Tag: nanotechnology

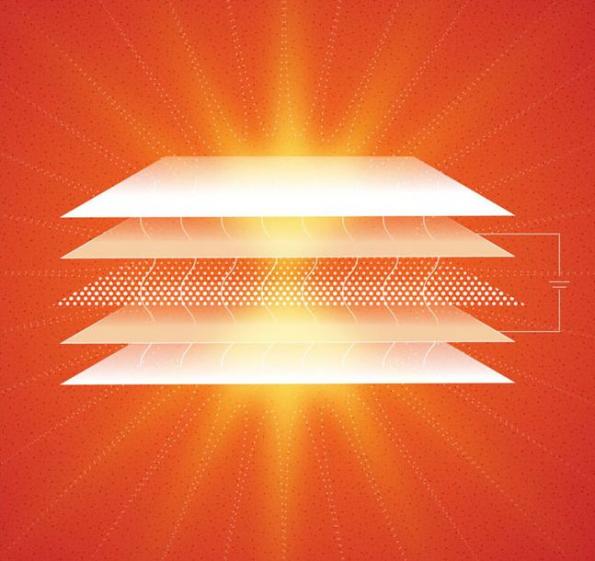

Physicists demonstrate atomically-thin ultra-fast room temperature LED

Graduate researchers at the City College of New York have demonstrated a LED based on half-light half-matter quasiparticles in atomically thin materials. By Julien Happich @ eenewsled.com This is also the first successful test of an electrically driven light emitter using atomically...

Continue Reading

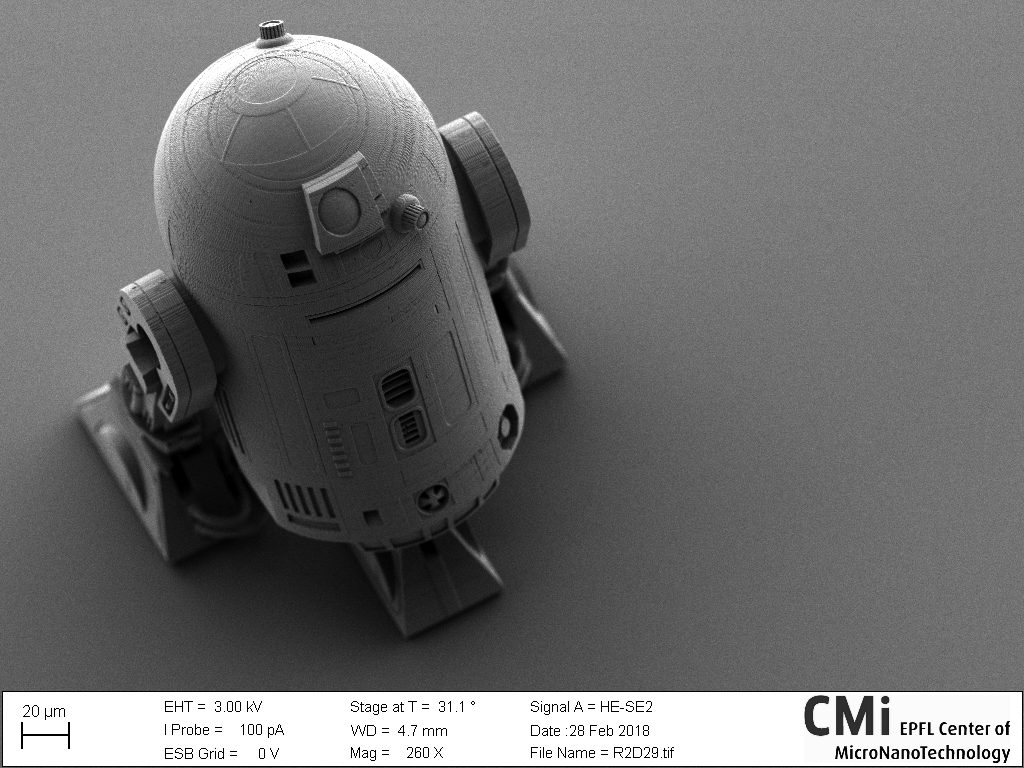

Micro R2D2 – Nanotechnology Picture of the Month Gallery

This is the 2018, February submitted for the nanotechnology image of the month. A long time ago in a galaxy far, far away.... *star wars theme* …. WAIT! In fact, the story unfolds right here and right now in the CMi with R2D2 battling armies of stormtroopers inside the SEM Merlin...

Continue Reading

SniffPhone – Screening for cancer made easy

A newly developed handheld medical diagnostic tool called the SniffPhone, analyses exhaled breath and is able to detect early signs of gastric cancer. The SniffPhone links via Bluetooth to a smartphone and is a totally novel application using nanotech chemical sensors, offering enormous...

Continue Reading

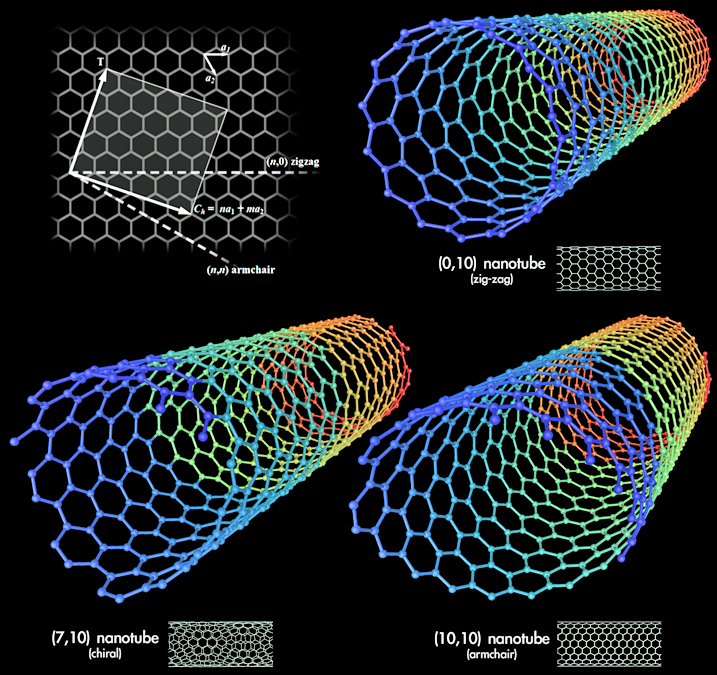

Long-fibre carbon nanotubes shown to be carcinogenic

by Thomas Scherer @ elektormagazine.com writes: Nanotechnology plays an indispensable role in modern materials research and new products. Carbon nanotubes (CNTs) enable production of novel materials with amazing properties. Progress is however not without risk and a recent study on...

Continue Reading

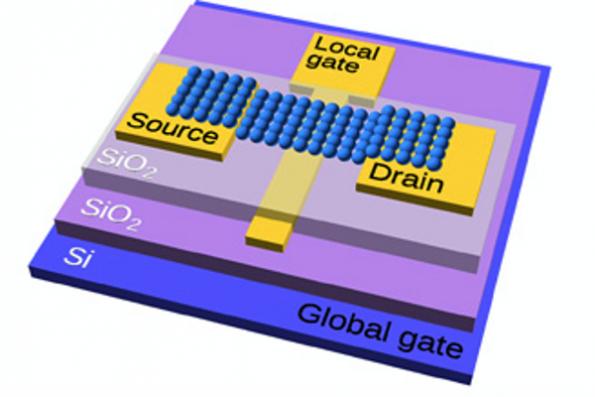

Coulomb Transistor — A New Concept Where Metal Nanoparticles Are Used In Place Of Semiconductor

A research group at the University of Hamburg has created a unique coulomb transistor that operates on the principle of the voltage control of the electron band gap in metallic quantum-dot nanoparticles. This Single-electron transistor represents an approach to develop less...

Continue Reading

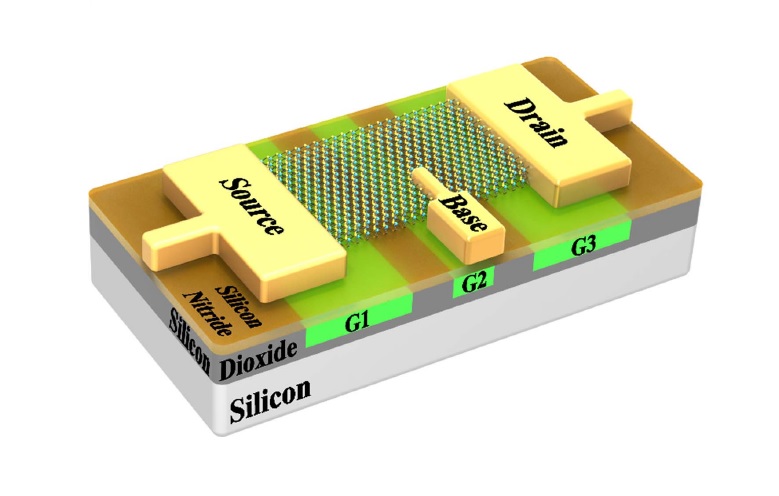

SUNY Polytechnic Creates 3-in-1 Device That Can Be A Diode, A MOSFET And A BJT

In a recently published study, a team of researchers at SUNY Polytechnic Institute in Albany, New York, has suggested that combining multiple functions in a single semiconductor device can significantly improve device's functionality and efficiency. Nowadays, the semiconductor...

Continue Reading

Early Diagnosis Now Possible With Smart Bandage

IoE era is here since we are able now to add mobile radio capabilities in our applications! The latest incarnation of the cell phone network will offer internet connectivity and possibilities that could only be dreamt of previously depending on your standpoint, and many more...

Continue Reading

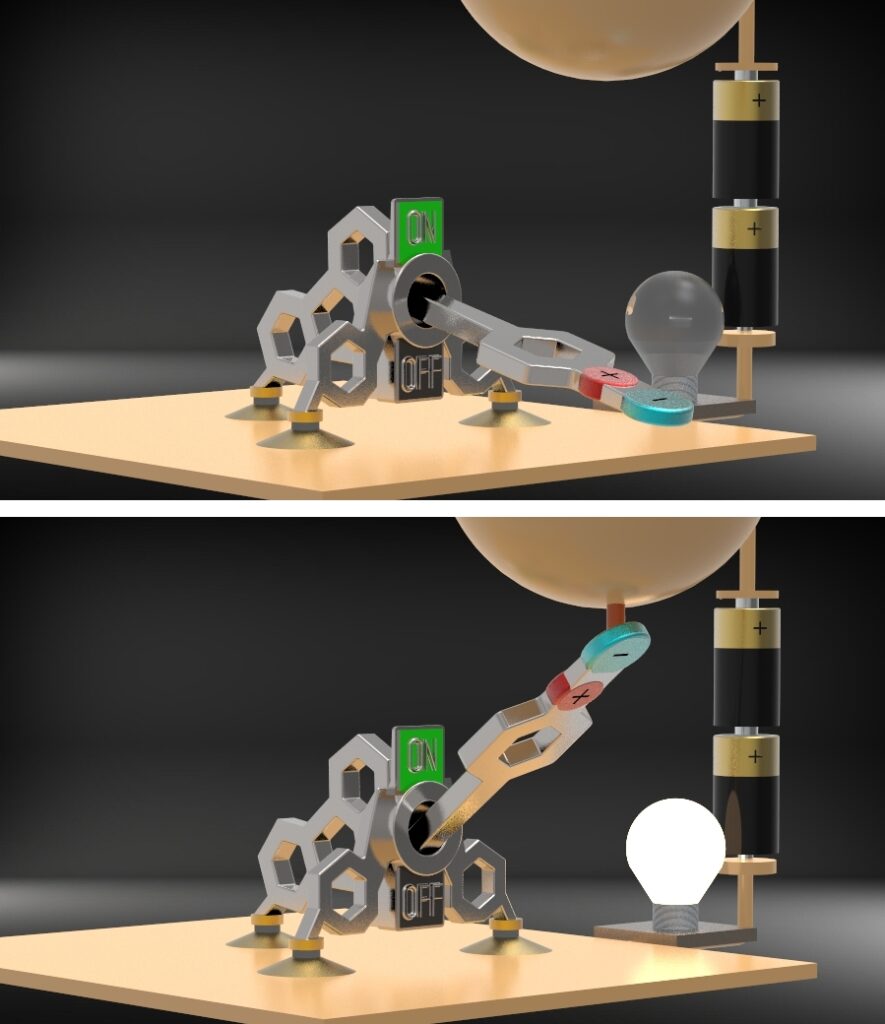

Reliable molecular switch

by Eric Bogers @ elektormagazine.com: Nanotechnology repeatedly breaks new records in the area of miniaturization. However, there are physical limits when reducing the size of electronic components and these will be reached in the near future. This means that new materials and...

Continue Reading