Conexio Stratus Pro- nRF9161 Powered Dev Kit with LTE-IoT, DECT NR+, GNSS and Much More

Conexio Technologies, Inc. has recently introduced Conexio Stratus Pro, a battery-powered development board built around Nordic Semiconductor's nRF9161 cellular modem. The unique aspect of this board is that it has support for LTE-M, NB-IoT, and GPS connectivity and to make things even...

Continue Reading

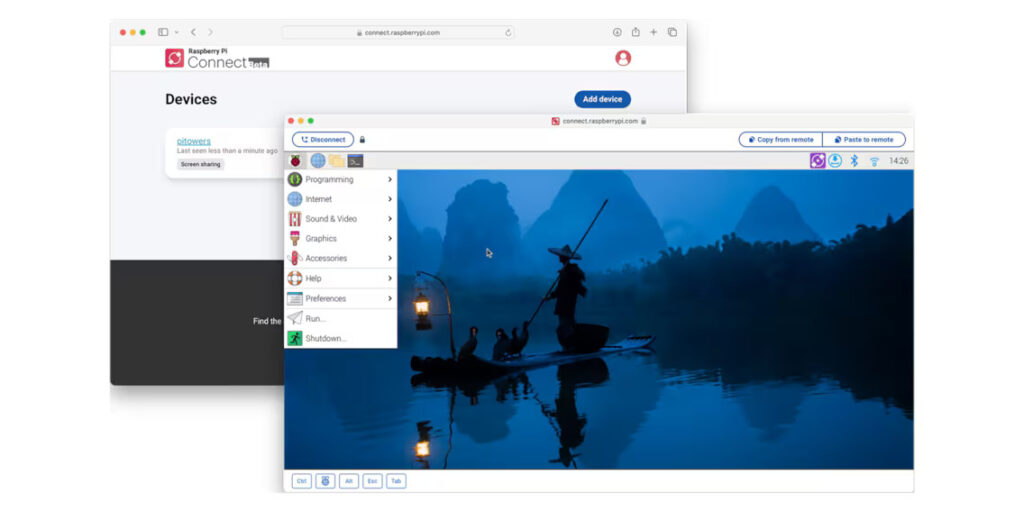

Raspberry Pi Connect: Remote Access Tool for the Small Computer

The Raspberry Pi now has an official remote access tool. Raspberry Pi Connect makes setting up remote access to the small computer easier. With Raspberry Pi Connect, you can access your single-board computer from anywhere in the world using a browser. Provided it is a Raspberry Pi 400,...

Continue Reading

Minisforum AtomMan X7 Ti Mini PC with Touchscreen and Intel 185H Processor

The newly launched AtomMan X7 Ti by Minisforum is a compact mini PC designed for diverse computing needs. It features robust specifications, including the Intel Core Ultra 9 185H processor for high processing power and Intel Arc Graphics for enhanced performance in gaming and graphic...

Continue Reading

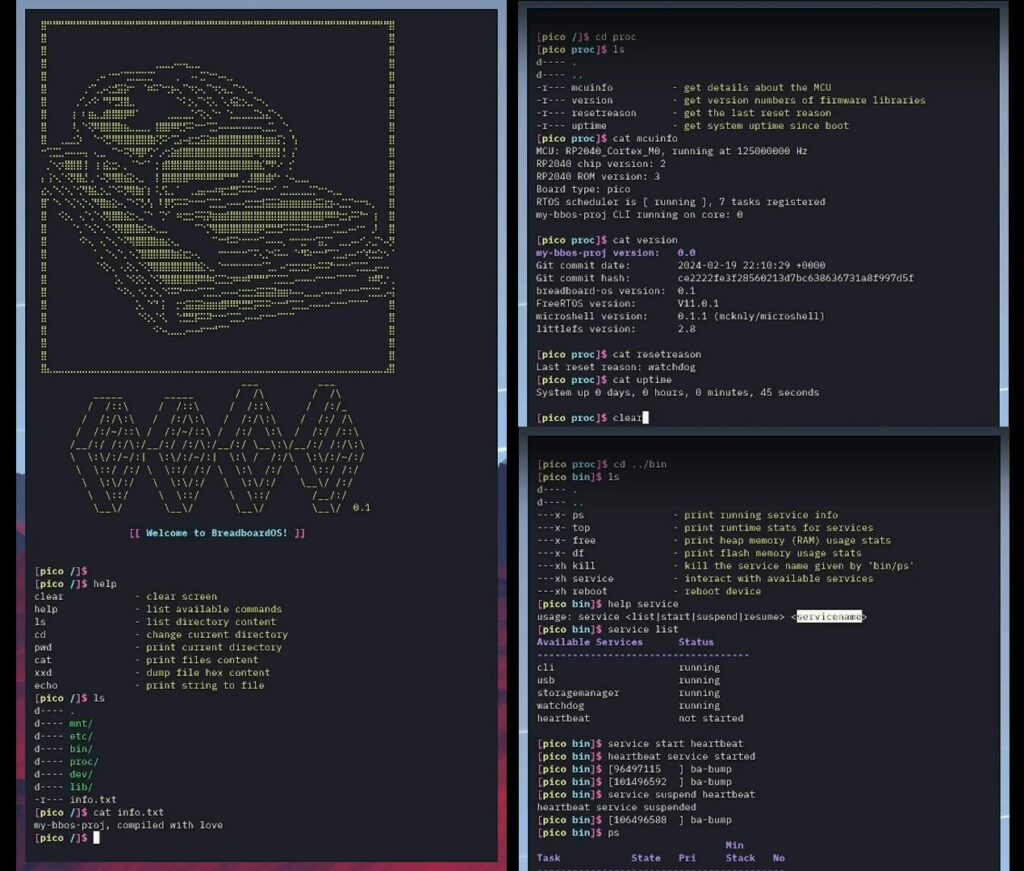

BreadboardOS Firmware for Raspberry Pi RP2040 Features a Linux-Like Terminal

Cavin McKinley’s BreadboardOS is an open-source firmware platform for the Raspberry Pi RP2040 MCU, built around FreeRTOS and featuring a command-line interface (CLI) reminiscent of the Linux terminal. The terminal implementation is based on a customized fork of the Microshell project,...

Continue Reading

Makerfabs Agrosense_Air Review – A LoRa Powred Temperature and Humidity Sensor for Industrial and Agricultural Applications

The Makerfabs Agrosense_Air is a robust LoRa-powered temperature and humidity sensor designed for use in agricultural and industrial environments. As the module features built-in LoRa capabilities, it features wireless data transmission over long distances (up to 2km in urban settings...

Continue Reading

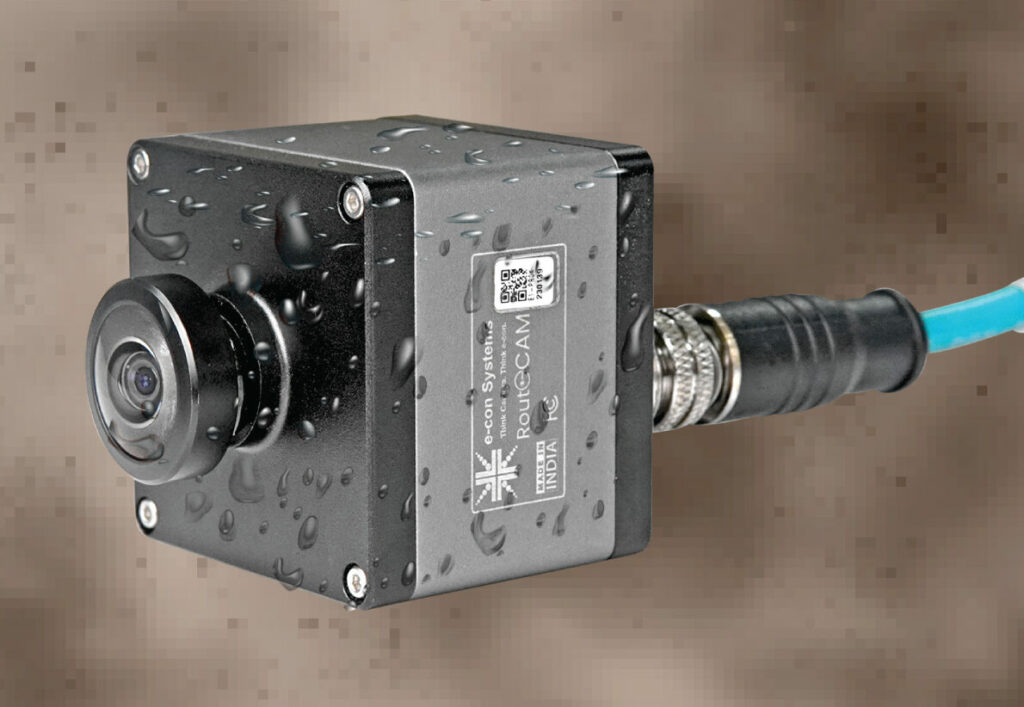

e-con Systems Unveils new Robust All-Weather Global Shutter Ethernet Camera for Outdoor Applications

e-con Systems™, a global leader in embedded vision solutions, introduces a new Outdoor-Ready Global Shutter GigE camera — RouteCAM_CU25, the powerful addition to its high performance Ethernet camera series, RouteCAM. This Full HD Power over Ethernet (PoE) camera excels in...

Continue Reading

DC-DC Boost & Buzzer Driver Reference Design

Author: Irena Zhuravchak, Technical Documentation Apps Engineer, Renesas Electronics, Lviv, Ukraine Introduction What do alarm systems, timers, smart keychains, and other notification systems have in common? They all need a buzzer, and consequently, a buzzer driver. The driver must...

Continue Reading

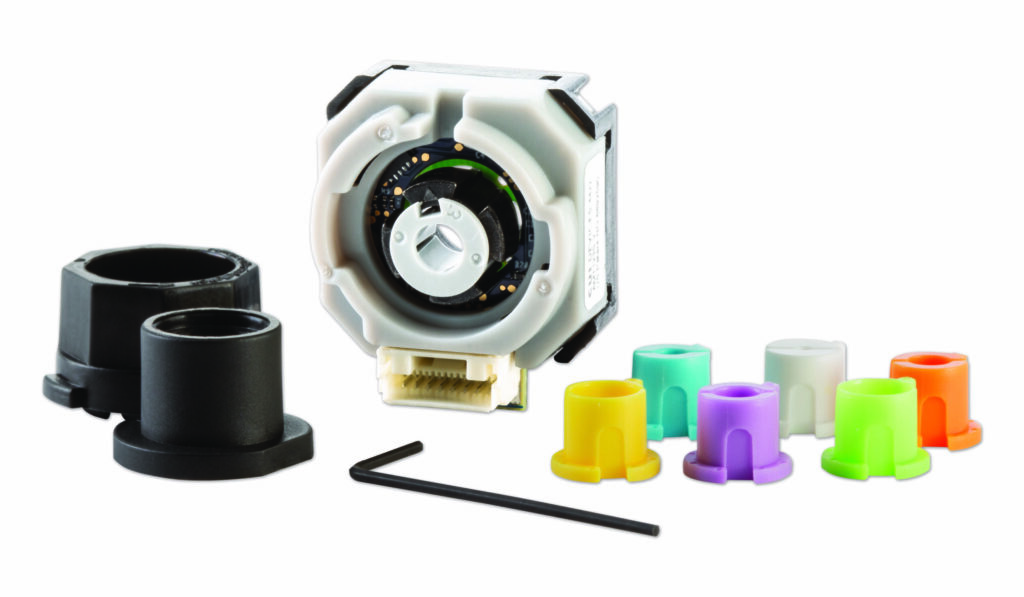

New Incremental Encoder Supports Smaller Shaft Sizes from 1 to 6.35 mm

CUI Devices’ Motion and Control Group today announced the introduction of a new model to its AMT incremental encoder family that supports smaller motor shaft sizes from 1 mm to 6.35 mm (1/4 inch). The AMT12 series, based on CUI Devices' proprietary capacitive ASIC technology, brings...

Continue Reading