W01 U2500 by 52Pi: High-Speed Networking and NVMe Expansion for Raspberry Pi 5

The W01 U2500 by 52Pi is a versatile HAT designed specifically for the Raspberry Pi 5, offering a unique combination of NVMe SSD expansion and USB 2.5G network capabilities. This compact solution is powered by the reliable Realtek RTL8156BG chipset, ensuring seamless integration with...

Continue Reading

Qualcomm’s RB3 Gen 2 Development Kit: Advanced IoT Development Platform

The Qualcomm® RB3 Gen 2 Development Kit is the latest iteration in the RB3 series, designed to enhance performance and accessibility for IoT development. Powered by the advanced Qualcomm® QCS6490 Chipset, this kit offers a significant upgrade over its predecessor, with substantial...

Continue Reading

Arduino Unveils Opta Digital, Analog Expansion Modules for Bigger PLC Projects

Arduino has announced two new entries in its Opta programmable logic controller (PLC) family, designed for those projects that are a little too complex for a single controller: the Opta Digital and Opta Analog Expansion Modules. These new modules offer additional pins and true analog...

Continue Reading

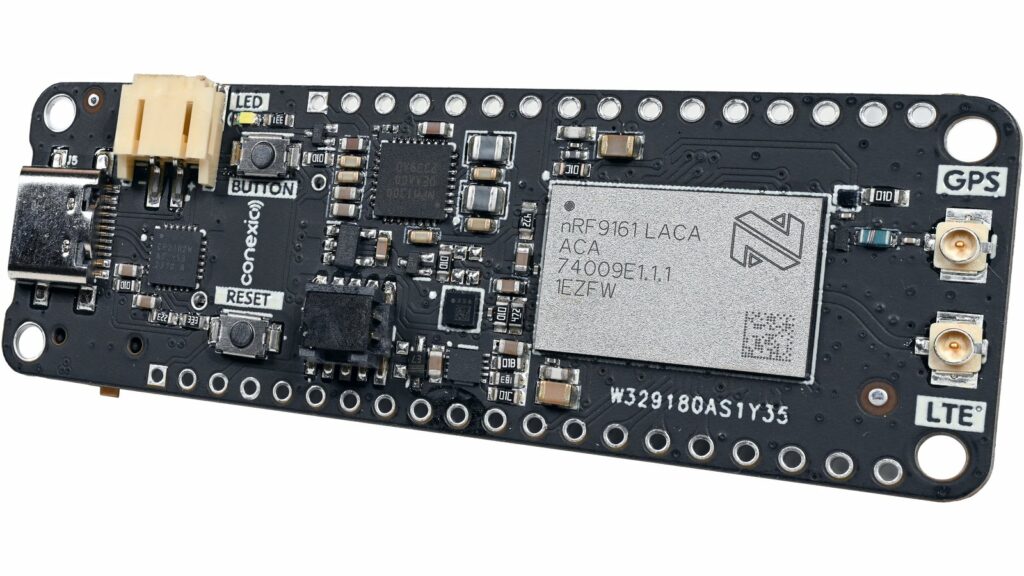

Seamless Worldwide IoT: Conexio Debuts Stratus Pro with Global Cellular Compatibility

Conexio Technologies has unveiled the Conexio Stratus Pro, an advanced cellular-based microcontroller board designed for IoT applications. This new product, available soon on Crowd Supply, features the Nordic Semiconductor nRF9161 SiP and nPM1300 PMIC in a Feather form factor, enhancing...

Continue Reading

Mekotronics R57 is A Rockchip RK3576 Powred fanless mini PC with dual GbE Ethernet and 6 TOPS AI Power

Mekotronics R57 is a fanless AI mini-PC powered by a Rockchip RK3576 octa-core Cortex-A72/A53 SoC SoC. Other than that it has dual GbE Ethernet, 6 TOPS NPU RS232, RS485, and digital inputs and outputs, and in terms of RAM and Storage it includes up to 4GB LPDDR5, a 32GB eMMC...

Continue Reading

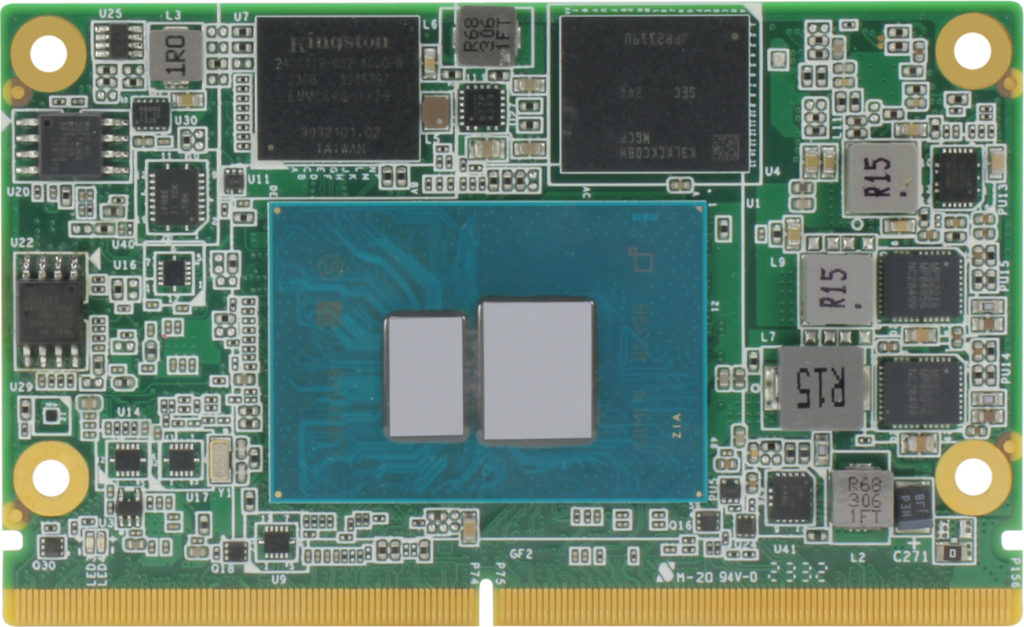

AAEON Revives its SMARC Module Line in Style with the uCOM-ADN

Incredibly robust and with extensive connectivity, the uCOM-ADN offers a compact, efficient, and versatile tool for building industrial IoT applications. AAEON, a leader in industrial IoT and AI Edge solutions has released the uCOM-ADN, a SMARC module powered by Intel® Atom® x7425E,...

Continue Reading

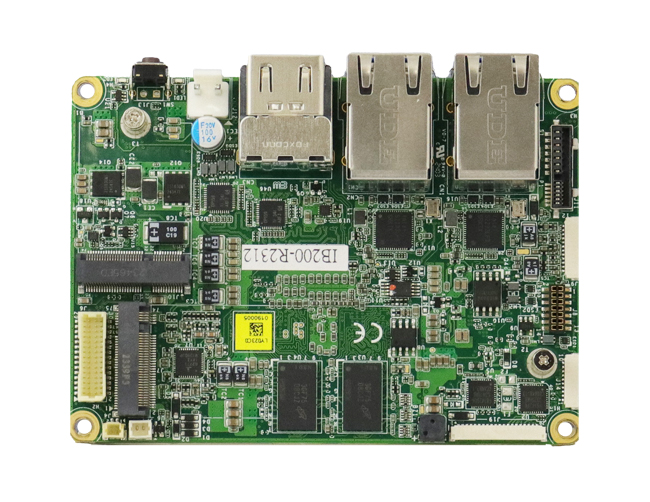

IBASE Unveils First Ultra-Compact 2.5” Single Board Computer

IBASE Technology Inc., a global leader in embedded computing solutions, proudly unveils its first ultra-compact 2.5” single board computer (SBC) designed for edge computing applications. The advanced IB200 SBC offers exceptional graphics processing performance with the AMD...

Continue Reading

Conexio Stratus Pro- nRF9161 Powered Dev Kit with LTE-IoT, DECT NR+, GNSS and Much More

Conexio Technologies, Inc. has recently introduced Conexio Stratus Pro, a battery-powered development board built around Nordic Semiconductor's nRF9161 cellular modem. The unique aspect of this board is that it has support for LTE-M, NB-IoT, and GPS connectivity and to make things even...

Continue Reading