Category: Mcu

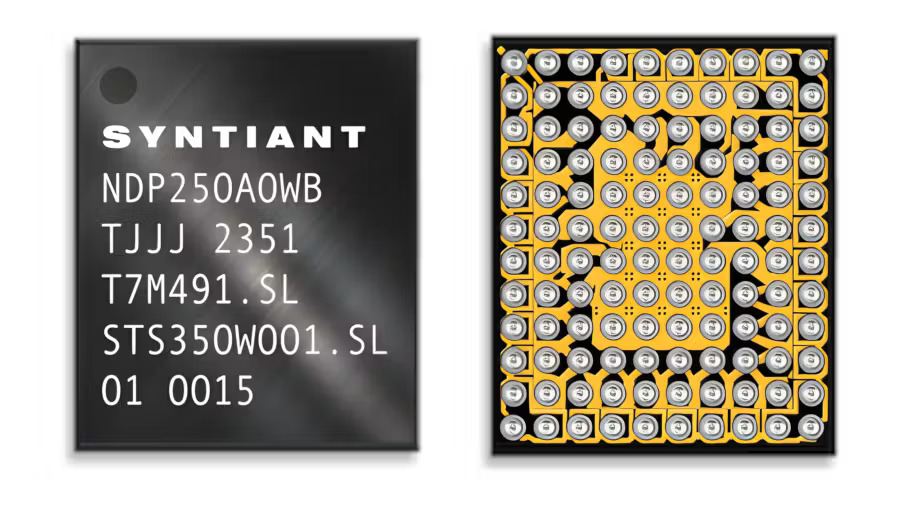

Syntiant Unveils NDP250: A Breakthrough in Microwatt AI Processing for Always-On Applications

Syntiant, a leading provider of on-device deep learning solutions, has introduced its latest innovation: the NDP250 Neural Decision Processor. Boasting an impressive 30 giga-operations per second (GOPS) performance, the NDP250 sets a new standard for efficiency in AI processing. This...

Continue ReadingSilicon Labs Streamlines Energy Harvesting Product Development for Battery-Free IoT

Silicon Labs' most energy-efficient Wireless SoC to date with energy harvesting-ready capabilities Silicon Labs, a leader in secure, intelligent wireless technology for a more connected world, today announced their new xG22E family of Wireless SoCs, Silicon Labs' first-ever family...

Continue Reading

Espressif’s ESP32-C5 Features a Dual-Band Wi-Fi 6 Radio with MU-MIMO, TWT, and More

Espressif Systems has recently introduced the ESP32-C5 a MCU with dual-band (2.4 & 5.0 GHz) WiFi-6 and Bluetooth 5.0 LE support. Previously we have seen Espressif release many MCU such as the ESP32-C6, and ESP32-C61, both of which are capable of handling 2.4GHz radio connectivity,...

Continue Reading

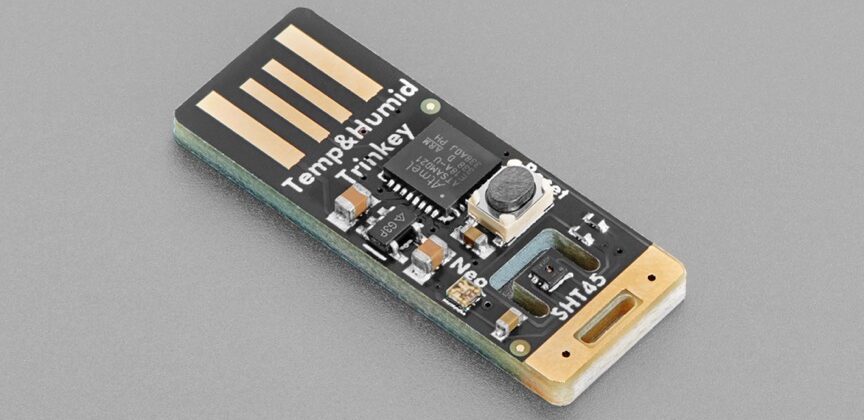

Adafruit’s Trinkey is A Thumb-Drive-Sized Temperature and Humidity Sensor

Adafruit has recently added two new members to the Trinkey family, the Adafruit SHT45 Trinkey and the Adafruit SHT41 Trinkey both of those are designed to add temperature and humidity-sensing capabilities to any USB HOST device. The main difference between the two boards lies in their...

Continue Reading

MCX A: All-Purpose MCU and FRDM Development Platform

In embedded systems and IoT devices, versatile and powerful microcontrollers are essential. NXP Semiconductors addressed this demand by introducing the MCX A series of MCUs, which are designed to fulfill a wide range of application requirements. This series is part of the MCX Family...

Continue Reading

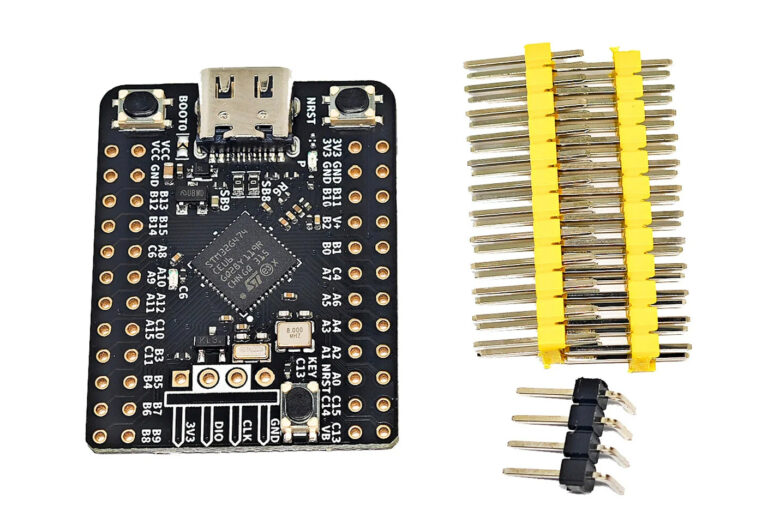

Introducing WeAct STM32G4: Tiny Development Board with Versatile Microcontroller Options

The WeAct STM32G4 is a compact development board that utilizes the STMicro STM32G4 Arm Cortex-M4F mixed-signal microcontroller. This microcontroller operates at a clock speed of 170 MHz and comes equipped with DSP (Digital Signal Processing) instructions, making it suitable for a wide...

Continue Reading

STMicroelectronics reveals advanced ultra-low-power STM32 microcontrollers

New flagship in ultra-low-power consumes less, delivers more at effective cost STMicroelectronics has introduced a new generation of energy-conscious and cost-effective microcontrollers (MCUs) that can reduce energy consumption by up to 50% compared to previous product generations....

Continue Reading

STMicroelectronics breaks the 20nm barrier for cost-competitive next-generation microcontrollers

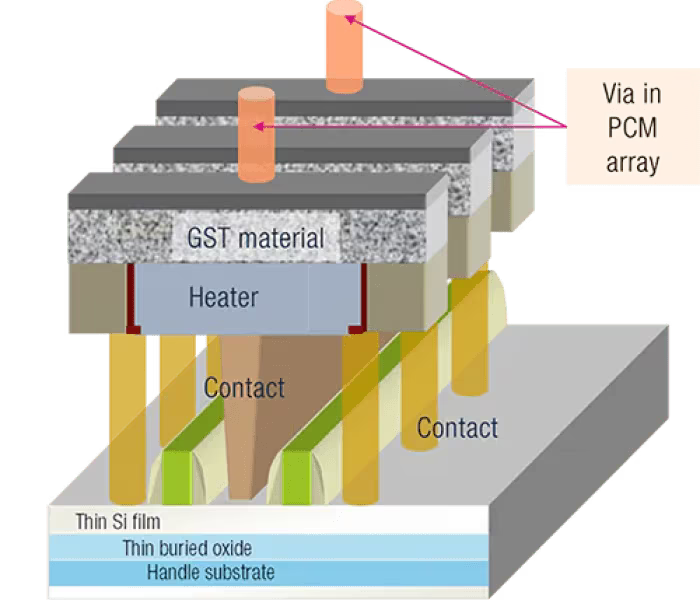

Highlights First STM32 microcontroller based on new technology to sample to selected customers in the second half of 2024. 18nm FD-SOI with embedded phase change memory (ePCM) to deliver a leap in performance and power consumption. STMicroelectronics announces an advanced...

Continue Reading