 4" > "#define OLED_RESET LED_BUILTIN" rest of the code is same as ArduinoPretty much to display anything we first need to clear the previous screen usingdisplay.clearDisplay(); // Clear the bufferThen draw the objecttestdrawline(); // Draw a lineShow it on the hardwaredisplay.display(); // Make them visible on the display hardware!Wait for some time before displaying the next item.delay(2000); // Wait for 2 secondsIn this example we are displaying few items like text, lines, circles, scrolling text, triangles and more. Go ahead and use your imagination and display whatever you want on these tiny displays.AttachmentsStep 8: Customizing Text & Adding Images

Sometimes your code needs to display custom fonts andimages. If you are very good in bit mapping then you just need to create a byte arrays by turning on or off the tiny LEDs of the display to create custom fonts and images.However, I am not very good in doing these mappings and don't want to spend hours creating the bit map tables.So, what are my options? I generally use two websites to generate custom fonts and images. The links are provided in the description below.Custom Fonts------------Go to the font converter website, select the font family, style, size, Library Version as "Adafruit GFX Font" and then hit the "Create" button. On the right hand side of this page you can see how your font is going to look like on the actual display.Based on your selection the webpage generates the fonts header file. Create a file called "modified_font.h" in the same folder where your code is and copy and save the generated code into it. Then you just need to include the header file in your code to use the custom font.#include "modified_font.h"Then, you just need to set the font before displaying the text to apply the custom font to it.display.setFont(&Your_Fonts_Name);You can get the name of the font from the header file you just added to your project. Thats it, easy.Memory is always a concern while using custom fonts, so always consider the bytes that will be consumed by the memory. Just remember Arduino UNO has only 32K of memory.Custom Images-------------To display a bitmap image on your screen you first need to create a 128 x 64/32 sized image.I am using the good old "MS Paint" to create a 128 x 64 bitmap image which I will then upload to this image converter website. The website converts images into byte-strings, which can be used with Arduino and OLED displays.Start by uploading the image to the website. Then put a check on the "Invert image colors" check-box and change the "Output code format" to "Arduino Code" next select the orientation and hit the "Generate Code" button to generate the byte array. The "Preview" section shows you how your image will look like on the actual display.I have included the code along with this tutorial which you can use to display your images. You just need to replace the array in my code with the one you just generated and then load it to your Arduino.Attachments

Step 9: Connecting 2 Displays

Connecting two 128 x 64 displays to your project is easy.You just need to unsolder the 0Ohm resistor from 0x78 address and put it on 0x7A and then use the 0x3D address in your code instead of the default 0x3C.You must be wondering why we are using the 0x3C and 0x3D address and not the actual 0x78 and 0x7A. Arduino accepts 7-bit address and not the 8-bit hardware addresses. So, we first need to convert the 8-bit address to binary, and then chop off the least significant bit to get the 7 bits. Then convert the 7 bits to HEX to get the 0x3C or 0x3D addresses which you enter in your code.First, initialize the display by giving it a unique name:Adafruit_SSD1306 display1(OLED_REST);Adafruit_SSD1306 display2(OLED_REST);Then in your code use the display 1 and display 2 to call the begin statements with the device addresses in them:display1.begin(SSD1306_SWITCHCAPVCC, 0x3C); // display 1 op address 0x3Cdisplay2.begin(SSD1306_SWITCHCAPVCC, 0x3D); // display 2 op address 0x3DThat's it, you can now go ahead and do whatever you want using either Display 1 or Display 2 in the rest of your code. I have provided an example with this tutorial.Wiring is exactly the same as what we have done before, pretty much you just need to add another display to the same I2C pins of either the Arduino or NodeMCU. Based on the addresses, the MCU then sends the data on the I2C data line.Attachments

Step 10: Connecting More Than 2 Displays

Now, what if you want to hook up more than 2 displays?Arduino has limited number of pins and hence you cannot have more than a certain amount of shields attached to it. Moreover, it has only one pair of I2C buses.So, how can we attach more than 2 I2C displays to an Arduino? The trick is to use a TCA9548 Multiplexer.TCA9548 allows a single micro-controller to communicate with up to '64 sensors' all with the same or different I2C address by assigning a unique channel to each sensor slave sub-bus.When we talk about sending data over 2 wires to multiple devices we then need a way to address them. Its same as the postman coming on a single road and dropping the mail packets to different houses because they have different addresses written on them.The Multiplexer connects to 3V3, GND, SDA and SCL lines of the micro-controller. The slave sensors are connected to one of eight SCL/SDA slave ports on the board. The channels are selected by sending the TCA9548A its I2C address (0x70 {default} - 0x77) followed by the channel number (0b00000001 - 0b10000000). You could have at the max 8 of these multiplexers connected together on 0x70-0x77 addresses in order to control 64 of the same I2C addressed parts. By connecting the three address bits A0, A1 and A2 to VIN you can get different combination of the addresses. I will explain this in-depth in my next tutorial on TCA9548A breakout board. For now, lets just hook up 8 OLEDs to this board and have a quick look at the code.Connection:VIN to 5V (or 3.3V)GND to groundSCL to I2C clockSDA to I2C dataThen wire up the sensors to VIN, GND and use one of the SCn / SDn multiplexed busesNow, Int the code lets start by including the "Wire" library and by defining the multiplexers address.#include "Wire.h"#include#define MUX_Address 0x70 // TCA9548A Encoders addressThen we need to select the port we want to communicate to and send the data on it using this function:void tcaselect(uint8_t i) {if (i > 7) return;Wire.beginTransmission(MUX_Address);Wire.write(1 << i);Wire.endTransmission();}Next we will initialize the display in the setup section by calling "u8g.begin();" for each display attached to the MUX "tcaselect(i);"Once initialized, we can then do whatever we want just by calling the function "tcaselect(i);" where "i" is the value of the multiplexed bus and then sending the data and clock accordingly.Attachments

Step 11: Advantages and Disadvantages

The image of an OLED is beautiful. However, OLEDs also havedisadvantages. Because OLED screens contain organic material, their lifespan is shorter than LCD displays. Additionally, many OLED displays get burn-ins after showing the same image for a long time. After a burn-in, the image stays on the screen even after showing another image. So make sure you keep refreshing the screen every few seconds. Water can instantly damage the organic materials of these displays.AdvantagesNo need for a backlightDisplays are very thin and lightweightLow power consumptionViewing angles are wider than LCDsBrightness and contrast are greatHigh speed and have low response timeDeep black colorDisadvantagesCostly technologyShort lifecycleOLEDS are more likely to burn-inWater damageStep 12: Common Errors

To conclude the tutorial lets talk about few common errorspeople make while using these displays:- Always triple check the pins before using it in your project- Pick up the right library address in the header file and in your code#define SSD1306_I2C_ADDRESS 0x3C // in Adafruit_SSD1306.handdisplay.begin(SSD1306_SWITCHCAPVCC, 0x3C); // in your codeIf the address is wrong the OLED will not display anything- The display size must be changed in the driver before it can be used. If it is not changed you will get an error message when attempting to verify the code#error ("Height incorrect, please fix Adafruit_SSD1306.h!");- If using NodeMCU make sure you replace the OLED_RESET from 4 to LED_BUILTIN#define OLED_RESET LED_BUILTINI have scene people making all sorts of things using this OLED display. Some have even made video games and all. I am really not interested in making a video game using this tiny display. However, I will now leave you to explore your imaginations and come out with amazing ideas.- Add Image: http://javl.github.io/image2cpp/- Custom Text: http://oleddisplay.squix.ch/#/home- Adafruit display library: https://github.com/adafruit/Adafruit_SSD1306- Adafruit GFX library: https://github.com/adafruit/Adafruit-GFX-Library- u8glib library: https://code.google.com/archive/p/u8glib/ or https://github.com/olikraus/u8glibIf you want to use the smaller display use the default 128_32 otherwise for the bigger display comment the 128_32 and uncomment the 128X64 NO_ACK in your code (just uncomment the type of screen you are using) (fonts are in the fonts library)Attachments

-

Has this ever happened to you?

You come back from a romantic dinner date and when you open the shutter door of your garage you realize that you left the garage light ON. You spent few hours outside with your partner to impress her and all the time this light bulb was on. You immediately turn around and look at her face to see a silent anger on her face. Alright, enough of that. So, in this tutorial, I am going to turn on and off the garage light using a PIR sensor. When the sensor detects a moving object, it turns on the light bulb and when the moving object is gone, it turns it off. Lastly, I am going to make sure that light bulb only turn on during the night time (when its dark).

Step 1: Logic

In this project, I will be using a PIR sensor along with an LDR to turn on or off a light bulb using a Relay.

The things I need to consider before designing the circuit are:

- The bulb should only turn on when the room is dark and when a motion is detected.

- The bulb should turn off after 30 seconds of the object leaving the sensors proximity.

- Most important, we need to place the LDR in a place where it doesn't turn off the bulb as soon as it lights up.

Step 2: Hardware

For this tutorial we need:

A General Purpose PCB

2 x HC-SR501 PIR Sensor

2 x 1N4148 Small Signal Fast Switching Diodes

1 x 1N4007 High Voltage, High Current Rated Diode to protect the micro-controller from voltage spikes

1 x LDR

1 x 10K Trimmer Potentiometer

2 x 470 Ohms Resistor

1 x 10K Resistor

1 x 1K Resistor

1 x 2N3906 General Purpose PNP Transistor

1 x 2N2222 General Purpose NPN Transistor

1 x 5V Relay

1 x LED to display the status

5 x Terminal Blocks

1 x 220V to 5V Buck Step Down Module

Few Connecting Cables And General Soldering Equipments

Step 3: Assembly

Lets first connect the LDR and setup the light detection bit.

As we all know we need to setup a voltage divider to use the LDR in a circuit, so, I am adding this 10K POT and 470ohms resistor to setup the voltage divider bit. By adjusting the resistance of the POT we can adjust the intensity of sunlight at which this circuit will operate.

Now, lets install the PIR sensor. Connect the VCC to +5v and GND to ground. Then connect the 1N4148 diode to the OUT of the sensor. In this circuit, I am installing just one sensor however in the actual project I have used 2 sensors to capture a bit more than 180 degrees. So, to avoid the sensors from back-feeding each other we need to install a diode to the OUT pin of each sensor. If you want to capture motion at 360 degrees you may need 3 to 4 sensor and diode pair to achieve that.

Now that we have the PIR sensor and the LDR in place we need to add the 'AND' functionality. To achieve this I am adding a general purpose PNP transistor. When a motion is detected 'and' when the sunlight is at a certain intensity (adjusted by the POT) current flows out of the transistor.

Next, we need to amplify the current received from the collector of the PNP transistor and turn on and off the LED indicator and the Relay. A general purpose NPN transistor is used to achieve this. That's it all done.Step 4: What Have I Have Made

So, this is what I have made.

On my board components are pretty much soldered everywhere, but you may like to have them nicely installed to give it a bit more cleaner look. OK, so lets check out how this works.

Step 5: Demo

Alright, I have placed the board on this table to do a quick test. I haven't hooked up a light bulb to the circuit yet. However, the LED indicator should serve the purpose of this demonstration.

So, now I am going to turn off the light and make the room dark. Let's see if the sensor picks up motion and lights up the LED. Tada, it works.

Now, lets turn on the light of the room and see if the LED indicator turns off or not. Yessss, that works.

OK, finally just want to make sure that the light bulb turns off after 30 seconds of me moving out of the sensors proximity. Boom, and that concludes the project. I can now install it on the ceiling and make my partner happy.Instead of having 2 to 3 PIR sensors you can use one and install it at the corner of the wall. However, that will require a fair bit of wiring either inside the roof or on the ceiling, which will be way more expensive and tedious than installing 3 sensors an d putting the device in the middle of the room.

You can also swap the Arduino with a NodeMCU board and do a remote data logging to log the time when the sensor detected motion or when the light went on to record when people entered your garage and how long they stayed in there.

Step 6: Areas of Applications of PIR Sensors

This setup can be used to:

* Automate All Outdoor Lights

* Automate Lights of Basement, Garden or Covered Parking Areas

* Automate Lift Lobby or Common Staircases Lights

* Automate bedside or night lamp

* Create a Smart Home Automation & Security System and more..

Step 7: Thanks

Thanks again for watching this video! I hope it helps you. If you want to support me, you can subscribe to my channel and watch my other videos. Thanks, ca again in my next video.

-

Just before creating my next projects tutorial, which will be using a PIR sensor, I thought I might create a separate tutorial explaining the working of a PIR sensor. By doing that I will be able to keep my other tutorial short and to the point. So, without wasting time let’s discuss what is a PIR sensor and how we can use it in our project.

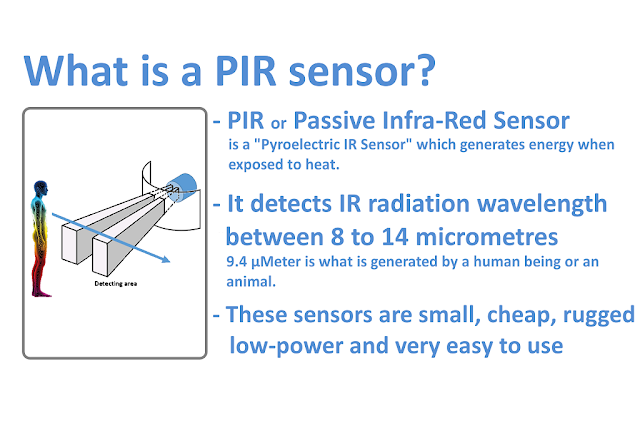

Step 1: Basic

What is a PIR sensor?PIR or "Passive Infra-Red" sensor is a "Pyroelectric IR Sensor" which generates energy when exposed to heat. Everything emits some low level of radiation, the hotter the object is, the more radiation is emitted. When a human or an animal (with IR radiation wavelength of 9.4µMeter) approaches the sensors range the sensor detects the heat in the form of infrared radiation. The sensor only detects the energy emitted by other objects and don't produce any, that's why the sensor is called a PIR or "Passive Infra-Red" sensor. These sensors are small, cheap, rugged, low-power and very easy to use.Step 2: Hardware

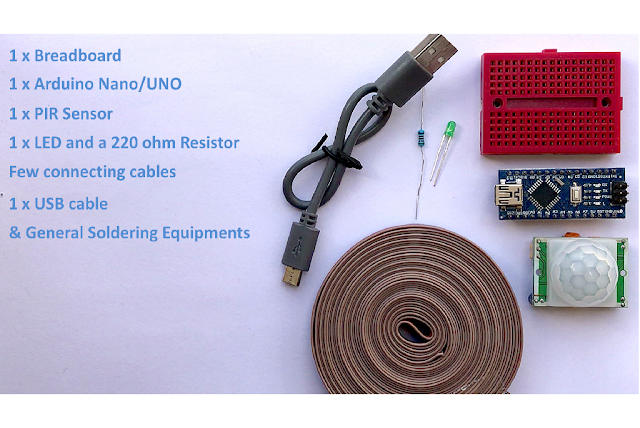

For this tutorial we need:

1 x Breadboard1 x Arduino Nano/UNO (Whatever is handy)1 x PIR Sensor1 x LED and a 220 ohm current limiting resistor to test the connectivityFew connecting cablesA USB cable to upload the code to the Arduino& General Soldering EquipmentsStep 3: Architecture

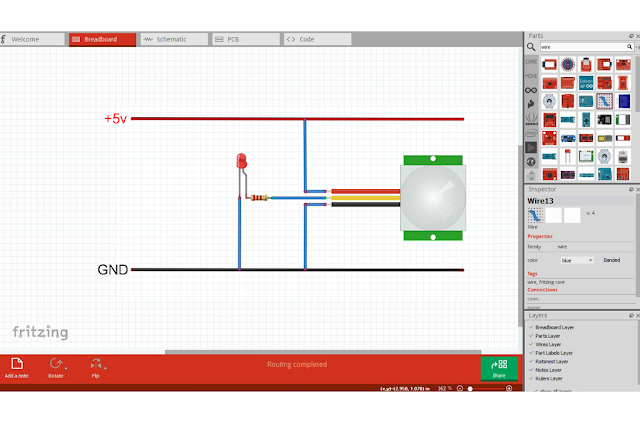

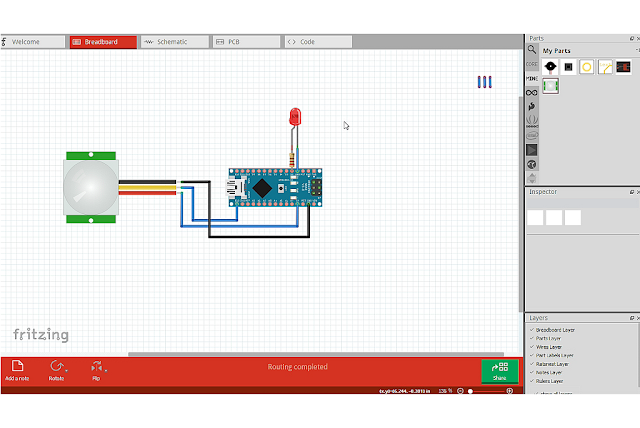

As we can see the sensor has two sides:1. Top or the Sensor Side2. Bottom or the Components SideThe Top consist of a specially designed 'High-Density Polythene' cover called "Fresnel Lens". This lens focuses the infrared rays to the underlying 'Pyroelectric Sensor'. 9.4 µMeter infrared rays can easily pass through the polyethylene cover. The sensors sensitivity range between 6 to 7 meters (20 feet) and the detection angle is 110 degrees x 70 degrees. The actual sensor is inside a sealed metal can. The can basically protects the sensor from noise, temperature and humidity. There is a tiny window made of IR-transmissive material to allow the IR signals to reach the sensor. Behind this window are 'two' balanced PIR sensors. In idle state, both sensors detect the same amount of IR radiation. When a warm body passes by, it first intercepts one of the two sensors, causing a positive differential change between the two halves. And then, when it leaves the sensing area, the reverse happens, and the sensor generates a negative differential change. When the pulse changes or in other words the PIR sensor detects motion, the output pin changes to "digital high" or 3.3V.The bottom bit consists of a bunch of circuitry. Few of them are of our interest.- Most PIR sensors have 3-pins VCC, GND and OUT. VCC and GND are to power the module (Operating voltage: DC 5V to 20V). The OUTPUT pin is the one which communicates with the micro-controller by sending digital pulse high (3.3v) when a motion is detected and digital low (0v) when no motion is detected. The pin-outs may vary between modules so always triple-check the pin-outs.- The BISS0001 or the "Micro Power PIR Motion Detector IC" gets the output from the sensor and after doing some minor processing it produces the digital output.- The module has two potentiometers one to adjust the sensitivity (which is up to 7m) and the other to adjust the time for which the output signal should stay high when an object is detected (it ranges from 0.3s to 5 mins).- There are 3 more pins on this module with a jumper between them to select the trigger modes.> 1st one is called "non-repeatable trigger" - this one goes low as soon as the delay time is over.> 2nd one is called "repeatable trigger" - it stays high as long as the object is in the proximity and will turn off once the object is gone and the delay is over. I will be using this mode for this project.If you want to do a quick test before going ahead with this tutorial please follow the steps below.A testing is also a good idea to test the range and duration of sensing.Step 4: Connecting Without Arduino

- Connect the VCC to the +5v rail of the breadboard- Connect the GND to the -ve rail- Connect the LED along with a 220 ohm resistor to the OUT pin of the sensorNow, when the sensor detects a motion, the output pin will go "high" and the LED will light up. Move back and forward to find out the sensing the range. Then to test the duration walk in front of the sensor and then walk away and use a stopwatch to find out how long the LED stayed on. You can adjust the time or sensitivity by adjusting the POTs on the board.Step 5: Connecting With Arduino