By transforming MXene-enhanced textiles into supercapacitors, a team of researchers from Drexel University and Accenture Labs have developed a flexible “patch” that could help power future wearables.

Dr.Yury Gogotsi, a professor in the College of Engineering at Drexel University, describes the breakthrough in a study he co-authored.

“This is a significant development for wearable technology.” “To fully integrate technology into fabric, we must also be able to seamlessly integrate its power source — our invention shows the path forward for textile energy storage devices.”

Video

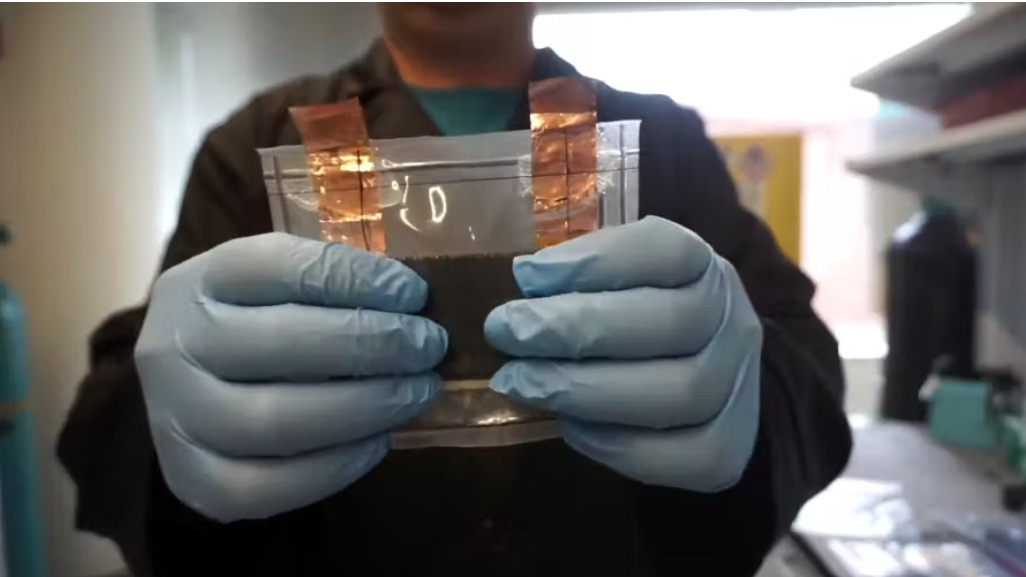

A smart fabric supercapacitor has been shown to be able to power real-world electronics, such as two Arduino microcontrollers. (source: Inman et al.)

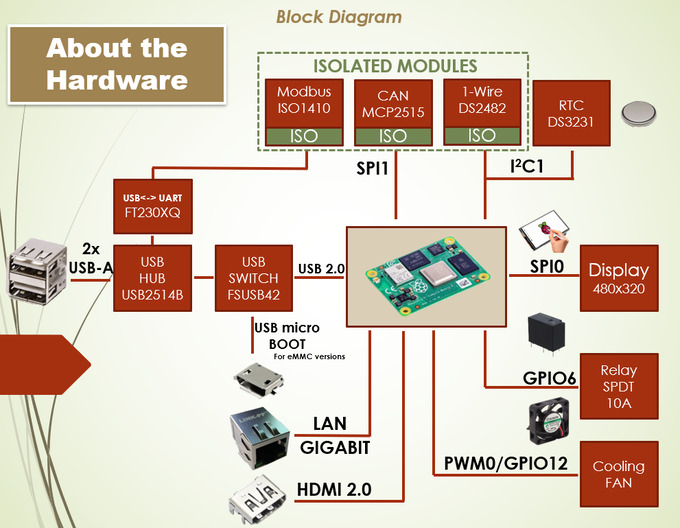

The work of the team built upon previous efforts to “functionalize” fabrics by using MXene, a family of two-dimensional inorganic compounds that were first described in 2011. These earlier efforts concentrated on the resilience and electrical conductivity of the materials. However, this time the researchers wanted to see if MXene-enhanced fabrics could be turned into energy storage systems with a high enough energy density to power real-world electronics. More specifically, they wanted to see if the MXene-enhanced fabrics could power two off-the-shelf Arduino microcontrollers, an Arduino Pro Mini 3.3 V and an Arduino Uno, which were connected to a temperature sensor and radio.

Tetiana Hryhorchuk, the co-author, explains,

“While there are many materials out there that can be integrated into textiles, MXene has a distinct advantage over other materials because of its natural conductivity and ability to disperse in water as a stable colloidal solution” “This means textiles can easily be coated with MXene without using chemical additives — and additional production steps — to get the MXene to adhere to the fabric. As a result, our supercapacitor showed a high energy density and enabled functional applications such as powering programmable electronics, which is needed for implementing textile-based energy storage into real-life applications.”

The design proposed by the group takes the form of a supercapacitor “patch,” which was constructed to maximize energy density and, as a result, minimize the use of active materials. This was done to keep costs down and to prevent the resulting clothing from being uncomfortable to wear. The production method is straightforward: first, woven cotton is doused in an MXene solution, and then an electrolyte composed of lithium chloride is layered on top. A cell is created by sandwiching two layers together to create it, and stacking five cells together was found to be suitable for driving the Arduino, offering a power output of up to 6V.

Alex Inman, the co-author, says,

“We came to the optimized configuration of a dip-coated, five-cell stack with an area of 25 square centimeters [around 3.9 square inches] to produce the electrical loading necessary to power programmable devices,”. “We also vacuum-sealed the cells to prevent degradation in performance. This packaging approach could be applicable to commercial products.”

The work done by the group has been published in the Journal of Materials Chemistry A under closed-access terms.