Industrial mini PC from ICOP Features Modern OS Support, Wide Temperature Range and Support for Various I/O Interfaces

Many times, when we think of an industrial mini computer, we expect to see a lot of ruggedness and extra capabilities that we would not find with a traditional desktop or laptop. Industrial computers usually come with really fast processors, plenty of memory and storage, strong hardware...

Continue Reading

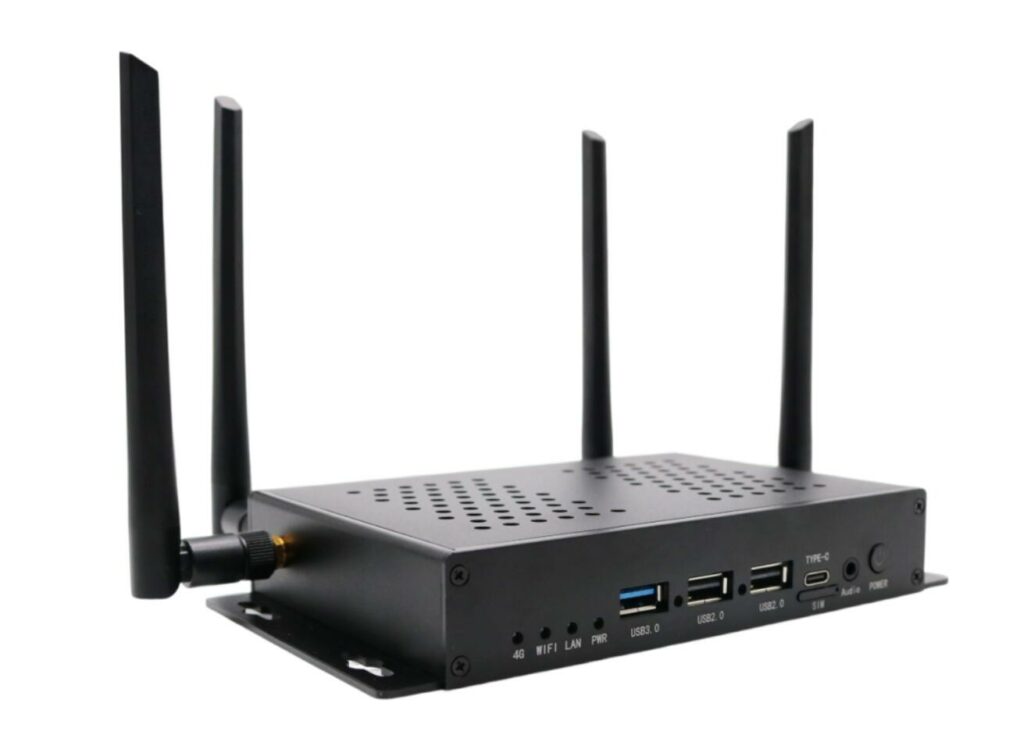

Mekotronics Includes 4G LTE connectivity and PoE support in their R58X-4G RK358 board

Mekotronics has released an upgrade to the original R58X RK3588 mini-computer, adding support for 4G LTE and Power over Ethernet (PoE). The compact R58X-4G mini PC is perfect for a wide range of applications including home entertainment, digital signage, light gaming, and remote work....

Continue Reading

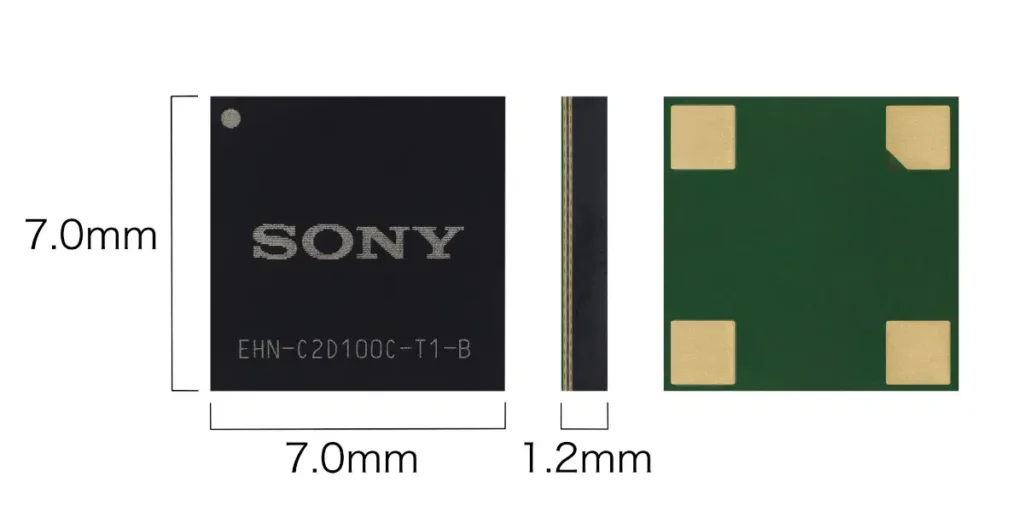

New Energy-Harvesting Module Uses Electromagnetic Wave Noise from Common Devices to Provide Electrical Energy for IoT Sensors

Sony Semiconductor Solutions has just developed a revolutionary energy-harvesting module that turns electromagnetic noise energy into usable power for sensors – a breakthrough in sustainable power supply technology intended to help resolve power supply issues arising from embedded...

Continue Reading

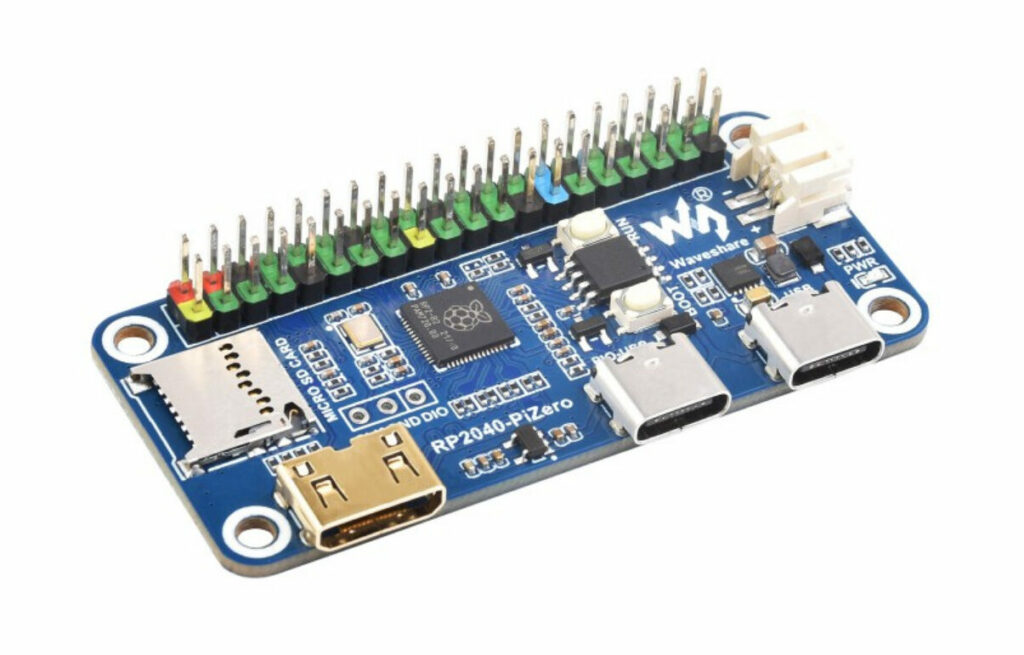

RP2040 Pi Zero Development Board is a Mix of Low-cost, Small Form Factor, High Power and Multiple Connection Interfaces

Waveshare, a China-based Electronic Specialist whose expertise over the years has unveiled some of the most reliable electronic components and modules for engineers, designers, and makers around the world, recently released a new cost-effective development board with a mix of small form...

Continue Reading

Arduino Series B Funding gets a major support from ARM

Arduino has announced a $22 million boost in its Series B funding project intended to support their expansion into enterprise and break into the large-scale Industrial IoT market. This massive fundraiser includes a big investment from Arm and the reasons are not far-fetched after all....

Continue Reading

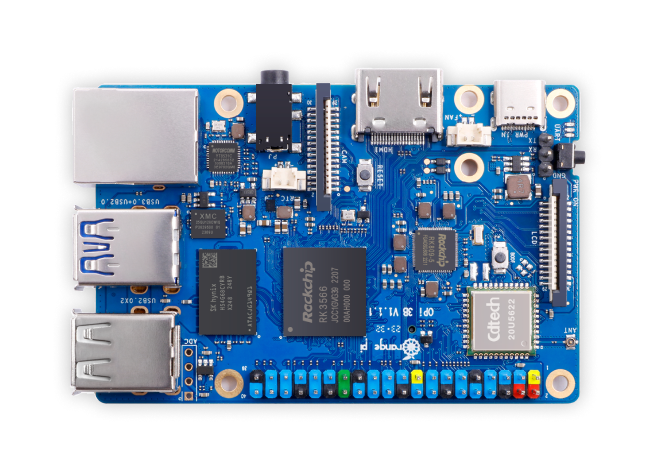

Orange Pi 3B – RK3566 SBC offers exceptional value for its features

Shenzen Xunlong Software has unveiled its latest SBC, The Orange Pi 3B. Housing a Rockchip RK3566 SoC, this device hosts many unique features you don't often find in a credit card-sized form factor—notably, a full-sized HDMI port and an M.2 key socket for storage. Priced at $35, the...

Continue Reading

AlgoLaser Delta 22W Laser Engraver : A Budget-Friendly Machine For Makers

New Tools to Inspire Creativity As a consultant in the 3D printing space, one of my goals is to help fellow makers discover affordable tools and technologies that can unlock new possibilities. When I came across reports of the upcoming AlgoLaser Delta laser engraver, my interest was...

Continue Reading

Turing RK1 SOM – Pricier yet Superior Raspberry Pi Alternative

Turing Machines, a maker of cluster computers has recently launched its anticipated Turing RK1 system-on-module (SOM). Equipped with a robust Rockchip RK3588 Arm processor and a 6 TOPS NPU, this module, priced at $130, presents itself as an alternative to the Raspberry Pi Compute Module...

Continue Reading