Tag: Batteries

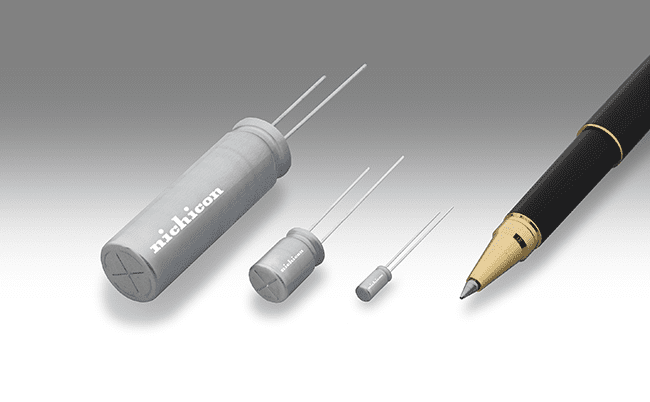

SLB Series Lithium-Ion Rechargeable Batteries enable ultra-fast charge/discharge

Nichicon Corporation’s SLB series of small lithium-ion rechargeable batteries, featuring ultrafast charge/discharge rates, long life, and high stability, have been adopted for use on the stylus pens (“S Pens”) of the Galaxy Note 10 and Note 10+, smartphone models by Samsung...

Continue Reading

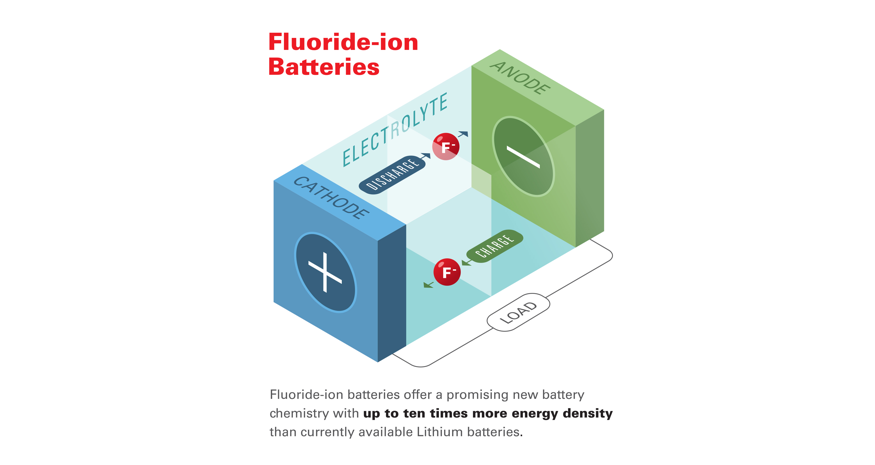

Researchers Develop new Battery chemistry with 10X More Energy Density over Lithium

New co-authored paper demonstrates potential ten-fold energy density increase over existing lithium-ion battery technologies. Scientists from Honda Research Institute have collaborated with researchers at California Institute of Technology (Caltech) and NASA's Jet Propulsion Laboratory...

Continue Reading

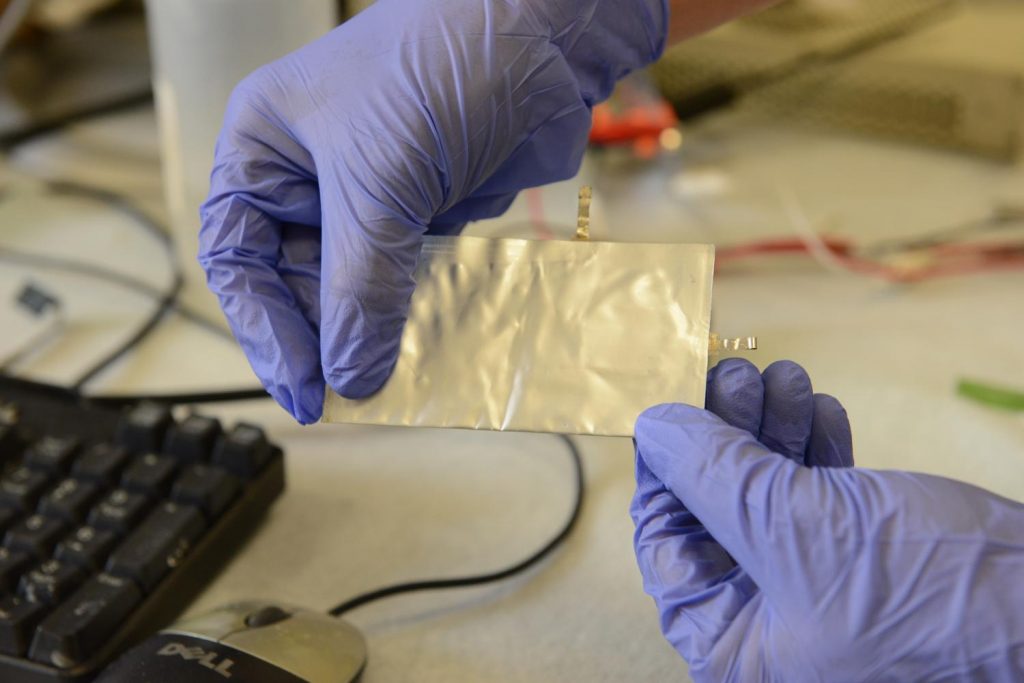

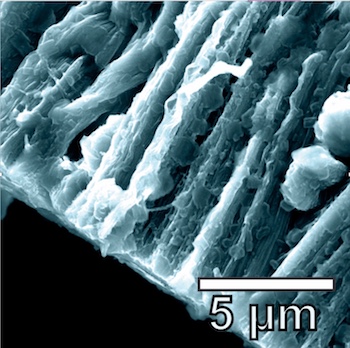

Malleable Micro – Batteries for Wearable Technology

A new innovative technology for wearables is taking over the market of future technology. Wearables are portable systems that house sensors to make measurements from the wearer's body. Powering these wearables requires flexible batteries that adapt to the specific material, and deliver...

Continue Reading

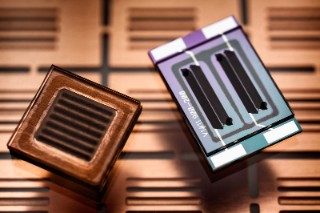

Materials that will bring better Aluminium batteries

Giant Strides have been moving towards research and production of aluminum batteries. Different teams are working hard to ensure the production of sustainable Aluminium batteries. Recently, Standford University scientists released the first high-performance aluminum battery that can last...

Continue Reading

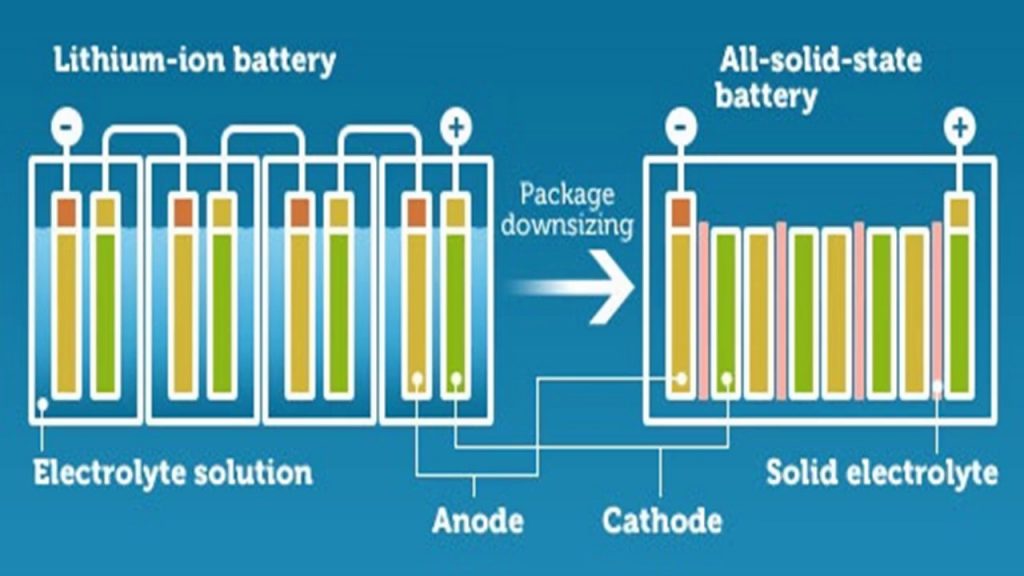

Solid State Li-ion Batteries – High Energy-Dense Batteries Are Closer Than Before

The Interuniversity MicroElectronicss Centre (IMEC) is an independent research center which deals with nanoelectronics and digital technologies. Their headquarters are situated in Leuven, Belgium. Recently IMEC began to research and prototype Solid State Lithium-ion batteries. Solid State...

Continue Reading

New Batteries with 3 & 15 Times Energy Density

With the rapid growth of battery-based devices and tools, efficient energy storage systems are becoming more and more important. Of course there are many researches running around the world working on novel battery technologies. Two new cell technologies are working to deliver energy...

Continue Reading

ChargEST, A Travel Adapter To Charge Your Devices

When you travel, it’s a bit frustrating to fill your luggage with lots of chargers, cables, and adapters to fit your charging needs. In addition to the space it takes which makes it harder to bring every kind of charger you may need. ChargEST is designed to become your charging...

Continue Reading

An Introduction to LiPo Batteries

Average Man Vs Raspberry Pi has a handy article on LiPo batteries. LiPo batteries – to fear or not to fear? Up until very recently, I was petrified. Whilst most other competitors at Pi Wars 2015 were happily using this angry and volatile battery technology, Average Man over...

Continue Reading