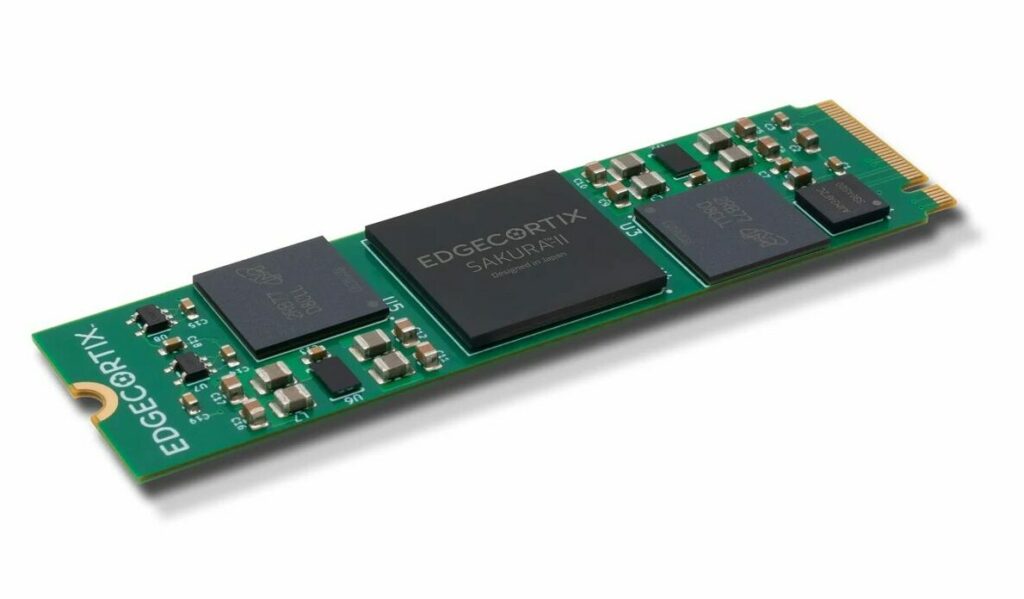

SAKURA-IIEdgeCortix Launches SAKURA-II Platform to Power the Next Wave of Generative AI at the Edge

The next-generation high performance, energy efficient Edge AI accelerator addresses the latest Generative AI solutions at the edge from vision to billions of parameters large language models EdgeCortix® Inc., a leading fabless semiconductor company specializing in energy-efficient...

Continue Reading

TerraMaster Unveils Its Highest-Performing 2-Bay NAS F2-424, Powered by Intel’s Latest Quad-Core Processor for Ultimate Performance

TerraMaster, a professional brand focused on providing innovative storage products for homes and businesses, recently introduced the F2-424, a new upgrade of F2-423. The brand-new F2-424 adopts the Intel Celeron N95 4-core 4-thread processor, 8GB DDR5 memory, two 2.5GB network...

Continue Reading

Raspberry Pi Introduces M.2 HAT+ for High-Speed Peripheral Connectivity

The Raspberry Pi Foundation has unveiled the M.2 HAT+, an innovative accessory designed to enhance the capabilities of the Raspberry Pi 5. This new add-on allows users to connect M.2 peripherals, such as NVMe drives and AI accelerators, to the Raspberry Pi 5’s PCIe 2.0 interface,...

Continue Reading

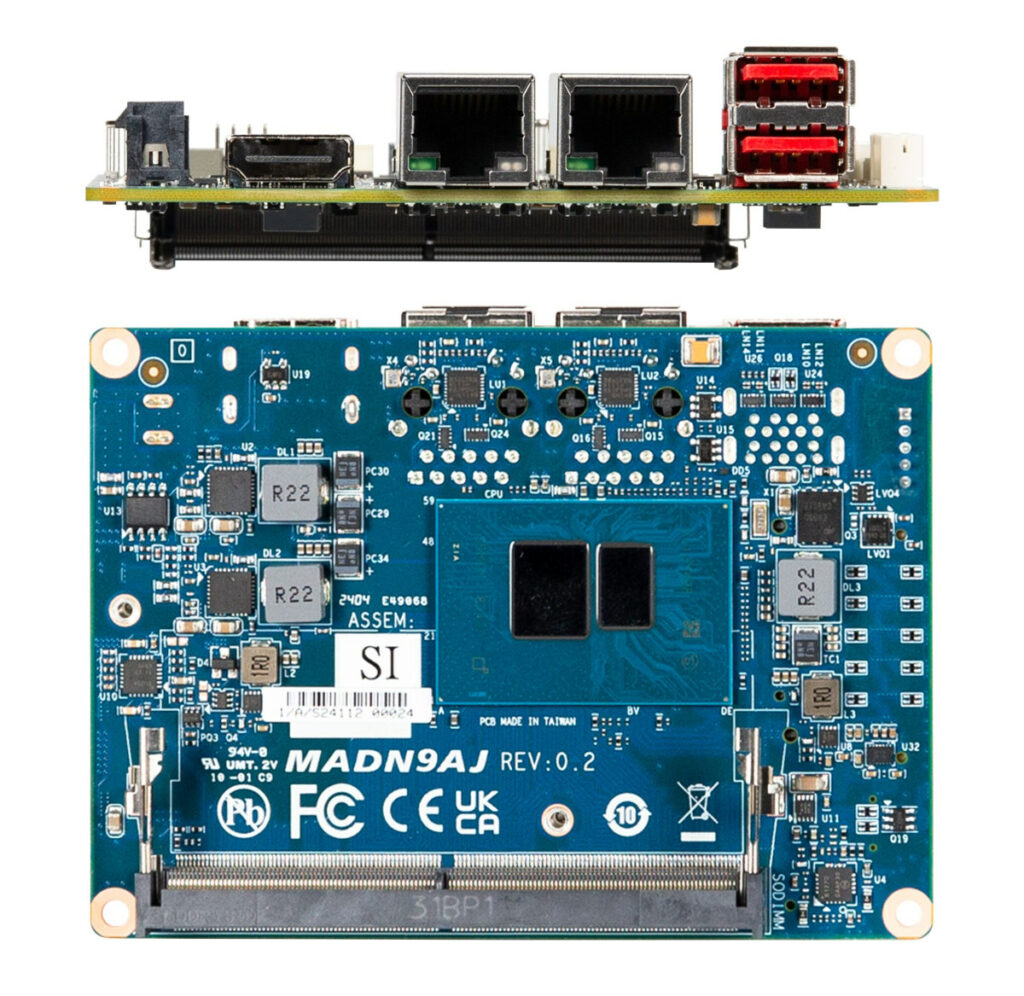

GIGAIPC PICO-N97A: Pico-ITX SBC with Intel Processor N97

GIGAIPC PICO-N97A Pico-ITX SBC features an Intel Processor N97 quad-core Alder Lake-N processor coupled with up to 16GB DDR5 SO-DIMM memory and M.2 SATA or NVMe storage designed for passively cooled and enclosed systems for Industry 4.0 applications in smart cities, retail, and...

Continue Reading

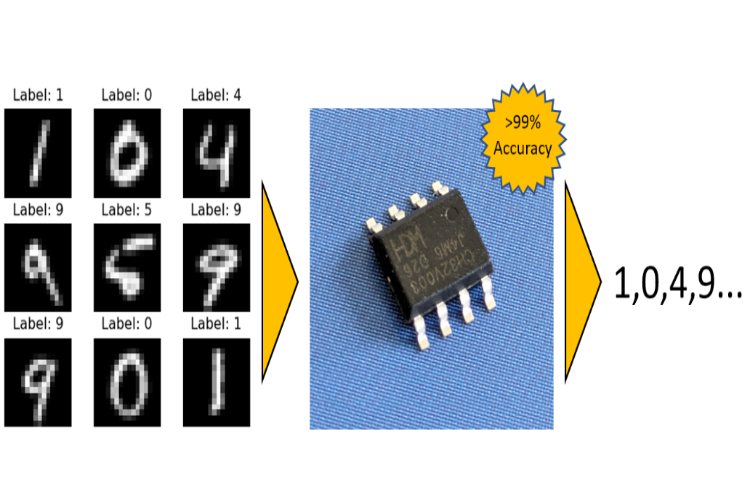

BitNetMCU Slims Down TinyML Models

The BitNetMCU framework simplifies the process of training accurate neural networks for deployment on low-end microcontrollers, such as the 15-cent CH32V003. While major releases of new generative artificial intelligence (AI) tools, like large language models and text-to-image...

Continue Reading

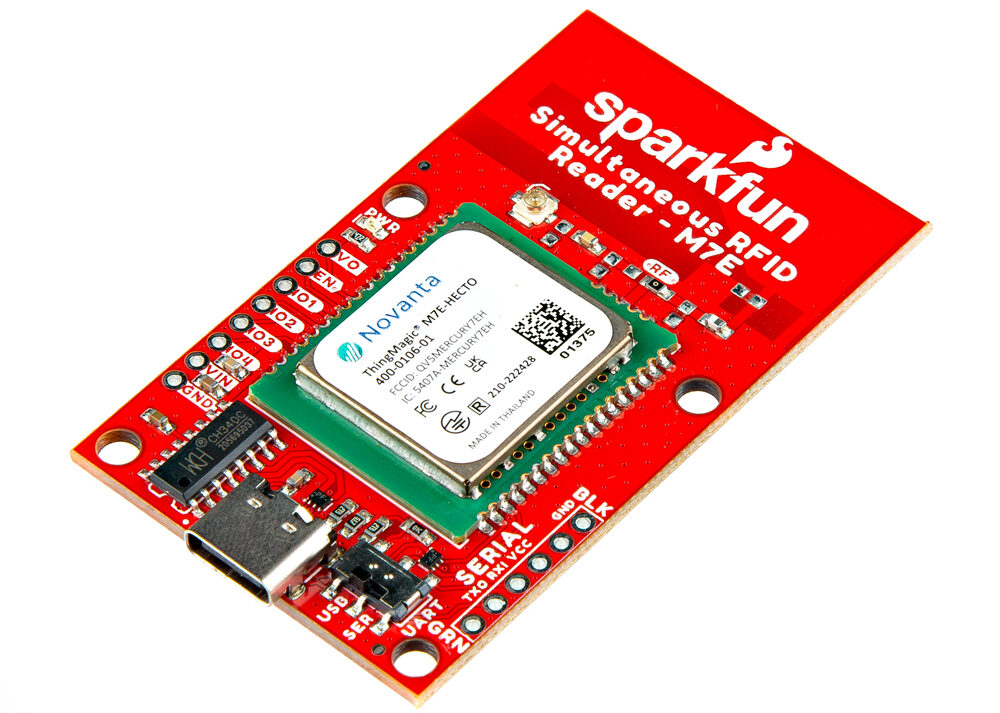

SparkFun M7E Hecto RFID Reader – A Simultaneous RFID Reader with USB-C Interface

The SparkFun M7E Hecto RFID Reader is a high-performance RFID reader for reading UHF RFID tags. The Tag is built around a powerful M7E-HECTO module by JADAK and can read up to 300 tags per second and write at 80 milliseconds. The module's power is also adjustable, so it offers a 1-2...

Continue Reading

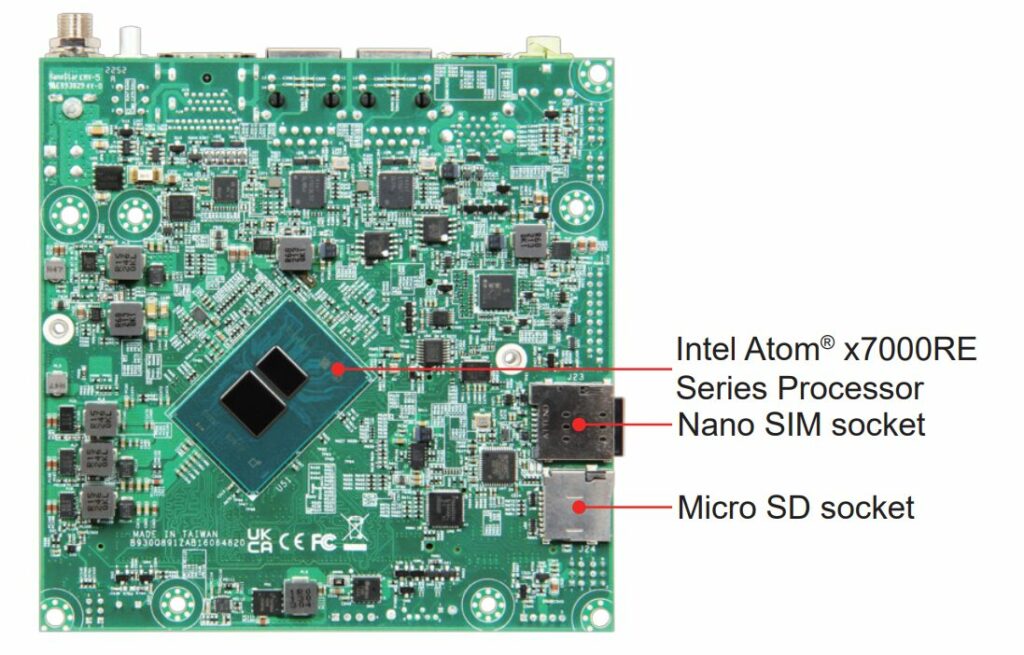

NANO-6064-ASL: Nano-ITX Industrial Embedded Board

The industrial setting often calls for advanced SoCs and Dev boards that can operate at a wide range of temperatures. In this context, NANO-6064-ASL provides a processing platform that not only can handle industrial temperatures ranging from -40°C to 85°C but also performs at...

Continue Reading

The University of Washington Develops A Recyclable PCB Made From Vitrimers

Researchers at the University of Washington (UW) have created A new kind of PCB what they are calling a “Vitrimers PCB” or vPCB for short. The unique characteristic of this PCB is that it's made to be recycled. In the lab, scientists manufactured functional prototypes of Internet...

Continue Reading