Leaderboard

Popular Content

Showing content with the highest reputation since 05/08/2023 in all areas

-

Solar-powered Bee Hotel w/ Particle Argon (ongoing project)

Jolin He and one other reacted to JamesMVictoria for a topic

Nice one, I like it.2 points -

Ultrasonic Sensor with Home Assistant

JorgeMiller reacted to CETECH for a topic

In this blog, I will show you how to integrate an ultra-sonic sensor with ESPHome in home assistant. An ultra sonic sensor is a device that can measure the distance to an object by sending and receiving sound waves. It can be used for various applications, such as obstacle detection, level measurement, parking sensors, etc. What is ESPHome and Home Assistant? ESPHome is a system that allows you to easily create and manage custom firmware for ESP8266 and ESP32 devices. It uses a simple configuration file that defines the components and sensors you want to use and generates the code and binary files for you. You can then upload the firmware to your device using a USB cable or over-the-air (OTA) updates. Home Assistant is an open-source platform that allows you to control and automate your smart home devices. It supports hundreds of integrations with different services and devices, such as lights, switches, sensors, cameras, media players, etc. You can access and control your home assistant from a web browser, a mobile app, or a voice assistant. ESPHome and Home Assistant work very well together, as they can communicate with each other using the native API. This means that you can easily add your ESPHome devices to your home assistant without any extra configuration or coding. You can also use home assistant to monitor and control your ESPHome devices, and create automations based on their states and events. How to Integrate Ultra Sonic Sensor with ESPHome in Home Assistant To integrate an ultra-sonic sensor with ESPHome in home assistant, you will need the following: An ESP8266 or ESP32 device, such as NodeMCU, Wemos D1 Mini, or Xiao ESP32 S3 Sense An ultra sonic sensor, such as HC-SR04 A breadboard and some jumper wires A computer with ESPHome and Home Assistant installed. Get PCBs for Your Projects Manufactured You must check out PCBWAY for ordering PCBs online for cheap! You get 10 good-quality PCBs manufactured and shipped to your doorstep for cheap. You will also get a discount on shipping on your first order. Upload your Gerber files onto PCBWAY to get them manufactured with good quality and quick turnaround time. PCBWay now could provide a complete product solution, from design to enclosure production. Check out their online Gerber viewer function. With reward points, you can get free stuff from their gift shop. Also, check out this useful blog on PCBWay Plugin for KiCad from here. Using this plugin, you can directly order PCBs in just one click after completing your design in KiCad. Let's start with hardware the setup Connect the ultra-sonic sensor to your ESP device using the breadboard and jumper wires. The wiring diagram is shown below: Connect VCC to 5V and GND to Gnd and Trigger to pin 0 and ECHO to pin 1. Home Assistant Setup Next, navigate to the Home Assistant and open the ESPHome. Next, select one of your ESP devices or create a new one. In this case I'm going to use my existing device. Open the yaml file and add these following. sensor: - platform: ultrasonic trigger_pin: 0 echo_pin: 1 name: "Ultrasonic Sensor" update_interval: 2s Then next, click install. and choose your prefer method. I'm going to use wirelessly. Because my device is already connected with my network. Wait until it finishes the upload. Then navigate to the device property and here you can see the Sensor measurement. Next, add the measurement to the dashboard. Conclusion In this blog, I have shown you how to integrate an ultra-sonic sensor with ESPHome in home assistant. This is a simple and effective way to use an ultra-sonic sensor in your smart home projects. You can also use other types of sensors and components with ESPHome and home assistant and create your own custom firmware and integrations. I hope you found this blog helpful and informative. If you have any questions or feedback, please leave a comment below. Thank you for reading!1 point -

I ordered a LYG55T024FS52S motor (https://www.hurst-motors.com/lyg55geared.html), but I misread the information about the capacitor. I thought it said capacitor was supplied with the motor, but that was only for the 115 VAC motors. Since I ordered the 24V, mine did not come with a capacitor. So I’m looking to buy one. The spec sheet says I need a 20/15 mfd 50/60 Hz capacitor. This is the closest I’ve found: http://www.mcmaster.com/7245K721/ Will that work for this purpose?1 point

-

Integrating DHT11 with Beetle ESP32 C3 and Home Assistant

JamesMVictoria reacted to CETECH for a topic

This project will allow you to monitor environmental conditions in your home automation setup. Here are the steps to achieve this: Integrating DHT11 with Beetle ESP32 C3 and Home Assistant 1. Components Required Before we begin, gather the necessary components: BeetleESP32C3 development board DHT11 temperature and humidity sensor Jumper wires USB cable for programming A computer with the Arduino IDE or ESPHome installed Get PCBs for Your Projects Manufactured You must check out PCBWAY for ordering PCBs online for cheap! You get 10 good-quality PCBs manufactured and shipped to your doorstep for cheap. You will also get a discount on shipping on your first order. Upload your Gerber files onto PCBWAY to get them manufactured with good quality and quick turnaround time. PCBWay now could provide a complete product solution, from design to enclosure production. Check out their online Gerber viewer function. With reward points, you can get free stuff from their gift shop. Also, check out this useful blog on PCBWay Plugin for KiCad from here. Using this plugin, you can directly order PCBs in just one click after completing your design in KiCad. 2. Flashing ESPHome to Beetle ESP32 C3 Install ESPHome on your computer. You can follow the instructions in my previous blog. Create an ESPHome configuration file (e.g., dht11.yaml) with the following content: sensor: - platform: dht pin: 0 model: dht11 temperature: name: "Living Room Temperature" humidity: name: "Living Room Humidity" update_interval: 5 s Replace placeholders (YourWiFiSSID, YourWiFiPassword, etc.) with your actual values. Compile and upload the configuration to your Beetle ESP32 C3 using the ESPHome CLI. 3. Integrating with Home Assistant Open Home Assistant. Click on Configuration (bottom left) and go to Integrations. Click the + button and select ESPHome. Enter the IP address of your ESP32 (leave the port as 6053) and click Finish. 4. Viewing Temperature and Humidity Once integrated, Home Assistant will discover the Beetle ESP32 C3 module and create entities for temperature and humidity. You can access these entities in Home Assistant’s dashboard and display them as cards or graphs. And that’s it! You’ve successfully integrated the DHT11 sensor with your Beetle ESP32 C3 and Home Assistant. Feel free to customize and expand this project based on your needs. Happy monitoring! 🌡️💧🏠1 point -

How to Support Virtual Network on Linux 4.1.15?

BreanneJJustice reacted to Forlinx for a topic

Taking the FETMX6ULL-C platform as an example, if you want to use VPN, you need to open the tun configuration in the kernel in the following way: Kernel Compilation Choose either of the two methods below: 1. Modify the.config file directly Locate the.config file in the kernel source path. Find the CONFIG _ TUN in the file and modify it as follows: Replace the kernel's config file with .config. * Subject to actual use. Recompile the kernel. 2. Configure the TUN using the graphical configuration interface Make menuconfig. Locate the following locations: Save and exit after modification, which can be seen in.config Replace the kernel's config file with .config. * Subject to actual use. Recompile the kernel. Update kernel: The arch/arm/boot/zImage file is generated after compilation, and the kernel can be replaced either by updating the kernel separately or by re-burning it. Use this file to replace the file with the same name in the target path of the flashing tool. Refer to the single-step kernel update chapter of the FETmx6ull-c User's Manual to replace the zImage file separately. Compilation module: In the kernel source code, some of the drivers are compiled in the form of modules, which are loaded from the specified path by the kernel version number when the system boots. When we recompile the kernel and update the kernel, the kernel version number in the system will be changed, the kernel version number can be viewed through the uname -r command. When you update the kernel, the uname -r version number changes, but the version number in the path where the module is stored (/lib/modules/) does not change. It may cause the module to fail to load, typically after updating the kernel, WiFi cannot be used. As seen below, the name under uanme -r and the name under /lib/modules/ are not the same, so you can't load the module when you go to the/lib/modules/$(uname -r) directory when booting up, and you need to change both names to be the same. You can solve this problem in two ways: 1. Modify the module load path and change to the version number of the kernel; 2. Repackage modules; The first method has two disadvantages: a. Not suitable for batch modification; b. Not suitable for changing the module driver; So it is possible to repackage the module when compiling the kernel: After executing the above operation, .tmp/root/modules.tar.bz2 will be generated, which can replace the file with the same name under the target path in the flashing tool. It is also extracted directly in the file system:1 point -

seven segment display 0,28 inch with 6 pins only / programming etc.

KieranBlackburn reacted to HarryA for a topic

https://search.yahoo.com/search?p=2381BG-2-6&fr=opensearch1 point -

W25Q32JV FUNCTIONAL DESCRIPTIONS

Veswin reacted to Blunt Viscardi for a topic

W25Q32 refers to a specific model of serial flash memory produced by Winbond Electronics Corporation. In particular, the "W25Q32" is part of the W25Q series, which consists of a range of flash memory chips differing in capacity and features. Standard SPI Instructions: The W25Q32JV is accessed through an SPI-compatible bus consisting of four signals: Serial Clock (CLK), Chip Select (/CS), Serial Data Input (DI), and Serial Data Output (DO). Standard SPI instructions use the DI input pin to serially write instructions, addresses, or data to the device on the rising edge of CLK. The DO output pin reads data or status from the device on the falling edge of CLK. SPI bus operation Mode 0 (0,0) and 3 (1,1) are supported. The primary difference between Mode 0 and Mode 3 concerns the normal state of the CLK signal when the SPI bus master is on standby and data is not being transferred to the Serial Flash. For Mode 0, the CLK signal is typically low on the falling and rising edges of /CS. For Mode 3, the CLK signal is usually high on the falling and rising edges of /CS. Dual SPI Instructions: The W25Q32JV supports Dual SPI operation when using instructions such as "Fast Read Dual Output (3Bh)" and "Fast Read Dual I/O (BBh)". These instructions allow data to be transferred to or from the device at two to three times the rate of ordinary Serial Flash devices. The Dual SPI Read instructions are ideal for quickly downloading code to RAM upon power-up (code-shadowing) or for executing non-speed-critical code directly from the SPI bus (XIP). When using Dual SPI instructions, the DI and DO pins become bidirectional I/O pins: IO0 and IO1.1 point -

Except by doing physical projects, how can I make learning digital electronics fun?

Maria Erick reacted to HarryA for a topic

Why not read books that interest you? For example:: Digital Design and Computer Architecture1 point -

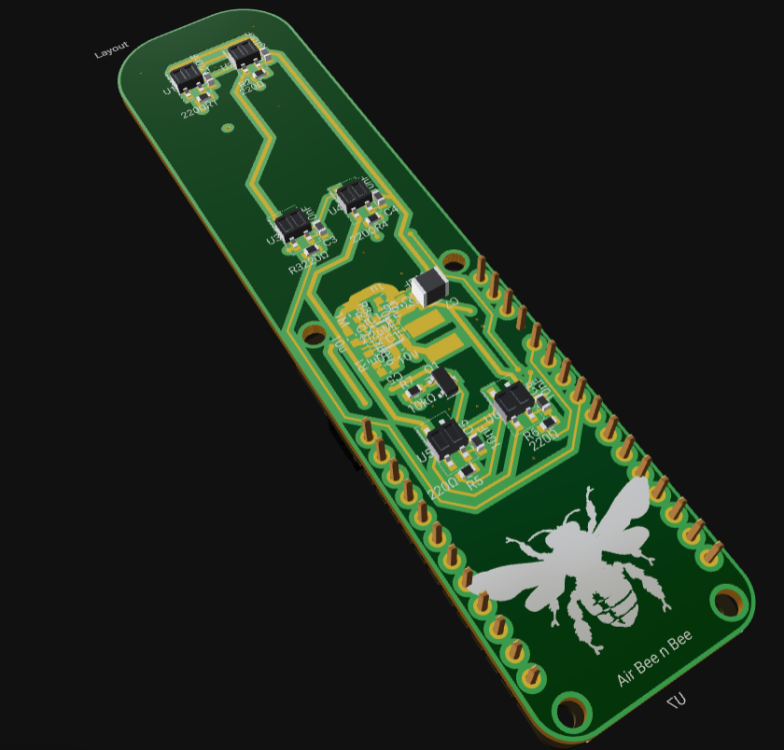

Solar-powered Bee Hotel w/ Particle Argon (ongoing project)

Jolin He reacted to Pete Ballotta for a topic

One of my teammates is working on an open Hardware Project that I thought to share. The product they’re developing is a bee hotel for native bees (not honeybees)! At the SF Climate hackathon, they integrated the Particle Argon onto a PCB with solar panels, MPPC, and a PWM PIR sensor for the bees. Here’s the link to the schematics, layout and 3D. I'll add a 3D screenshot at the bottom of the post. "A little bit of background, a native bee hotel houses sedentary bees which lay their eggs in tube structures, like hollow plant stems. We want to use PIR sensors along the tubes to get bee traffic data and build a country-wide bee traffic map. Solar Cells I’ve bumped into the IXYS KXOB25 series before and loved them for their reflowability. I wanted to connect them in parallel so the only constraint was that their output voltage is less than 5V, which is the maximum input voltage of the energy harvesting IC. Energy Harvesting I chose the LTC3105EDD 15 because I’ve seen it used to maximize solar cell power output in some nanosatellite projects I’ve browsed in the past. Although it doesn’t have an actual MPPT algorithm, it has a very attractive 250mV startup voltage which can potentially increase the times of day our device will provide power (dawn, dusk, cloud cover). All this needs real world testing which is coming next week. PIR Sensors These are paired infrared transmitters and receivers. As seen in the 3D view, we’re using 2 of them per bee tube to determine which direction the bees are going (in or out of the tube). Of course, this would need to be done in firmware. To save power (because these PIR diodes are super power hungry, we added a low side MOSFET that switches all three strings of PIR diodes (they are strung in series to get 1.1V drive from a 3.3V source). In theory, we can decrease the PWM duty cycle to as low as the PIR’s rise time and set the frequency to 1Hz which would save so much power. Future Steps Here are the unknowns that we’ll be researching. I already see some good answers in the forums, but please feel free to chime in! I’ve played with Edge Impulse in the past and we want to run a small tflite model on particle hardware that would determine what type of bee is in the hotel based on a short audio sample. We also want to send this data to a central server hosted by particle; in your experience how many weeks/months would it take to setup particle cloud to get up to 100 provisioned devices sending about 50 bytes of data to a central server? It would be awesome if we can get that done quickly."1 point -

What’up, community! Join us in this exciting journey of pushing the boundaries of technology and discovering new possibilities with Wio-WM1110 projects now! Discover more about Wio-WM1110 Module and Seeed Fusion PCBA Service The appealing new product, Seeed Studio Wio-WM1110, is the ultimate wireless module for developing low-power consumption, long-range IoT applications. Embedded with Semtech LR1110 and Nordic nRF52840, this module features Semtech’s LoRa technology for long-range wireless communication, GNSS tracking, Wi-Fi, and Bluetooth services while reducing complexity and cost. Additionally, don’t miss the magnificent function for asset tracking, inventory management, asset loss, and theft prevention. It is perfect for smart agriculture, wireless meter reading, and smart city applications. Wio-WM1110 module has been applied to SenseCAP S2120 8-in-1 LoRaWAN Weather Sensor and is widely used in smart agriculture, urban weather, etc. By capturing critical metrics such as air temperature, humidity, wind speed and direction, rainfall intensity, light intensity, UV index, and barometric pressure data and transmitting them via LoRaWAN®, the weather sensor enables you to access hyper-local weather information with ease. We are ready to illuminate and spread your ideas coupled with projects anytime! As an advocate for technology innovation and creativity, Seeed is thrilled to extend its support to the hardware community worldwide through the sponsorship of Wio-WM1110 projects. With Seeed Fusion PCB Assembly Service, everyone can explore their ideas and bring them to fruition without the hassle of sourcing and assembling components. If you have an interesting concept for Wio-WM1110 and are willing to share it with the community, share it with us and we can help you make it a reality with Seeed Fusion’s one-stop agile manufacturing capabilities. Get 2 boards fabricated and assembled completely free with Seeed Fusion’s turnkey PCB Assembly service. Meanwhile, if you have mass production requirements, we highly recommend taking advantage of the Seeed Fusion PCB Assembly service and getting the Wio-WM1110 modules. Find out more discounts below! Wio-WM1110 has been added to Seeed Open Parts Library, available for just USD$14.9! What does that mean? Like all PCBA OPL components, these parts are available for use with the Seeed Fusion PCB Assembly service at a lower price, but more importantly, these parts are stocked locally, so if all parts are sourced from the OPLs, then super fast PCB assembly can be realized from as little as 7 working days. Based on one part per PCBA. Until further notice. Can’t wait to apply? Then keep reading to discover more exciting details. One Step Closer to Wio-WM1110: Please fill out the form: click here to submit your bravo project ideas. Each person is limited to two PCBA boards 100% completely FREE for one design, including PCB fabrication, the cost of parts, assembly and shipping. The design must include Wio-WM1110. When preparing the BOM file, just add the Seeed SKU 114992865 or the part number Wio-WM1110 to your BOM file. Add the order to the cart then contact our customer support ([email protected]) to obtain the corresponding cash coupon for settlement. By participating in this event, you agree to review your experience with us and allow us to share it and the design with the community on our social media platforms (Facebook, Twitter, blog, etc.). The design does not need to be open-sourced and production files will not be shared with the public (unless you want to). We hope your experience will go on to inspire more users to embrace IoT, LoRaWAN® and its capabilities. Scale up your Wio-WM1110 Creation with Seeed Studio Co-Create Program! We will invite well-received Wio-WM1110 projects to the Seeed Studio Co-Create Program, where your products can be listed, sold and shipped directly by Seeed on the Seeed Studio Bazaar. We will also support designers to reach thousands of like-minded customers and distributors with Seeed’s global sales channels and social media presence. Don’t hesitate! It’s a great chance to show off your ideas and skills. Join forces with the Wio-WM1110 and fuel your passion for IoT1 point

-

LED Fader Using 555 Timer IC

Ashish Adhikari reacted to bidrohini for a topic

You did a lot of hard work I must say. For this type of fading effect, I always use Arduino or AVR microcontroller. It is very easy to do this with the PWM pins of the Arduino. But making the project this much compact and without programming really needs good skills. Good work.1 point -

Please help to determine which silk screen is genuine

Marie P Cox reacted to HarryA for a topic

First off one can not read the text on the second IC. They claim fake ICs come in two types; those that are commercial grade and sold as military grade. And those that are used from discarded equipment. The latter type may well have the correct text on them. I gather they do not manufacture fake ICs as they are too inexpensive to be bothered with.1 point -

Transformers PCB BADGE

Ashish Adhikari reacted to Satyadeo Vyas for a topic

Hi Ashish, Nicely explained ... I love reading your article1 point -

the USB tester

NieveHopkins reacted to bidrohini for a topic

You can take a look at the Klein Tools VDV512-101 Cable Tester.1 point -

Rechargeable D Cell Batteries And Silver Wire Making Ring

Satyadeo Vyas reacted to chanbuz for a topic

In this article, we survey d cell battery all Rechargeable D Cell Batteries is ideal and dependable. All battery execution is so acceptable on the grounds that we research all battery then we check all subtleties. At that point we recorded all data. We as of now compose the Longest Lasting D Batteries Reviews article you would first be able to check it. I trust this Rechargeable D Cell Batteries survey article is extremely useful for you. On the off chance that you need to know more updates you can follow our site since we audit the very best items and all innovation refreshes. For more info visit Chan Buz Silver wire for article making sterling Rings is helpful for you Sterling Silver Wire for Ring Making I hope you can find all the information about this. Some people like to make a ring using silver wire. In this article, we give you all information on the price of silver wire making rings and the best products. So first you can read our silver wire review article. Sterling silver wire 20 gauge is the best product of our listed items. First, we go to Amazon then we get all the information on this product then we list our notes Sterling Silver Wire for Ring Making. Then we begin reviewing our website. All our visitors already know that we review all the best and popular long lasting products.1 point -

Looks very interesting. I have a small PCBa company in the States. Assembling about 2000 board / month and an inspection service like this will really help me out. I just emailed your asking for the TEST account credentials. Thanks for the post.1 point

-

I use copper wire, not rice wire. They put rice in everything they make, especially batteries.1 point