Tag: SMT

JLCPCB assembly for 2022 and the Future + 54$ Coupon

JLCPCB for faster electronics manufacturing, carrying out its new standard PCB assembly service as an ace project created by JLCPCB, has been committed to reducing PCB assembly costs, improving ordering experience, speed up SMT lead-time, therefore, it gives the hand for professional...

Continue Reading

BeanCounter is an “Affordable” SMT Parts Counter that operates on a CR2032 coin cell

As a part of the Microchip Get Launched design competition, Virginia-based Great Big Factory, an electronic device manufacturer, has designed SMT parts counter that runs on a CR2032 coin cell– BeanCounter. Yet to be launched for crowdfunding on CrowdSupply, the manufacturer has...

Continue ReadingOpen Source Manual Pick And Place Machine For PCB Makers

Details about Pixel Pump, which is an open-source vacuum pump for manual SMT assembly have been posted on Crowd supply. It features a comfortable pen, a foot pedal, RGB LED buttons, and host a variety of features that make hand assembly a lot more fun. It is perfect for manual SMT...

Continue Reading

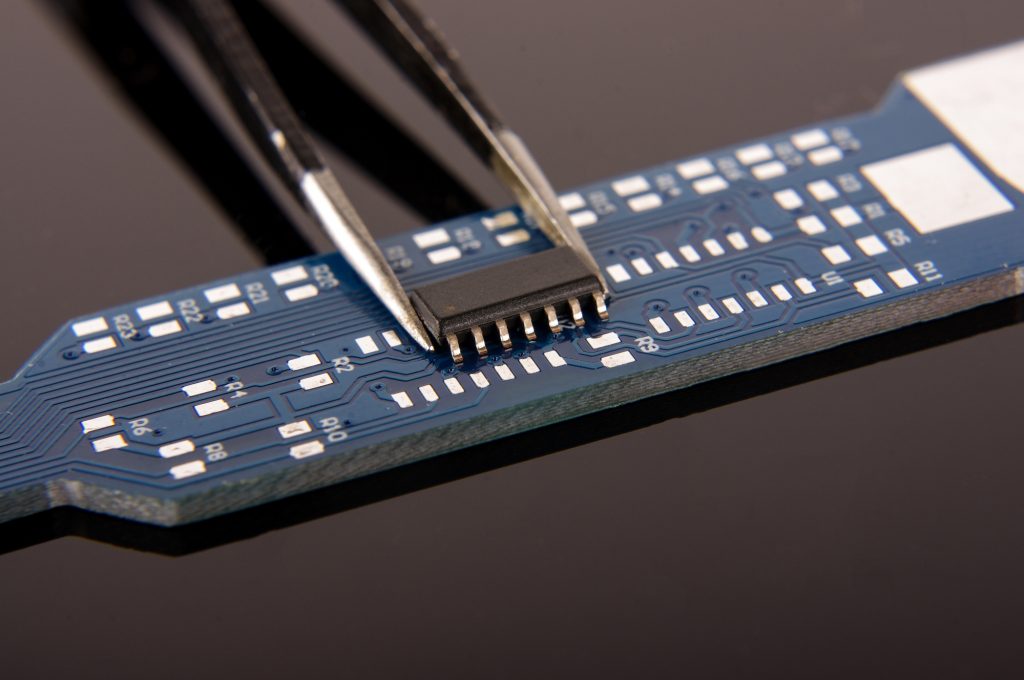

What Is Surface Mount Technology?

Surface Mount Technology was developed in the 1960s. During the 1970s and 1980s a revolution in the automation industry was begun, which raised the demand for Surface Mount Technology Components for a better assembly process. Before Surface Mount Technology, electronic components came...

Continue Reading

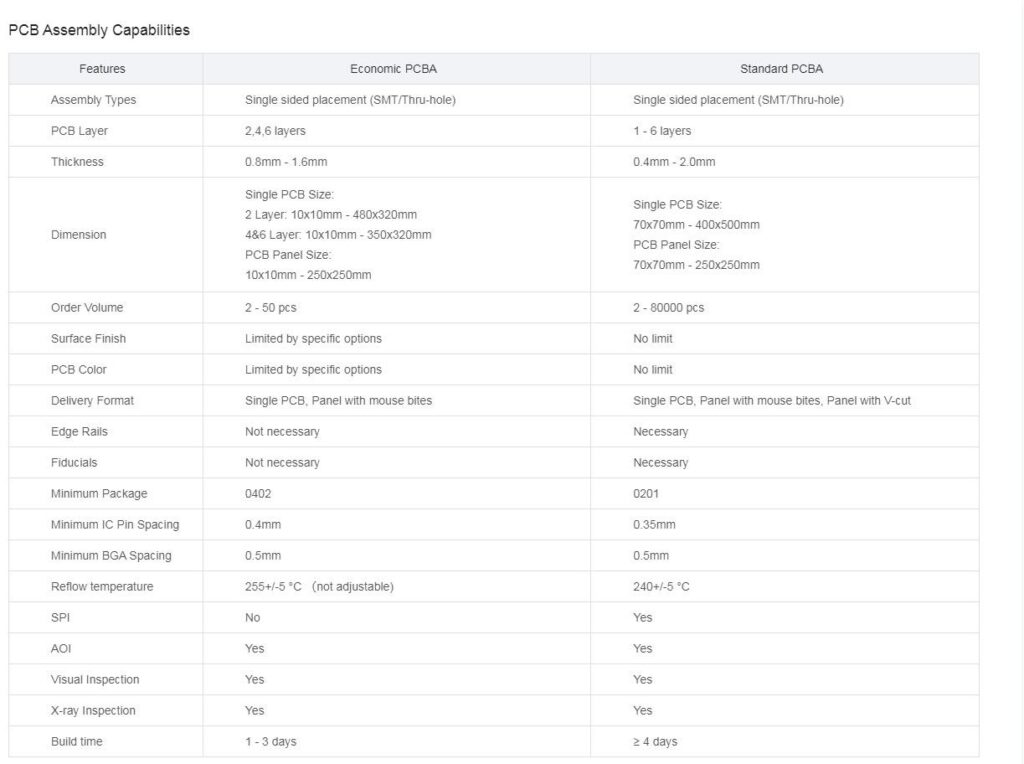

AOI in PCB & PCBA Manufacturing Process of PCBGOGO

PCB assembly consists of many steps. For PCBs with through-hole components, the assembly is quite easy. But for SMT components, elements are placed on the conductive pads with previously applied solder paste that holds the SMT parts together. Then the components are soldered to the...

Continue Reading

PCBgogo: Manufacture Your PCBs Fast and with Ease

For hobbyists and professionals, getting a reliable company to build your PCB is very important. One of these companies for building your PCB is PCBgogo. PCBgogo is one of the largest and most popular PCB manufacturers. Located in Shenzhen, China, the facility is built in over 2400 sqm...

Continue Reading

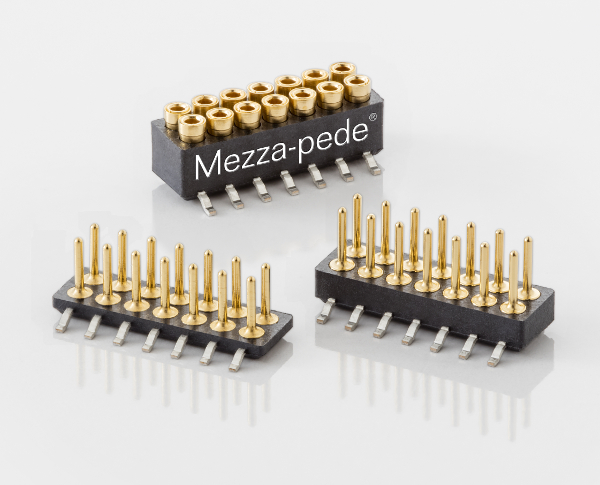

Mezza-pede 1.0mm pitch SMT Connectors from Advanced Interconnections Corp

Mezza-pede® 1.0mm pitch SMT Connectors from Advanced Interconnections Corp. are designed for low profile board-to-board or flex cable-to-board applications where long-term reliability and a compact size are required. With Advanced’s enclosed screw-machined socket, 6-finger contact,...

Continue Reading

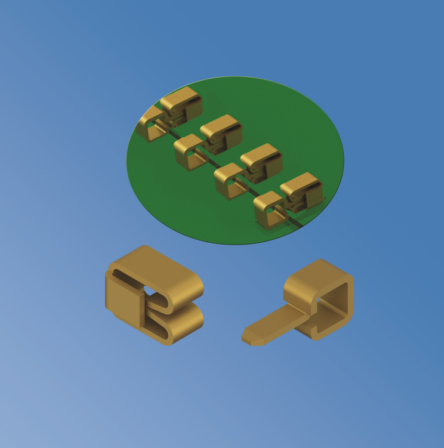

New SMT PCB Connectors to Transmit Signals or Power Across PC Boards

New, Low Profile, SMT PCB Edge Connectors from Keystone. New Hyde Park, NY, A new series of SMT PC Board Connectors designed to transmit signals or power across PC Boards are the latest connectivity devices available from Keystone Electronics Corp. Quickly and easily set-up, these...

Continue Reading