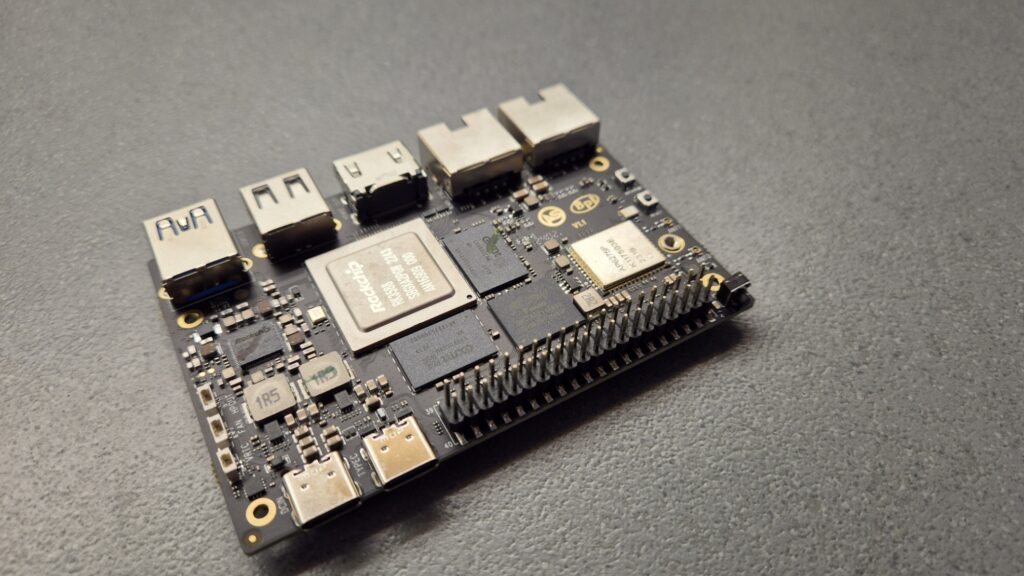

ArmSom Sige7 Review- A Rockchip RK3588 SBC with Dual 2.5GbE Ethernet, NVMe Storage, and Triple Display Output

Introduction The ArmSoM-Sige7 is a compact single-board computer (SBC) powered by the RK3588, an octa-core 64-bit SoC clocked at 2.4 GHz. The SoC features a 6TOPS NPU for AI tasks and supports up to 32GB of LPDDR4x RAM and 128GB of eMMC flash storage. It includes an M.2 2280 socket for...

Continue Reading

X-SENSE SC07-WX WiFi Smoke & CO Alarm Review – Your Smart Home Guardian for Smoke and CO

The X-Sense SC07-WX is a battery-powered smoke and carbon monoxide detector that combines Wi-Fi connectivity with a smartphone app for remote monitoring and alerts. The sensor uses a photoelectric smoke sensor and an advanced electrochemical carbon monoxide sensor for fast and...

Continue Reading

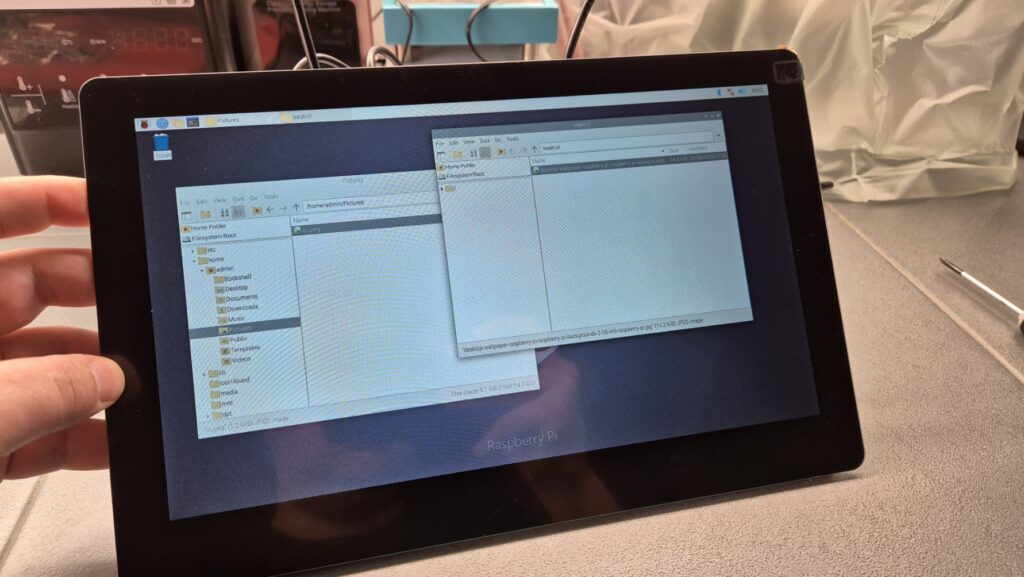

CrowVision 11.6” Capacitive Touch Display Review – Compatible with Raspberry Pi, BeagleBone, Jetson Nano, and More

The CrowVision is an 11.6” IPS Capacitive Touchscreen Display module specially designed to be attached to most single-board computers(SBC) with adjustable mounting holes in the back. The display features a resolution of 1366×768, so for an 11.6” it translates to 135ppi. It offers...

Continue Reading

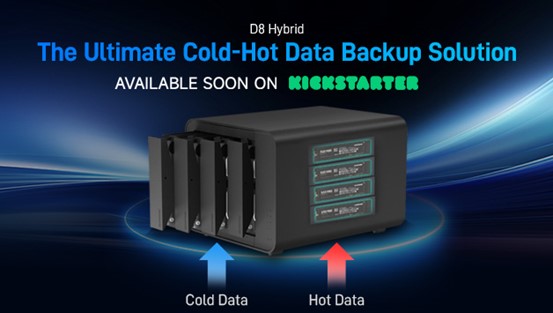

TerraMaster Launches the Industry’s First 8-bay 10Gbps Hybrid Storage with an Early Bird 33% Discount

TerraMaster, a professional brand that focuses on providing innovative storage products for homes and businesses, has recently released the D8 Hybrid which is the industry's first hybrid HDD NVMe SSD enclosure. It can hold 4 SATA HDDs/SSDs and 4 M.2 2280 NVMe SSDs, with a capacity of...

Continue Reading

Arduino Introduces 4G Global Connectivity for Portenta in Mini-PCIe Form Factor

Arduino Pro has introduced a groundbreaking solution for IoT development with the launch of 4G global connectivity for its Portenta board, now available in a compact Mini-PCIe form factor. This innovation enables developers to swiftly create IoT devices with seamless global 4G cellular...

Continue Reading

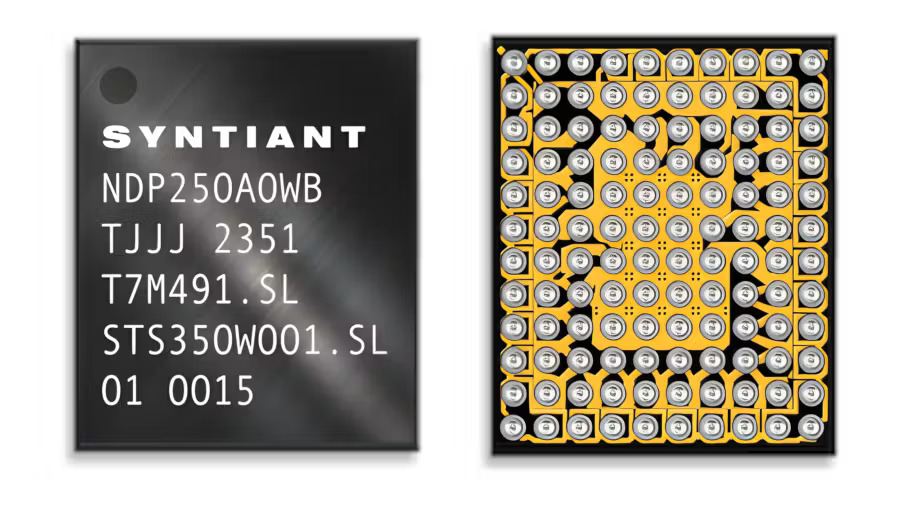

Syntiant Unveils NDP250: A Breakthrough in Microwatt AI Processing for Always-On Applications

Syntiant, a leading provider of on-device deep learning solutions, has introduced its latest innovation: the NDP250 Neural Decision Processor. Boasting an impressive 30 giga-operations per second (GOPS) performance, the NDP250 sets a new standard for efficiency in AI processing. This...

Continue Reading

Tangram Vision Self-Calibrating HiFi 3D Sensor Features ROS 2 Integration and On-Device AI

The Team at Tangram Vision has recently introduced Self-Calibrating HiFi 3D Sensor a cutting-edge depth sensing solution designed primarily for robotics applications. The camera module integrates high-fidelity 3D sensing with on-device AI capabilities, to provide a Plug-'n'-Play...

Continue Reading

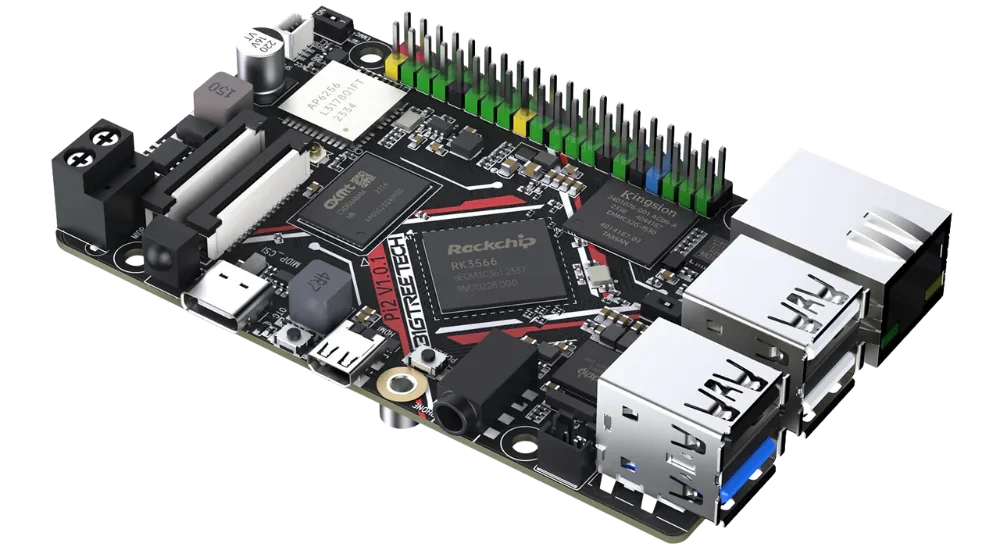

Rockchip RK3566 Powred BIGTREETECH Pi 2 Features Gigabit Ethernet, Dual-band Wi-Fi and more

The BIGTREETECH Pi 2 is a powerful single-board computer (SBC) powered by the Rockchip RK3566 chipset. It boasts 2GB of LPDDR4 RAM and a 32GB eMMC module, offering robust performance and ample storage capacity. With features like Gigabit Ethernet, dual-band Wi-Fi, and Bluetooth 5.2, it...

Continue Reading