Category: DIY

MicroBeast is A Z80-Based DIY 8-Bit Computer Kit

MicroBeast is an eight-bit, Z80-based DIY computer kit built using readily available components. The device features a built-in keyboard, a unique 24-character display, USB-C for power, and various I/O options. Additionally, it integrates the CP/M operating system, which allows users...

Continue Reading

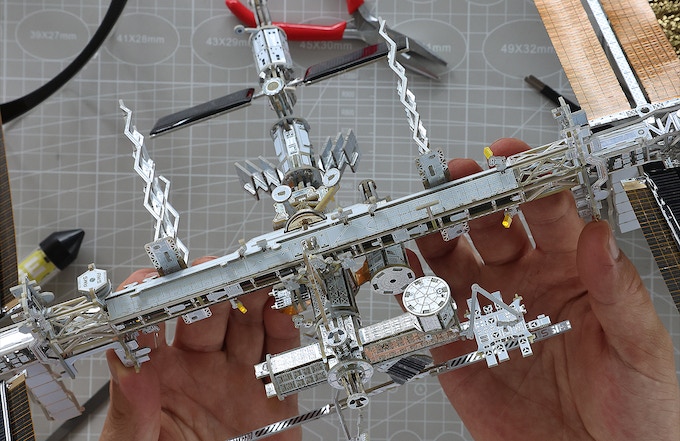

Space O: Do-it-yourself electronic kits that are inspired from NASA

A Geek Club is a group of designers and engineers who make electronic construction kits for people in over 70 countries around the world who are interested in learning more. Their engineering and robotics kits are made to stretch your mind, improve your skills, and help you learn more...

Continue Reading

DIY CircuitMess Chatter Uses LoRa Connectivity for Text Messaging

Satellite messaging devices have been around for several decades and with the introduction of various energy-efficient wireless technologies, many hobbyists and startups designed smartphone-like messaging devices, one being CircuitMess’ Chatter that uses LoRa communication and does...

Continue Reading

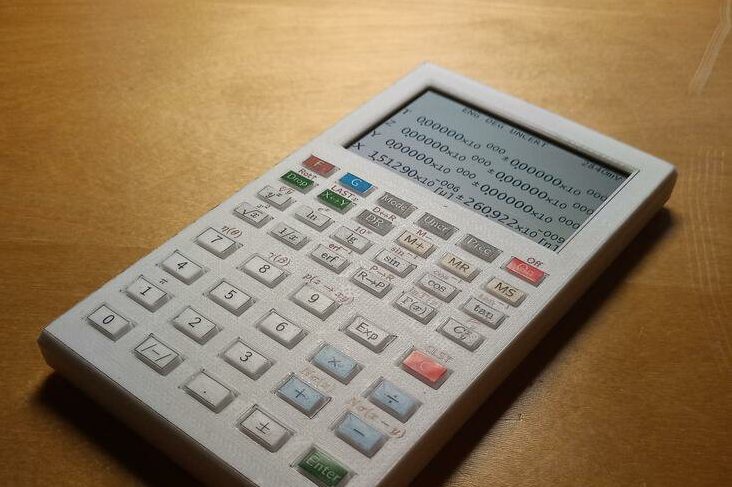

OpenRPNCalc: Custom scientific RPN calculator based on STM32

Reverse Polish Notation (RPN) is a popular method for representing mathematical expressions. In this notation, the operator symbol comes after the operands in contrast to the Polish notation, where the operators are placed preceding the operands. For example, the Polish notation for the...

Continue Reading

3D Printed Moon Lithophane Lamp

Lithophanes are artistic creations on ultra-thin translucent porcelain that is visible only when backlit with a light source. They are etched or modeled artworks made by a 2D image. The 2D image is first processed to make its gray-scale representation, and then, depending on the color,...

Continue Reading

Keybon: DIY a Functional (but Elegant) Macro Keyboard

So, we have all been there. Looking at our keyboard, adding bindings with our extra keys, but then to go "what did I put in that key?". It happens to the best of us, no matter how used you are with your apps, games, or workflow. A solution for this, which we have seen used a lot for...

Continue Reading

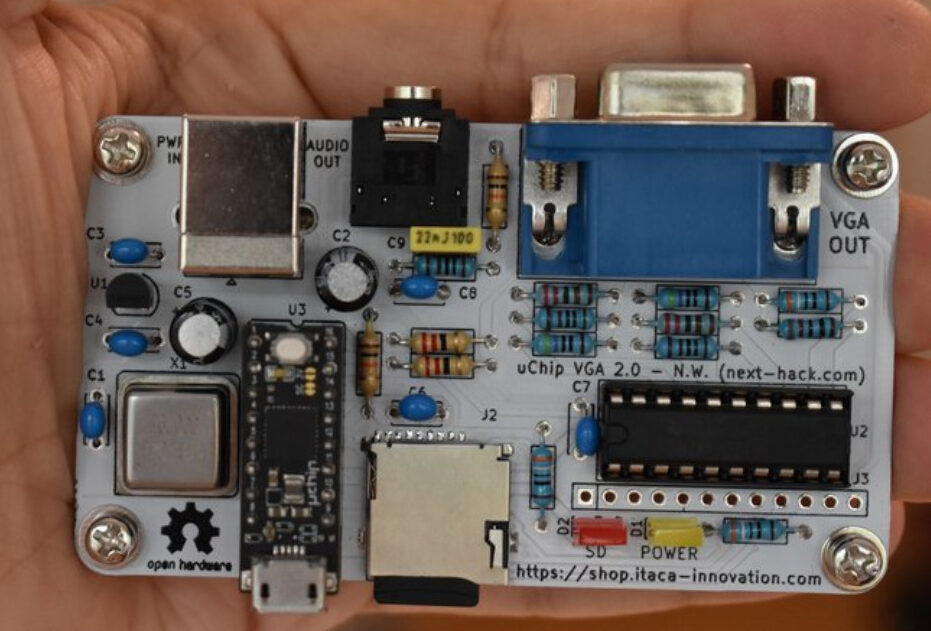

uChip VGA 2.0 is an Open hardware DIY retro-gaming console

Itaca Innovation has launched a campaign on Crowdsupply for a DIY open hardware retro-gaming console called uSVC. The uSVC is a simple, DIY game console that enables you to create and play retro-style 8-bit games with standard USB controllers and keyboards. It comes as a kit, so you...

Continue Reading

Teracube 2e: Next Evolution of Sustainable Phones

A mobile phone nowadays is an essential, probably the one thing we can't live without, with 7.2 mobile devices being in use worldwide. But did you ever take a moment to realize where all the old phones are? Electronic waste is a big concern, with 50 million tons being generated this...

Continue Reading