Tag: thermoelectric

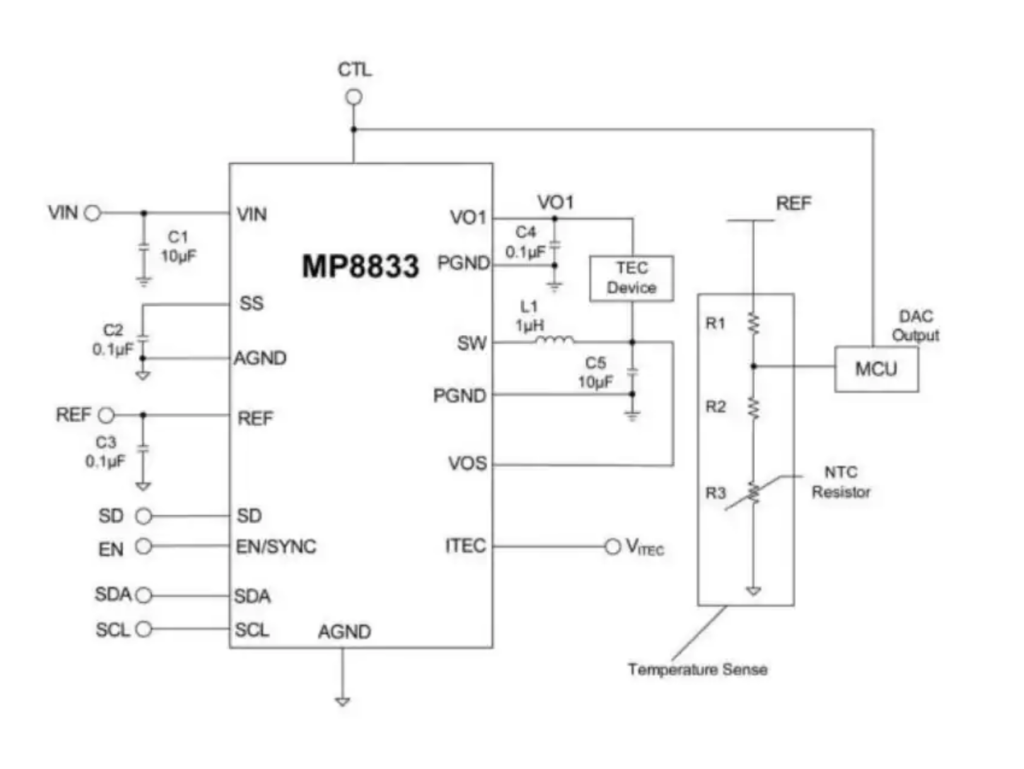

MP8833 1.5 A Thermoelectric Cooler Controller

Monolithic Power Systems monolithic thermoelectric cooler controller has built-in internal power MOSFETs Monolithic Power Systems introduces the MP8833, a monolithic thermoelectric cooler controller with built-in internal power MOSFETs. It achieves 1.5 A of continuous output current...

Continue Reading

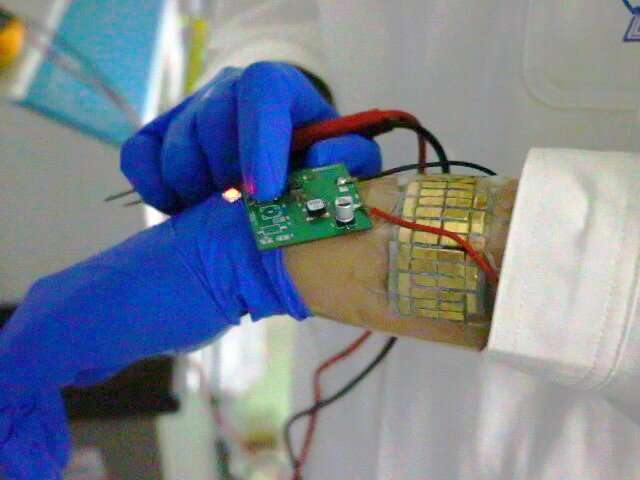

New Energy Harvesting System will Power Wearables using Heat Generated by Your Skin

While several advancements in battery technology, thanks to increased research in the field, have driven up the potential and range of applications for wearables, there are some application areas of wearables that are still being hindered by power, with issues ranging from the size of...

Continue Reading

Monolithic Power Systems (MPS) MP8833x Thermoelectric Cooler Controllers

Monolithic Power Systems (MPS) MP8833x Thermoelectric Cooler Controllers feature built-in internal power MOSFETs and achieves 1.5A continuous output current. These controllers include TEC current monitor, external SYNC function, and EN/SD for power sequencing. The MP8833x cooler...

Continue Reading

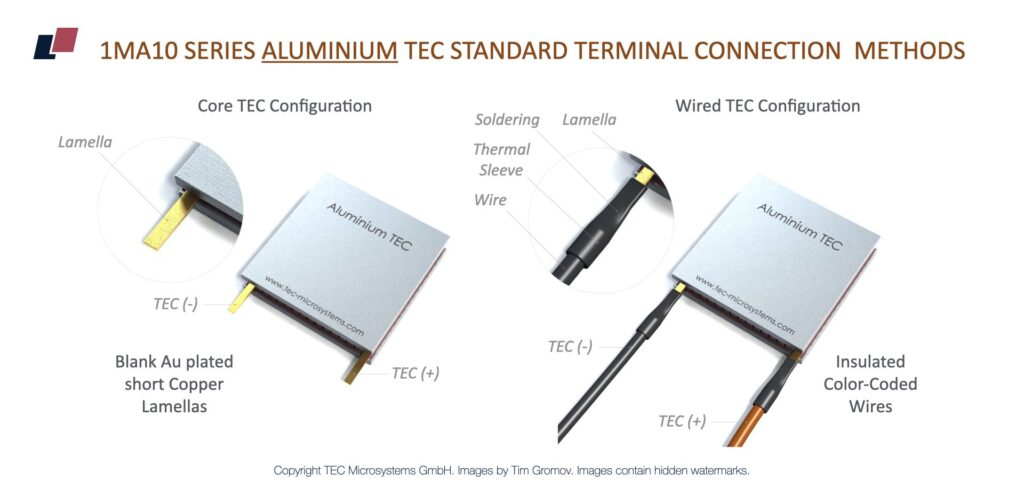

TEC Microsystems Introduces New Thermoelectric Coolers with Aluminum Plates

TEC Microsystems introduces the new 1MA10 Series of thermoelectric coolers, with aluminum plates instead of ceramics. All 1MA10 thermoelectric coolers have bare metal, aluminum plates instead of ceramics. Aluminum instead of ceramics is the key approach in TEC manufacturing. According...

Continue Reading

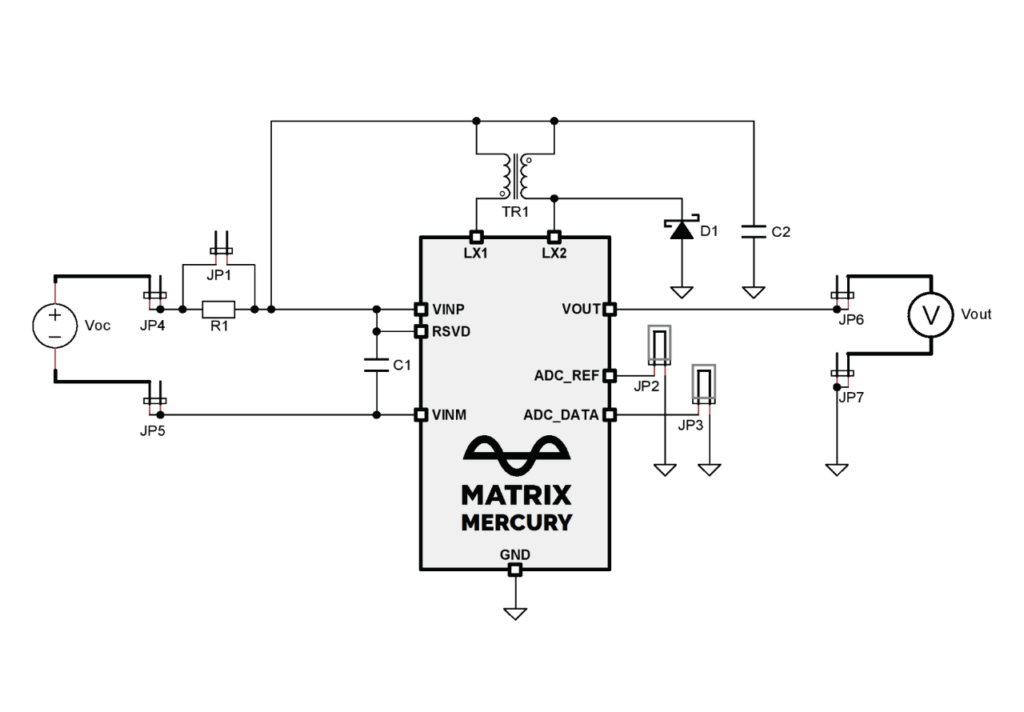

Mercury DC/DC Boost Converters harvest energy from TEGs

MATRIX Industries' nanopower energy harvesting boost converter with microwatt cold-start, input impedance matching, and regulated output MATRIX Industries' Mercury is a family of highly integrated DC/DC boost converters that are ideal for harvesting and managing surplus energy...

Continue Reading

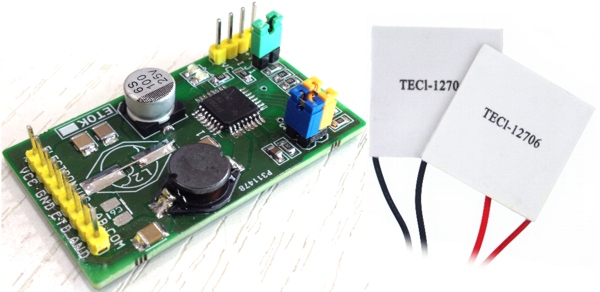

3A Thermoelectric Cooler (TEC) Driver

3A TEC Driver Module is a complete power stage solution to drive Thermoelectric Cooler (TEC). The required DC voltage input controls the output current. It consists of the Texas instruments DRV593 power driver IC, along with a few discrete passive components required for operation. It...

Continue Reading

Body Heat Provides Wearables With Eternal Power

The first watch to make use of the body's natural heat to uphold battery charge in wearables is now even being crowdfunded on Indiegogo. Who else but researchers from Texas A&M University (a hot place) came up with the solution. In today's wearables battery life is a...

Continue Reading

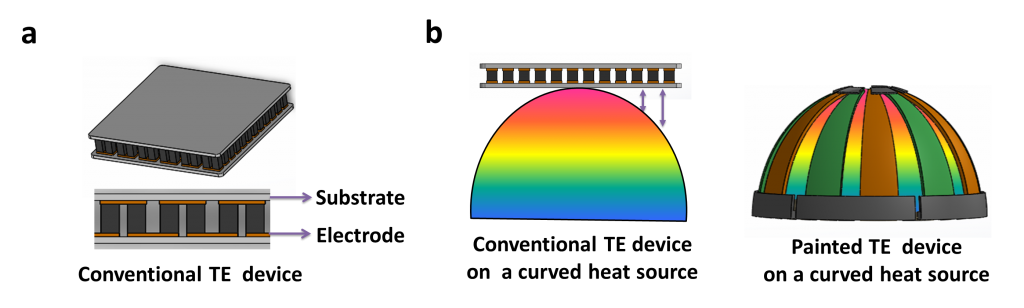

New Thermoelectric Paint To Convert Heat Into Electricity

Scientists at the Ulsan National Institute of Science and Technology have developed a thermoelectric coating that can be directly painted onto any surface to turn it into thermal generator. This new technique can be used to convert waste heat into electricity from objects of almost any...

Continue Reading