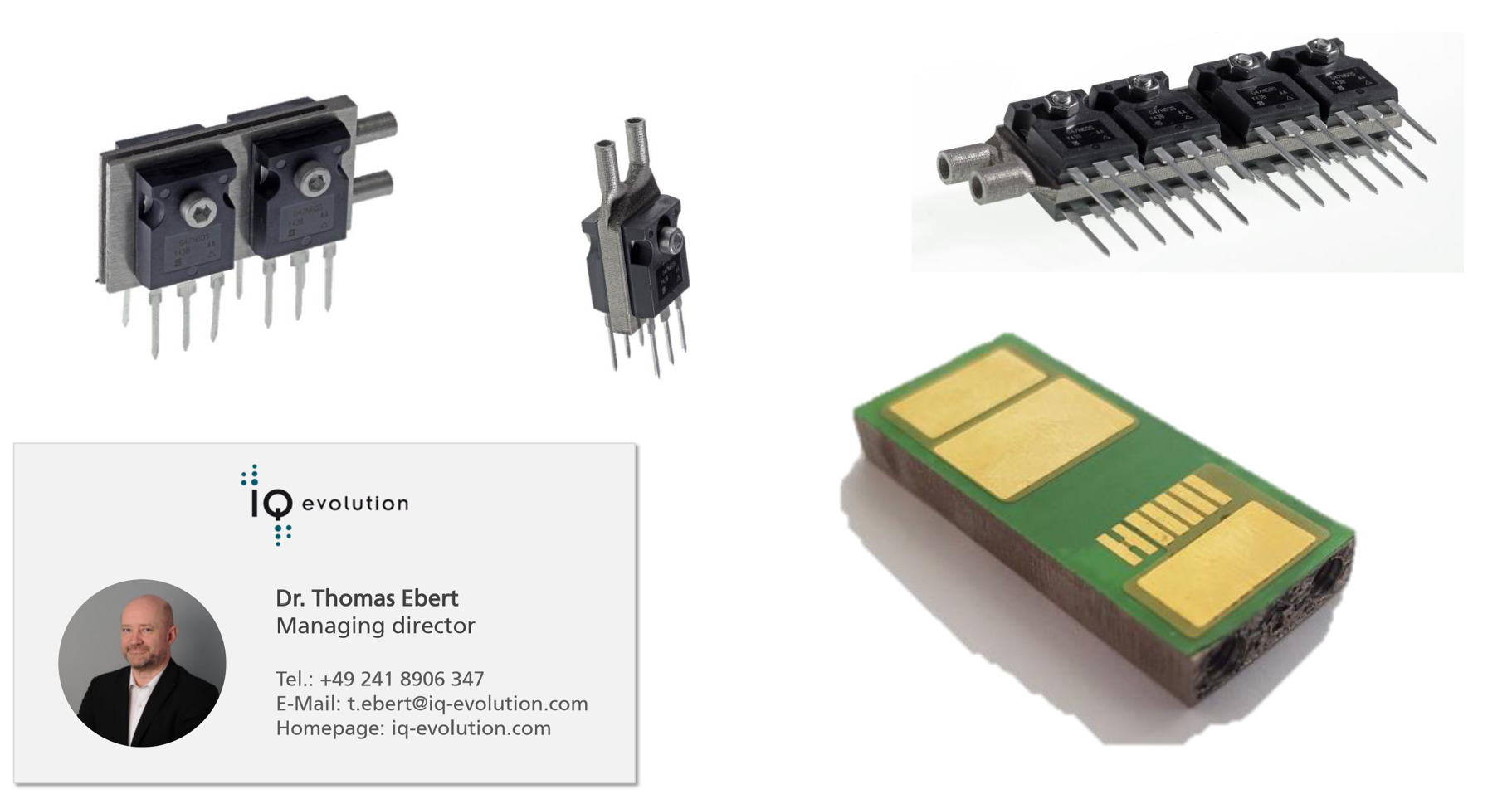

3D printed liquid cooled heatsinks cool down TO-247 transistors

Standard Transistor Cooler Made by 3D-printing using SLM (Selective Laser Melting) A very effective way to dissipate the high heat flux densities of electronic power modules or power devices with high power density is the use of micro-coolers or micro-channel heat sinks made by SML. These active small cooling elements can transmit up to 1000 W/mm².Besides a design for the often used TO-247 housings, all other housing types are available. Even customized designs in other shapes and thicknesses are possible

The coolers are produced by SLM procedure, the Selective Laser Melting. The procedure is also known as LPBF (Laser Powder Bed Fusion).IQ evolution refined this 3D-metal-printing process over more than 10 years, especially to the requirements of building microstructures. Rapid Prototyping and completed mass production are both efficiently producible with this technology. For more information about the the3D-printing process please use our download-center: http://iq-evolution.com/downloads_de/

more information: www.iq-evolution.com & https://eepower.com/technical-articles/innovating-3d-printed-liquid-cooled-heatsinks/