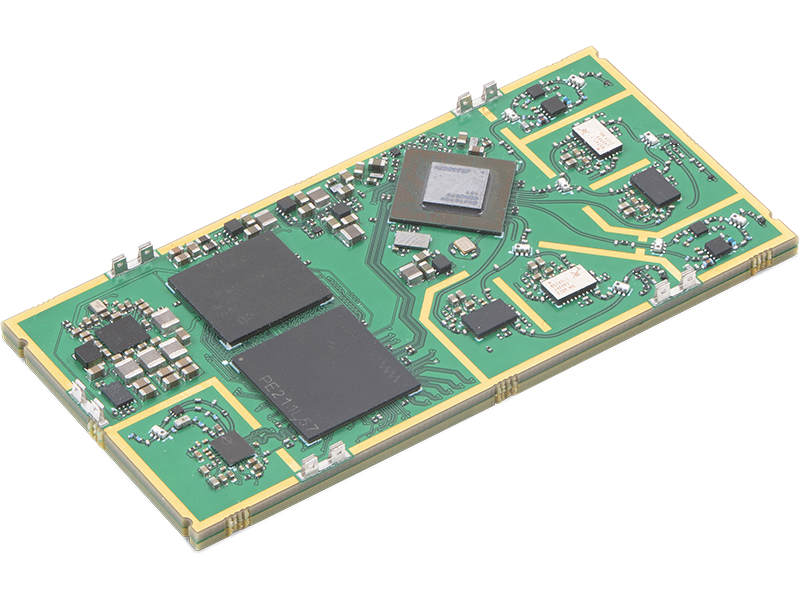

8devices TobuFi – A Qualcomm QCS405 Powered SoM for drones and robotics

8devices TobuFi is a System on Module (SoM) powered by Qualcomm QCS405 SoC. The module features 1GB LPDDR3, and 8GB of eMMC storage with USB 3.0, HDMI, I2S, DMIC, SDC, UART, SPI, I2C, and GPIO. Networking options include dual-band Wi-Fi 6 and Wi-Fi 5 capabilities, Ethernet and...

Continue Reading

Hardkernel’s ODROID-H4, H4+ and H4 Ultra SBC’s Features Intel N97, and i3-N305 and Intel SoC

In a recent update, Hardkernel added three new SBCs to their ODROID series the ODROID H4, ODROID H4+, and ODROID H4 Ultra. The ODROID H4 and the H4+ features a 4-core Intel N97 processor, while the flagship H4 Ultra utilizes the 8-core Intel i3 N305 processor. The N97 is an Intel...

Continue Reading

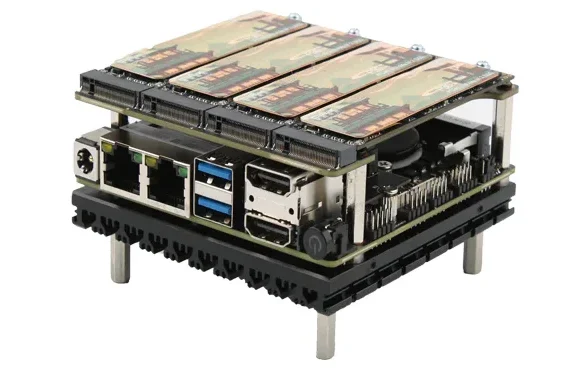

Radxa Fogwise AirBox – A SOPHON SG2300x-Powered Device Built for AI/ML Applications

The Radxa Fogwise AirBox is a compact, embedded multimedia device powered by the octa-core SOPHON SG2300x SoC. This small yet powerful device features Gigabit Ethernet and an M.2 E Key for wireless connectivity, along with an M.2 M Key for SSD storage. With up to 16GB LPDDR4X RAM and...

Continue Reading

CWWK X86 P5 – A Compact Alder Lake N-Powered Development Board with 4 M.2 NVMe Expansion Support

The CWWK X86 P5 is a versatile mini PC and development board powered by the 12th Gen AlderLake-N Series of SoCs. It is available in three variants featuring the N100 (quad-core), N200 (quad-core), or Core i3-N305 (octa-core) processors. Equipped with dual 2.5GbE ports using Intel i226V...

Continue Reading

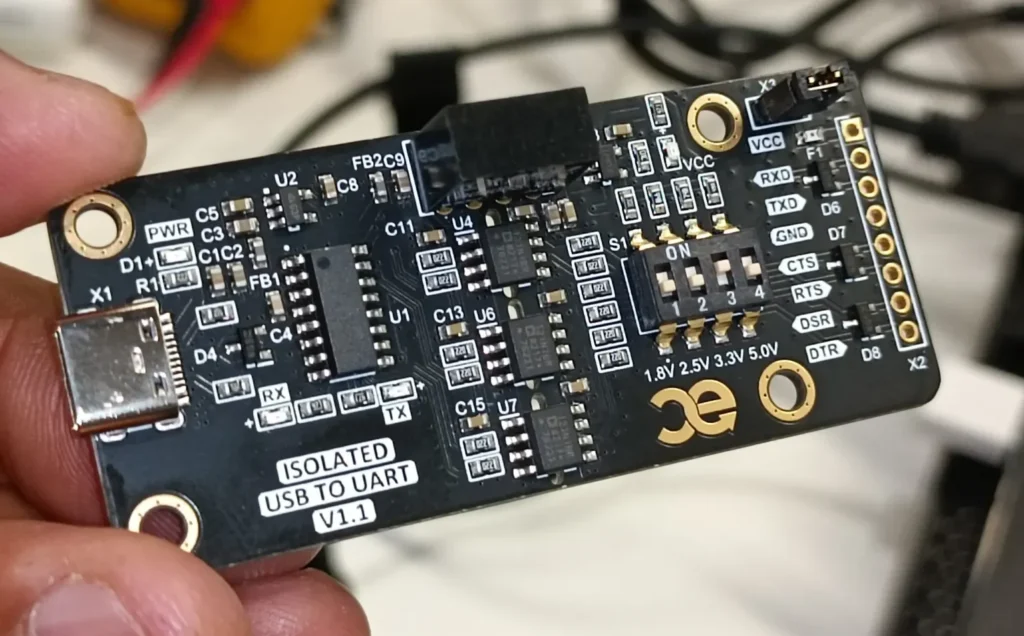

CAPUF Embedded Industrial Grade Isolated USB to UART Converter: Secure, Reliable, and Versatile

Introducing the Industrial grade Isolated USB to UART Converter, a solution developed by CAPUF Embedded. This converter is essential in embedded systems, facilitating tasks like viewing debug messages, flashing programs, and configuring devices via command/response protocol. The...

Continue Reading

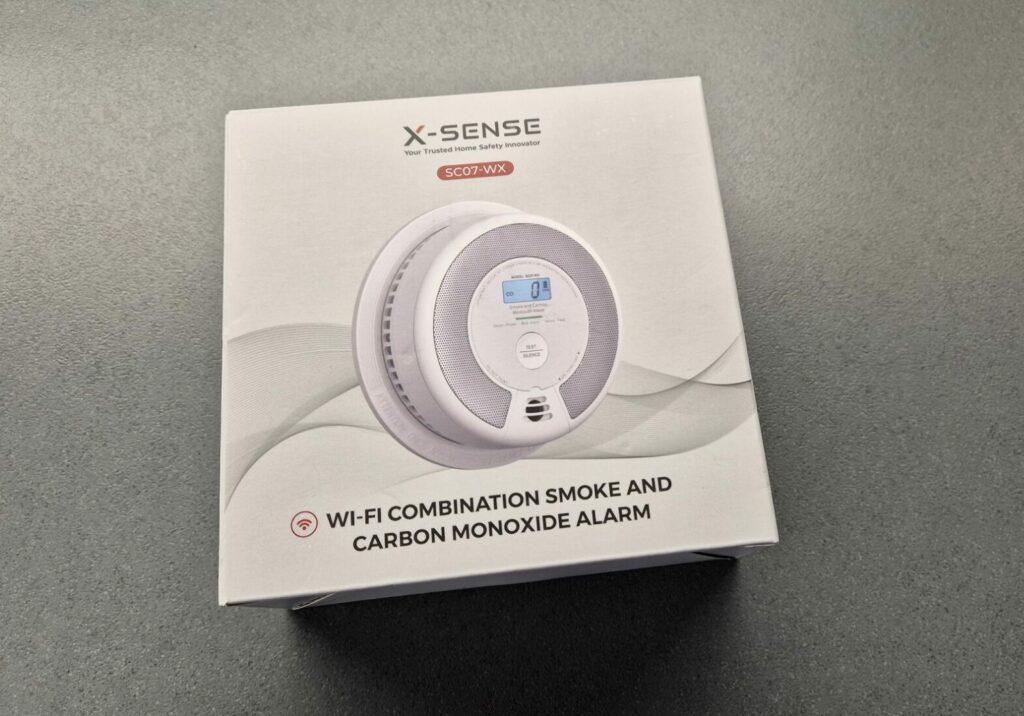

X-SENSE SC07-WX WiFi Smoke & CO Alarm Review – Your Smart Home Guardian for Smoke and CO

The X-Sense SC07-WX is a battery-powered smoke and carbon monoxide detector that combines Wi-Fi connectivity with a smartphone app for remote monitoring and alerts. The sensor uses a photoelectric smoke sensor and an advanced electrochemical carbon monoxide sensor for fast and...

Continue Reading

ARM Unveils Ethos-U85 NPU and Corstone-320 Platform for Enhanced Edge AI

Arm Targets the AIoT with High-Performance Ethos-U85 NPU and Corstone-320 Platform New accelerator boasts four times the peak performance and a 20 percent power efficiency boost over its predecessors. Arm has announced its latest designs for the Artificial Intelligence of Things (AIoT)...

Continue Reading

Introducing SenseCAP Watcher: Seeed Studio’s AI-Powered Smart Monitoring Solution

Seeed Studio's SenseCAP Watcher Combines Local TinyML with Cloud LLMs to Deliver Smart Monitoring Seeed Studio's SenseCAP Watcher is a cutting-edge device that merges the power of local TinyML (Tiny Machine Learning) with cloud-based Large Language Models (LLMs) to provide intelligent...

Continue Reading