0-30 Vdc Stabilized Power Supply with Current Control 0.002-3 A

- 1.023.699 Views

- medium

- Tested

Copyright of this circuit belongs to smart kit electronics. In this page we will use this circuit to discuss for improvements and we will introduce some changes based on original schematic.

General Description

This is a high quality power supply with a continuously variable stabilised output adjustable at any value between 0 and 30VDC. The circuit also incorporates an electronic output current limiter that effectively controls the output current from a few milliamperes (2 mA) to the maximum output of three amperes that the circuit can deliver. This feature makes this power supply indispensable in the experimenters laboratory as it is possible to limit the current to the typical maximum that a circuit under test may require, and power it up then, without any fear that it may be damaged if something goes wrong. There is also a visual indication that the current limiter is in operation so that you can see at a glance that your circuit is exceeding or not its preset limits.

Technical Specifications

- Input Voltage: ……………. 24 VAC

- Input Current: ……………. 3 A (max)

- Output Voltage: …………. 0-30 V adjustable

- Output Current: …………. 2 mA-3 A adjustable

- Output Voltage Ripple: …. 0.01 % maximum

- PCB dimensions: 123 x 85 mm

Features

- Reduced dimensions, easy construction, simple operation.

- Output voltage easily adjustable.

- Output current limiting with visual indication.

- Complete protection of the supplied device against over loads and malfunction.

How it Works

To start with, there is a step-down mains transformer with a secondary winding rated at 24 V/3 A, which is connected across the input points of the circuit at pins 1 & 2. (the quality of the supplies output will be directly proportional to the quality of the transformer). The AC voltage of the transformers secondary winding is rectified by the bridge formed by the four diodes D1-D4. The DC voltage taken across the output of the bridge is smoothed by the filter formed by the reservoir capacitor C1 and the resistor R1. The circuit incorporates some unique features which make it quite different from other power supplies of its class. Instead of using a variable feedback arrangement to control the output voltage, our circuit uses a constant gain amplifier to provide the reference voltage necessary for its stable operation. The reference voltage is generated at the output of U1.

The circuit operates as follows: The diode D8 is a 5.6 V zener, which here operates at its zero temperature coefficient current. The voltage in the output of U1 gradually increases till the diode D8 is turned on. When this happens the circuit stabilises and the Zener reference voltage (5.6 V) appears across the resistor R5. The current which flows through the non inverting input of the op-amp is negligible, therefore the same current flows through R5 and R6, and as the two resistors have the same value the voltage across the two of them in series will be exactly twice the voltage across each one. Thus the voltage present at the output of the op-amp (pin 6 of U1) is 11.2 V, twice the zeners reference voltage. The integrated circuit U2 has a constant amplification factor of approximately 3 X, according to the formula A=(R11+R12)/R11, and raises the 11.2 V reference voltage to approximately 33 V. The trimmer RV1 and the resistor R10 are used for the adjustment of the output voltages limits so that it can be reduced to 0 V, despite any value tolerances of the other components in the circuit.

Another very important feature of the circuit, is the possibility to preset the maximum output current which can be drawn from the p.s.u., effectively converting it from a constant voltage source to a constant current one. To make this possible the circuit detects the voltage drop across a resistor (R7) which is connected in series with the load. The IC responsible for this function of the circuit is U3. The inverting input of U3 is biased at 0 V via R21. At the same time the non inverting input of the same IC can be adjusted to any voltage by means of P2.

Let us assume that for a given output of several volts, P2 is set so that the input of the IC is kept at 1 V. If the load is increased the output voltage will be kept constant by the voltage amplifier section of the circuit and the presence of R7 in series with the output will have a negligible effect because of its low value and because of its location outside the feedback loop of the voltage control circuit. While the load is kept constant and the output voltage is not changed the circuit is stable. If the load is increased so that the voltage drop across R7 is greater than 1 V, IC3 is forced into action and the circuit is shifted into the constant current mode. The output of U3 is coupled to the non inverting input of U2 by D9. U2 is responsible for the voltage control and as U3 is coupled to its input the latter can effectively override its function. What happens is that the voltage across R7 is monitored and is not allowed to increase above the preset value (1 V in our example) by reducing the output voltage of the circuit.

This is in effect a means of maintaining the output current constant and is so accurate that it is possible to preset the current limit to as low as 2 mA. The capacitor C8 is there to increase the stability of the circuit. Q3 is used to drive the LED whenever the current limiter is activated in order to provide a visual indication of the limiters operation. In order to make it possible for U2 to control the output voltage down to 0 V, it is necessary to provide a negative supply rail and this is done by means of the circuit around C2 & C3. The same negative supply is also used for U3. As U1 is working under fixed conditions it can be run from the unregulated positive supply rail and the earth.

The negative supply rail is produced by a simple voltage pump circuit which is stabilised by means of R3 and D7. In order to avoid uncontrolled situations at shut-down there is a protection circuit built around Q1. As soon as the negative supply rail collapses Q1 removes all drive to the output stage. This in effect brings the output voltage to zero as soon as the AC is removed protecting the circuit and the appliances connected to its output. During normal operation Q1 is kept off by means of R14 but when the negative supply rail collapses the transistor is turned on and brings the output of U2 low. The IC has internal protection and can not be damaged because of this effective short circuiting of its output. It is a great advantage in experimental work to be able to kill the output of a power supply without having to wait for the capacitors to discharge and there is also an added protection because the output of many stabilised power supplies tends to rise instantaneously at switch off with disastrous results.

Construction

First of all let us consider a few basics in building electronic circuits on a printed circuit board. The board is made of a thin insulating material clad with a thin layer of conductive copper that is shaped in such a way as to form the necessary conductors between the various components of the circuit. The use of a properly designed printed circuit board is very desirable as it speeds construction up considerably and reduces the possibility of making errors. To protect the board during storage from oxidation and assure it gets to you in perfect condition the copper is tinned during manufacturing and covered with a special varnish that protects it from getting oxidised and also makes soldering easier.

Soldering the components to the board is the only way to build your circuit and from the way you do it depends greatly your success or failure. This work is not very difficult and if you stick to a few rules you should have no problems. The soldering iron that you use must be light and its power should not exceed the 25 Watts. The tip should be fine and must be kept clean at all times. For this purpose come very handy specially made sponges that are kept wet and from time to time you can wipe the hot tip on them to remove all the residues that tend to accumulate on it.

DO NOT file or sandpaper a dirty or worn out tip. If the tip cannot be cleaned, replace it. There are many different types of solder in the market and you should choose a good quality one that contains the necessary flux in its core, to assure a perfect joint every time.

DO NOT use soldering flux apart from that which is already included in your solder. Too much flux can cause many problems and is one of the main causes of circuit malfunction. If nevertheless you have to use extra flux, as it is the case when you have to tin copper wires, clean it very thoroughly after you finish your work.

In order to solder a component correctly you should do the following:

- Clean the component leads with a small piece of emery paper.

- Bend them at the correct distance from the components body and insert he component in its place on the board.

- You may find sometimes a component with heavier gauge leads than usual, that are too thick to enter in the holes of the p.c. board. In this case use a mini drill to enlarge the holes slightly. Do not make the holes too large as this is going to make soldering difficult afterwards.

- Take the hot iron and place its tip on the component lead while holding the end of the solder wire at the point where the lead emerges from the board. The iron tip must touch the lead slightly above the p.c. board.

- When the solder starts to melt and flow wait till it covers evenly the area around the hole and the flux boils and gets out from underneath the solder.

- The whole operation should not take more than 5 seconds. Remove the iron and allow the solder to cool naturally without blowing on it or moving the component. If everything was done properly the surface of the joint must have a bright metallic finish and its edges should be smoothly ended on the component lead and the board track. If the solder looks dull, cracked, or has the shape of a blob then you have made a dry joint and you should remove the solder (with a pump, or a solder wick) and redo it. Take care not to overheat the tracks as it is very easy to lift them from the board and break them.

- When you are soldering a sensitive component it is good practice to hold the lead from the component side of the board with a pair of long-nose pliers to divert any heat that could possibly damage the component.

- Make sure that you do not use more solder than it is necessary as you are running the risk of short-circuiting adjacent tracks on the board, especially if they are very close together.

- When you finish your work, cut off the excess of the component leads and clean the board thoroughly with a suitable solvent to remove all flux residues that may still remain on it.

Construction (… continued)

As it is recommended start working by identifying the components and separating them in groups. Place first of all the sockets for the ICs and the pins for the external connections and solder them in their places. Continue with the resistors. Remember to mound R7 at a certain distance from the printed circuit board as it tends to become quite hot, especially when the circuit is supplying heavy currents, and this could possibly damage the board. It is also advisable to mount R1 at a certain distance from the surface of the PCB as well. Continue with the capacitors observing the polarity of the electrolytic and finally solder in place the diodes and the transistors taking care not to overheat them and being at the same time very careful to align them correctly.

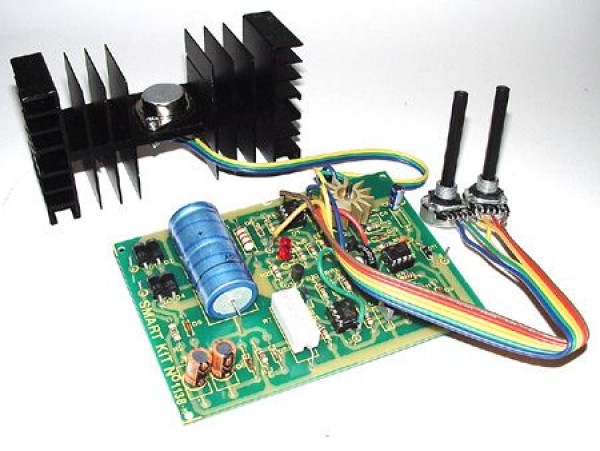

Mount the power transistor on the heatsink. To do this follow the diagram and remember to use the mica insulator between the transistor body and the heatsink and the special fibber washers to insulate the screws from the heatsink. Remember to place the soldering tag on one of the screws from the side of the transistor body, this is going to be used as the collector lead of the transistor. Use a little amount of Heat Transfer Compound between the transistor and the heatsink to ensure the maximum transfer of heat between them, and tighten the screws as far as they will go.

Attach a piece of insulated wire to each lead taking care to make very good joints as the current that flows in this part of the circuit is quite heavy, especially between the emitter and the collector of the transistor.

It is convenient to know where you are going to place every thing inside the case that is going to accommodate your power supply, in order to calculate the length of the wires to use between the PCB and the potentiometers, the power transistor and for the input and output connections to the circuit. (It does not really matter if the wires are longer but it makes a much neater project if the wires are trimmed at exactly the length necessary).

Connect the potentiometers, the LED and the power transistor and attach two pairs of leads for the input and output connections. Make sure that you follow the circuit diagram very care fully for these connections as there are 15 external connections to the circuit in total and if you make a mistake it may be very difficult to find it afterwards. It is a good idea to use cables of different colours in order to make trouble shooting easier.

The external connections are:

- 1 & 2 AC input, the secondary of the transformer.

- 3 (+) & 4 (-) DC output.

- 5, 10 & 12 to P1.

- 6, 11 & 13 to P2.

- 7 (E), 8 (B), 9 (E) to the power transistor Q4.

- The LED should also be placed on the front panel of the case where it is always visible but the pins where it is connected at are not numbered.

When all the external connections have been finished make a very careful inspection of the board and clean it to remove soldering flux residues. Make sure that there are no bridges that may short circuit adjacent tracks and if everything seems to be all right connect the input of the circuit with the secondary of a suitable mains transformer. Connect a voltmeter across the output of the circuit and the primary of the transformer to the mains.

The voltmeter should measure a voltage between 0 and 30 VDC depending on the setting of P1, and should follow any changes of this setting to indicate that the variable voltage control is working properly. Turning P2 counter-clockwise should turn the LED on, indicating that the current limiter is in operation.

Data

Adjustments

If you want the output of your supply to be adjustable between 0 and 30 V you should adjust RV1 to make sure that when P1 is at its minimum setting the output of the supply is exactly 0 V. As it is not possible to measure very small values with a conventional panel meter it is better to use a digital meter for this adjustment, and to set it at a very low scale to increase its sensitivity.

Warning

While using electrical parts, handle power supply and equipment with great care, following safety standards as described by international specs and regulations.

CAUTION

This circuit works off the mains and there are 220 VAC present in some of its parts.

Voltages above 50 V are DANGEROUS and could even be LETHAL.

In order to avoid accidents that could be fatal to you or members of your family please observe the following rules:

- DO NOT work if you are tired or in a hurry, double check every thing before connecting your circuit to the mains and be ready

- to disconnect it if something looks wrong.

- DO NOT touch any part of the circuit when it is under power.

- DO NOT leave mains leads exposed. All mains leads should be well insulated.

- DO NOT change the fuses with others of higher rating or replace them with wire or aluminium foil.

- DO NOT work with wet hands.

- If you are wearing a chain, necklace or anything that may be hanging and touch an exposed part of the circuit BE CAREFUL.

- ALWAYS use a proper mains lead with the correct plug and earth your circuit properly.

- If the case of your project is made of metal make sure that it is properly earthen.

- If it is possible use a mains transformer with a 1:1 ratio to isolate your circuit from the mains.

- When you are testing a circuit that works off the mains wear shoes with rubber soles, stand on dry non conductive floor and keep one hand in your pocket or behind your back.

- If you take all the above precautions you are reducing the risks you are taking to a minimum and this way you are protecting yourself and those around you.

- A carefully built and well insulated device does not constitute any danger for its user.

If it does not work

Check your work for possible dry joints, bridges across adjacent tracks or soldering flux residues that usually cause problems.

Check again all the external connections to and from the circuit to see if there is a mistake there.

- See that there are no components missing or inserted in the wrong places.

- Make sure that all the polarised components have been soldered the right way round. – Make sure the supply has the correct voltage and is connected the right way round to your circuit.

- Check your project for faulty or damaged components.

Parts List

| Part | Value | Note |

|---|---|---|

| R1 | 2.2 kΩ | 1W |

| R2 | 82 Ω | 1/4W |

| R3 | 220 Ω | 1/4W |

| R4 | 4.7 kΩ | 1/4W |

| R5-R6-R13-R20-R21 | 10 kΩ | 1/4W |

| R7 | 0.47 Ω | 5W |

| R8-R11 | 27 kΩ | 1/4W |

| R9-R19 | 2.2 kΩ | 1/4W |

| R10 | 270 kΩ | 1/4W |

| R12-R18 | 56kΩ | 1/4W |

| R14 | 1.5 kΩ | 1/4W |

| R15-R16 | 1 kΩ | 1/4W |

| R17 | 33 Ω | 1/4W |

| R22 | 3.9 kΩ | 1/4W |

| RV1 | 100 kΩ | trimmer |

| P1-P2 | 10 kΩ | linear pontesiometer |

| C1 | 3300 uF/50V | electrolytic |

| C2-C3 | 47uF/50V | electrolytic |

| C4 | 100nF | polyester |

| C5 | 200nF | polyester |

| C6 | 100pF | ceramic |

| C7 | 10uF/50V | electrolytic |

| C8 | 330pF | ceramic |

| C9 | 100pF | ceramic |

| D1-D2-D3-D4 | 1N5402-3-4 | 2A diode - RAX GI837U |

| D5-D6 | 1N4148 | - |

| D7-D8 | 5.6V | Zener |

| D9-D10 | 1N4148 | - |

| D11 | 1N4001 | diode 1A |

| Q1 | BC548 | NPN transistor or BC547 |

| Q2 | 2N2219 | NPN transistor |

| Q3 | BC557 | PNP transistor or BC327 |

| Q4 | 2N3055 | NPN power transistor |

| U1-U2-U3 | TL081 | operational amplifier |

| D12 | LED diode | - |

Feedback

Another implementation of this power supply is located here – in Czech language

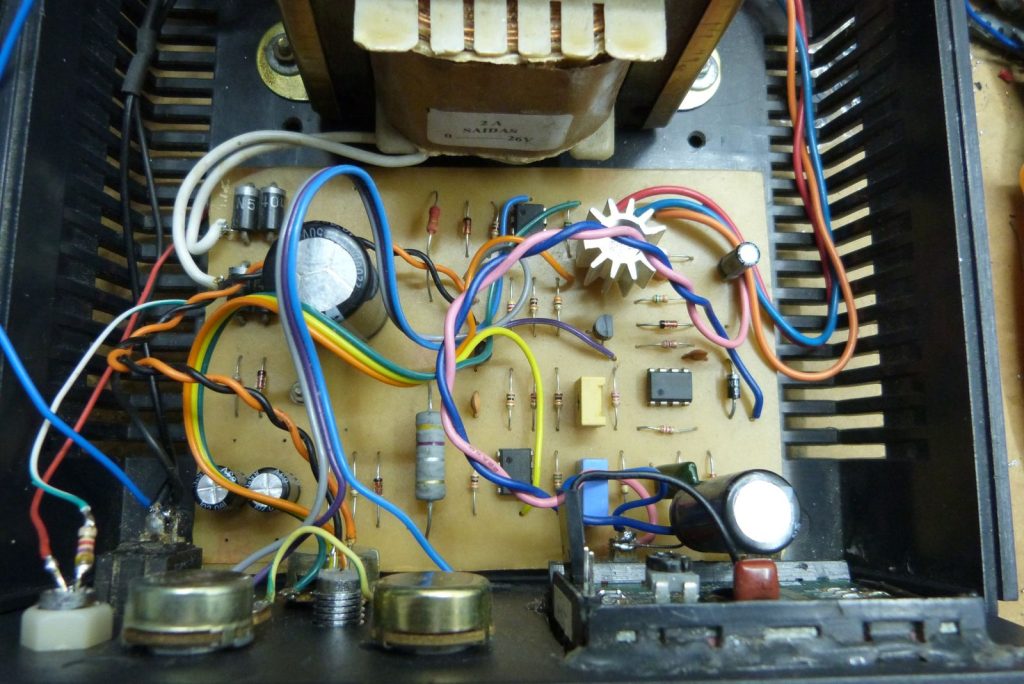

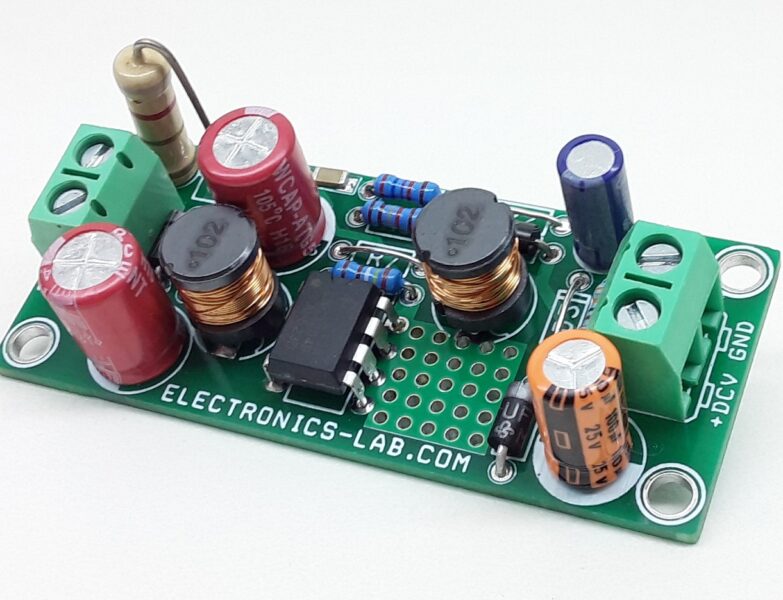

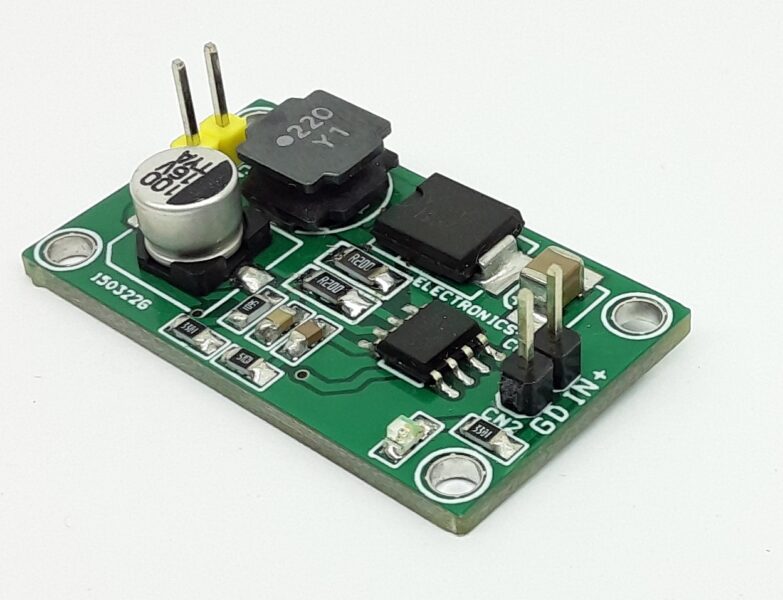

here is a board made by Sam Carmel and worked nice

Daniel’s build of PSU – front view with LCD voltmeter

Potensiometers for coarse and fine voltage adjustment and current regulator

Daniel’s build of PSU – internal view. A mobile phone charger is used as power supply for voltmeter

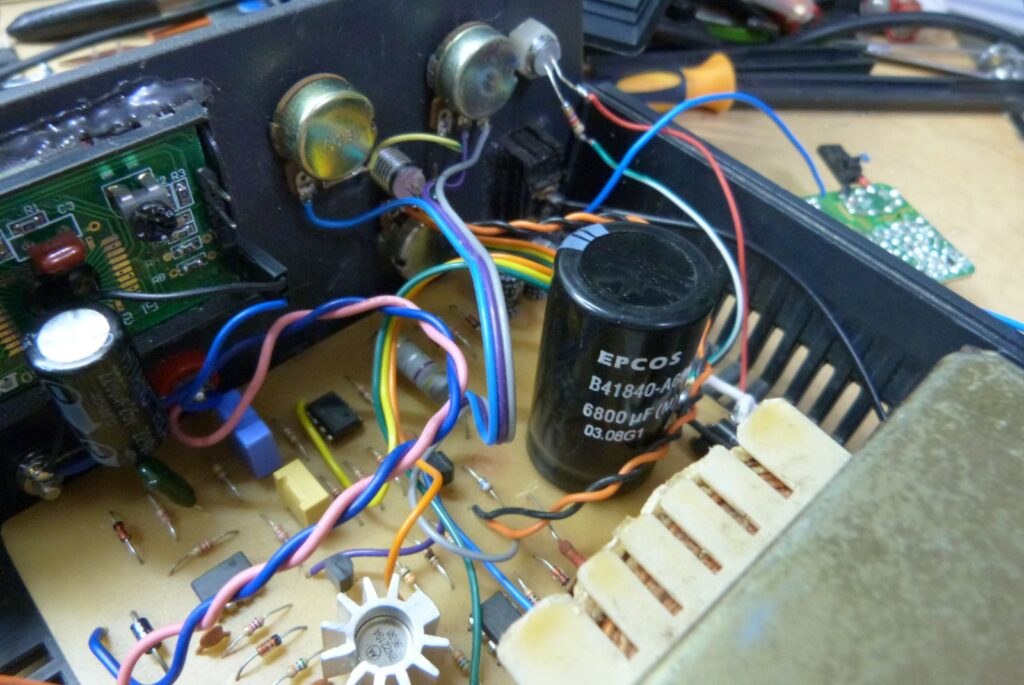

Daniel’s build of PSU – internal view. He is going to change 2200uF a 6800uF capacitor to reduce ripple in high load.

Daniel’s build of PSU – internal view. new capacitor (6800uF x 40V) to improve ripple filtering

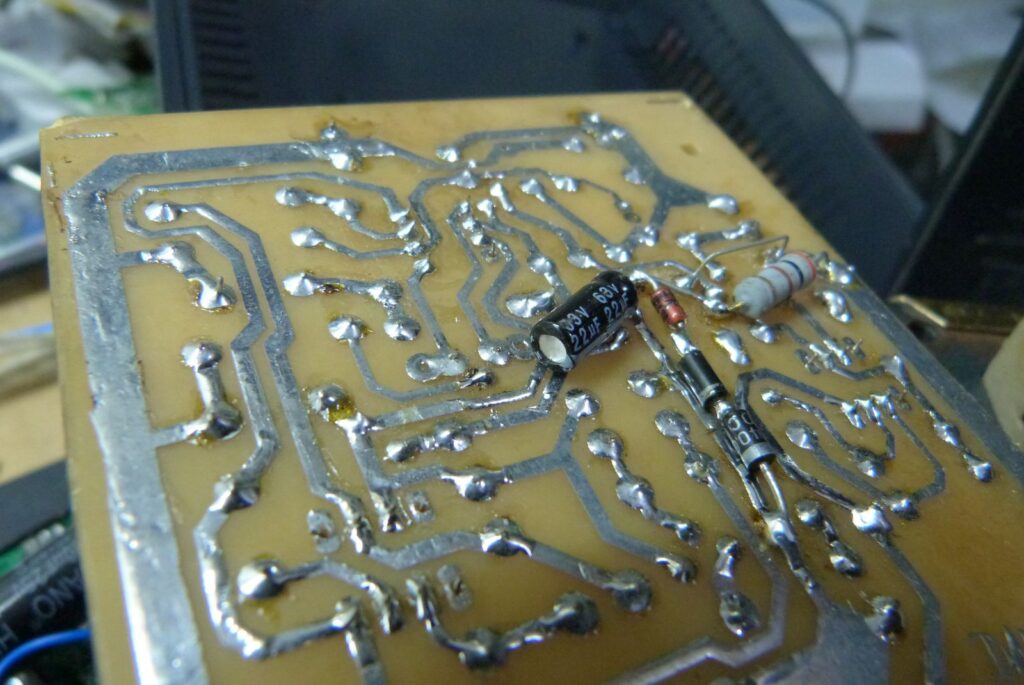

Daniel’s build of PSU – internal view. Modification to protect the LM311

Received the following email from Daniel on 06/2012:

I only face a problem with one of the biggest plagues in electronics now… Fake components. I bougth a fake 2N2219 and it last 100ms (or less) in my first try. As the piece was new I never suspected on it. I spent 2 hours looking for the problem and I could not believe when I test it… I had more two I bougth togeter, they had the same destiny… For my lucky I had a box with old components (some dates from the 70´s) and there I found a genuine Motorola 2N2219… This is running perfect. This was the only difficulty I found…

Received the following email from Ivan on 02/2010:

Ok. I bulid your project about a day ago. Mounted all the parts on the pcb and then concluded that there is some serious problems in this schematics. First, 2N3055 will overheat, so you have to connect two of them in parallel with emitter resistors 0.1ohm/5w. Second, maximal voltage between ‘+’ and ‘-‘ of TL081 is 36VDC.If you connect them as it is shown in this circuit diagram that voltage will be about 45VDC, so they will burn down immediately. To fix this problem you have to reconnect all pins number 7 of U1, U2 and U3, emitter of Q3 and ‘upper’ end of R19 to out of an 7809 with 18V zener diode between ‘common’ pin and ‘-‘ of 3300uF cap, and input of 7809 connect to ‘+’ of the same cap. Now, on pin number 7 and mentioned parts you’ll have 27VDC, and total voltage will be 32.6VDC. Third, instead of using 3300uF, use 4700 or 6800uF/63VDC to reduce the ripple on higher currents (2-3A). The rest of the circuit is perfect. I like it cause it is so inexpensive and easy to make with those simple reconstructions i mentioned.

Are there any ready made pcb’s with no components mounted, available for this project ?

You a slightly modified version of this power supply as a kit from Banggood for about 10 bucks. The project code is SKU179821.

iwant 0to30v 500ma to 5amp shortcircuit protection pcb or assamble bord send price 9980977928

yes, here -> http://www.banggood.com/pt/0-30V-2mA-3A-Adjustable-DC-Regulated-Power-Supply-DIY-Kit-p-958308.html

Yes a ready made PCB with components is available at ali express in cheap price . please search with same name of this article on ali express.

Yes, here I used this scheme

http://got.by/1hwxr3

Here is my ready power supply

but unfortunately in Russian

I did it .but it didn’t work

I tried to know the reason but no way

Maybe the reason from me

Did any body built this and were functional ?

Hi Mohammed,

I have been using this excellent power supply that I constructed since 1982. more than 30 years! It works well. You need to be an experienced electronic constructor for this circuit due to the polarities of diodes and zener diodes, transistors etc. What is the result when you switch your unit on? Descrivbe the problem, maybe I can assist. Do you have a electronic background?

Sir thanks for asking the problems of this 0-30v 3Amp China made power supply PCB.

Excellent design but It does not work. I used D 1047, BC557, BD137 and BC548 as the package includes. Initially it showed me 24V out put when the V pot turned fully clock wise. Un expectedly the fan regulator got S.C. and I replaced it Still I cant find the fault. When testing initially I used a 24V 2 Amp transformer. When I used a 24 V 3Amp transformer the whit led keeps lit but no output.

Suvindra

find out for fake components,if not check with individual block like rectifier,filter and regulator stages

Sir Required power supply kit 0-30 v 5AMP send price

sir you can contact me on my email will help you atulghatage@gmail.com

Thanks for finally writing abkut >0-30 VDC

Stabgilized Power Supply with Crrent Control

0.002-3 A – Electronics-Lab <Loved it!

What is the purpose of the 18V zener proposed by Ivan ? The 18V zener seems to have no effect.

An 18 volt zener in the ground leg of the 7809 raises the output voltage to 27 volts regulated.

Ivan’s proposal burned the 7809. It regulates it for a while until it eventually burns up and melts its own pins off.

can i use a 24v dc as a input to have current and voltage control

The circuit must be connected to 24V alternating current power, and direct current is forbidden.

i was not thinking clear and tried testing it with a dc psu..

which components might be damaged from this unfortunate mistake? im getting my input voltage out on my output and the same voltage on the output of all the opamps.. the voltage on the negative rail is .8 volts.. nothing happens when i turn my pots.. i tried changing all the 081’s no difference

You MUST have -5v on the negative rail. It’s mandatory for this schem.

Hi there,

What’s the software you used in designing this board??

WHERE SHOULD RV1 BE CONNECTED IN (PIN NOS.) U2

connect to pin 1 and pin 5 ( offset pins )

I see that the transformer used in the picture is labeled 24V 3A and that the design is for a 3A capability to the load. Has this arrangement ever been tested for full 3A output at 30Vdc?? It’s been my experience (many years) that a good rule of thumb for transformers is that under rated load the rectified and filtered voltage will be about the same as the transformer specs. That is, the dc output from a full wave rectifier and filter will be 24vdc with a 3A load when using a 24V 3A transformer. It seems to me that a transformer with a higher current rating must be used in order to achieve 30Vdc at 3A. After all, the supplied voltage must always be higher than 30Vdc if one wants 30Vdc out.

tnx

please tell me.

What IC can I use for voltage regulator

Which voltage regulator do you mean?

Can I get calculation for this project?

Hi. I built this power supply. I have a problem. To bring the voltage to zero, increase to the maximum value (40V). That may be happening?

I also build and finish this project but when power is on the voltages is stay at 34v and all controls are not function P1, P2 even the VR1 is disable. can you please help me any suggestion for this is appreciated.

recheck Q2 = 2N2219 NPN transistor position. confirm emmiter to 2n3055 base.

Hey can i ask you if you find a solution for this problem because i have the same error.

please can you send how to make stabilized power supply Variable from 220v 24V & 5V + 7A in Output

What is the pcb size?

8,5 cm x 12 cm

Please tell me what the printing size of pcb.

8,5 cm x 12 cm

Brother if i download the above image file of the pcb and resize it to 8.5cm x 12cm would it work for me??? Quality is nice you’ve put a nice project on internet.

Sure, try it by fitting an ic to it’s socket.

Can we use a 3 A bridge rectifier instead of D1, D2, D3, D4 ? plz reply ?

Sure, just remove the diodes and make sure you connect the bridge rectifier the correct way.

yes bro you can use 3A bridge rectifier

Can this circuit be modified to generate 0 to -30VDC? Do you have a recommended circuit to generate negative voltage?0 to -VDC.

Charge pump? Thanks

Branch it in reverse and you have -30 V

What if I wanted to add an LED indicator for when the circuit enters constant voltage? Where can I put the LED? Thanks

How does this circuit compare with others that use the LM2596 chip? I’ve seen designs with voltage and current limiting, like this one. For example, with three potentiometers: http://m.aliexpress.com/item/1841588052.html

Hi

I have power supply 24 volt /5 amp and I want to make current control circuit 0:5 amp for it.

Can you help me to do it

How does this circuit compare with others that use the LM2596 chip? I’ve seen designs with voltage and current limiting, like this one. For example, with three potentiometers: http://m.aliexpress.com/item/1841588052.html

hi there, i’d like to know what is the correct and final schematic of this power supply once the corrections have been made! thanks a lot

I did everything an my setup does not working.

Current limitter is working perfectly, but voltage limiter from P1 not working, voltage stay the same no matter of P1 position except when is at minimum, when voltage drop at 0 V

got it working, forgot to make circuit between C9 an pin 2 of U2 😉

hey it works properly?

Can i get the Calculations

HI i made the above supply and i got an output around 25V but My potentiometers dont seem to work at all. I can neither vary current nor the voltage. Can anyone suggest me a possible problem,,,….with my circuit.

dosent work it was awful

There are reports that this power supply works. I suggest you to follow the PCB design and not the schematic itself. Please also check all your connections and parts placement.

to who it may concern this design is all over ebay just a few changes made transistor and layout

With the TL081 OPs the circuit will not work reliably with a transformer of more than about 20 V. The maximum voltage will be somewhere near 24 V then. For getting 30 V, one needs an OP that can withstand a higher supply. At 3 A current chances are the output transistor will blow up – check the SOA diagram of the Transistor and use some derating for not so perfect cooling. So the 3 A might be OK with a 15 V transformer.

Could you provide the pcb layout for above circuit?

I’m from philippines and there is no available 2n2219 in my country. what is your suggested replacement part for 2n2219? pls. replay. thank you

BD139 works well

D 882

Hy,

If anyone would like just the pcb to be built please contact me I can do it for you.

I am interested in PCB Specify price

We are sorry, we don’t sell PCBs, but you can find a kit of this power supply on ebay.

Yes i would like a PCB to be made let me know its cost and courier charges and time required

We are sorry, we don’t sell PCBs of this project, but you can find them on Alixepress.

If I want to limit the maximum current to 1A or 2A – how can I do this?

My concern is that with 30V and 3A – if the output is short circuited, 90 Watt will put into Q4 – that requires a massive heatsink…

To limit the current you have to set P2 to a lower value, so that the current limiting circuitry triggers at 1A or 2A

Choose a 30V 1A transformer. If shorted it can only deliver 30W for dissipation at Q4.

You will need to experiment with the values of R17, R18, P2, to ensure that P2 cannot command more than 1Amp which would cause the transformer to overheat.

Hy .

Bought two kits from Aliexpress one works well ! !

The second raises not go 12 volts. . .

A help please. .

I found fixes the problem. .

27 KOhm 27O KOhm Placing WRONG. .

how could you hope to have 30v Dc from 24v dc with a linear regulator? magic?

you’lose some volt because the rectifier, because the transistor Q4 etc

i don’t need your answer :p

Bravo, Ivan, Lurchi & Don

The comments are right, that is a seriously overhyped output.

Doubling the 2N3055 and using a 7809 or similar to get 27V to run the OPs is a great idea. However, U2 will then not be able to drive the OP stage much higher than about 18V or so under max current conditions.

I think with the right caps (2x6800uF or so) on a 0-30V 3A transformer, plus a different (i.e. expensive) choice of opamp [run from GND to the unregulated supply of about 44V] that can drive output close to those rails, it could actually do 30V @ 3A.

I did wonder about drive for the pass transisters if doubling up. However two transistors would only be sharing the current to assist in heat dissipation. Then I would expect lower base current for each transistor. So when ‘n’ma is needed for one transister then each of a pair would need ‘n/2’ma each so no change. I will breadboard this first before cutting metal.

yeah, however, Ivan’s email for adding 7809 just melts its own legs off. Is there any way to share the load even more (besides doubling 7809)?

I want solution for overheating U3 …….plz help me

hi ILESH could you find a solution yet i also have the same problem

I have the same problem did you find any solution