Leaderboard

Popular Content

Showing content with the highest reputation since 07/27/2015 in all areas

-

0-30V 0-3A Latest Data

AsSa and 3 others reacted to repairman2be for a topic

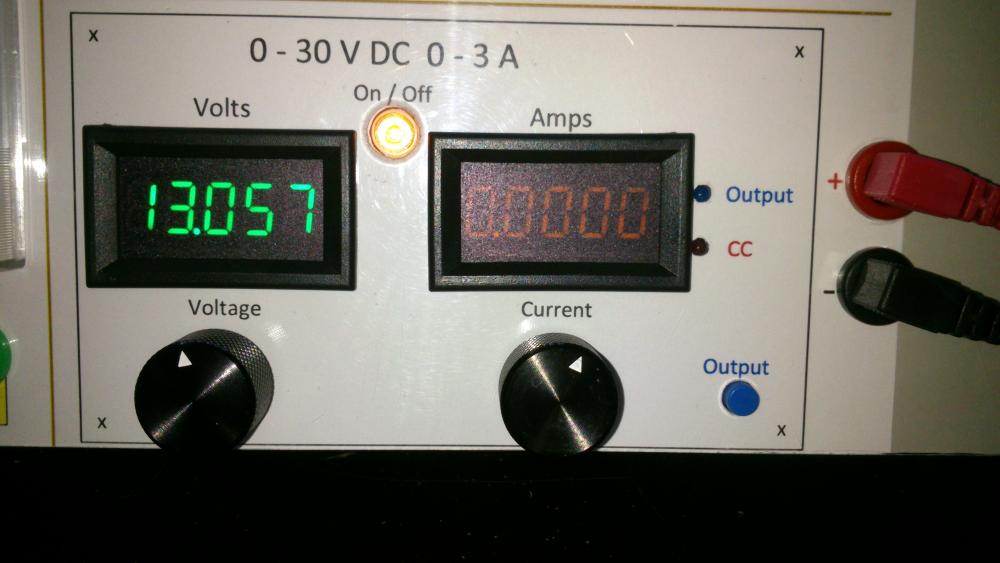

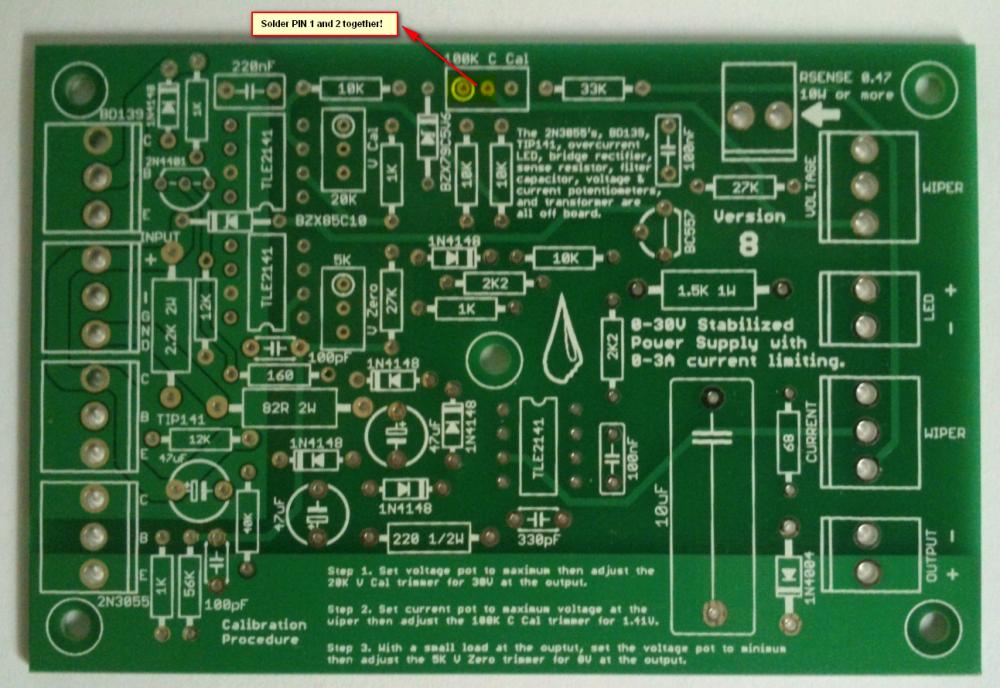

Hi all, Finally after some months have gone by, my build of the Power Supply is done. I have used liquibyte schematic Rev. 8 and had made the cirquit board according to the Gerber.zip file he posted here: 0-30V Stabilized Power Supply Page 88 posted October 6, 2014 "http://electronics-lab.com/community/index.php?/topic/29563-0-30v-stabilized-power-supply/&page=88" I left out D10 and R15 as per his description. I have plenty of boards leftover if someone has a need for it. There was only one mistake liquibyte made which have outlined in one of the pictures uploaded here. I was fortunate enough to get a big case with a Toroidal transformer from the scrapyard. Also many parts are recycled from various sources. Regards, William4 points -

Finally, my post with the Eagle .sch and .brd, full gerbers, and parts list for Digikey in a zip file. I'm also including many of the pics I took as I was building that were posted both before and after this post. I'm still not completely done and may add more pics later. One thing I have changed is the third transformer for the auxiliary circuitry for the temperature sensor and fans and the displays (I wanted a better transformer than the Radio Shack special I had on hand). Archive attached. 30V.zip3 points

-

Solar-powered Bee Hotel w/ Particle Argon (ongoing project)

Jolin He and one other reacted to JamesMVictoria for a topic

Nice one, I like it.2 points -

How to easily turn on/off all debug message on Arduino IDE

SharonWatkins and one other reacted to MrNams for a topic

But even if we disable debug, it will call print method and do not print anything. I mean we should make it something like #ifdef DEBUG Serial.print("\n debug controlled print"); #endif Here when we disable macro, its like code is not written for compiler, code will be removed in macro processing itself.2 points -

H Bridge PWM DC Motor Driver + PCB

senaka ranathunga and one other reacted to sam.moshiri for a topic

An H-Bridge (Full-Bridge) driver is quite popular in driving loads such as brushed DC motors and it is widely used in robotics and industry. The main advantages of using an H-Bridge driver are: high efficiency, rotation direction change, and braking the motor. In this article/video, I have introduced a complete H-Bridge DC motor driver using four IR3205 power MOSFETs and two IR2104 MOSFET drivers. Theoretically, the above-mentioned MOSFET can handle currents up to 80A, however, in practice we can expect to get currents up to 40A if the MOSFET temperature is kept as low as possible, using a big heatsink or even a fan. References Article: https://www.pcbway.com/blog/technology/Powerful_H_Bridge_DC_Motor_Driver.html [1]: IRF3205 Datasheet: http://www.irf.com/product-info/datasheets/data/irf3205.pdf [2]: IR2104 Datasheet: https://www.infineon.com/dgdl/Infineon-IR2104-DS-v01_00-EN.pdf?fileId=5546d462533600a4015355c7c1c31671 [3]: 1N5819 Datasheet: https://www.diodes.com/assets/Datasheets/ds23001.pdf [4]: IR2104 Schematic Symbol, PCB Footprint, 3D Model: https://componentsearchengine.com/part-view/IR2104PBF/Infineon [5]: IRF3205 Schematic Symbol, PCB Footprint, 3D Model: https://componentsearchengine.com/part-view/IRF3205ZPBF/Infineon [6]: CAD Plugins: https://www.samacsys.com/library-loader-help2 points -

Non Contact Hand Sanitizer Dispenser, Easy, Cheap, No Arduino!

sam.moshiri and one other reacted to admin for a topic

Thanks for sharing your project with us. Could you give more details on the control board?2 points -

The original circuit should work fine up to 15V at 1A if you replace the old opamps with the newer higher voltage ones. You probably should recalculate the resistors that set the maximum voltage and current outputs. If the Chinese kit uses the transistor that shorts the opamp output when the power is turned off then the resistors that feed the transistor need to be recalculated for the reduced voltage. I have used perforated stripboard for many projects including very complicated ones. The copper strips are cut to length with a drill-bit and become almost half the wiring of a pcb. The parts and a few short jumper wires become the remainder of the wiring. Only one wire is in each hole so changing a part is easy like on a pcb.2 points

-

Hi, as promised I made an English translation of my working. Maybe there is few mistakes and I am sorry for that ! Good reading. ExplicationEN.pdf2 points

-

I use copper wire, not rice wire. They put rice in everything they make, especially batteries.2 points

-

0-30 Vdc Stabilized Power Supply

electron234 and one other reacted to elctro123 for a topic

So Finally which version of schematic is correct / flawless to build the PSU ?2 points -

February 23 above on this page has the latest schematic of the revised 3A lab power supply.2 points

-

Does anyone has LM3914 pspice library? i desperately need it..pleeeeease!2 points

-

Low power solenoid?

AmelieScott and one other gave a reaction for a topic

I want to apply force for an extended amount of time (10 secs to a couple minutes) using a solenoid actuator. Unfortunately, it seems that solenoids use a lot of power when they are active. Is there a solenoid type that will only use power when switching between active and not active? There's probably a way I can do this with an external mechanism, but I was wondering if there may be commercial solenoids that have this built-in. Thanks, Jessica2 points -

Illegal content (ebook/magazines/software) will be deleted without any notice. Thanks2 points

-

Overload Protector A16 ???

joeydennis11 and one other reacted to tjolle62 for a topic

In a few circuit diagrams i have they refer to a what seems to me is a transistor with B C E as a overload protector and with number A16 and i have looked for a few hours on the net and i can't find anything on this little fellow, Anyone knows what I'm looking for and wanna share that info Please .... Come on !! 48 visits !! some one must know what it is !!! PNP is it also...........2 points -

Overload Protector A16 ???

joeydennis11 and one other reacted to tjolle62 for a topic

At last i got a theori from a totally different place and he wasn't shure either but he had a weak memory that it could be 1A16 and a PNP transistor but after several deep searches on the I-net it didn't make any kind of senses whatsoever ???2 points -

Car battery to parallel port

tracythomas50 and one other reacted to MP for a topic

When you use your resistive divider to drop the voltage down to 5 volts, you just need to select values of resistors to limit the current. This is basic ohm's law. V/R. Was this your question or did I misunderstand? I am not sure how you intend to monitor status by using one 5 volt pin. As an interface to the parallel port, you could use an LM3914. This would give you the resolution you need. There are also many other ways to proceed. You need to convert from analog to digital to read anything useful from the parallel port. MP2 points -

Car battery to parallel port

tracythomas50 and one other reacted to Omni for a topic

Hi TJBraza, http://www.analog.com/UploadedFiles/Data_Sheets/ADT7485A.pdf Although, it will probably require a small program written in C or Visual basic to convert the string MSB & LSB into a more easier read etc... Take a moment and review the data sheet, the IC has a lot of potential.2 points -

SL100 & SK100 transistor

AmelieScott and one other reacted to alanng96 for a topic

I can't find SL100 & SK100 transistor :'( Which transistors can replace these? Thank you for your help~ ;)2 points -

Calm down people. It is not Mixos's fault, if it is against the law he has to remove the content. This site is very good for asking electronic related questions, I have yet to find a better one.2 points

-

I ordered a LYG55T024FS52S motor (https://www.hurst-motors.com/lyg55geared.html), but I misread the information about the capacitor. I thought it said capacitor was supplied with the motor, but that was only for the 115 VAC motors. Since I ordered the 24V, mine did not come with a capacitor. So I’m looking to buy one. The spec sheet says I need a 20/15 mfd 50/60 Hz capacitor. This is the closest I’ve found: http://www.mcmaster.com/7245K721/ Will that work for this purpose?1 point

-

seven segment display 0,28 inch with 6 pins only / programming etc.

KieranBlackburn reacted to HarryA for a topic

https://search.yahoo.com/search?p=2381BG-2-6&fr=opensearch1 point -

W25Q32JV FUNCTIONAL DESCRIPTIONS

Veswin reacted to Blunt Viscardi for a topic

W25Q32 refers to a specific model of serial flash memory produced by Winbond Electronics Corporation. In particular, the "W25Q32" is part of the W25Q series, which consists of a range of flash memory chips differing in capacity and features. Standard SPI Instructions: The W25Q32JV is accessed through an SPI-compatible bus consisting of four signals: Serial Clock (CLK), Chip Select (/CS), Serial Data Input (DI), and Serial Data Output (DO). Standard SPI instructions use the DI input pin to serially write instructions, addresses, or data to the device on the rising edge of CLK. The DO output pin reads data or status from the device on the falling edge of CLK. SPI bus operation Mode 0 (0,0) and 3 (1,1) are supported. The primary difference between Mode 0 and Mode 3 concerns the normal state of the CLK signal when the SPI bus master is on standby and data is not being transferred to the Serial Flash. For Mode 0, the CLK signal is typically low on the falling and rising edges of /CS. For Mode 3, the CLK signal is usually high on the falling and rising edges of /CS. Dual SPI Instructions: The W25Q32JV supports Dual SPI operation when using instructions such as "Fast Read Dual Output (3Bh)" and "Fast Read Dual I/O (BBh)". These instructions allow data to be transferred to or from the device at two to three times the rate of ordinary Serial Flash devices. The Dual SPI Read instructions are ideal for quickly downloading code to RAM upon power-up (code-shadowing) or for executing non-speed-critical code directly from the SPI bus (XIP). When using Dual SPI instructions, the DI and DO pins become bidirectional I/O pins: IO0 and IO1.1 point -

Except by doing physical projects, how can I make learning digital electronics fun?

Maria Erick reacted to HarryA for a topic

Why not read books that interest you? For example:: Digital Design and Computer Architecture1 point -

BGA rework Process?

Moises Campos reacted to HarryA for a topic

Is Rolling Meadows, IL 60008 near you? see: https://www.solder.net/training-courses/bga-rework-training/ See for low key diy rework: https://www.instructables.com/BGA-rework/1 point -

Need help in project development

Varun Flores reacted to Nancesar for a topic

Hi friends. I'm still quite new to this business, but now I'm writing a project that will allow real-time temperature monitoring. So far, this is at a theoretical stage and needs your advice and experience. I'm using a MLT028Q40-5 TFT display with a controller through the driver and it works great. I need help with data to import from an NTC temperature sensor.1 point -

If it is a 120 volt Cuisinart blender then you can get one here: They ship world wide. Else search for "1 uf 250vac capacitor" https://www.ebay.com/itm/281873849657 That is a horrible url !1 point

-

Transistor Substitute.

Zaldy Macayan reacted to HarryA for a topic

see: https://www.nteinc.com/semiconductors/ComplPr.php They list matched complementary pairs that maybe helpful like the NTE128/NTE129 at 80 volts and 1 ampere. And many others as well.1 point -

If the transformer is rated at 24VAC/2A then it provides a maximum power of 24V x 2A= 48VA. But if the output is 30V at 2.0A then the load uses 30V x 2A= 60VA plus heating power. The peak of 24VAC is 40V which feeds the bridge rectifier which charges the main filter capacitor to the peak voltage minus the rectifier forward voltage. So then the transformer must produce 40V at 2.0A= 80VA which is much more than the overloaded 48VA. 80VA/24V= 3.33A, not 2A. For a regulated output of 30.0VDC at 3A then I recommended using a transformer rated at 28VAC/4.3A. For an output current of 3A then you must look at how much heat is produced by the single output transistor which is why I recommended using two output transistors to share the heat. Edited with strike-throughs.1 point

-

0-30 Vdc Stabilized Power Supply

Catalin Ghercoias reacted to detonatorinf for a topic

Hahahaha. I promise i will make a better one.1 point -

DIY - SOLAR BATTERY CHARGER

davidjackson reacted to Ashish Adhikari for a topic

Hi Everyone, In this tutorial I am going to show you how to charge a Lithium 18650 Cell using TP4056 chip utilizing the solar energy or simply the SUN. Wouldn’t it be really cool if you can charge your mobile phones battery using the sun instead of a USB charger. You can also use this project as a DIY portable power bank. The total cost of this project excluding the battery is just under $5. The battery will addup another $4 to $5 bucks. So the total cost of the project is some what around $10. All components are available on my website for sale for really good price, the link is in the description below. Step 1: Hardware Requirement For this project we need: - A 5v Solar Cell (make sure it is 5v and not anything less than that) - A general purpose circuit board - A 1N4007 High Voltage, High Current Rated Diode (for reverse voltage protection). This diode is rated at forward current of 1A with peak reverse voltage rating of 1000V. - Copper Wire - 2x PCB Screw Terminal Blocks - A 18650 Battery Holder - A 3.7V 18650 Battery - A TP4056 battery protection board (with or without the protection IC) - A 5 V power booster - Some connecting cables - and general soldering equipments Step 2: How the TP4056 Work Looking at this board we can see that it has the TP4056 chip along with few other components of our interest. There are two LEDs on board one red and one blue. The red one comes on when it is charging and the blue one comes on when the charging is done. Then there is this mini USB connector to charge the battery from an external USB charger. There are also these two points where you can solder your own charging unit. These points are marked as IN- and IN+ We will be utilizing these two point to power this board. The battery will be connected to these two point marked as BAT+ and BAT- (pretty mush self explanatory) The board requires an input voltage of 4.5 to 5.5v to charge the battery There are two versions of this board available in the market. One with battery discharge protection module and one without it. Both boards offer 1A charging current and then cut off when finished. Furthermore, the one with protection switches the load off when the battery voltage drops below 2.4V to protect the cell from running at too low (such as on a cloudy day) - and also protects against over-voltage and reverse polarity connection (it will usually destroy itself instead of the battery) however please check you have it connected correctly the first time. Step 3: Copper Legs These boards gets really hot so I will be soldering them a bit above the circuit board. To achieve this I am going to use a hard copper wire to make legs of the circuit board. I will then be sliding the unit on the legs and will solder them all together. I will put 4 copper wires to make 4 legs of this circuit board. You can also use - Male Breakable Pin Headers instead of the copper wire to achieve this. Step 4: Assembly The assembly is very simple. The solar cell is connected to the TP4056 battery charging board's IN+ and IN- respectively. A diode is inserted at the positive end for the reverse voltage protection. Then the BAT+ and BAT- of the board is connected to the +ve and -ve ends of the battery. (That all we need for charging the battery). Now to power an Arduino board we need to boost up the output to 5v. So, we are adding a 5v voltage booster to this circuit. Connect the -ve end of the battery to the IN- of the booster and +ve to IN+ by adding a switch in between. OK, now lets have a look at what I have made. - I have connected the booster board straight to the charger however I will recommend putting a SPDT switch there. So when the device is charging the battery its only charging and not getting used Solar cells are connected to the input of the lithium battery charger (TP4056), whose output is connected to the 18560 lithium battery. A 5V step-up voltage booster is also connected to the battery and is used to convert from 3.7V dc to 5V dc. Charging voltage is typically around 4.2V. Voltage booster's input ranges from 0.9 to 5.0V. So it will see around 3.7V at it's input when the battery is discharging, and 4.2V when it's recharging. The output of the booster to the rest of the circuit will keep it's 5V value. Step 5: Testing This project will be very helpful to power a remote data logger. As we know, the power supply is always a problem for a remote logger and most of the times there is no power outlet available. A situation like that forces you to use some batteries to power your circuit. But eventually, the battery will die. Question is do you want to go there and charge the battery? Our inexpensive solar charger project will be an excellent solution for a situation like this to power an Arduino board. This project can also solve the efficiency issue of Arduino when in sleep. Sleep saves battery, however, the sensors and power regulators (7805) will still consume battery in idle mode draining the battery. By charging the battery as we use it, we can solve our problem. Thanks again for watching this video! I hope it helps you. If you want to support me, you can subscribe to my channel and watch my other videos. Thanks, ca again in my next video. TP4056.pdf1 point -

New Proteus Libraries for Engineering Students

PalGreen reacted to CarlWilson for a topic

Thanks for the resources!!! I am currently working on the project "Electronic circuits of information collection and processing systems". The topic is very interesting, since I need to investigate the development of the linearizer of the first sensor with smooth and piecewise-linear approximation. It is also necessary to determine the value of the DC component extraction device from the signal of the second sensor. In addition to your recommended resources, I also used the writingcheap.com service, which helped me with the theoretical part of my work of developing an analog-to-digital converter. Using the information of this site http://www.analog.com/en/products/analog-to-digital-converters.html I was able to summarize the results of my research. You have an extremely helpful channel for students on YouTube. You have an extremely helpful channel for students on YouTube.1 point -

Looking for someone to design a small board for me!

PhillipGok reacted to abid369 for a topic

I am a regular PCB designer. Check my designs specimens. If you have such inqyiry in future then e-mail me at [email protected] or call on +923214322695 Sample Designs.zip1 point -

0-30V 0-3A Latest Data

Prithul reacted to repairman2be for a topic

Hi Prithul, I believe the answer you are looking for is here: "http://electronics-lab.com/community/index.php?/topic/29563-0-30v-stabilized-power-supply/&page=84" audioguru: Post August 31, 2014 A bit more was mentioned on page 87 Please open a new thread if you want to find out more, as this thread is for completed projects. Thanks1 point -

PCB manufactureres

rrp0727 reacted to Soldertraining for a topic

PCB Manufacturer uses: Front-end tool data preparation, Preparing the photo tools, Print inner layers, Etch inner layers, Register punch and Automatic Optical Inspection (AOI), Lay-up and bond, Drilling the PCB, Electroless copper deposition, Image the outer layers, Plating, Apply solder mask, Silk-screen and cure.1 point -

A modern day 0 - 30V, 0 - 3A Linear Power Supply?

electron234 reacted to audioguru for a topic

The ebay kit that is a copy of the original faulty Greek power supply on this site is also sold by Banggood and Amazon. Banggood is selling it at a clearance price since they probably had many complaints. They have modified it a little and are selling it again as a kit with a 28V/2A rating and an LCD meter for it. The very nice looking 30V/10A power supply is extremely cheap. Its ad has no detailed spec's. It does not even say if the voltage and current are regulated. If something looks to be too good then it probably is not true.1 point -

Need help with a project

sam g fire reacted to jknightandkarr for a topic

I am trying to make this KITT's dash compass andi have the leds and using a microcontroller to power them but need help on how to wire them so i use the least amount of conponents possable. I thought of darlington transistor ic's but on the 4 10 led bargraph onesi think both anode n cathode will need darlington transistors. 4 1 for either common cathode or anode and 10 more for the other lead for make the patterns. I might be able to use 1 darlington transistor ic to make the yellow triangle leds work using just 4 i/o pins, but i think i need 14 for the red bargraps whats the best way to wire the bargraph leds up? Thanks. Joe1 point -

0-30V 0-3A Latest Data

ile113 reacted to monkfinger for a topic

Hi all Ok, this is my end result. Built and tested and works quite well. I started with the version posted at the start of this thread. However I had a couple of problems with the current limiter. I didn't have much success with the current limiter clamping the input of U2 - sometimes it would not go right down to 0V, sometimes it would go just below. Just below was a big problem for me - U2 would start to oscillate, with bad consequences for anything connected to the output of the Q4... It would then drive the output high just when I wanted the current limit to become active I should add that I did not use TL2141 or MC34071s, this might be the root of my problem. I fixed this issue with a small change to circuit layout rather than going to expensive opamps. My mods (compared to the circuit posted on start of this thread): * current limit - I removed D9. To replace this, I added another BC548 - the base is driven by the current flowing through the current limit LED. The collector of this BC548 clamps the output of U2 (exactly like the existing BC548 driven by the negative rail). This arrangement means we don't care how close to its supply voltage the output of U3 can go. It avoids the possibility of driving the input of U2 out of spec. Clamping the output of U2 is much more like how the integrated voltage regulators work. It seems better to my mind, to keep U2 out of the loop when current limit is active. [Edit: note that U2 will need a small heatsink with this arrangement] * some rearrangement of the opamp power connections, for all three opamps... U1 & U3 are run via 15V zener diodes, to give a supply of approx 30V. That allows almost any cheap opamp to be used for U1 & U3 (741s or TL071 etc). U2 is connected to unregulated 44V and to the output side of the 0R47. * I used a MC33171 opamp for U2. It is high voltage, but much cheaper (they are £0.60 in UK) than TL2141 or MC34071 (both are £5 here). It is a low power IC by comparison. * 0-30V 4A transformer. * 2 x 6800uF smoothing caps.a big thanks to the contributors on this thread for their efforts, my project was greatly speeded up by borrowing a lot of their ideas Edit: * I also changed the 0R47 to 0R2, as the 0R47 generated too much heat at 3A for my liking. This also means R18 changes to 330K. These two values are not shown on the schematic here.1 point -

An Ultrasonic Cleaner--Schematic

FranceRouze reacted to GOKAR for a topic

Looking for an Ultrasonic Cleaner schematic. Gokar1 point -

About 53 years ago the CD4046A was introduced but it had many problems. It was replaced a few years later by the improved CD4046B and MC4046B and HEF4046B. Your CD4046A must be one of the very old ones with problems. Look on the datasheets of an A and of a B to see the differences.1 point

-

LM3914 pspice library

joeydennis11 reacted to admin for a topic

Here are two SPICE models found online that will simulate the main IC functions including:- a) bar/dot mode selection, dot mode carry for cascaded ICs, c) resistor-programmed hi/lo reference voltages, d) output current selection, e) non-grounded V- and divider ladder, f) independent V+ and Vled, g) leakage current of outputs, h) segment overlap and i) supply current variation with V+ and Vref output load. This model is build by user "alec_t" at electro-tech-online.com forum. LM3914.zip LM3914asc.zip1 point -

Nobody makes an LA4058. You got the numbers mixed up, the schematic shows a Sanyo LA4508. Your 13.6V transformer must feed the rectifiers on the Power Part of the schematic. Maybe you fed the transformer wrongly to the amplifier instead of to the rectifiers? Then probably many parts are destroyed. Your 13.6V transformer will produce a peak of 19.2V and the rectifiers reduce it to +17.2V. With a 17V supply the LA4508 produces about 6W at clipping into 4 ohms per channel. Who told you 100W? It has fairly high distortion at low and high frequencies and it cuts frequencies above only 5kHz. Your amplifier probably uses one LA4508 for left woofer and left tweeter and the second LA4508 is probably used for right woofer and right tweeter.1 point

-

Hi all, I am looking for a circuit that operates in 9-12 DC and will generate voltage in 2-3KV range with negiligible current. I came across many designs but interested if anyone knows any circuit that uses common step down transformer with primary and secondary reversed as the first step in conversion.I am planning to use Cockcroft–Walton multiplier to increase the voltage from transformer. Flyback transformers are difficult to find /not familar for me to use.But would defenitely consider if its readily available I came across this circuit and like to know if something similar can be tried with a step down transformer http://www.aaroncake.net/circuits/flampdrv.asp If anyone know any schematic with small flyback transformers I would be glad to try.I am only concerened about availability. The whole purpose is to make a negative ion generator to clean dust from my vinyls. I donot want to use the ones based on Pizo electric but somehing that will generate a massive negative ion flow that will neutralize all sticky dust on my LPs .The prime consideration is making it as small as possible.1 point

-

1 point

-

c828 transistor

joeydennis11 reacted to audioguru for a topic

It is probably an Oriental 2SC828 transistor. Go to www.datasheetarchive.com to see its spec's and to see substitution guides.1 point -

High Voltage low amperage

HaddyS reacted to Kevin Weddle for a topic

A transformer will deliver a high enough voltage that you want. High voltage transformers are expensive, but can usually be found in electronics products no longer used, and be cascaded for high voltgage. Be aware that high voltage burns and shock can occur, and a high enough voltage can lay you in the hospital.1 point -

Possibly a flyback converter? They can usually be output current limited by limiting the current availiable to the transformer. Do you need it to be highly efficient or are you not too fussed?1 point

-

diy 2.1 pc speaker

FranceRouze reacted to audioguru for a topic

The TDA2003 does not bridge well because the output offset voltage are not matched for the two amplifiers like a monolithic bridged amplifier IC. But you might be lucky so try it. With a 14.4V supply the bridged output at clipping into 4 ohms is 14 watts. If your speakers are 8 ohms then the power is 8 Watts. If the supply voltage is less than 14.4V then the power is less. You should make an active crossover circuit.1 point -

Hi all, I'm new here. I have just assembled a FM Micromitter (Miniature FM transmitter). http://www.siliconchip.com.au/cms/A_102010/article.html Construction went well with very few re soldered points (put a couple of things in the wrong way round, but hey I'm learning). When I went to do the testing and adjustment it says that I should be reading 5v between TP GND and pin 8 of IC1 but I only get a reading of 2.5v. Can anyone tell me why this might be and what the consequences of this might be. It DOES transmitt (I am currently transmitting on 88.9) but I loose the signal after approx 8M from the antenna. Is this related to my drop it voltage measured against what it should be? Should I trim my antenna to a specific length? Any comments or suggestions would be much appreciated. Regards David ???1 point