Category: Laser

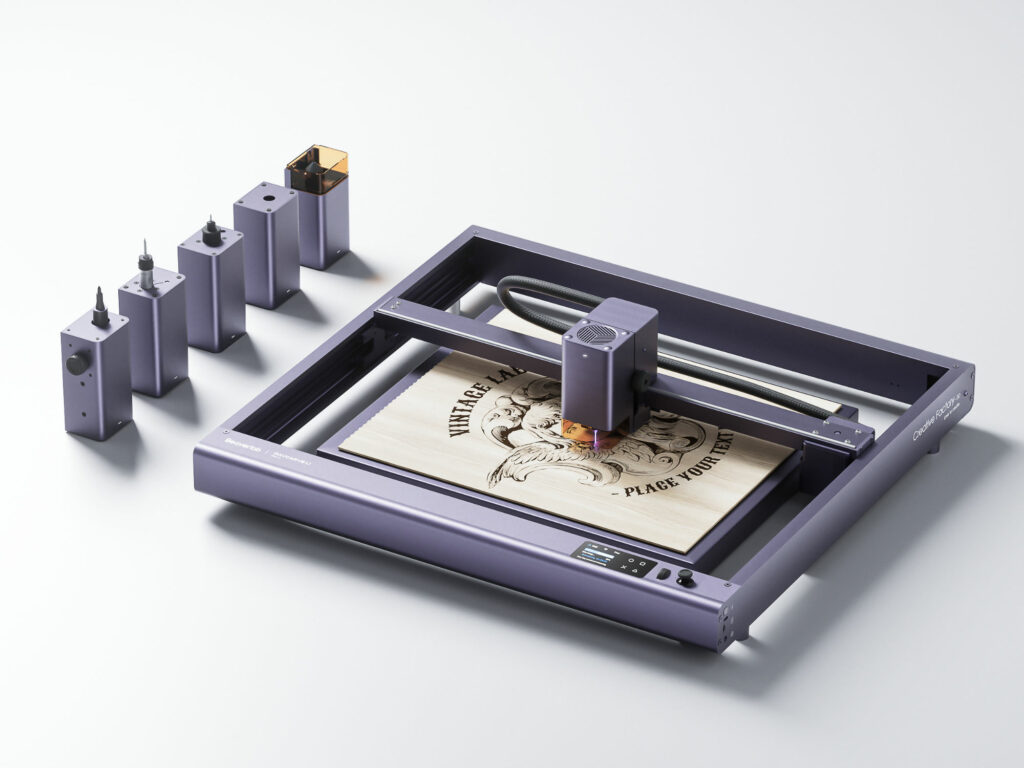

BEAVERLAB Davcarve L1 is live on Kickstarter on October 10 with 55% OFF

BEAVERLAB is excited to announce the launch of a Kickstarter campaign for Davcarve L1, the world's first dual-laser, multi-module engraver and cutter. Backers can enjoy significant discounts of up to 55% off during the campaign, which starts on October 10 2023. Support the innovative...

Continue Reading

AlgoLaser Delta 22W Laser Engraver : A Budget-Friendly Machine For Makers

New Tools to Inspire Creativity As a consultant in the 3D printing space, one of my goals is to help fellow makers discover affordable tools and technologies that can unlock new possibilities. When I came across reports of the upcoming AlgoLaser Delta laser engraver, my interest was...

Continue Reading

Mecpow X3 Pro: Unveiling its High-Precision Engraving Magic

Whether you're a hobbyist, a business owner, or a DIY enthusiast, a laser engraver becomes a convenient tool if you are into creating custom designs. It allows you to develop custom-engraved products using various materials, such as wood, acrylic, leather, fabric, and even certain types...

Continue Reading

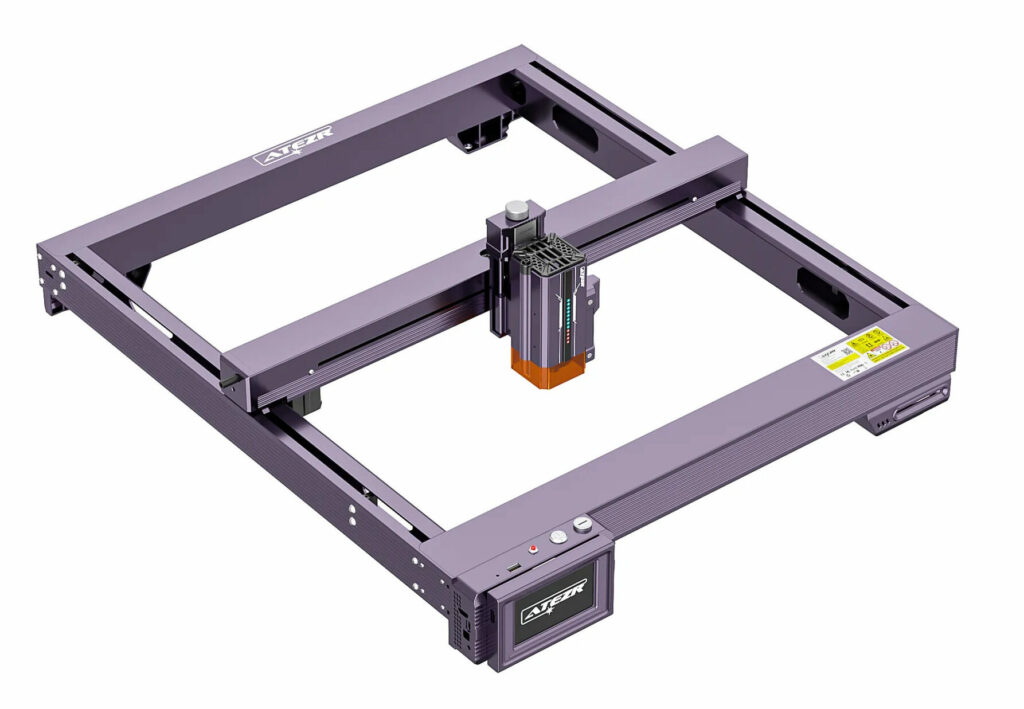

Atezr’s Second-Generation Engravers L2 Offers New Technical Upgrade

Introduction Atezr, an innovative and trailblazing brand within the laser engraving industry, recently unveiled a new series of cutting-edge laser engravers called L2, representing the second generation of their product line. The L2 models are available in three variants: 10W, 20W, and...

Continue Reading

Ortur Laser Master 3 Engraver Review

Introduction Laser engraving and cutting have been a key part of rapid and precision prototyping and production processes since the machines became widely available. They allow users from the comfort of their homes or mini-workshops to build precision products and engrave them at a...

Continue Reading

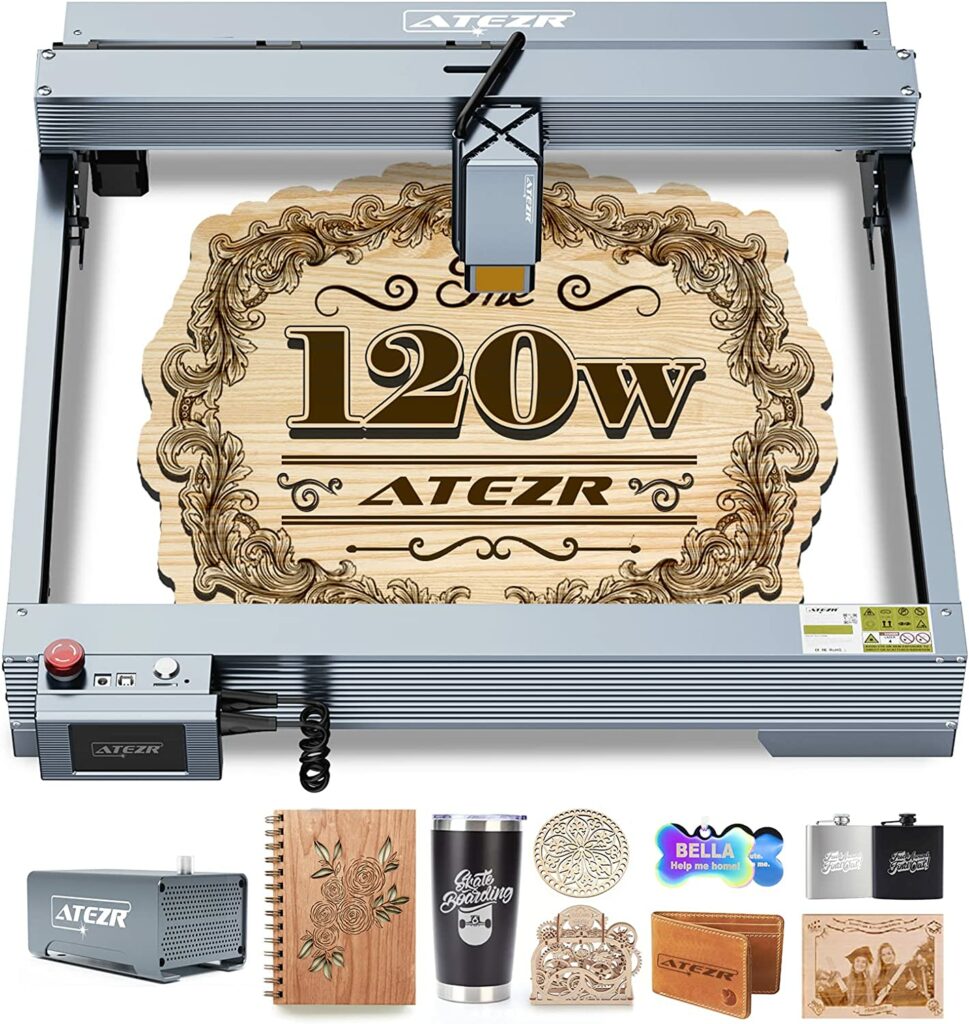

Exploring The All New ATEZR P20 Plus 20W Laser Engraver

ATEZR P20 PLUS Laser Cutter Machine Atezr P20 Plus Laser Engraving Machine is a machine designed specifically for laser engraving. The name of the machine, however, is deceptive. And it's not just limited to that, either. You can use the P20 to engrave on a variety of substrates,...

Continue Reading

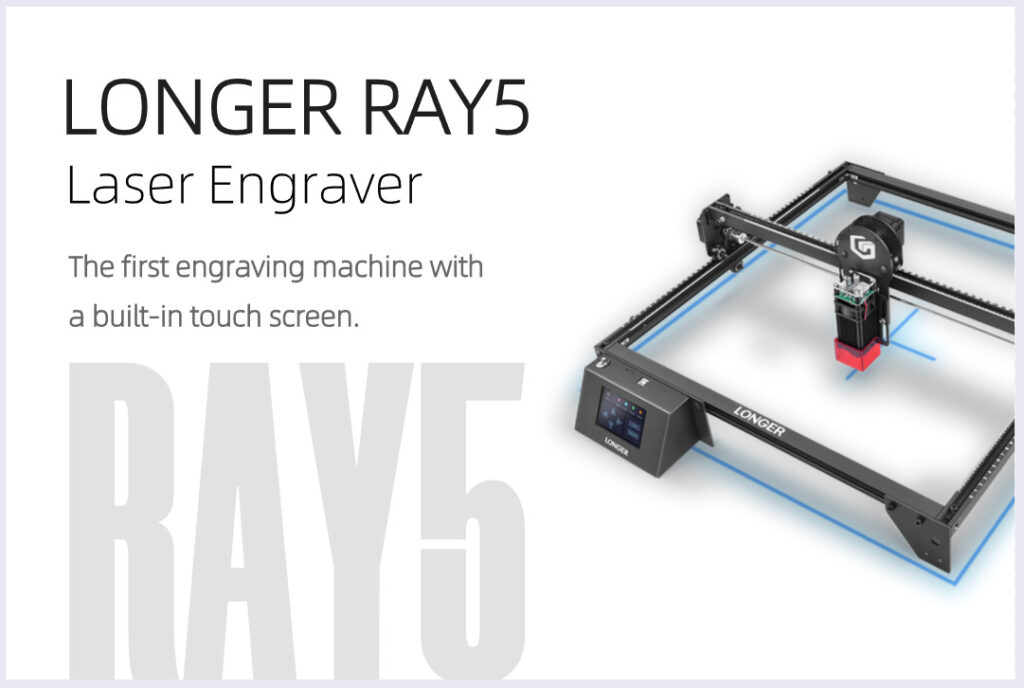

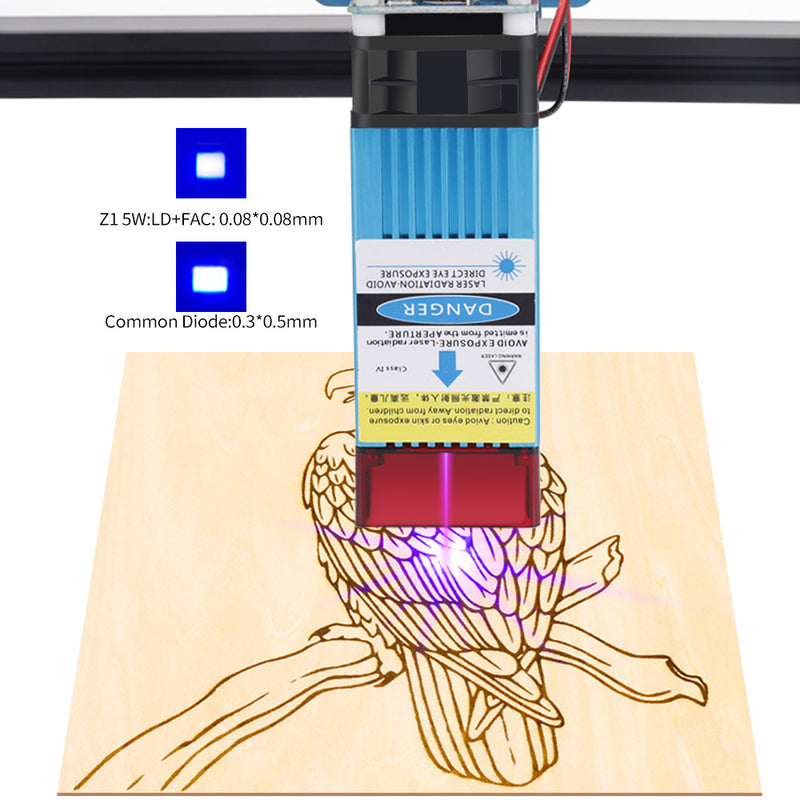

LONGER RAY5 Laser Engraver: Is it meant for you?

Laser engraving technology has been widely used by designers, makers, and hobbyists to engrave solid marks on different types of materials that are exposed to the engraver machine. Laser engraving machines are designed for cutting, etching, marking, and engraving hard materials while...

Continue Reading

Meet the COMGO Z1 – A Powerful, Top of the Line, Low-Cost Laser Engraver Review

Introduction Laser engravers/cutters like 3D printers are bringing small-scale manufacturing closer to makers and hobbyists. As the technology advances, the competition between companies making them is getting stiffer, leading to the market being flooded with different types and makes,...

Continue Reading