CH32V003 USB Development Board: An Affordable and Versatile Platform for USB Peripheral Projects

LECTRONZ has introduced a new USB Development Board called CH32V003. It's designed for people who like to tinker with RISC-V microcontrollers. The main part of the board is a microcontroller with part no CH32V003F4U6 made by WCH. It can run at speeds up to 48MHz, has 16KB of storage for...

Continue Reading

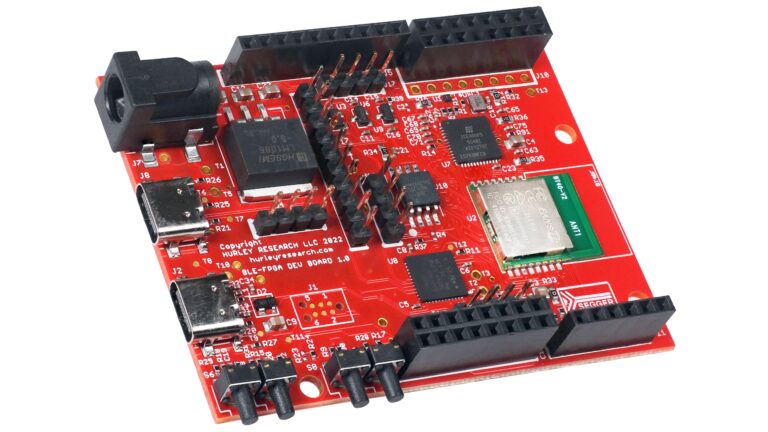

Introducing NRFICE: A Bluetooth FPGA Board for Edge Computing and IoT Applications

The NRFICE is a Bluetooth FPGA board designed to be compatible with the Arduino UNO form factor. It combines two key components: the dual-core nRF5340 Bluetooth SoC and the LatticeICE40UP5K FPGA. The Lattice ICE40UP5K FPGA is known for its low power consumption and high performance,...

Continue Reading

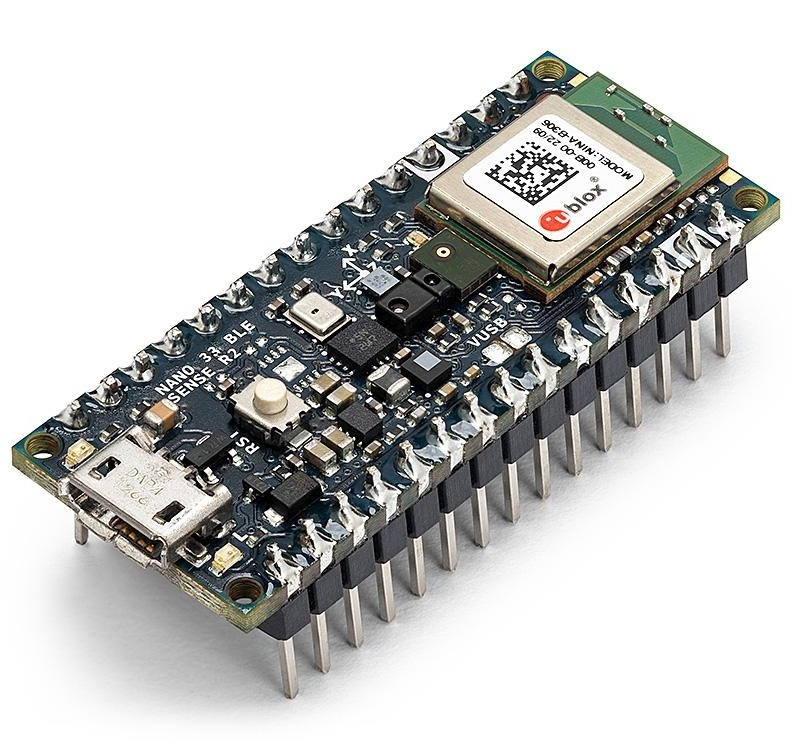

Introducing Arduino Nano 33 BLE Rev2: Enhanced Hardware and Performance Upgrades

The Arduino Nano 33 BLE Rev2 is an updated version of the popular Arduino Nano 33 BLE board. It has several improvements, including dual-IMU (Inertial Measurement Unit) support for better motion sensing, an upgraded power supply for improved performance, and other enhancements. Despite...

Continue Reading

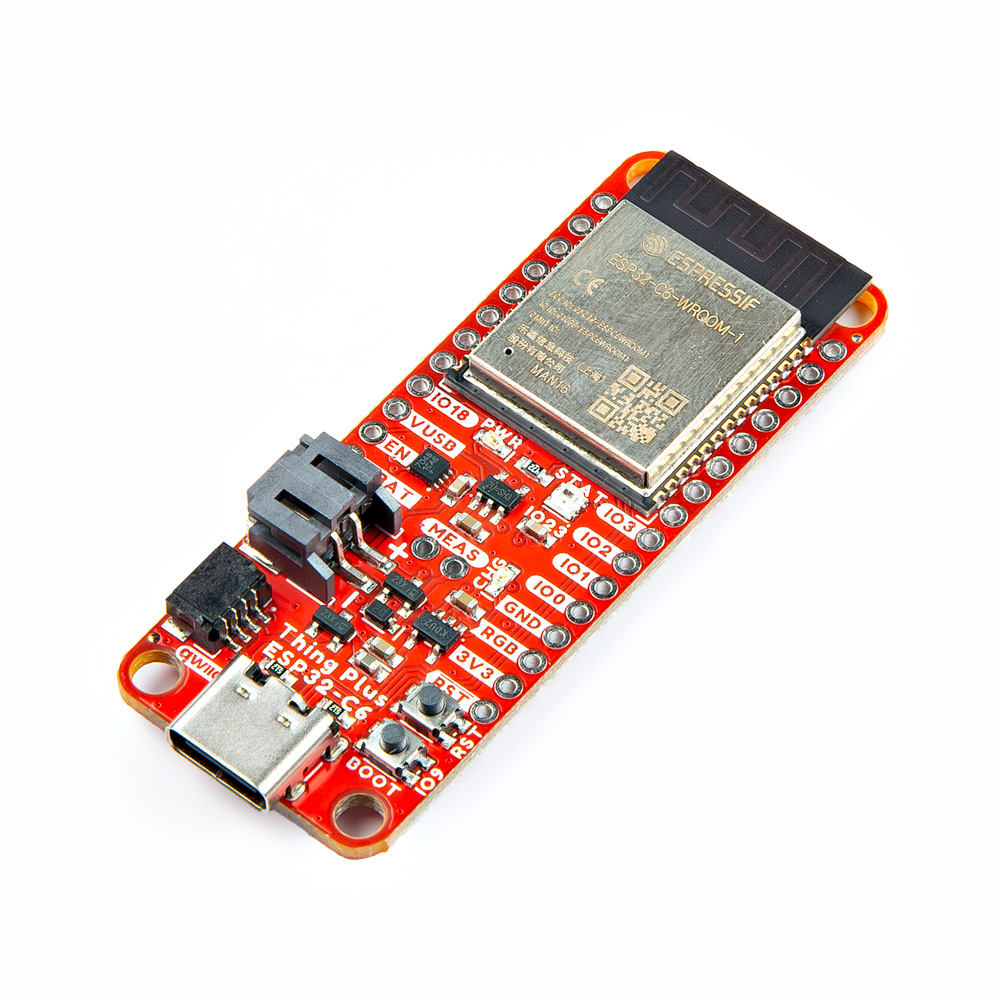

SparkFun Introduces ESP32-C6 Thing Plus: Revolutionizing IoT Projects

The SparkFun ESP32-C6 Thing Plus is expected to bring significant advancements to IoT projects due to its user-friendly design, advanced features, and seamless connectivity capabilities. Located in Boulder, Colorado, SparkFun Electronics has officially launched the ESP32-C6 Thing Plus,...

Continue Reading

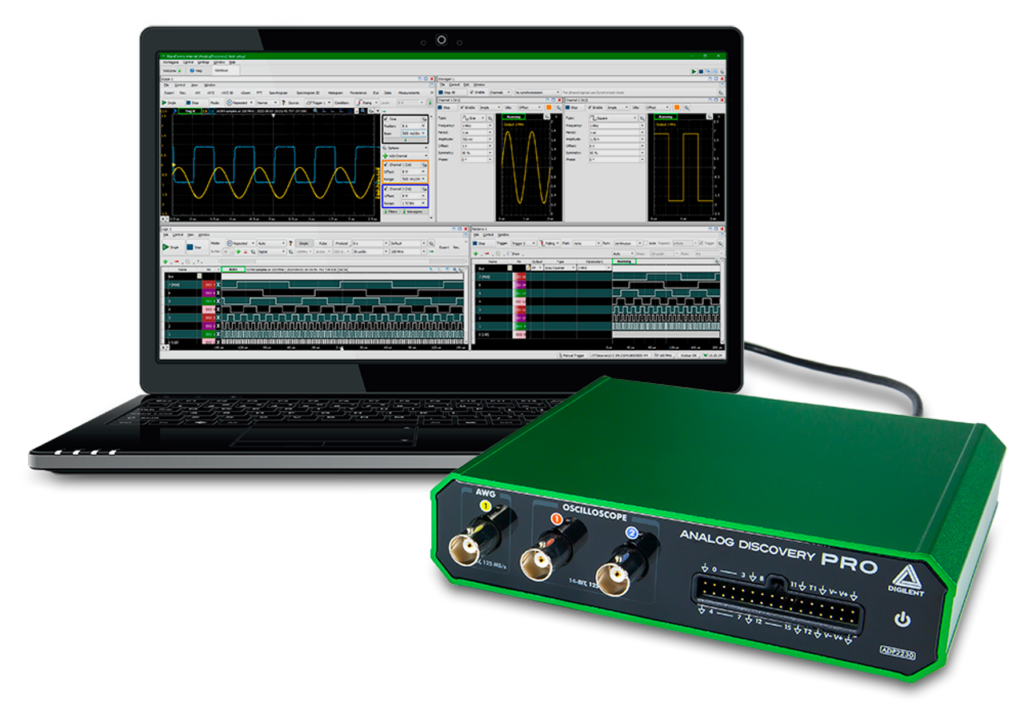

Analog Discovery Pro ADP2230 – USB Oscilloscope with Waveform Generator, Logic Analyzer, and Variable Power Supply Available for $749.00

The ADP2230 has 16 digital input/output channels that work with 3.3 V CMOS, can sample up to 125 MS/s, and buffer up to 128 MS per channel. It also includes an analog output channel with a 15 MHz bandwidth and 14-bit resolution, capable of producing standard, modulated, and custom...

Continue Reading

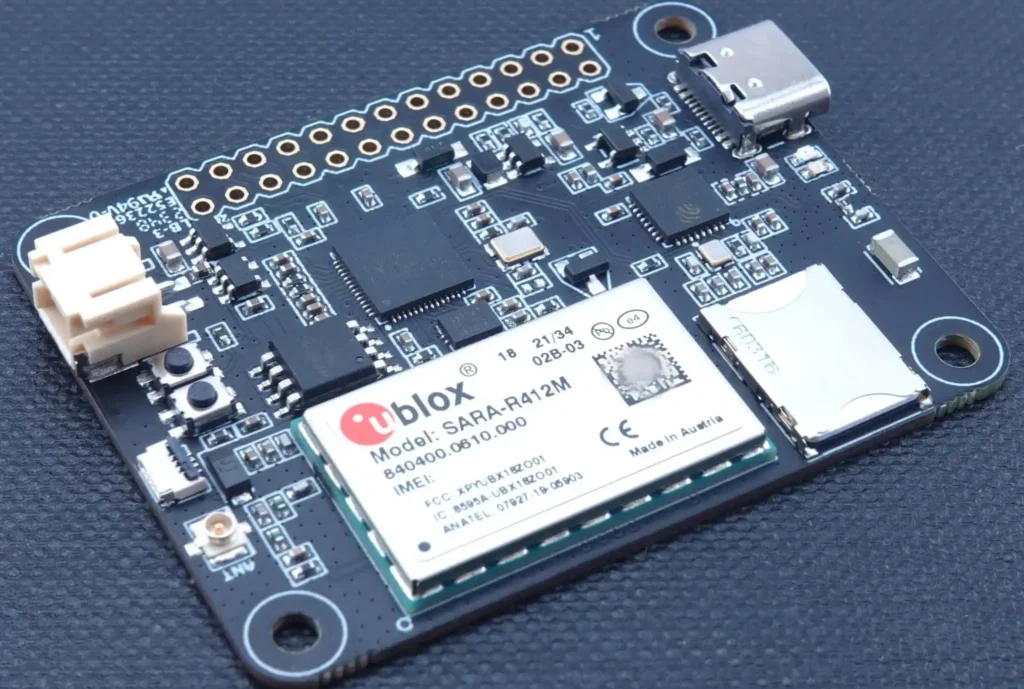

ILabs’ New RP2040 Connectivity Board Features u-blox SARA-R412M LTE (Cat M1/NB-IoT) and ESP32 Modules

ILabs' RP2040 Connectivity Board is an RP2040-based development board with u-blox SARA-R412M for LTE (Cat M1/NB-IoT) and Espressif's ESP32-C3FN4 for WiFi/BLE, designed for versatile IoT applications from remote monitoring to smart connected devices. We've covered various connectivity...

Continue Reading

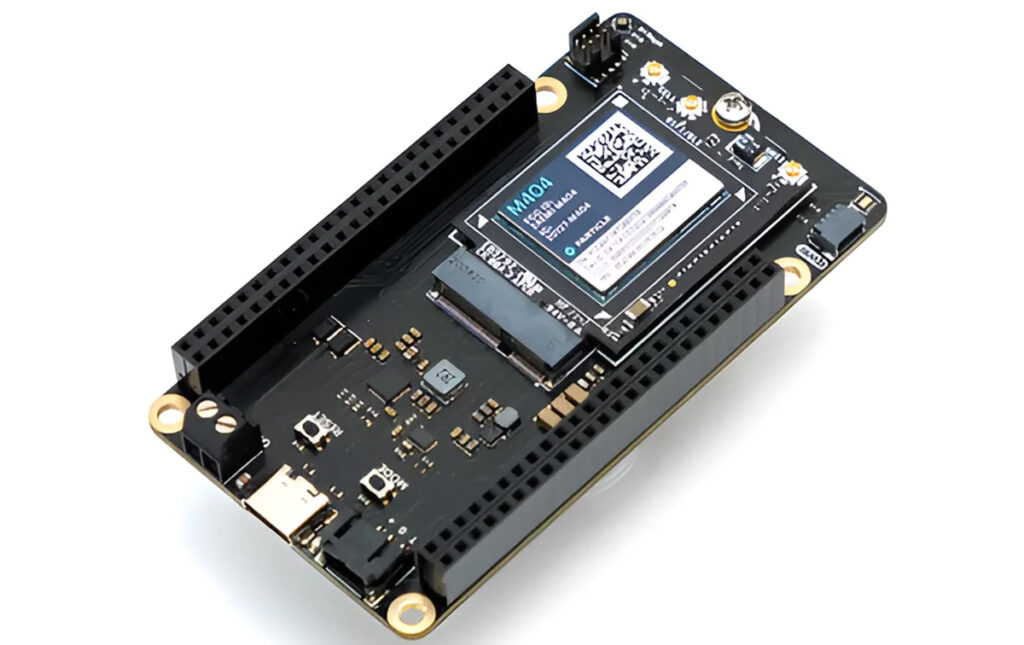

Particle Announces M-Series Muon Dev Board Featuring LoRaWAN and Satellite Connectivity Options

Particle has recently announced its multi-radio modules with support for Wi-Fi, cellular, LoRaWAN, and even satellite communications on a single device, which we have covered in our M-SoM modules article, but what we haven't written about is the Muon Dev Board which is the dev board...

Continue Reading

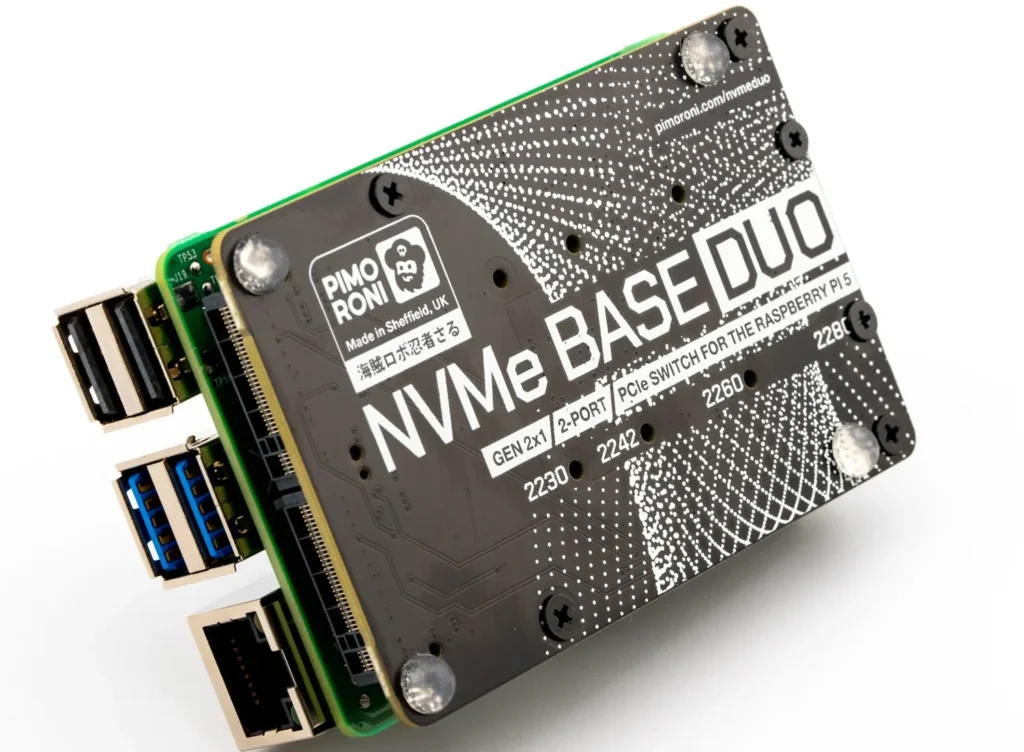

Pimoroni’s NVMe Base Duo Brings Dual SSD Support to the Pi 5

Pimoroni's NVMe Base Duo for Raspberry Pi 5, features dual M-key NVMe SSD that supports 2230 to 2280 SSDs while utilizing PCIe Gen 2 technology for fast storage speeds. With dual SSD support, this device is built for media centers and server applications. A few months ago, Pimoroni...

Continue Reading