Arduino Introduces 4G Global Connectivity for Portenta in Mini-PCIe Form Factor

Arduino Pro has introduced a groundbreaking solution for IoT development with the launch of 4G global connectivity for its Portenta board, now available in a compact Mini-PCIe form factor. This innovation enables developers to swiftly create IoT devices with seamless global 4G cellular...

Continue Reading

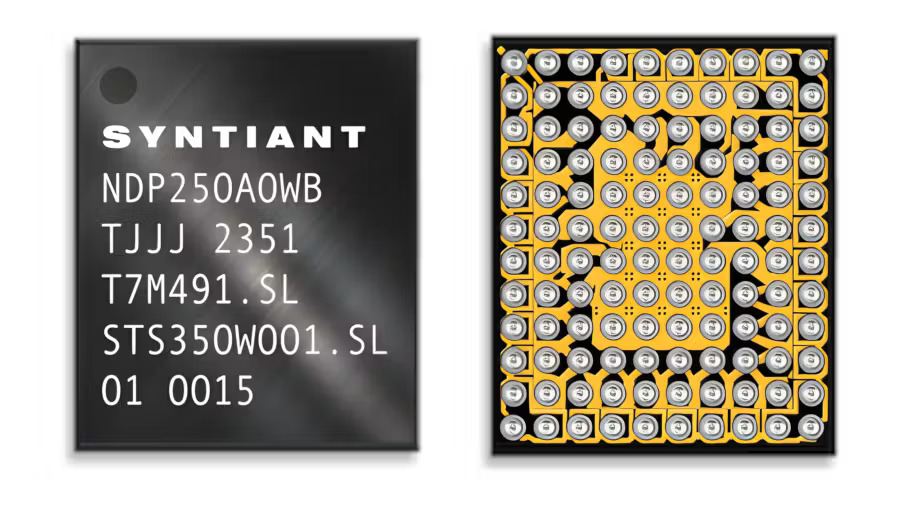

Syntiant Unveils NDP250: A Breakthrough in Microwatt AI Processing for Always-On Applications

Syntiant, a leading provider of on-device deep learning solutions, has introduced its latest innovation: the NDP250 Neural Decision Processor. Boasting an impressive 30 giga-operations per second (GOPS) performance, the NDP250 sets a new standard for efficiency in AI processing. This...

Continue Reading

Tangram Vision Self-Calibrating HiFi 3D Sensor Features ROS 2 Integration and On-Device AI

The Team at Tangram Vision has recently introduced Self-Calibrating HiFi 3D Sensor a cutting-edge depth sensing solution designed primarily for robotics applications. The camera module integrates high-fidelity 3D sensing with on-device AI capabilities, to provide a Plug-'n'-Play...

Continue Reading

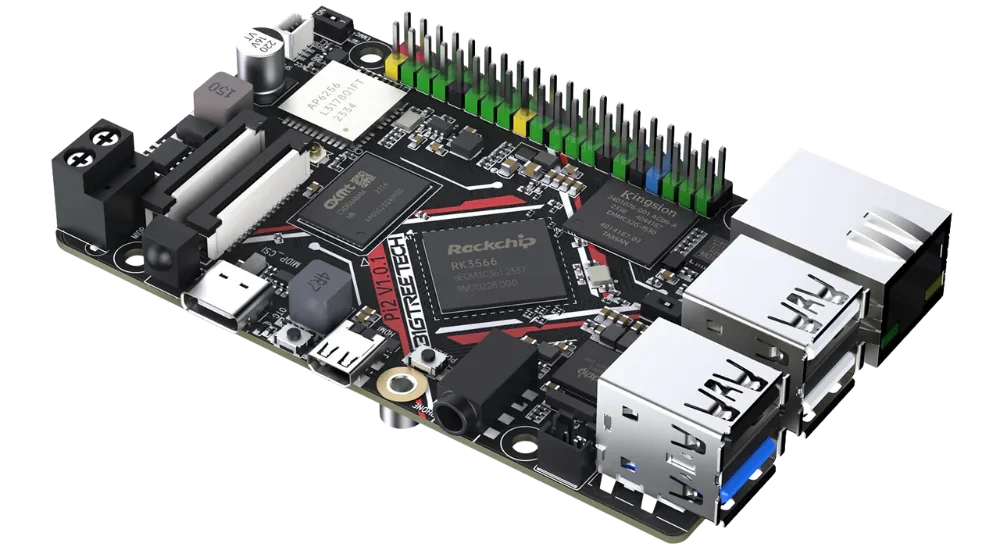

Rockchip RK3566 Powred BIGTREETECH Pi 2 Features Gigabit Ethernet, Dual-band Wi-Fi and more

The BIGTREETECH Pi 2 is a powerful single-board computer (SBC) powered by the Rockchip RK3566 chipset. It boasts 2GB of LPDDR4 RAM and a 32GB eMMC module, offering robust performance and ample storage capacity. With features like Gigabit Ethernet, dual-band Wi-Fi, and Bluetooth 5.2, it...

Continue Reading

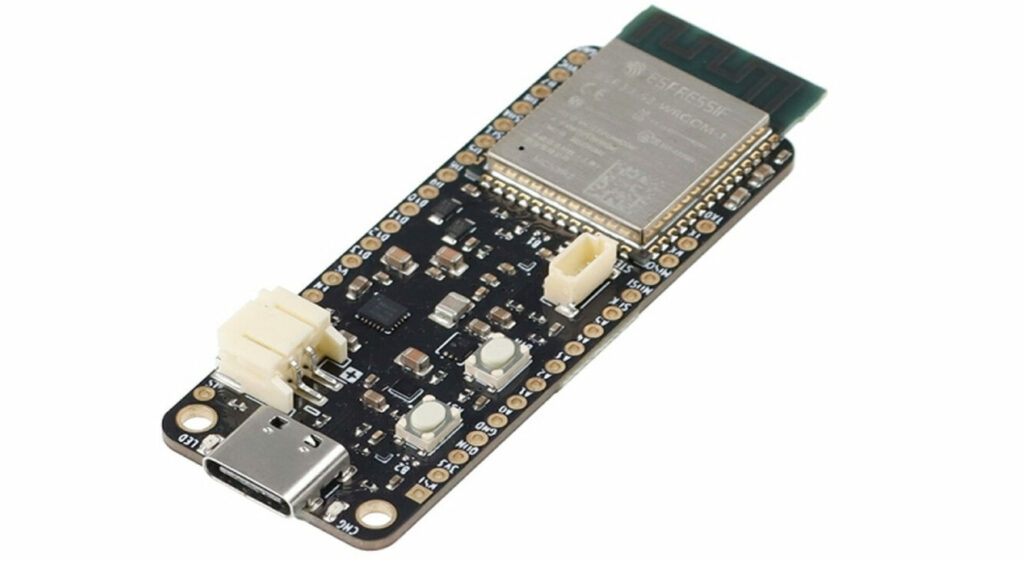

ESP32-S3 PowerFeather – An Adafruit Feather-shaped dev board with lithium battery and solar support

The ESP32 PowerFeather is a Low Power, solar-capable, Li-ion/LiPo powered IoT development board in a Feather-compatible format. The board is built around an ESP32-S3 and supports up to 18V DC input meaning you can directly connect your soler pannel to this board. Previously, we wrote...

Continue Reading

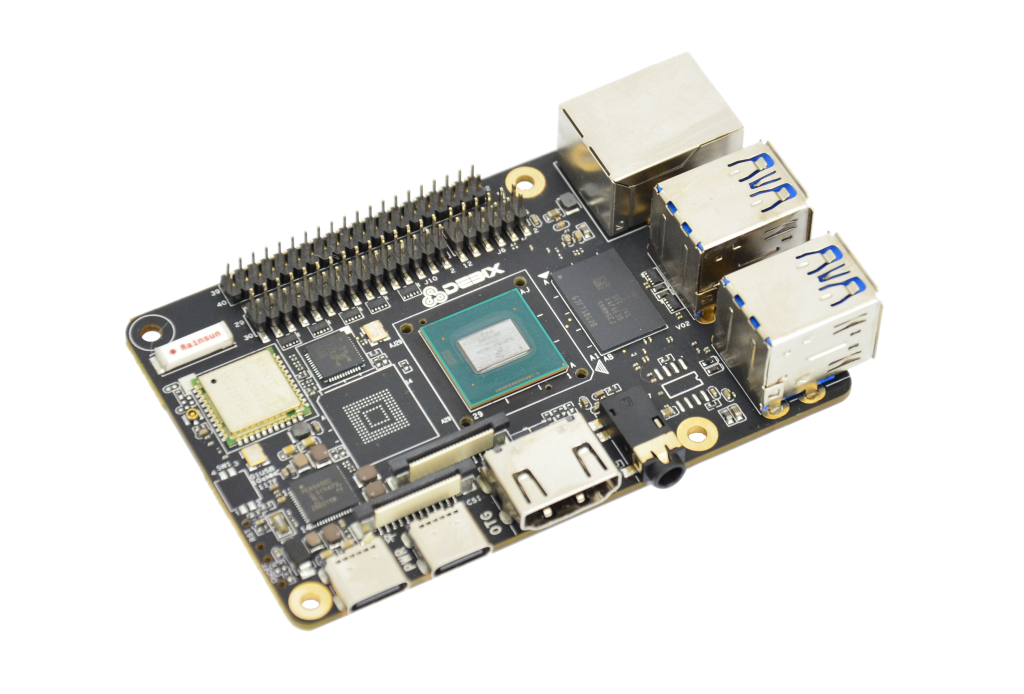

OKdo & DEBIX Launch DEBIX Infinity Industrial SBC with i.MX 8M Plus SoC

At Embedded World 2024, OKdo and DEBIX in a joint venture have announced DEBIX Infinity Industrial SBC. The SBC is powered by an NXP i.MX 8M Plus Quad Lite processor, and features dual GbE ports, dual-band Wi-Fi, Bluetooth 5.2, and many other features. The NXP i.MX 8M Plus is a...

Continue Reading

Seeedstudio LinkStar-H68K-1432 V2 is A Tiny Pocket Router with 2x1GbE + 2×2.5GbE ports

After the succession of LinkStar-H68K, Seed Studio has announced LinkStar-H68K-1432 V2 a pocket-sized router powered by the Rockchip RK3568 SoC. The most interesting feature of this router is that it features 2 x 1GbE and 2 x 2.5GbE ports with dual-band Wi-Fi 6 and a 4K-capable HDMI 2.0...

Continue Reading

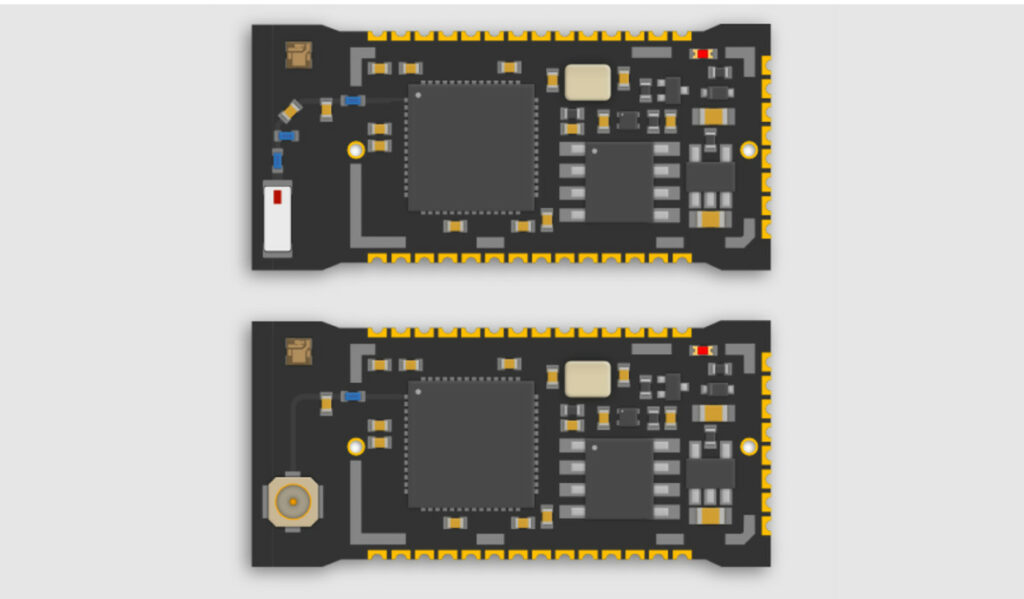

Unexpected Maker NanoS3 Features ESP32-S3 in Self-proclaimed world’s smallest from factor

Seon Rozenblum, better known as Unexpected Maker, has recently launched what they claimed to be the world’s smallest fully-featured ESP32-S3 module it packs all the peripherals, and wireless connectivity features of an ESP32-S3 module and features the tiny package size as the original...

Continue Reading