-

Posts

14 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Events

Posts posted by Guy Shemesh

-

-

As I said, they dry out..

-

The epcos informaion is only valid for epcos 🙂

Electrolytic capacitors from 1990 is generally something to beware of. They contain liquid or gel electrolyte which basically dries out over time. from 1990 up to now its 30+ years, I'd say that failure is quite certain. Moreover, the failure can damage other areas in your circuit.

I would just replace these..

Good luck

Guy

-

Hi Dave,

Yes you can, just make sure you get the polarities right. You need to verify that the + of the battery goes to the + of the camera, and same for the -.

Typically electronic circuits are protecting against this but you shouldn't try it.

Just check your old battery and make sure the new battery has the + and - signs at the same locations.

Best wishes

Guy

-

Hi Paul

Check your VRef circuit around U1, it seems very suspicious to me. To which Vref voltage you are designing for ?

I would replace this small circuit altogether.. seems like a mistake in the schematics there.

Best of Luck

Guy

ePiccolo Engineering

-

Hi,

A full diagram would have been more helpful to understand the circuit, with your provided circuit its hard to tell. You need to specify at the very least the other pins 16 and 3 of the TL494.

However from the point of connection alone - trimpot touching the 0.1 ohm sense resistors - it looks like current limit control where the trimpot is controlling the current and the MCU setting the high side with GPIO - much like an enable signal.

Again without further details I can't tell for sure.

Good luck with your studies

-

You are very welcome 😀

-

That would be the best! Good luck

-

Oh!

I'm sorry to see this, looks like there is further damage. The caps are severely damaged..

No I would not recommend to try and save this board.

I would let it go

-

Hello Jim,

I think the fix would be fairly easy, assuming that P6 is the only diode that got burned. If the failure propagated elsewhere in the circuit there might be more damage but my gut feeling says you have a really good chances here.

Looking at the Viper IC I see it is self protected, Overtemperature, overcurrent and overvoltage protection - so I wouldn't bother to replace it. You just need to pick a diode at a rating similar or high to the P6 diode. If you have the exact P/N that would be the best, otherwise just pick a diode with slightly bigger dimensions.

Now the trick is a follows. You don't want to get into the over temperature problem again. This is a design flaw of this circuit and part of the fix would be to avoid it as well. So what to do? Apparently you could help to cool the replaced P6 diode just by leaving its wire leads uncut on both sides long. When you install the new P6 diode, don't cut the wires on both sides. Take care that these leads wont touch anything unintentionally in the circuit, you could also bend them in directions to ensure this. Moreover, you could even extend these leads or just add solder to the excessive leads, this really helps to cool them since more mass - more surface area - better heat transfer to ambient.

I had a similar issue with a customer who brought in a really expensive microphone's power supply. It was not our design but we promised to look at it anyway and bang - same issue - diodes heating up and burning the circuit.

If anything unclear you could also post pictures here after the fix and before powering the unit.

Good luck

Guy

-

By the way, an extremely useful and free tool can be downloaded from here:

It does require installation on the PC, and it groups many useful PCB calculators in one program.

I have no connection to it, other than using it.

enjoy

-

Sounds like you are already on your way 😀

Regarding schematics, some very well known mics have their schematics published, for example you can google "neumann u87 schematic" or "schoeps microphones schematic". The information is there..

I wish you much success with your efforts.

Guy

-

It looks very nice, I also like the layout and the fact you used polygon pours on both sides.

I think one improvement would be to make edge plating on the sides, it helps dissipate the heat off the main board.

If you can add schematics to the post that would also be interesting to see.

Thanks

-

Hi Peter.

It's quite a difficult question to answer, since building microphones can be a full time profession. I'd start with the dynamic microphones first, in these there is usually not much electronics inside - there is the transducer and usually a transformer. So with good hands and a good soldering iron you can probably fix the microphones, i.e if there are loose connections or just swap in replacement parts.

Ribbons are also simple in their internals. usually just a thin corrugated foil surrounded by magnets and a transformer. Here also you can fix but you need to be very careful since the aluminum foil is extremely fragile. Please be sure to start on microphones that you fell you have nothing to lose on and have in hand lots of replacement foil.

With condensers, I would refrain from advising you to repair yourself. Condensers require deep knowledge of the electronic circuit. You can however swap in a microphone capsule if you see you capsule is damaged.

Other option with condensers is to start out with a ready kit with instructions and just solder it.

I hope this helps you. You can check my page also at facebook ePiccloMicrophones, or check out my webpage:

Best of luck

Guy

In depth guide to PCB Vias and PCB design

in Electronic Resources

Posted

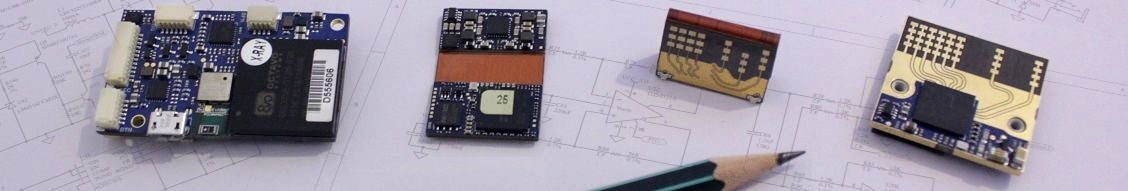

Hello friends

I have written a detailed guide on PCB vias. The concept of the via is intuitive and could be easily understood, however in order to design the most suitable via for a specific board requires profound understanding of the PCB manufacturing process. The cost of the PCB, reliability and the manufacturer's yield are all dependent on proper via design.

This is one of the reasons why complex boards require us to pay relatively high "tooling". The manufacturer needs to learn our gerbers and inspect our via design and in some cases even to make changes prior to manufacturing. The customer many times doesn't even know his PCB vias were changed, unless he specifically requests to inspect the production gerbers.

This guide is suitable for anyone who wish to strengthen his knowledge in PCB design. Any comments please write to me freely.

https://www.epiccolo.com/articles/pcb-vias-guide