You have probably heard the term “OEM” before and chances are that you are within arm’s reach of several OEM products wherever you are seated presently. OEM, short for “Original Equipment Manufacturer”, refers to a company that produces systems or components that may be used in another company’s end products. OEMs are usually the first inventors and designers but not the sellers of the finished products. They license out the products they make to be used as components in another’s company products, hence marketing them under the other company’s brand name.

What an OEM Service Means

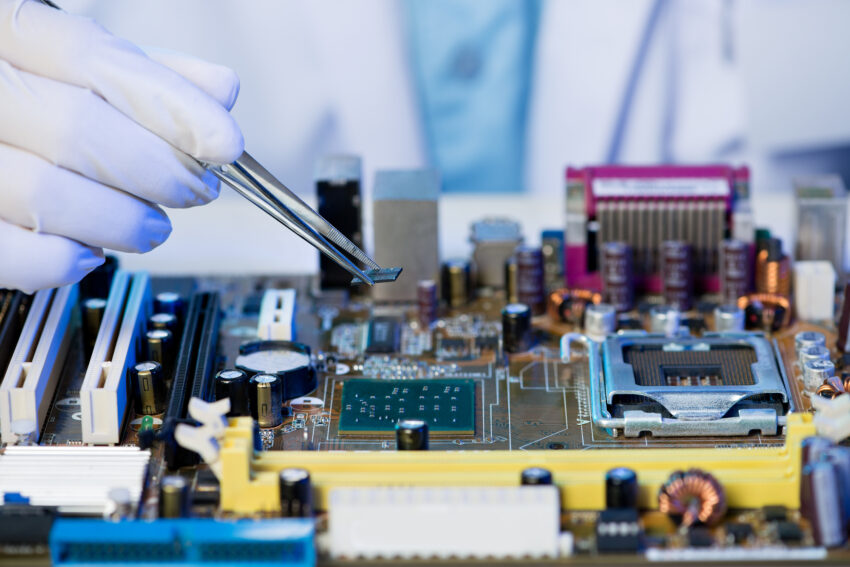

So an OEM service is typically a collaboration between a supplier who shows willingness and ability to make customized designs of products according to the needs and specifications of a buyer. Many brand-name electronics and appliances we see today are good examples of OEM services. A common one is a relationship that exists between a manufacturer of individual electronic components and a company such as Samsung or Sony that put the OEM parts together to make their own finished products. Another great example is the automotive industry. The car you bought was not entirely manufactured by the car company; some parts of the car such as the airbags, navigation units, spark plugs, air conditioners, dashboards, sensors, and even the engines, were manufactured by or outsourced from other companies. You will be shocked to know how small the efforts put by the company in supplying the parts were, compared to branding and marketing.

Is it also the computer manufacturers who integrate several OEM parts such as software and processors into the solutions they sell, or the Ralph Lauren company that bought customized fasteners from a maker of buttons to be used in a shirt that boldly carries the banded RL stamp on it? OEM services are literally scattered everywhere around us. The question is …

Why OEM Service?

Partnering with an OEM helps enterprises increase efficiency, reduce labor cost, streamline processes, save time and save money.

OEM products are usually cheaper due to an increased level of production. “The OEM excels in building one product and one product only, and thrives by building hundreds of thousands, or even millions of those products on a cost-effective, streamlined basis,” says TheStreet. When an OEM undertakes contract manufacturing of components, the reseller is allowed more time to focus on its core capabilities and processes as it would not have to develop each part or system by itself. The company also does not have to incur the extra costs or increased capacity involved in manufacturing those components in-house (like having to build manufacturing facilities). All they need to do is just integrate the outsourced parts into their system and sell under their own brand name.

OEMs also deliver a good return on investment to the partnering company by ensuring they make sure products that live up to expectations.

“OEM parts, components and products extend the life of the partnering company’s product with a no account casinos list, thus maintaining top performance and saving money with replacement parts and increasing the company’s financial bottom line.”

Most organizations now try to reduce their OEM and vendor complexity by just patronizing a centralized support or service system, as like David Subia rightly said in his IBM blog,

“trying to support IT solutions that include products from several vendors would be like having to manage the roughly 30,000 parts that make up your car. Would you have multiple vendors managing each part, or go to one trusted mechanic to ensure that it performs efficiently, safely, and at minimal cost to maintain?”

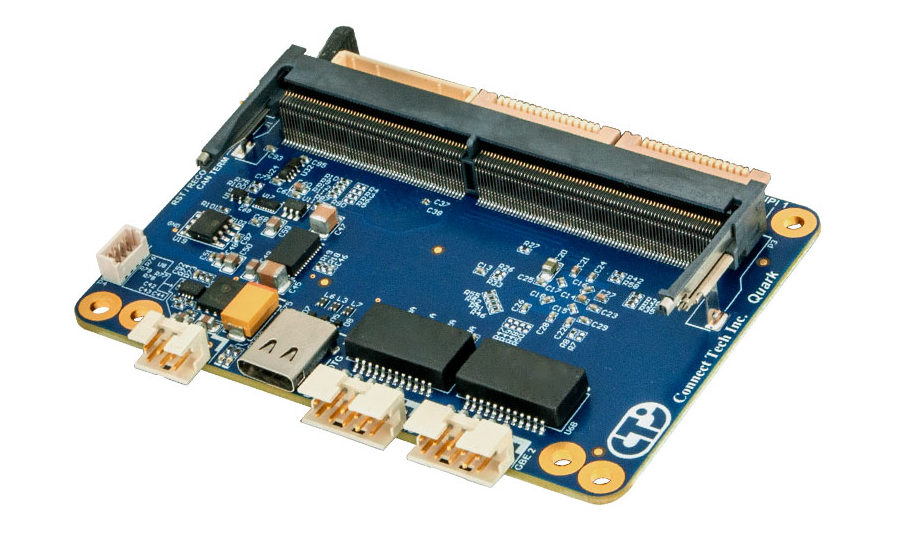

PCBWay OEM Service

With several years of experience in PCB prototype and fabrication, PCBWay is one of the most experienced and trusted PCB manufacturing companies in China.

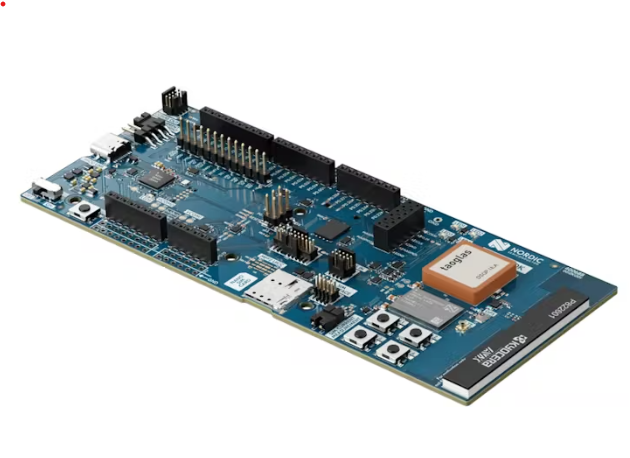

PCBWay in partnership with strategic alliance partners has a contract manufacturing service that includes product design, product development, engineering validation, PCBA manufacturing service, and supply chain management. This One Stop Shop Solution aims at simplifying and managing all the complexities at one stop, providing all the services you may need – from early design concepts to packaging fully assembled devices that are ready for shipment. They work closely with manufacturers throughout the whole process to ensure reduced cost while maintaining performance.

PCBWay OEM services focus on achieving product manufacturing and intelligence while the clients focus on product performance. The company page reveals that “PCBWay OEM uses the Internet, Internet of Things, and cloud technology to deeply transform the entire value chain of the electronics manufacturing industry, realize centralized order input, digital engineering technical services, and highly digital workshops, helping factories to produce according to customer needs.”

PCBWay OEM Services provide high-quality electronic products for global brands while maintaining quality and on-time supply chain services.

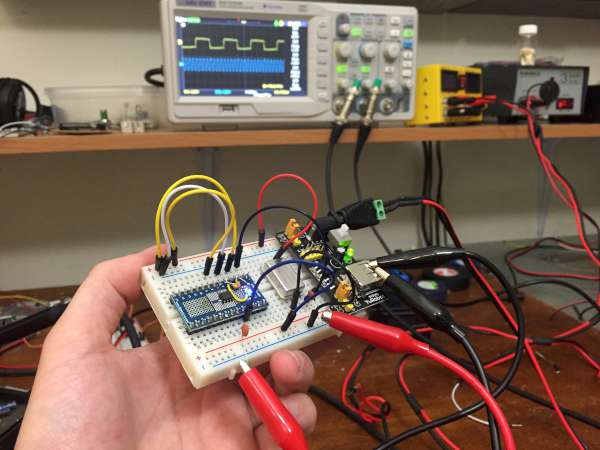

Examples of PCBWay-OEM Solutions and Design Cases

PCBWay OEM has recorded quite a number of success stories already, let’s take a quick look at some of them.

Client: A high-tech technology client that manufactures smart grid solutions, energy-efficient power generation, and distribution solutions.

Scope of Contract: Design and production of PCB board, selection and replacement of domestic chips, molding and plastic injection, assembly of finished products, and final inspection testing and certification performance.

Achievements: PCBWay-OEM was able to reduce the total production cost by 15%, successfully helped the client solve the global chip shortage problem, met all the US and European requirements, and still had a fast turnaround time completing PCB designs and delivering some samples to clients in 30 days.

The Fengmi step-less frequency conversion smart fan featuring a 99-gear speed control, a mobile APP intelligent control, 16 feather fan blades, and power saving mode, took only 5 months from research and development to mass production.

PCBWay-OEM did not only undertake the material procurement and overall production process, but it also saw the intelligent upgrade of the fan. It utilized its strong supply chain support to ensure the quality of each product. The circuit boards, SMT, molds, sheet metal and assembled finished products were all completed by self-operated factories.

Quantities Delivered: 100,000 units

Customer’s Requirement:

“We would like to protect the sensor against humidity, dirt, or any other damage that could be introduced due to the fact that it is in contact with the skin and the air. But this protection layer should be transparent in order to help the performance of the sensor. Do you have any special resin or something to protect it? We were thinking of something that could be adapted to any shape.”

Conclusion

In summary, PCBWay-OEM services help clients complete integrated R&D tasks faster and better, achieve rapid and sustainable development, and eventually deliver stable, reliable, and efficient products. Feel free to contact them for a quote on design concept development, engineering services, appearance models, functional prototype, quick turn tooling, injection molding, or contract manufacturing.

(stock photos from depositphotos.com)

Consider: OEM and ODM are not the same…

An Original Equipment Manufacturer (OEM) [1] is generally perceived as a company that produces non-aftermarket parts and equipment that may be marketed by another manufacturer. It is a common industry term recognized and used by many professional organizations such as SAE International, ISO, and others. However, the term is also used in several other ways, which causes ambiguity. It sometimes means the maker of a system that includes other companies’ subsystems, an end-product producer, an automotive part that is manufactured by the same company that produced the original part used in the automobile’s assembly, or a value-added reseller.

An Original Design Manufacturer (ODM) [2] is a company that designs and manufactures a product, as specified, that is eventually rebranded by another firm for sale. Such companies allow the firm that owns or licenses the brand to produce products (either as a supplement or solely) without having to engage in the organization or running of a factory.

* References:

1. Original Equipment Manufacturer (OEM)

https://en.wikipedia.org/wiki/Original_equipment_manufacturer

2. Original Design Manufacturer (ODM)

https://en.wikipedia.org/wiki/Original_design_manufacturer