Tag: graphene

Researchers Develop a Graphene Based Sensor to Visualize Electric Fields

As silicon-based fabrication technology is reaching its operational limits, there is increasing research attention towards developing circuits with 2D materials. The 2D materials are crystals consisting of a single layer of atoms, with their thickness ranging from a single to a...

Continue Reading

Graphene energy harvesting chips closer to availability

Nanotechnology company NTS Innovations says it has achieved a major milestone in its development of a graphene energy harvesting (GEH) clean energy source that can operate in any environment. GEH is the act of harvesting energy at the nanoscale level from the naturally occurring...

Continue Reading

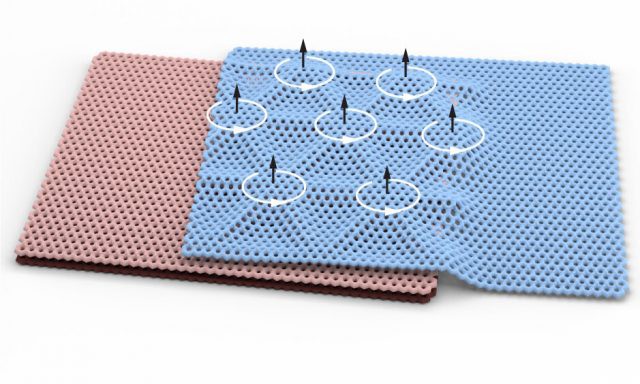

New Study shows Rare form of Magnetic and Electrical Property in stack-twisted Graphene

A group of scientists at Columbia University and the University of Washington has found unique electronic states along with an uncommon kind of magnetism, can develop in a three-layer graphene structure. The work was inspired by current research studies of twisted monolayers or twisted...

Continue Reading

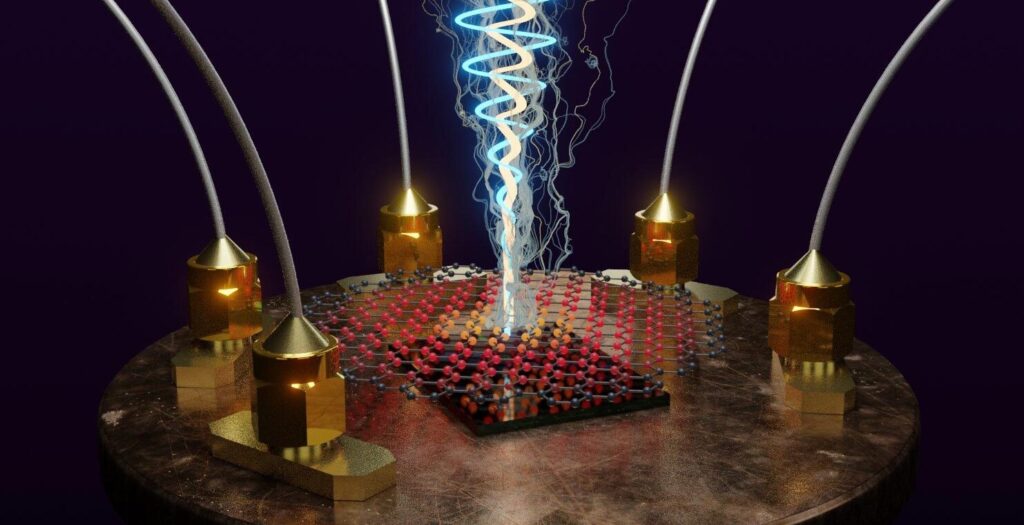

Graphene Infused Most Sensitive Microwave Sensor

A new microwave radiation sensor with the sensitivity of up to 1 single photon, has been developed by research funded by the US Army and various pristine universities. This sensor is a microwave bolometer that can improve thermal imaging, radio communications, and RADAR by 100,000...

Continue Reading

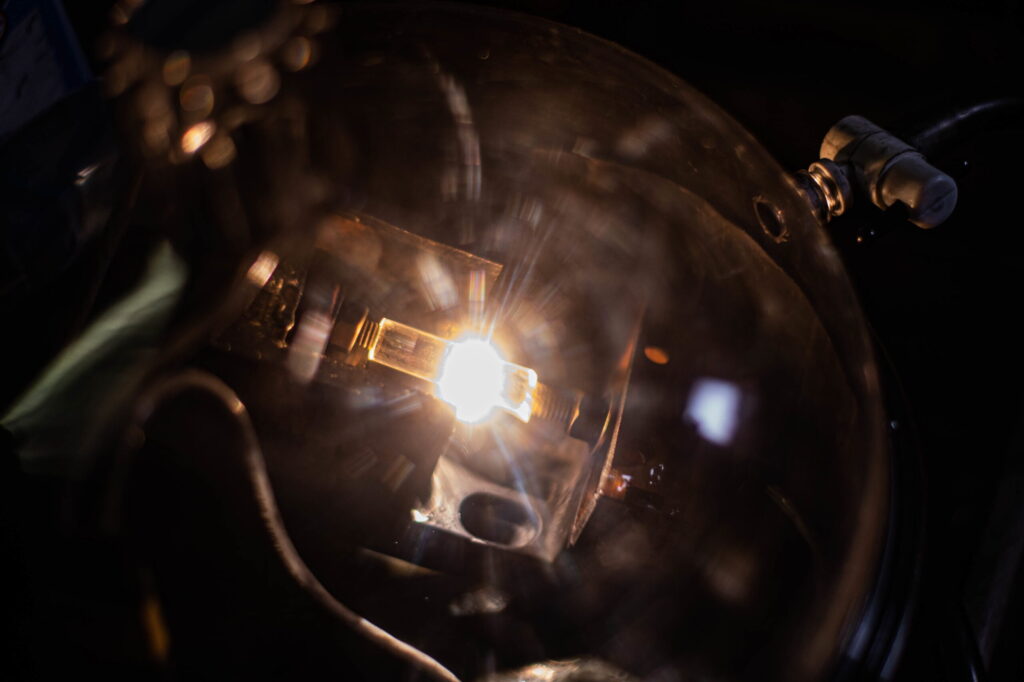

Flash Graphene Synthesis – Electricity Turns Garbage into Graphene

Graphene is the thinnest yet one of the most strong materials known to man while being only one atom thick. On top of that, graphene is an excellent conductor of heat and electricity and has remarkable light absorption abilities. It is truly a material that could change the world, with...

Continue Reading

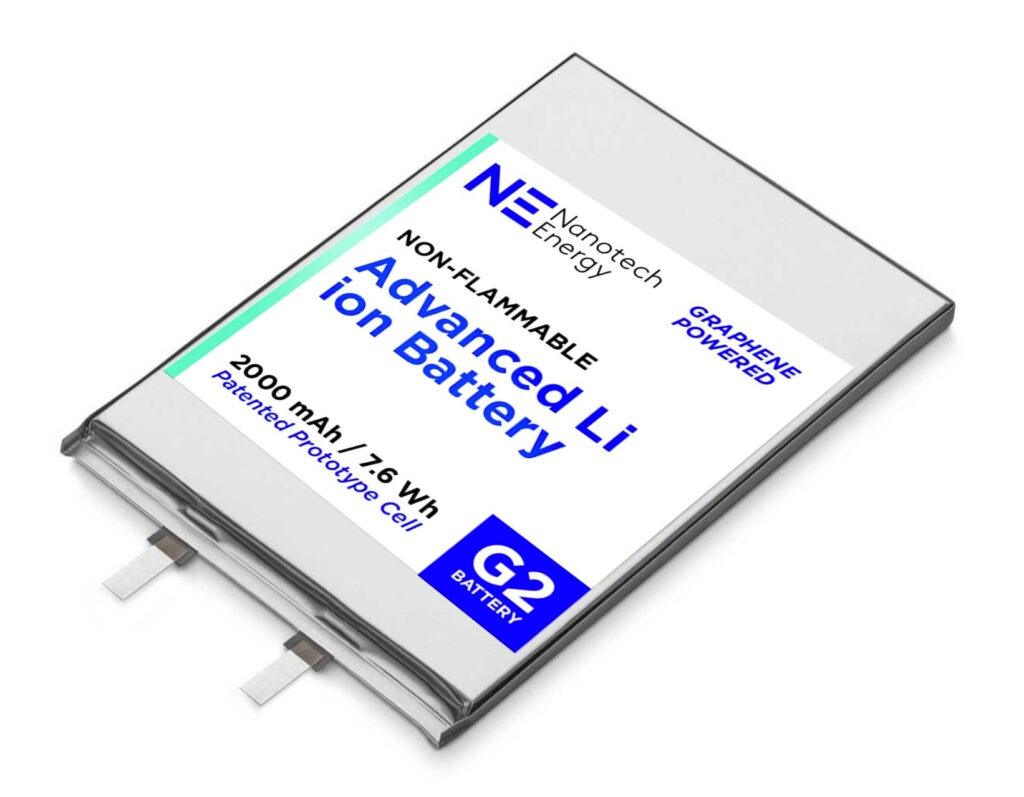

Non-flammable, efficient and fast-charging lithium-ion 18650 batteries in mass production Q1 2021

Nanotech Energy Inc. announced that beginning in the first quarter of 2021, the company will mass produce non-flammable, efficient, and fast-charging lithium-ion 18650 Batteries. These cell-type batteries are used in devices including, but not limited to, laptop computers, cordless...

Continue Reading

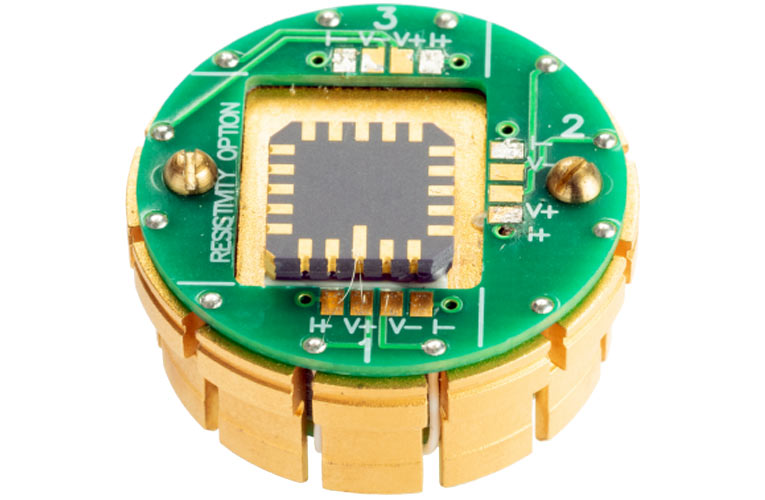

New Graphene Hall Effect Sensor to Improve Accuracy and Precision in Magnetic Measurement Applications

The Cambridge-based startup, Paragraf has collaborated with the Magnetic Measurement section at CERN to demonstrate the potential of graphene-based Hall effect sensors to improve accuracy in magnetic measurement applications. Overcoming the shortfalls of existing Hall effect sensors...

Continue Reading

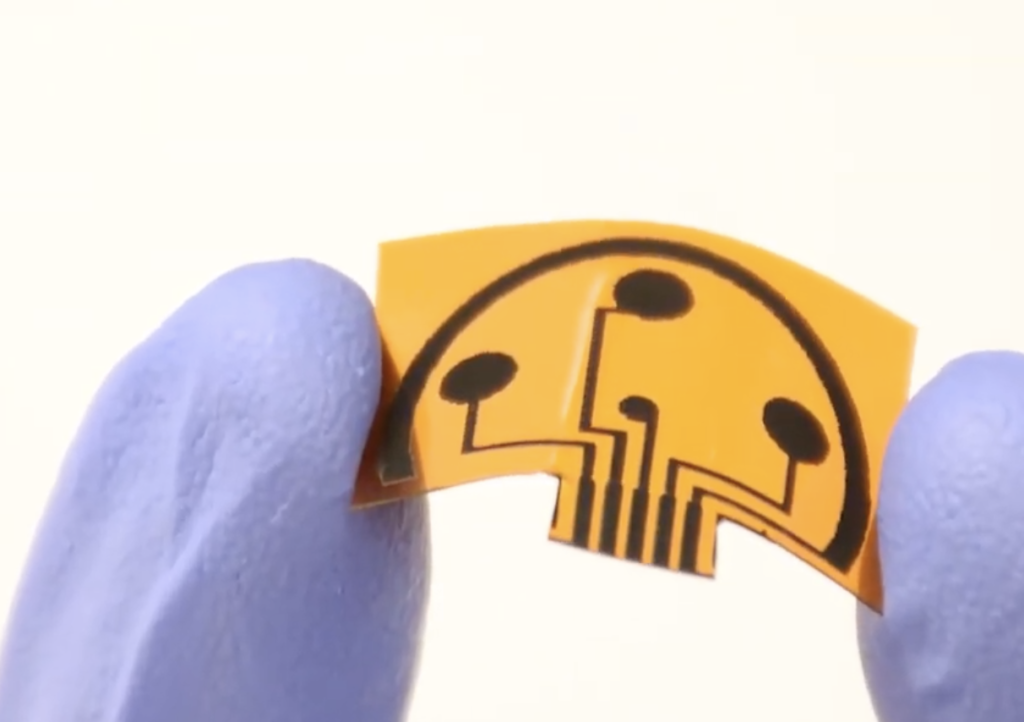

Caltech’s Low-Cost Sweat Sensor Tracks Stress Through Cortisol Levels

From tracking diabetes to the detection of diseases like Cystic Fibrosis, a lot of ideas around monitoring/analyzing human sweat, as a non-invasive method of detecting or monitoring diseases has been around for a while. Leveraging on this idea, a team of researchers at Caltech, led by...

Continue Reading