Category: Technology

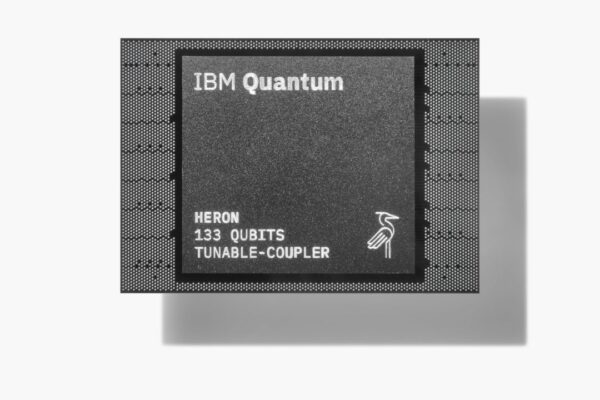

IBM Advances Quantum Computing Roadmap with Heron Chip and System Two Launch

IBM has recently revealed updates to its quantum roadmap, marking a significant milestone by introducing the 133-qubit Heron chip and the groundbreaking System Two quantum computer. Heron stands out as the inaugural member of a new series of scalable quantum processors, meticulously...

Continue Reading

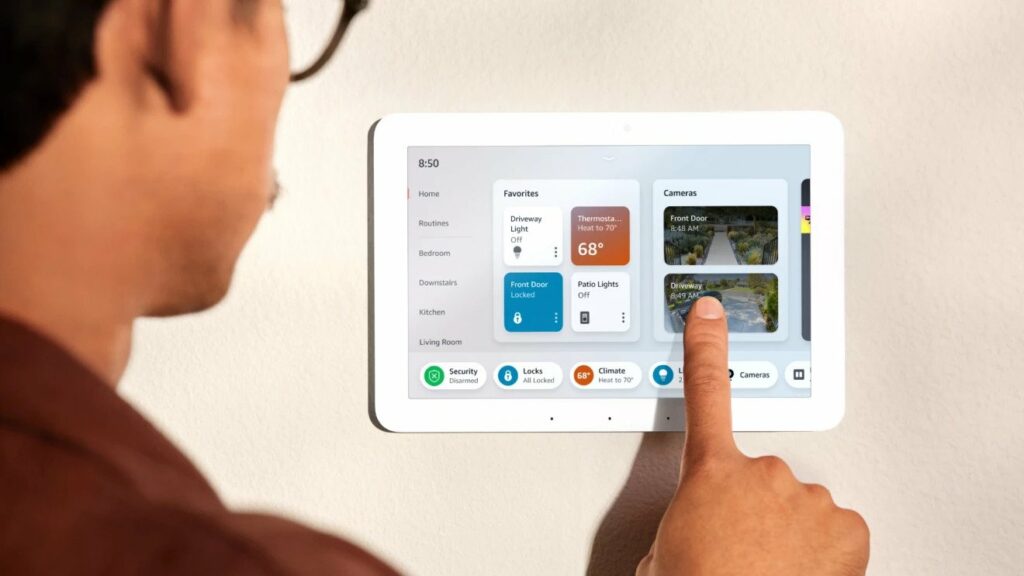

Amazon improves user experience of controlling smart homes with Alexa

Amazon highlights the challenges with your current interaction with Alexa. It believes that even though Alexa has improved the way people control their smart homes, there are still challenges. Users often have to remember specific phrases or device names, make multiple requests, or even...

Continue Reading

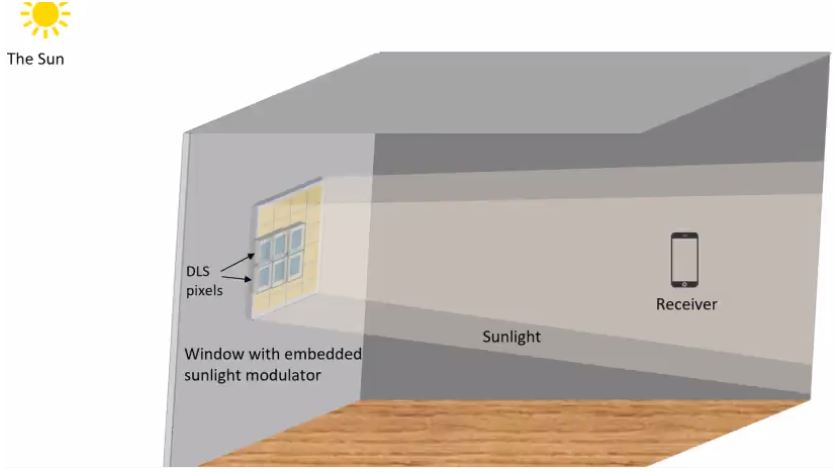

Transmit Data Wirelessly Just By Streaming Sunlight Through Smart Windows

We have seen systems wirelessly transmit data through different means but never have we seen modulated sunlight being used to send data. Some scientists at the King Abdullah University of Science and Technology, a private research institution located in Saudi Arabia, made some special...

Continue Reading

Cat M1 vs Cat 1 vs Cat 4: Connectivity for Telematics

Through increased adoption of data-driven telematics use cases in vehicles, there has been a rising need for telematics edge hardware across a range of vehicles. Telematics and connected vehicle solutions help unlock value across a range of vehicle types: passenger cars, heavy duty...

Continue Reading

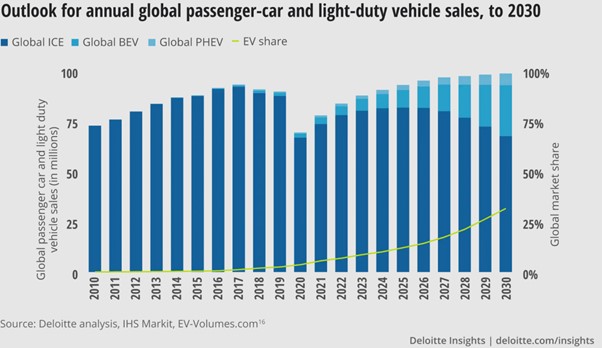

Telematics for Electric Vehicles

Since 2019, The EV Market has taken great strides and is set to transform the automotive industry. Automotive OEMs have increased spend on R&D on electric models and sustainable technology. Governments have introduced regulations and incentives to accelerate the shift to electric...

Continue Reading

Intel’s Loihi 2 – Next-Generation Neuromorphic Research Chip

The shift from offline training using labeled datasets in parallel computing to learn on-the-fly through neuron firing rules in Neuromorphic Computing has significantly aided the ever-increasing demand for artificial intelligence in a range of applications. Intel’s first-generation...

Continue Reading

What is AI inference at the edge?

The conventional style of using network connectivity in bringing artificial intelligence models to improve performance and efficiency needs some modification to meet the demands from the embedded systems to the automobile industry. Before directly jumping to the role of AI inference at...

Continue Reading

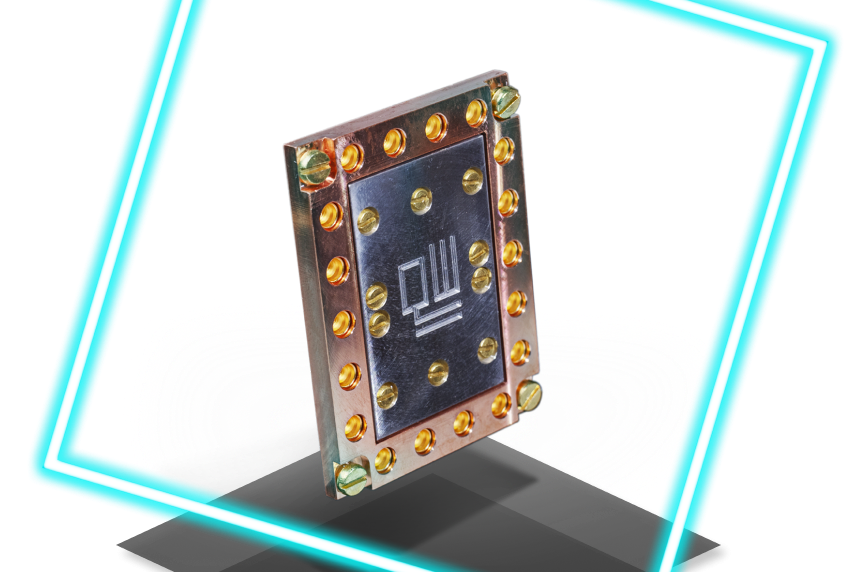

First commercially available superconducting quantum processor

The Dutch startup QuantWare has announced the launch of the world’s first commercially available superconducting processor for quantum computers (QPU). This is the first time superconducting quantum processors have been made available ‘off the shelf’, and is being seen as a...

Continue Reading